light NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 15 of 1833

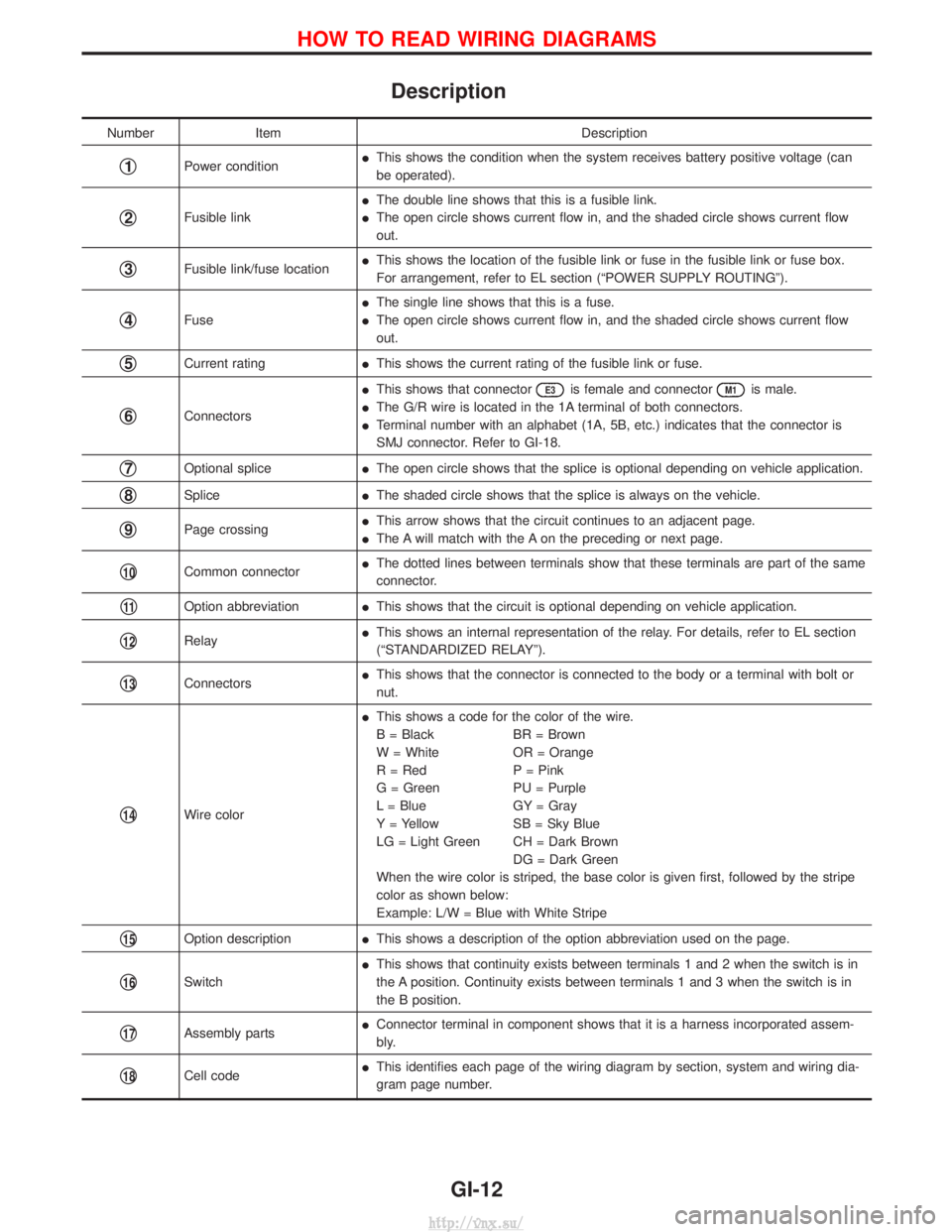

Description

NumberItem Description

q1Power conditionI

This shows the condition when the system receives battery positive voltage (can

be operated).

q2Fusible link I

The double line shows that this is a fusible link.

I The open circle shows current flow in, and the shaded circle shows current flow

out.

q3Fusible link/fuse location I

This shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (ªPOWER SUPPLY ROUTINGº).

q4Fuse I

The single line shows that this is a fuse.

I The open circle shows current flow in, and the shaded circle shows current flow

out.

q5Current rating IThis shows the current rating of the fusible link or fuse.

q6Connectors I

This shows that connector

E3is female and connectorM1is male.

I The G/R wire is located in the 1A terminal of both connectors.

I Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-18.

q7Optional splice IThe open circle shows that the splice is optional depending on vehicle application.

q8Splice IThe shaded circle shows that the splice is always on the vehicle.

q9Page crossing I

This arrow shows that the circuit continues to an adjacent page.

I The A will match with the A on the preceding or next page.

q10Common connector I

The dotted lines between terminals show that these terminals are part of the same

connector.

q11Option abbreviation IThis shows that the circuit is optional depending on vehicle application.

q12Relay I

This shows an internal representation of the relay. For details, refer to EL section

(ªSTANDARDIZED RELAYº).

q13Connectors I

This shows that the connector is connected to the body or a terminal with bolt or

nut.

q14Wire color I

This shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

q15Option description IThis shows a description of the option abbreviation used on the page.

q16Switch I

This shows that continuity exists between terminals 1 and 2 when the switch is in

the A position. Continuity exists between terminals 1 and 3 when the switch is in

the B position.

q17Assembly parts I

Connector terminal in component shows that it is a harness incorporated assem-

bly.

q18Cell code I

This identifies each page of the wiring diagram by section, system and wiring dia-

gram page number.

HOW TO READ WIRING DIAGRAMS

GI-12

http://vnx.su/

Page 26 of 1833

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

I Heat sensitive

I Freezing

I Water intrusion

I Electrical load

I Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

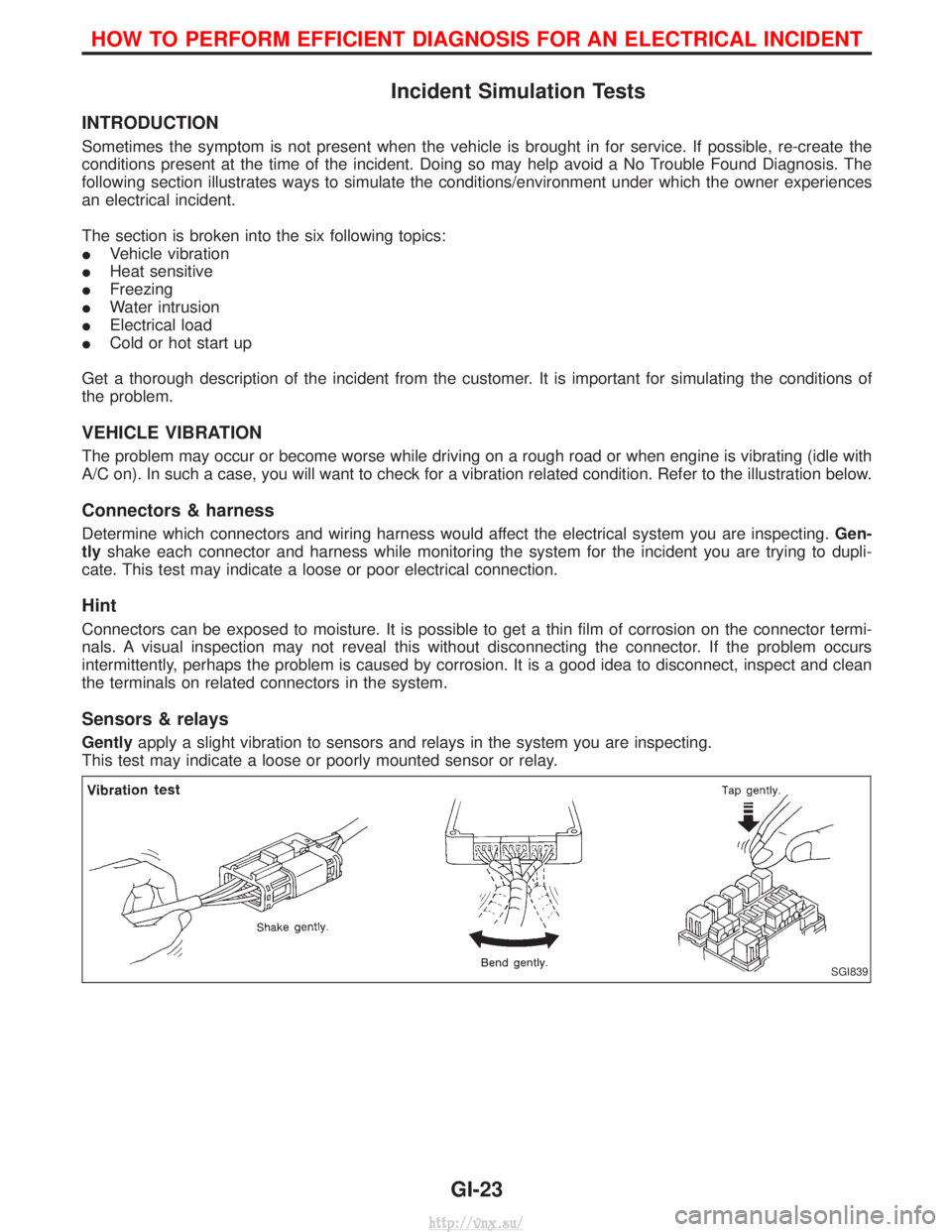

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gen-

tly shake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23

http://vnx.su/

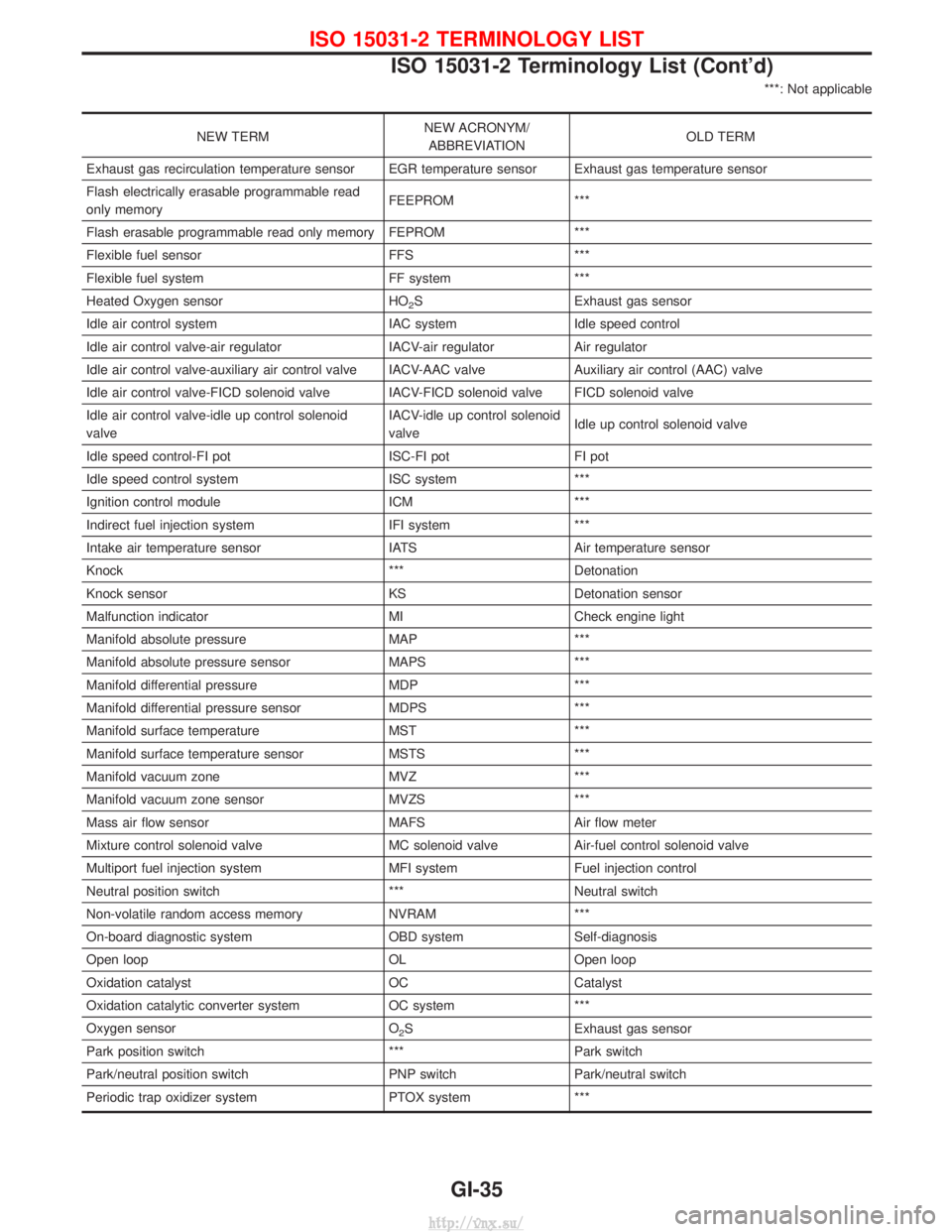

Page 38 of 1833

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATION OLD TERM

Exhaust gas recirculation temperature sensor EGR temperature sensor Exhaust gas temperature sensor

Flash electrically erasable programmable read

only memory FEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Heated Oxygen sensor HO

2S Exhaust gas sensor

Idle air control system IAC systemIdle speed control

Idle air control valve-air regulator IACV-air regulatorAir regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valve IACV-idle up control solenoid

valve

Idle up control solenoid valve

Idle speed control-FI pot ISC-FI potFI pot

Idle speed control system ISC system***

Ignition control module ICM***

Indirect fuel injection system IFI system***

Intake air temperature sensor IATS Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Neutral position switch *** Neutral switch

Non-volatile random access memory NVRAM ***

On-board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O

2S Exhaust gas sensor

Park position switch ***Park switch

Park/neutral position switch PNP switch Park/neutral switch

Periodic trap oxidizer system PTOX system ***

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-35

http://vnx.su/

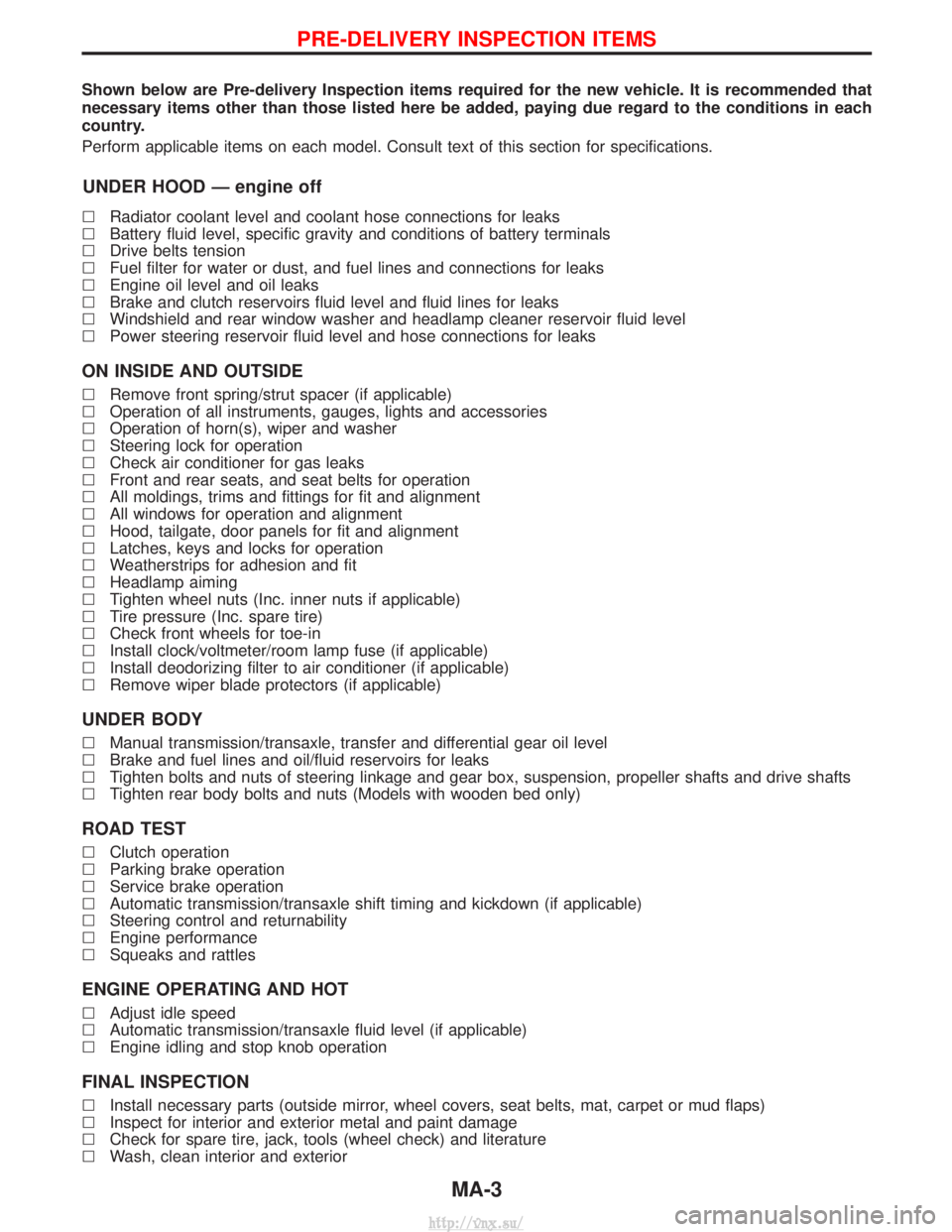

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 45 of 1833

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 63 of 1833

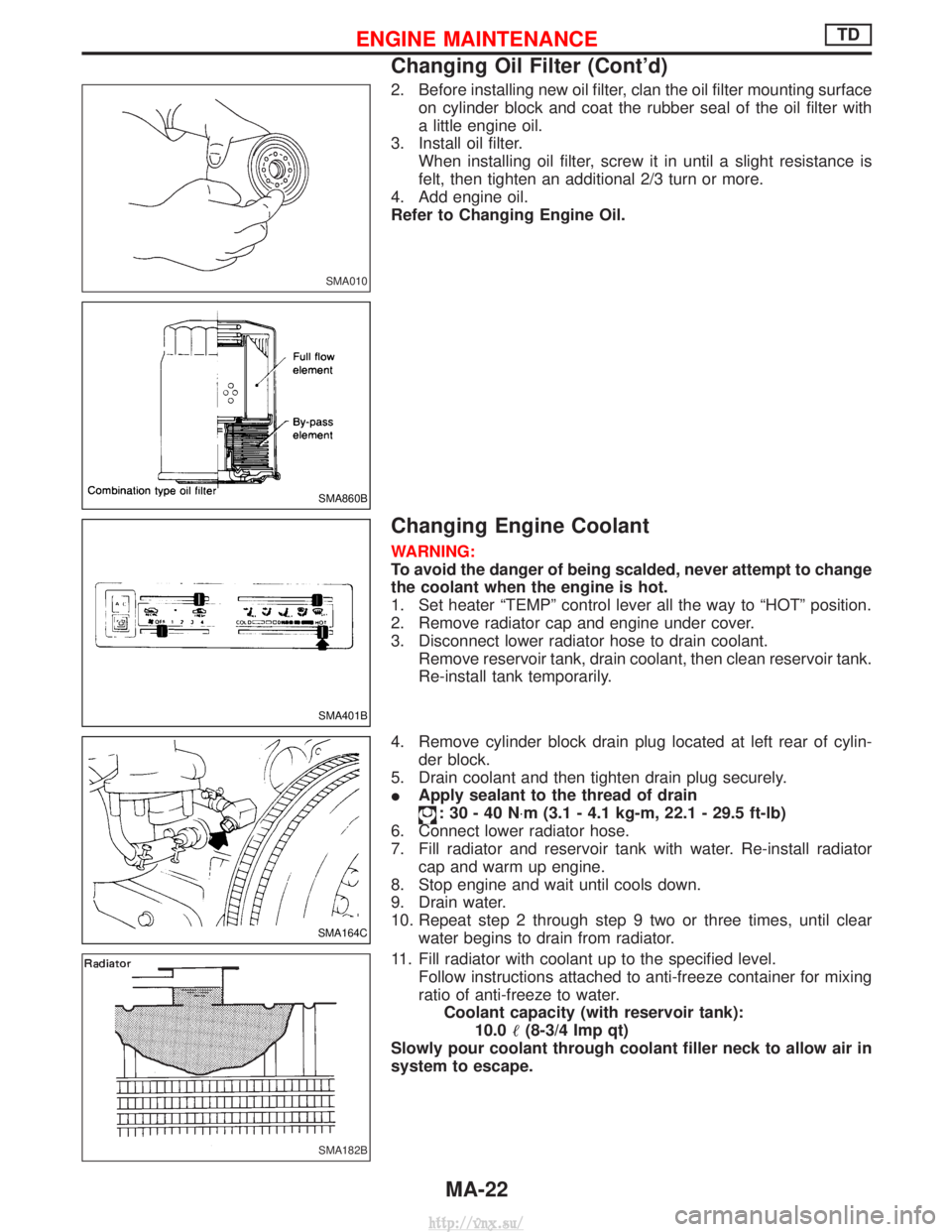

2. Before installing new oil filter, clan the oil filter mounting surfaceon cylinder block and coat the rubber seal of the oil filter with

a little engine oil.

3. Install oil filter. When installing oil filter, screw it in until a slight resistance is

felt, then tighten an additional 2/3 turn or more.

4. Add engine oil.

Refer to Changing Engine Oil.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never attempt to change

the coolant when the engine is hot.

1. Set heater ªTEMPº control lever all the way to ªHOTº position.

2. Remove radiator cap and engine under cover.

3. Disconnect lower radiator hose to drain coolant. Remove reservoir tank, drain coolant, then clean reservoir tank.

Re-install tank temporarily.

4. Remove cylinder block drain plug located at left rear of cylin- der block.

5. Drain coolant and then tighten drain plug securely.

I Apply sealant to the thread of drain

:30-40N ×m (3.1 - 4.1 kg-m, 22.1 - 29.5 ft-lb)

6. Connect lower radiator hose.

7. Fill radiator and reservoir tank with water. Re-install radiator cap and warm up engine.

8. Stop engine and wait until cools down.

9. Drain water.

10. Repeat step 2 through step 9 two or three times, until clear water begins to drain from radiator.

11. Fill radiator with coolant up to the specified level. Follow instructions attached to anti-freeze container for mixing

ratio of anti-freeze to water.Coolant capacity (with reservoir tank): 10.0 (8-3/4 Imp qt)

Slowly pour coolant through coolant filler neck to allow air in

system to escape.

SMA010

SMA860B

SMA401B

SMA164C

SMA182B

ENGINE MAINTENANCETD

Changing Oil Filter (Cont'd)

MA-22

http://vnx.su/

Page 65 of 1833

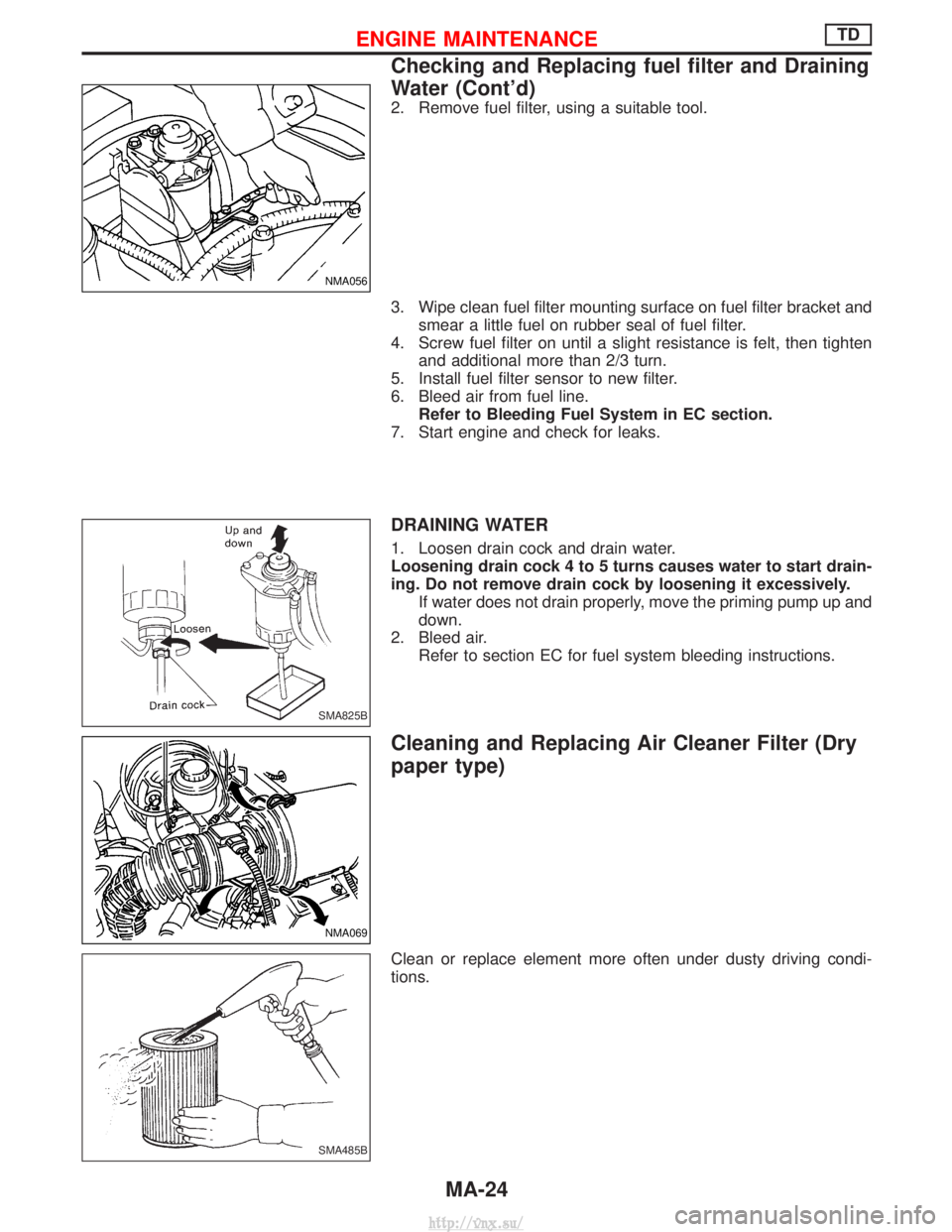

2. Remove fuel filter, using a suitable tool.

3. Wipe clean fuel filter mounting surface on fuel filter bracket andsmear a little fuel on rubber seal of fuel filter.

4. Screw fuel filter on until a slight resistance is felt, then tighten and additional more than 2/3 turn.

5. Install fuel filter sensor to new filter.

6. Bleed air from fuel line. Refer to Bleeding Fuel System in EC section.

7. Start engine and check for leaks.

DRAINING WATER

1. Loosen drain cock and drain water.

Loosening drain cock 4 to 5 turns causes water to start drain-

ing. Do not remove drain cock by loosening it excessively. If water does not drain properly, move the priming pump up and

down.

2. Bleed air. Refer to section EC for fuel system bleeding instructions.

Cleaning and Replacing Air Cleaner Filter (Dry

paper type)

Clean or replace element more often under dusty driving condi-

tions.

NMA056

SMA825B

NMA069

SMA485B

ENGINE MAINTENANCETD

Checking and Replacing fuel filter and Draining

Water (Cont'd)

MA-24

http://vnx.su/

Page 67 of 1833

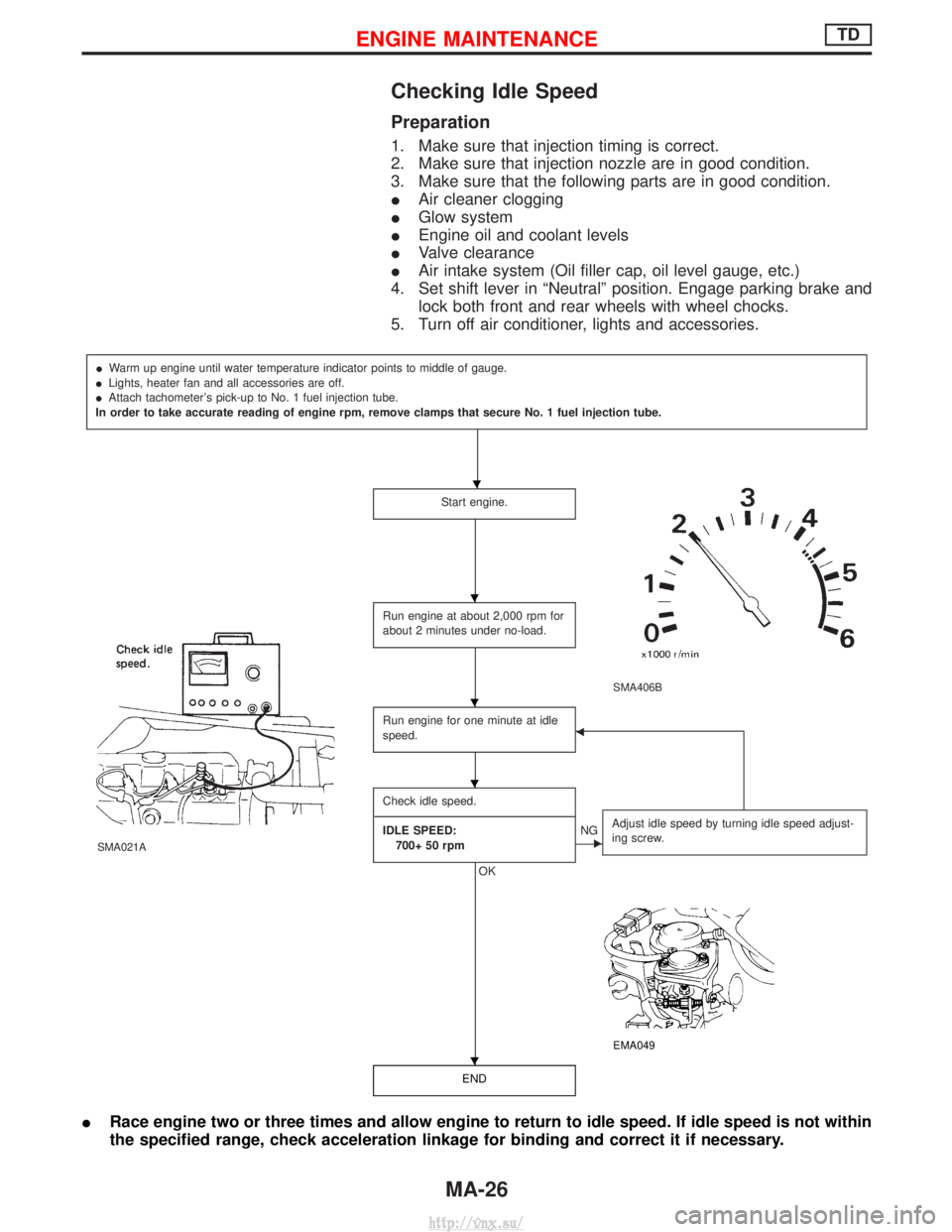

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

I Glow system

I Engine oil and coolant levels

I Valve clearance

I Air intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

I Warm up engine until water temperature indicator points to middle of gauge.

I Lights, heater fan and all accessories are off.

I Attach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- IDLE SPEED: 700+ 50 rpm

OK

ENG Adjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

I

Race engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

http://vnx.su/

Page 75 of 1833

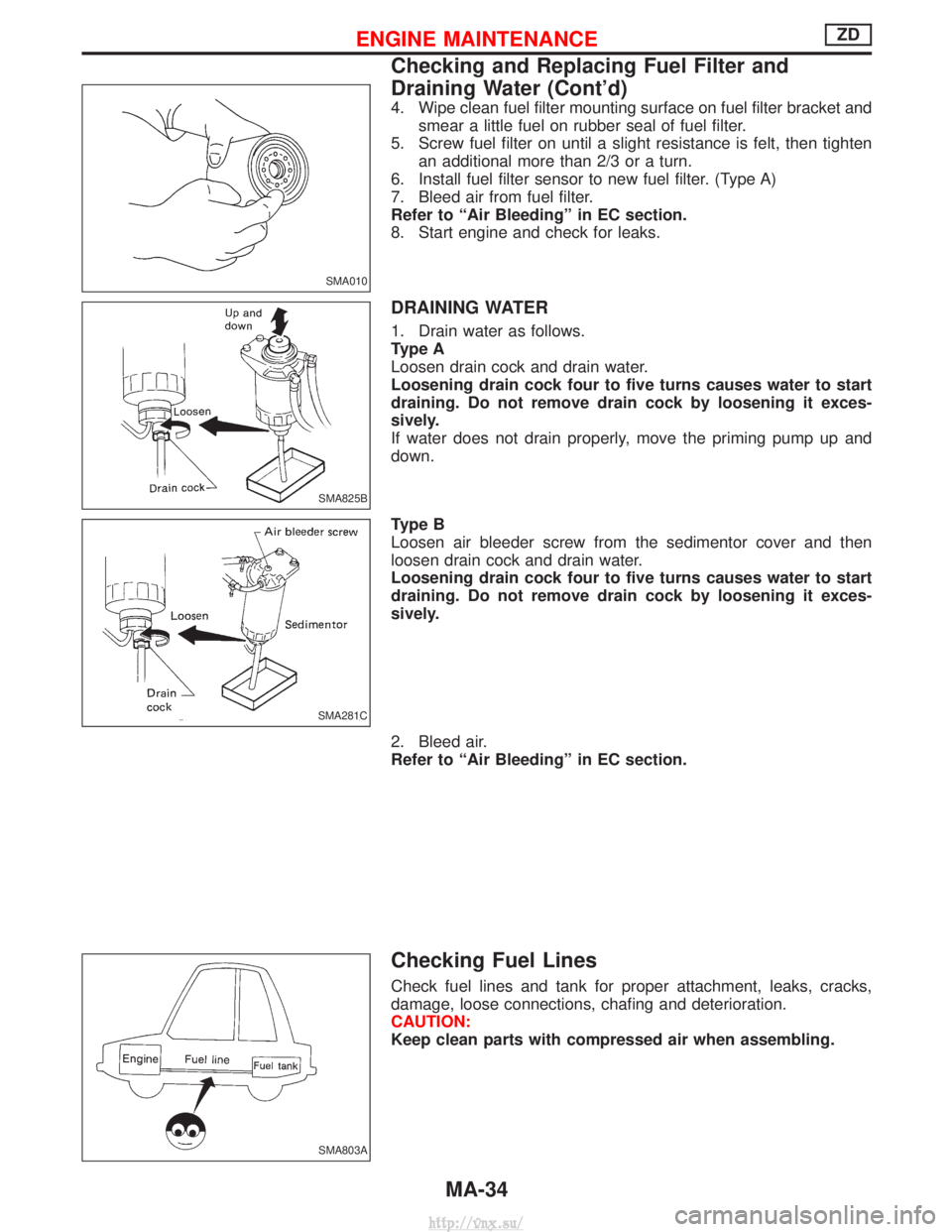

4. Wipe clean fuel filter mounting surface on fuel filter bracket andsmear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten an additional more than 2/3 or a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-34

http://vnx.su/

Page 115 of 1833

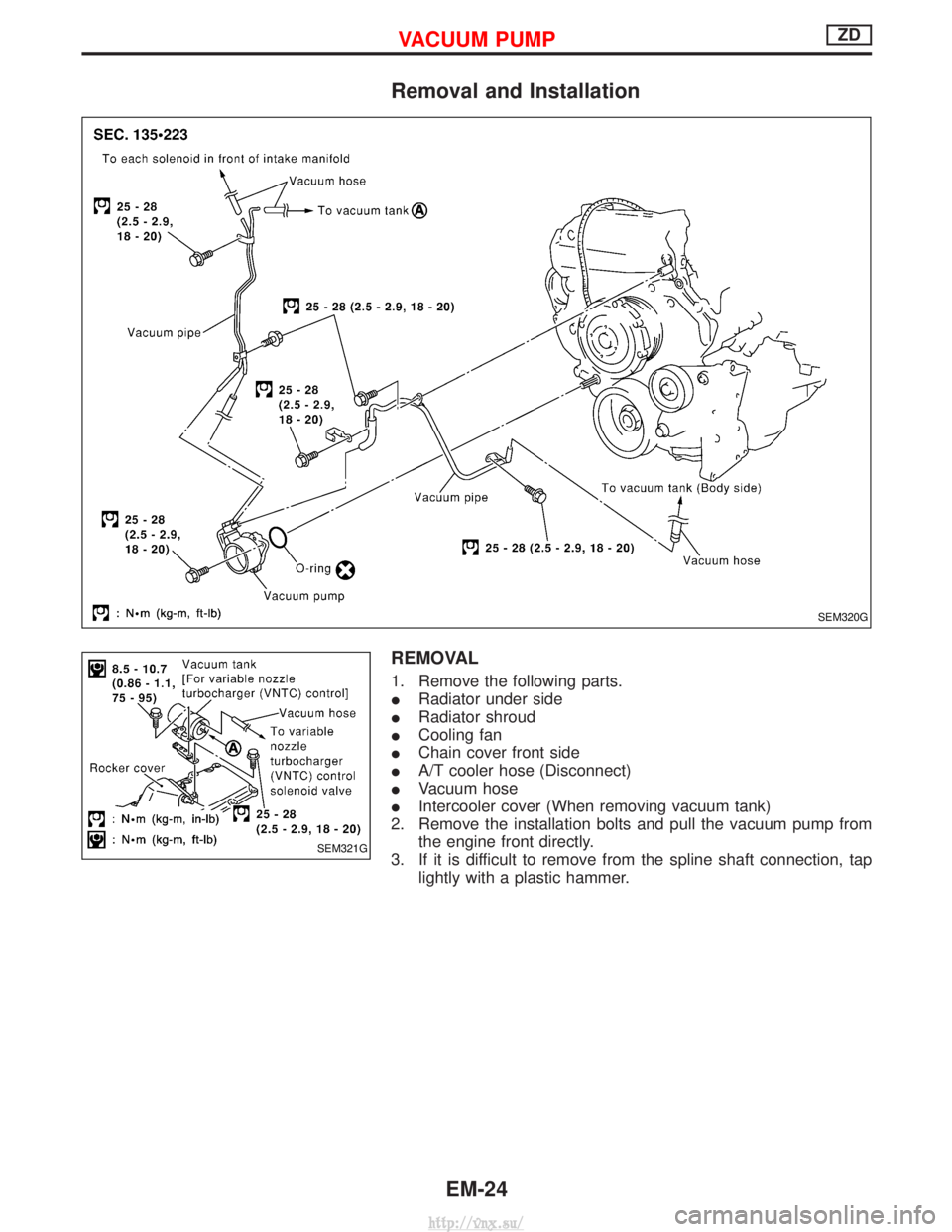

Removal and Installation

REMOVAL

1. Remove the following parts.

IRadiator under side

I Radiator shroud

I Cooling fan

I Chain cover front side

I A/T cooler hose (Disconnect)

I Vacuum hose

I Intercooler cover (When removing vacuum tank)

2. Remove the installation bolts and pull the vacuum pump from the engine front directly.

3. If it is difficult to remove from the spline shaft connection, tap lightly with a plastic hammer.

SEM320G

SEM321G

VACUUM PUMPZD

EM-24

http://vnx.su/