height NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 179 of 1833

Valve seat outer diameter (d)Intake 33.065 - 33.078 (1.3018 - 1.3023) 33.565 - 33.578 (1.3215 - 1.3220)

Exhaust 31.550 - 31.561 (1.2421 - 1.2426) 32.050 - 32.061 (1.2618 - 1.2622)

Height (h) Intake 6.75 - 6.85 (0.2657 - 0.2697) 6.75 - 6.85 (0.2657 - 0.2697)

Exhaust 7.35 - 7.45 (0.2894 - 0.2933) 7.35 - 7.45 (0.2894 - 0.2933)

Depth (L) Intake 43.65 - 44.35 (1.7185 - 1.7461)

Exhaust 43.65 - 44.35 (1.7185 - 1.7461)

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

Valve Seat (Cont'd)

EM-88

http://vnx.su/

Page 180 of 1833

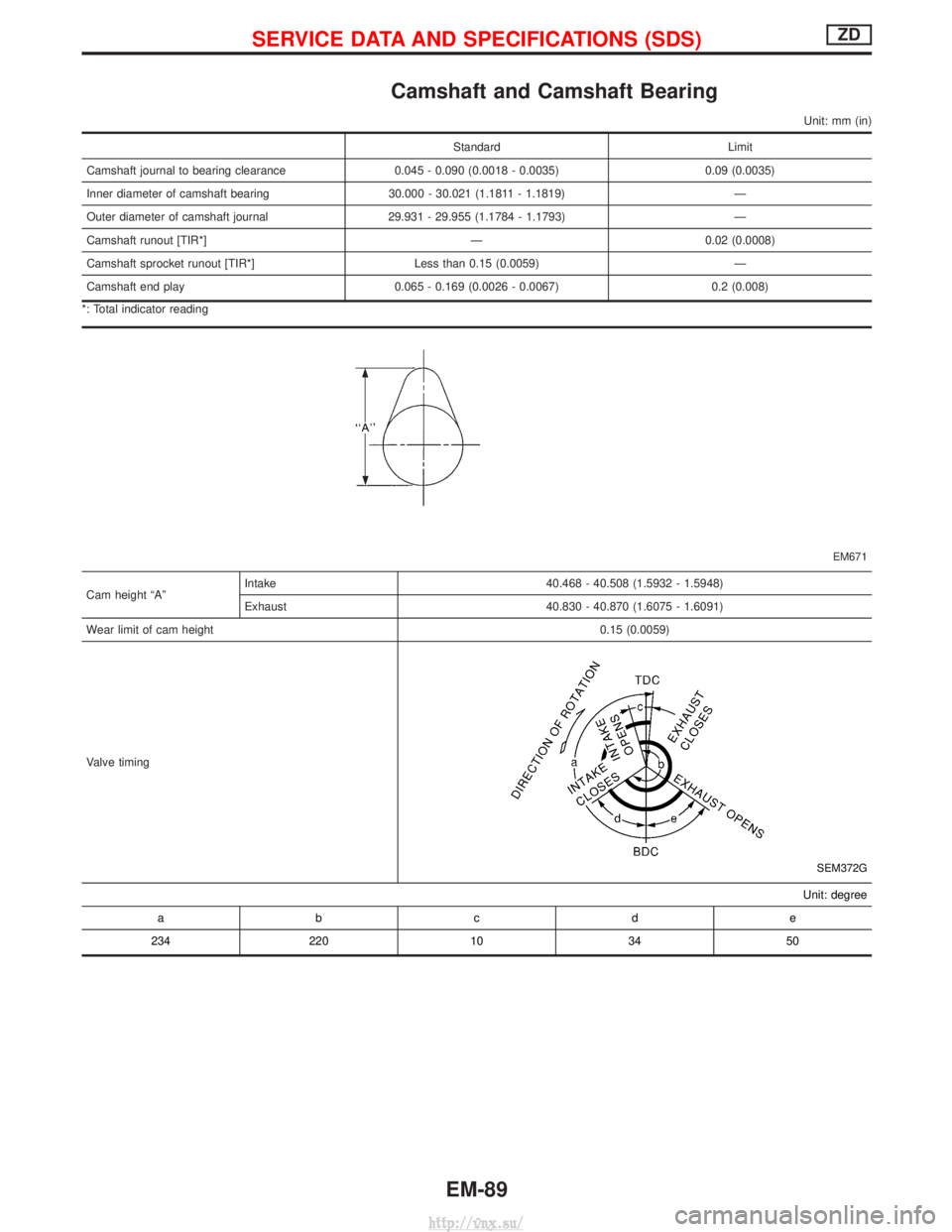

Camshaft and Camshaft Bearing

Unit: mm (in)

StandardLimit

Camshaft journal to bearing clearance 0.045 - 0.090 (0.0018 - 0.0035) 0.09 (0.0035)

Inner diameter of camshaft bearing 30.000 - 30.021 (1.1811 - 1.1819) Ð

Outer diameter of camshaft journal 29.931 - 29.955 (1.1784 - 1.1793) Ð

Camshaft runout [TIR*] Ð 0.02 (0.0008)

Camshaft sprocket runout [TIR*] Less than 0.15 (0.0059) Ð

Camshaft end play 0.065 - 0.169 (0.0026 - 0.0067) 0.2 (0.008)

*: Total indicator reading

EM671

Cam height ªAº Intake 40.468 - 40.508 (1.5932 - 1.5948)

Exhaust 40.830 - 40.870 (1.6075 - 1.6091)

Wear limit of cam height 0.15 (0.0059)

Valve timing

SEM372G

Unit: degree

abcde

234 220 10 34 50

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

EM-89

http://vnx.su/

Page 198 of 1833

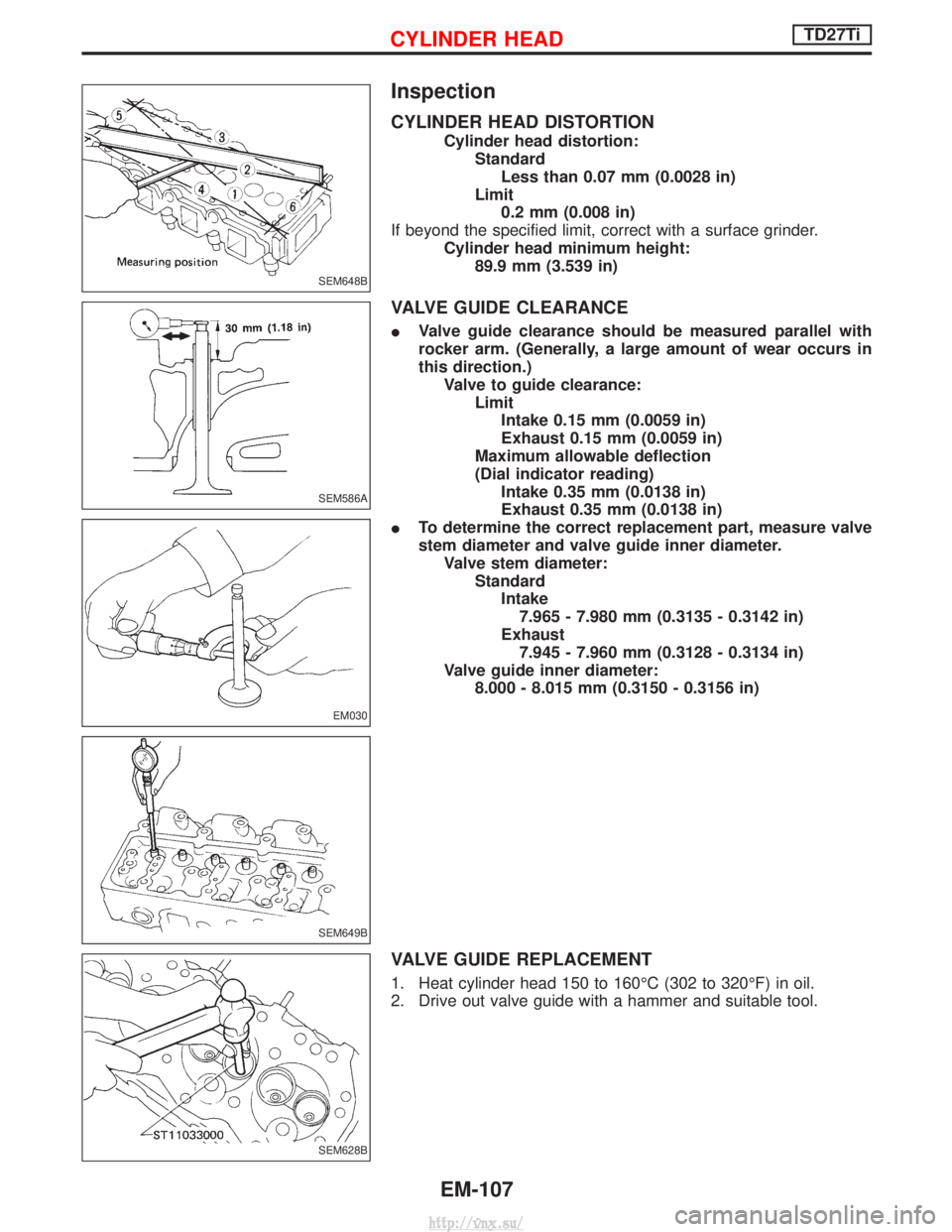

Inspection

CYLINDER HEAD DISTORTION

Cylinder head distortion:StandardLess than 0.07 mm (0.0028 in)

Limit 0.2 mm (0.008 in)

If beyond the specified limit, correct with a surface grinder. Cylinder head minimum height:89.9 mm (3.539 in)

VALVE GUIDE CLEARANCE

IValve guide clearance should be measured parallel with

rocker arm. (Generally, a large amount of wear occurs in

this direction.)

Valve to guide clearance: LimitIntake 0.15 mm (0.0059 in)

Exhaust 0.15 mm (0.0059 in)

Maximum allowable deflection

(Dial indicator reading) Intake 0.35 mm (0.0138 in)

Exhaust 0.35 mm (0.0138 in)

I To determine the correct replacement part, measure valve

stem diameter and valve guide inner diameter.

Valve stem diameter: StandardIntake7.965 - 7.980 mm (0.3135 - 0.3142 in)

Exhaust 7.945 - 7.960 mm (0.3128 - 0.3134 in)

Valve guide inner diameter: 8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Heat cylinder head 150 to 160ÉC (302 to 320ÉF) in oil.

2. Drive out valve guide with a hammer and suitable tool.

SEM648B

SEM586A

EM030

SEM649B

SEM628B

CYLINDER HEADTD27Ti

EM-107

http://vnx.su/

Page 228 of 1833

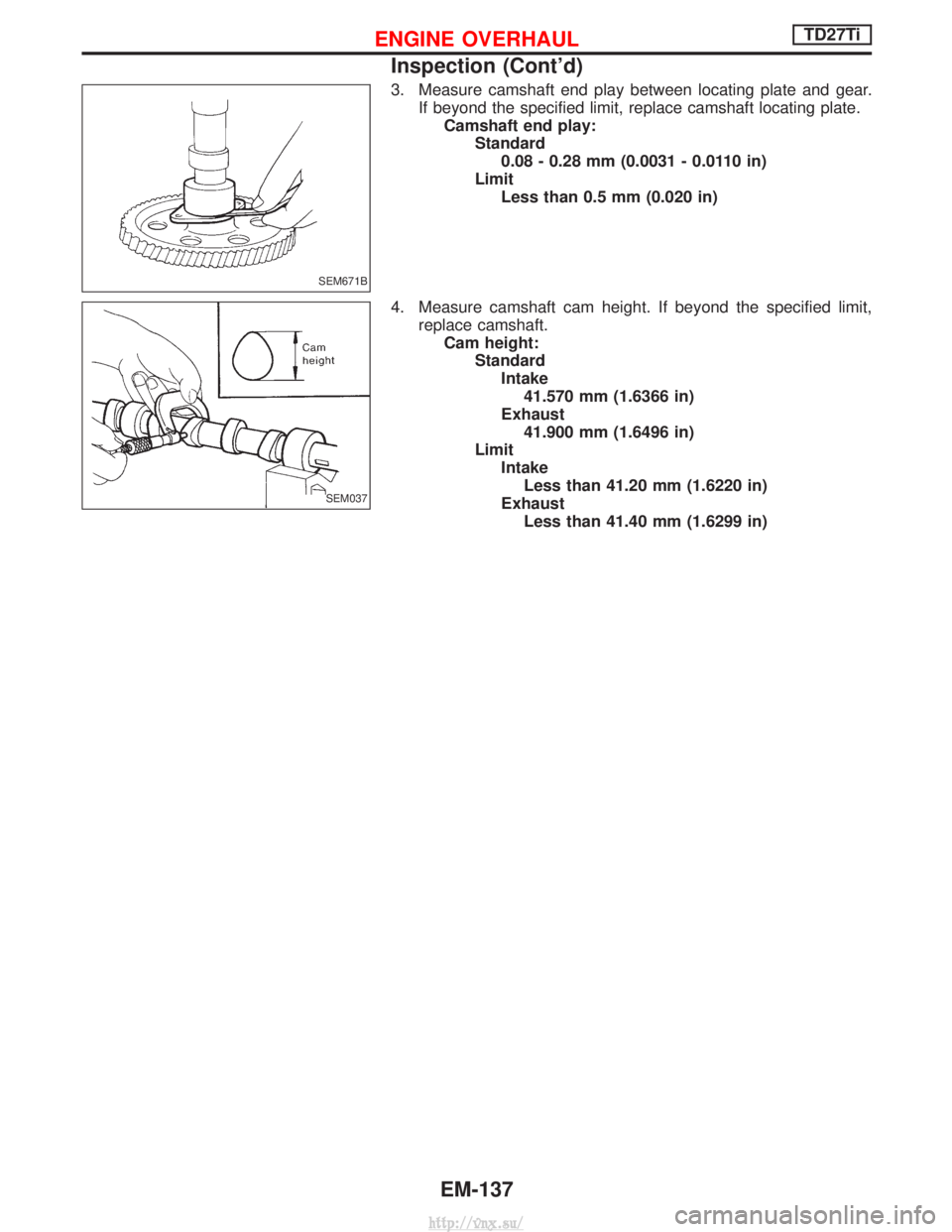

3. Measure camshaft end play between locating plate and gear.If beyond the specified limit, replace camshaft locating plate.Camshaft end play: Standard0.08 - 0.28 mm (0.0031 - 0.0110 in)

Limit Less than 0.5 mm (0.020 in)

4. Measure camshaft cam height. If beyond the specified limit, replace camshaft.Cam height: StandardIntake41.570 mm (1.6366 in)

Exhaust 41.900 mm (1.6496 in)

Limit IntakeLess than 41.20 mm (1.6220 in)

Exhaust Less than 41.40 mm (1.6299 in)

SEM671B

SEM037

ENGINE OVERHAULTD27Ti

Inspection (Cont'd)

EM-137

http://vnx.su/

Page 235 of 1833

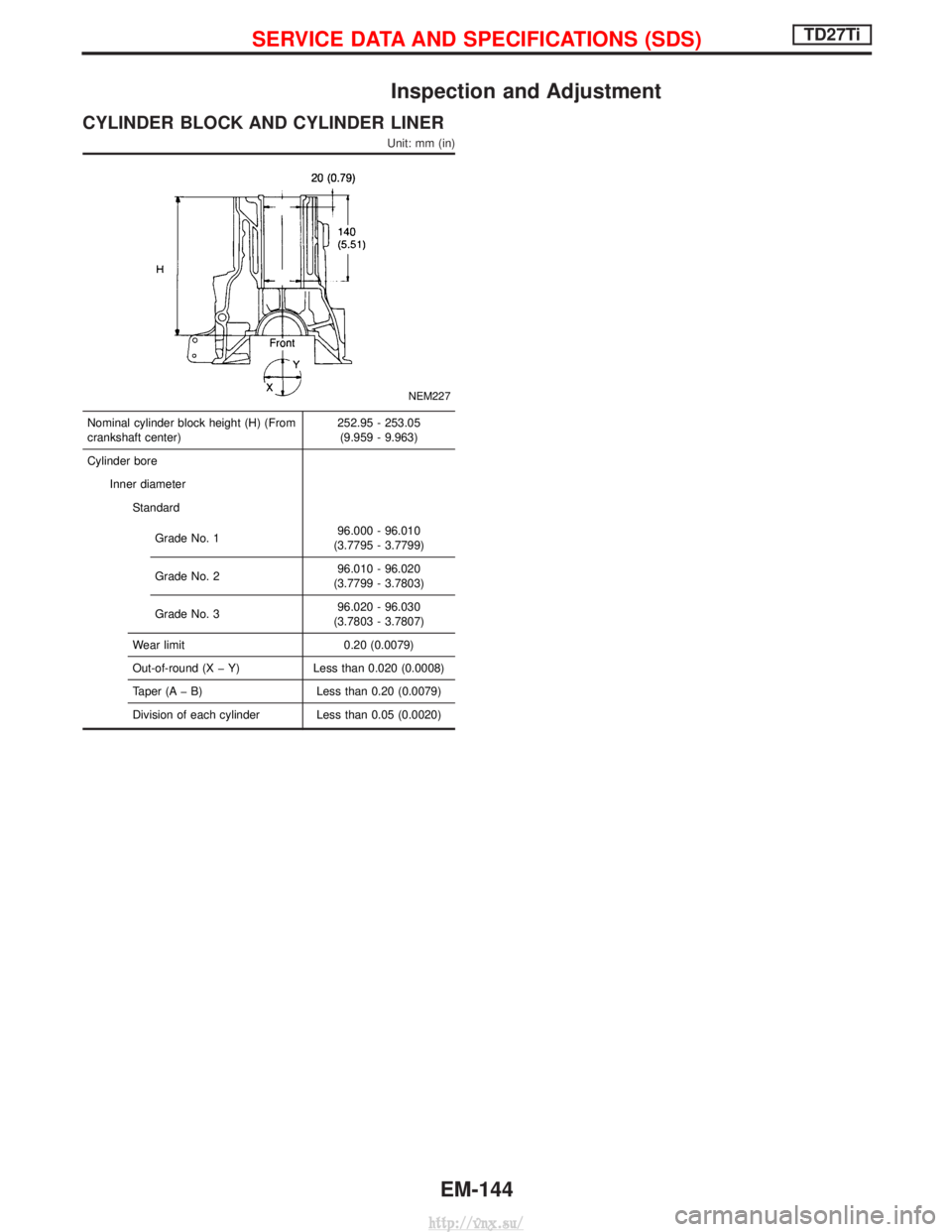

Inspection and Adjustment

CYLINDER BLOCK AND CYLINDER LINER

Unit: mm (in)

NEM227

Nominal cylinder block height (H) (From

crankshaft center)252.95 - 253.05

(9.959 - 9.963)

Cylinder bore Inner diameterStandard

Grade No. 1 96.000 - 96.010

(3.7795 - 3.7799)

Grade No. 2 96.010 - 96.020

(3.7799 - 3.7803)

Grade No. 3 96.020 - 96.030

(3.7803 - 3.7807)

Wear limit 0.20 (0.0079)

Out-of-round (X þ Y) Less than 0.020 (0.0008)

Taper (A þ B) Less than 0.20 (0.0079)

Division of each cylinder Less than 0.05 (0.0020)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-144

http://vnx.su/

Page 237 of 1833

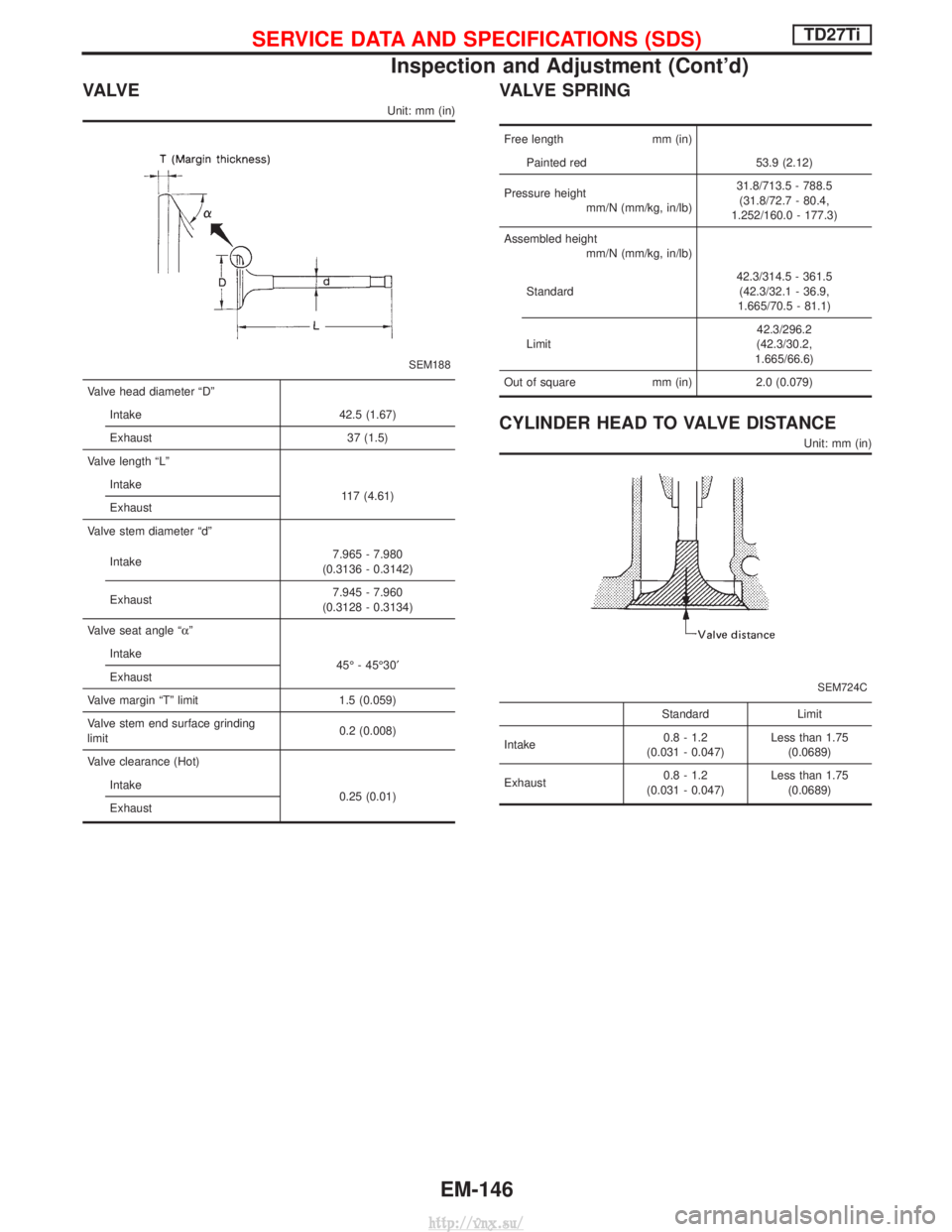

VA LV E

Unit: mm (in)

SEM188

Valve head diameter ªDºIntake 42.5 (1.67)

Exhaust 37 (1.5)

Valve length ªLº Intake 117 (4.61)

Exhaust

Valve stem diameter ªdº

Intake 7.965 - 7.980

(0.3136 - 0.3142)

Exhaust 7.945 - 7.960

(0.3128 - 0.3134)

Valve seat angle ªa º

Intake 45É - 45É30¢

Exhaust

Valve margin ªTº limit 1.5 (0.059)

Valve stem end surface grinding

limit 0.2 (0.008)

Valve clearance (Hot) Intake 0.25 (0.01)

Exhaust

VALVE SPRING

Free length mm (in)

Painted red 53.9 (2.12)

Pressure height mm/N (mm/kg, in/lb) 31.8/713.5 - 788.5

(31.8/72.7 - 80.4,

1.252/160.0 - 177.3)

Assembled height mm/N (mm/kg, in/lb)

Standard 42.3/314.5 - 361.5

(42.3/32.1 - 36.9,

1.665/70.5 - 81.1)

Limit 42.3/296.2

(42.3/30.2,

1.665/66.6)

Out of square mm (in)2.0 (0.079)

CYLINDER HEAD TO VALVE DISTANCE

Unit: mm (in)

SEM724C

Standard Limit

Intake 0.8 - 1.2

(0.031 - 0.047) Less than 1.75

(0.0689)

Exhaust 0.8 - 1.2

(0.031 - 0.047) Less than 1.75

(0.0689)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-146

http://vnx.su/

Page 238 of 1833

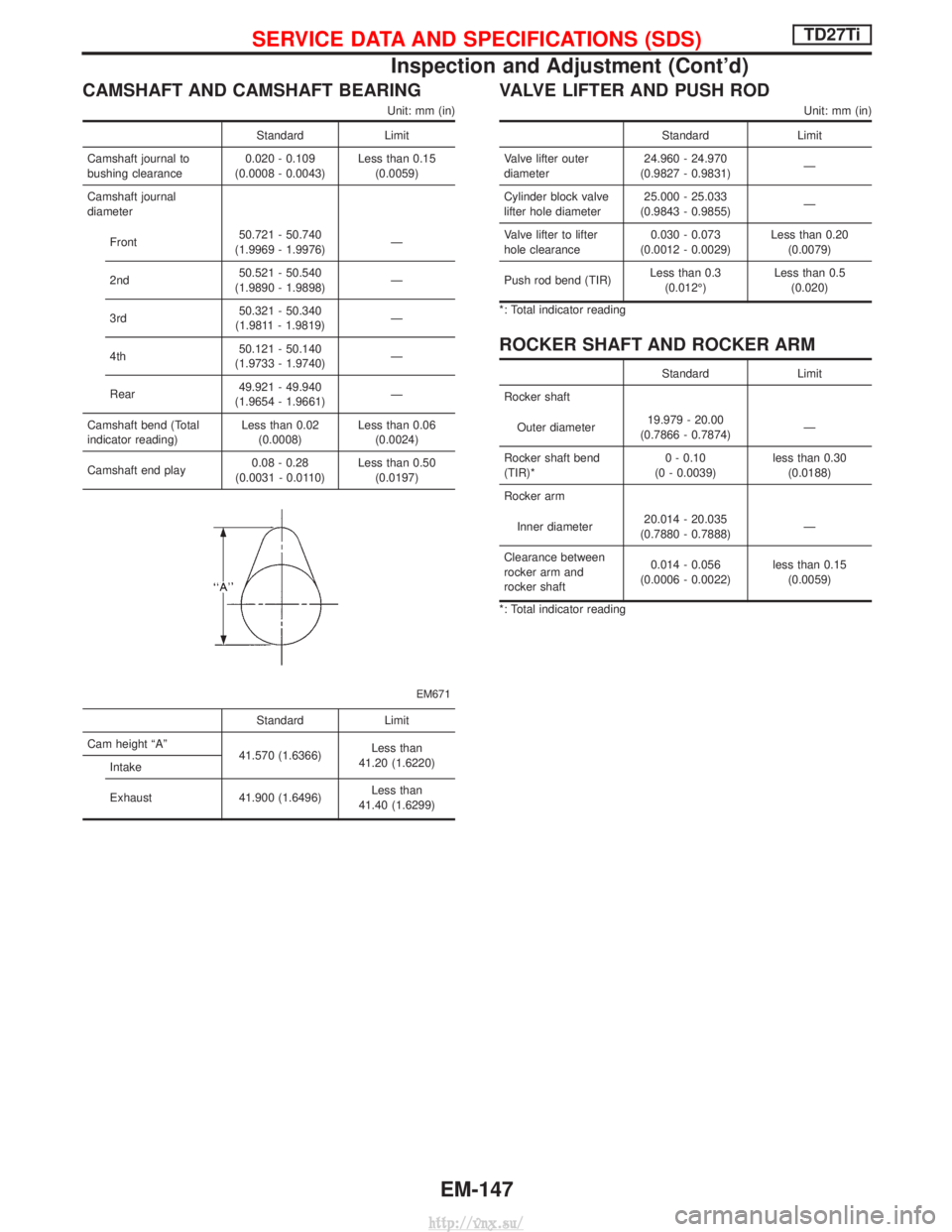

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

StandardLimit

Camshaft journal to

bushing clearance 0.020 - 0.109

(0.0008 - 0.0043) Less than 0.15

(0.0059)

Camshaft journal

diameter

Front 50.721 - 50.740

(1.9969 - 1.9976) Ð

2nd 50.521 - 50.540

(1.9890 - 1.9898) Ð

3rd 50.321 - 50.340

(1.9811 - 1.9819) Ð

4th 50.121 - 50.140

(1.9733 - 1.9740) Ð

Rear 49.921 - 49.940

(1.9654 - 1.9661) Ð

Camshaft bend (Total

indicator reading) Less than 0.02

(0.0008) Less than 0.06

(0.0024)

Camshaft end play 0.08 - 0.28

(0.0031 - 0.0110) Less than 0.50

(0.0197)

EM671

Standard Limit

Cam height ªAº 41.570 (1.6366)Less than

41.20 (1.6220)

Intake

Exhaust 41.900 (1.6496) Less than

41.40 (1.6299)

VALVE LIFTER AND PUSH ROD

Unit: mm (in)

Standard Limit

Valve lifter outer

diameter 24.960 - 24.970

(0.9827 - 0.9831) Ð

Cylinder block valve

lifter hole diameter 25.000 - 25.033

(0.9843 - 0.9855) Ð

Valve lifter to lifter

hole clearance 0.030 - 0.073

(0.0012 - 0.0029) Less than 0.20

(0.0079)

Push rod bend (TIR) Less than 0.3

(0.012É) Less than 0.5

(0.020)

*: Total indicator reading

ROCKER SHAFT AND ROCKER ARM

Standard Limit

Rocker shaft

Outer diameter 19.979 - 20.00

(0.7866 - 0.7874) Ð

Rocker shaft bend

(TIR)* 0 - 0.10

(0 - 0.0039) less than 0.30

(0.0188)

Rocker arm

Inner diameter 20.014 - 20.035

(0.7880 - 0.7888) Ð

Clearance between

rocker arm and

rocker shaft 0.014 - 0.056

(0.0006 - 0.0022) less than 0.15

(0.0059)

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-147

http://vnx.su/

Page 241 of 1833

AVAILABLE THRUST WASHER

Unit: mm (in)

Thrust washer thickness

Standard 2.275 - 2.325 (0.0896 - 0.0915)

Oversize 0.20 (0.0079) 2.475 - 2.525 (0.0974 - 0.0994)

0.40 (0.0157) 2.675 - 2.725 (0.1053 - 0.1073)

MISCELLANEOUS COMPONENTS

Unit: mm (in)

Gear trainBacklash of each gear

Standard 0.07 - 0.11 (0.0028 - 0.0043)

Limit 0.20 (0.0079)

Flywheel Runout (Total indicator

reading) Less than 0.15 (0.0059)

Front plate Warpage limit 0.2 (0.008)

Cylinder head Head surface distorsion

Standard Less than 0.07 (0.0028)

Limit 0.2 (0.008)

Minimum height 89.7 (3.532)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-150

http://vnx.su/

Page 527 of 1833

![NISSAN TERRANO 2004 Service User Guide 17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

I Do not bump glow plug heating element. If it is bumped NISSAN TERRANO 2004 Service User Guide 17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

I Do not bump glow plug heating element. If it is bumped](/img/5/57394/w960_57394-526.png)

17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

I Do not bump glow plug heating element. If it is bumped, replace glow plug with a new one.

I If glow plug is dropped from a height of 10 cm (3.94 in) or higher, replace with a new one.

I If glow plug installation hole is contaminated with carbon, remove it with a reamer or suitable tool.

I Hand-tighten glow plug by turning it two or three times, then tighten using a tool to specified torque.

:15-20N ×m (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

OK or NG

OK EGO TO 18.

NG EReplace glow plug.

18 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-252

http://vnx.su/

Page 694 of 1833

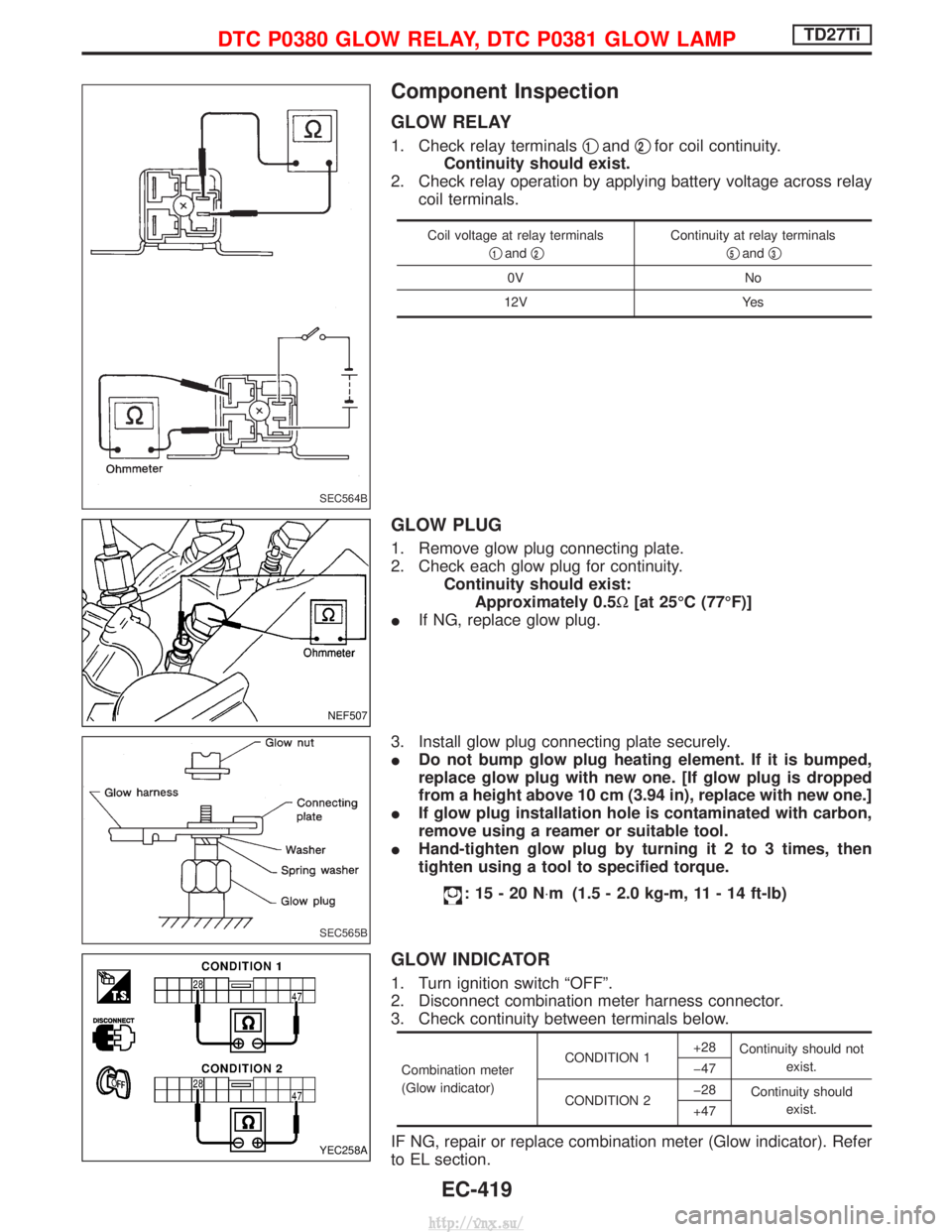

Component Inspection

GLOW RELAY

1. Check relay terminalsq1andq2for coil continuity.

Continuity should exist.

2. Check relay operation by applying battery voltage across relay coil terminals.

Coil voltage at relay terminals

q

1andq2

Continuity at relay terminals

q

5andq3

0V

No

12V Yes

GLOW PLUG

1. Remove glow plug connecting plate.

2. Check each glow plug for continuity.

Continuity should exist:Approximately 0.5W [at 25ÉC (77ÉF)]

I If NG, replace glow plug.

3. Install glow plug connecting plate securely.

I Do not bump glow plug heating element. If it is bumped,

replace glow plug with new one. [If glow plug is dropped

from a height above 10 cm (3.94 in), replace with new one.]

I If glow plug installation hole is contaminated with carbon,

remove using a reamer or suitable tool.

I Hand-tighten glow plug by turning it 2 to 3 times, then

tighten using a tool to specified torque.

:15-20N ×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

GLOW INDICATOR

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector.

3. Check continuity between terminals below.

Combination meter

(Glow indicator) CONDITION 1

+28

Continuity should not

exist.

þ47

CONDITION 2 þ28

Continuity should

exist.

+47

IF NG, repair or replace combination meter (Glow indicator). Refer

to EL section.

SEC564B

NEF507

SEC565B

YEC258A

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-419

http://vnx.su/