timing belt NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 44 of 1833

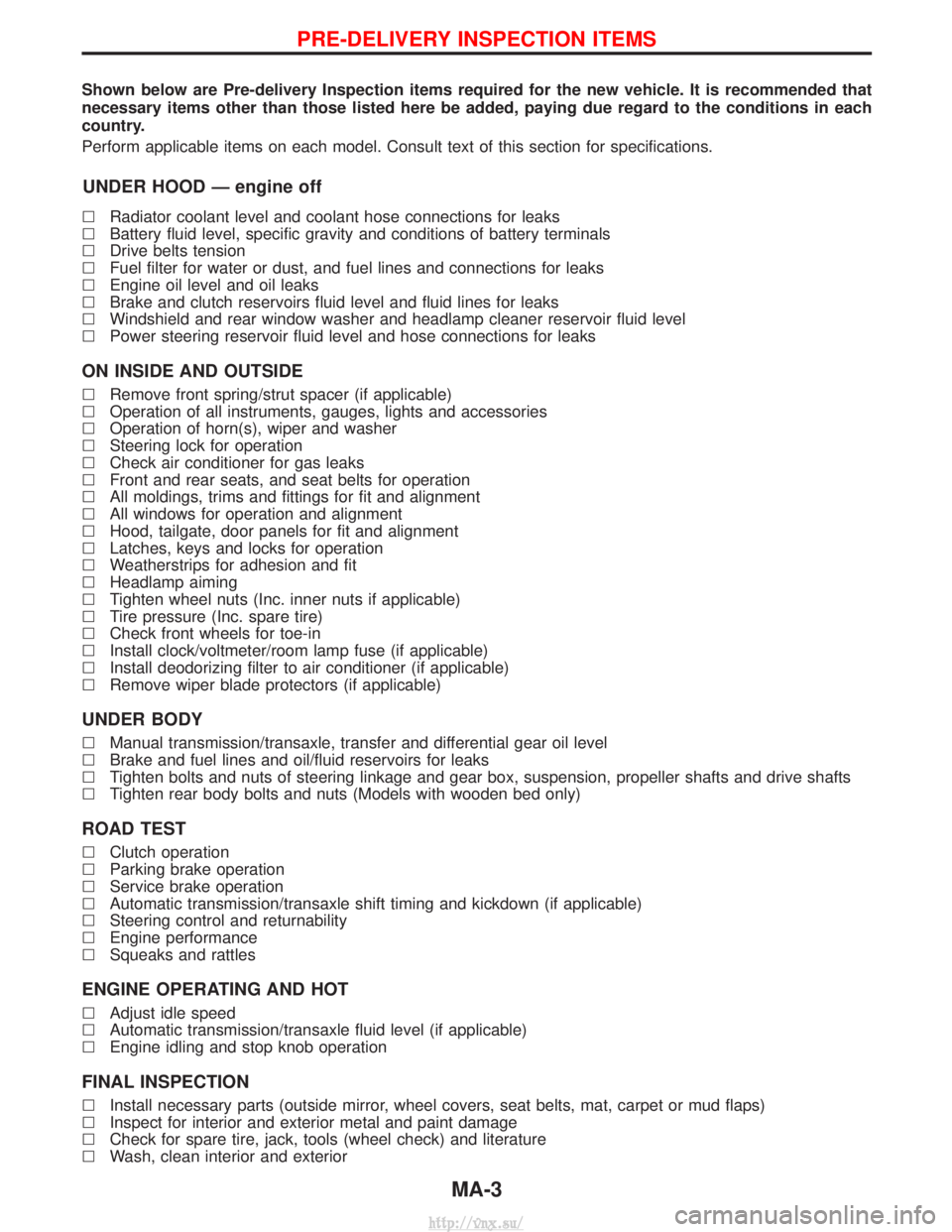

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 100 of 1833

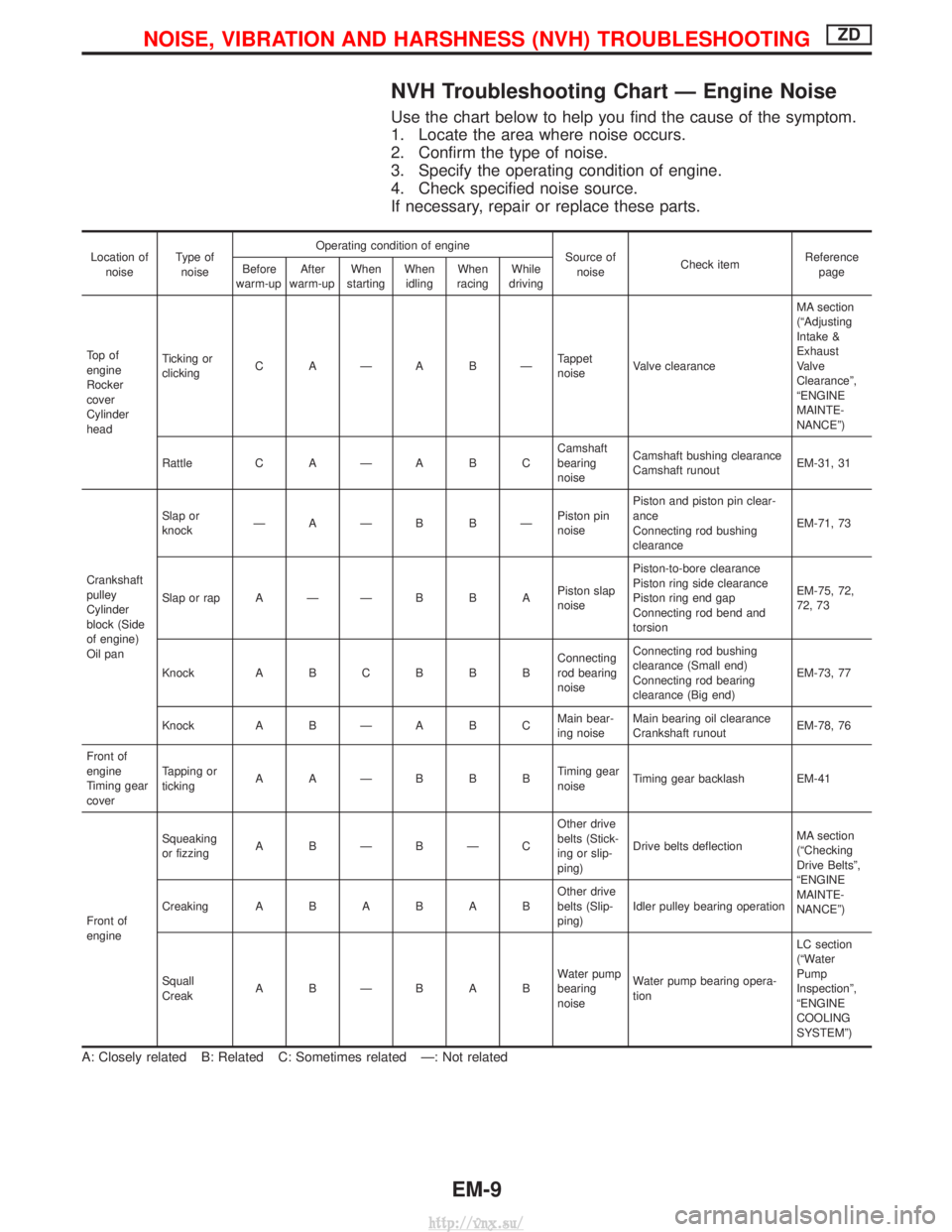

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location ofnoise Type of

noise Operating condition of engine

Source of

noise Check item Reference

page

Before

warm-up After

warm-up When

starting When

idling When

racing While

driving

To p o f

engine

Rocker

cover

Cylinder

head Ticking or

clicking

C AÐA BÐ Tappet

noiseValve clearance MA section

(ªAdjusting

Intake &

Exhaust

Valve

Clearanceº,

ªENGINE

MAINTE-

NANCEº)

Rattle C A Ð A B C Camshaft

bearing

noiseCamshaft bushing clearance

Camshaft runout

EM-31, 31

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil pan Slap or

knock

ÐAÐB BÐ Piston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearance

EM-71, 73

Slap or rap A Ð Ð B B A Piston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsion EM-75, 72,

72, 73

Knock A B C B B B Connecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)

EM-73, 77

Knock A B Ð A B C Main bear-

ing noiseMain bearing oil clearance

Crankshaft runout

EM-78, 76

Front of

engine

Timing gear

cover Tapping or

ticking

AAÐBBB Timing gear

noiseTiming gear backlash EM-41

Front of

engine Squeaking

or fizzing

A BÐBÐC Other drive

belts (Stick-

ing or slip-

ping)Drive belts deflection

MA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº)

Creaking

ABABAB Other drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

Creak ABÐBAB Water pump

bearing

noiseWater pump bearing opera-

tion LC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGZD

EM-9

http://vnx.su/

Page 117 of 1833

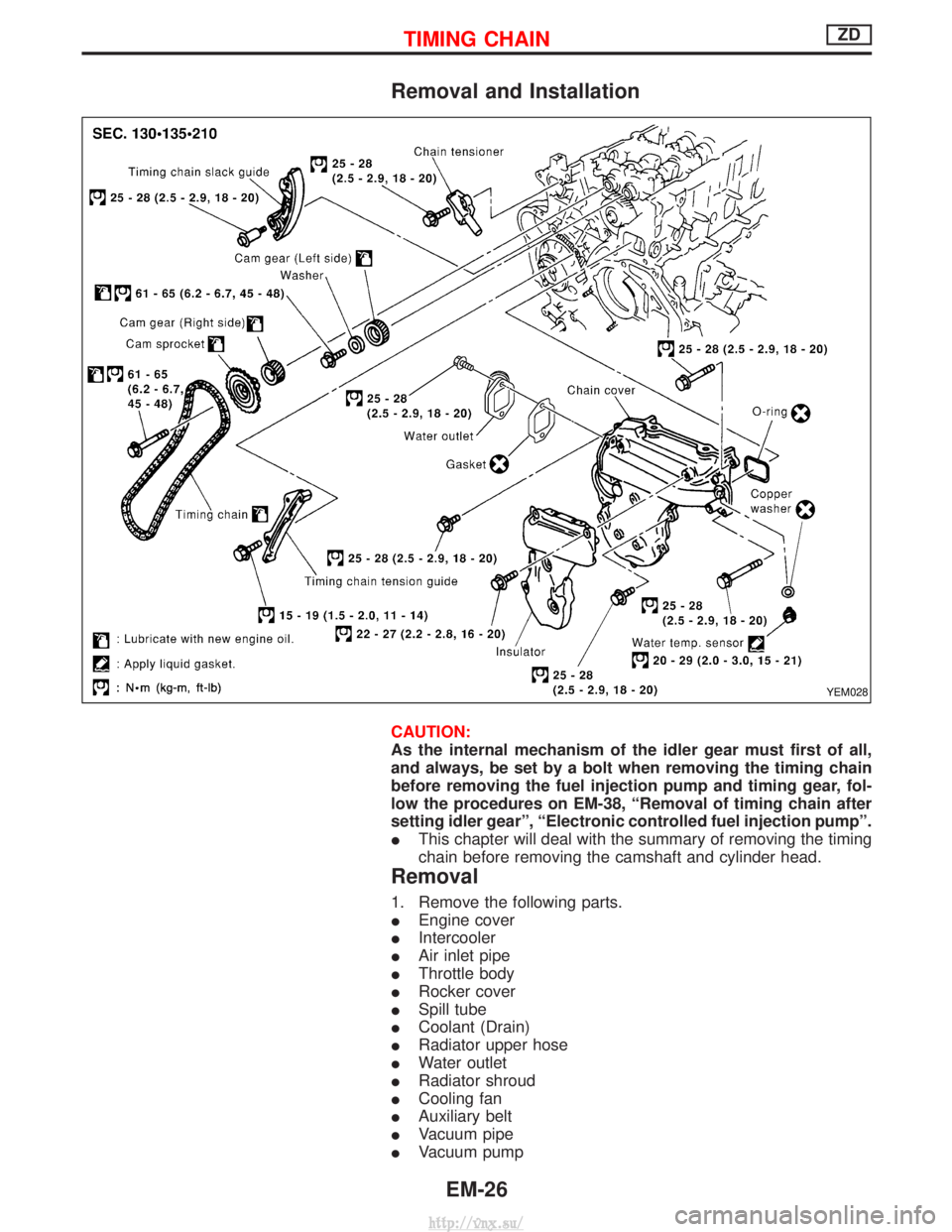

Removal and Installation

CAUTION:

As the internal mechanism of the idler gear must first of all,

and always, be set by a bolt when removing the timing chain

before removing the fuel injection pump and timing gear, fol-

low the procedures on EM-38, ªRemoval of timing chain after

setting idler gearº, ªElectronic controlled fuel injection pumpº.

IThis chapter will deal with the summary of removing the timing

chain before removing the camshaft and cylinder head.

Removal

1. Remove the following parts.

IEngine cover

I Intercooler

I Air inlet pipe

I Throttle body

I Rocker cover

I Spill tube

I Coolant (Drain)

I Radiator upper hose

I Water outlet

I Radiator shroud

I Cooling fan

I Auxiliary belt

I Vacuum pipe

I Vacuum pump

YEM028

TIMING CHAINZD

EM-26

http://vnx.su/

Page 159 of 1833

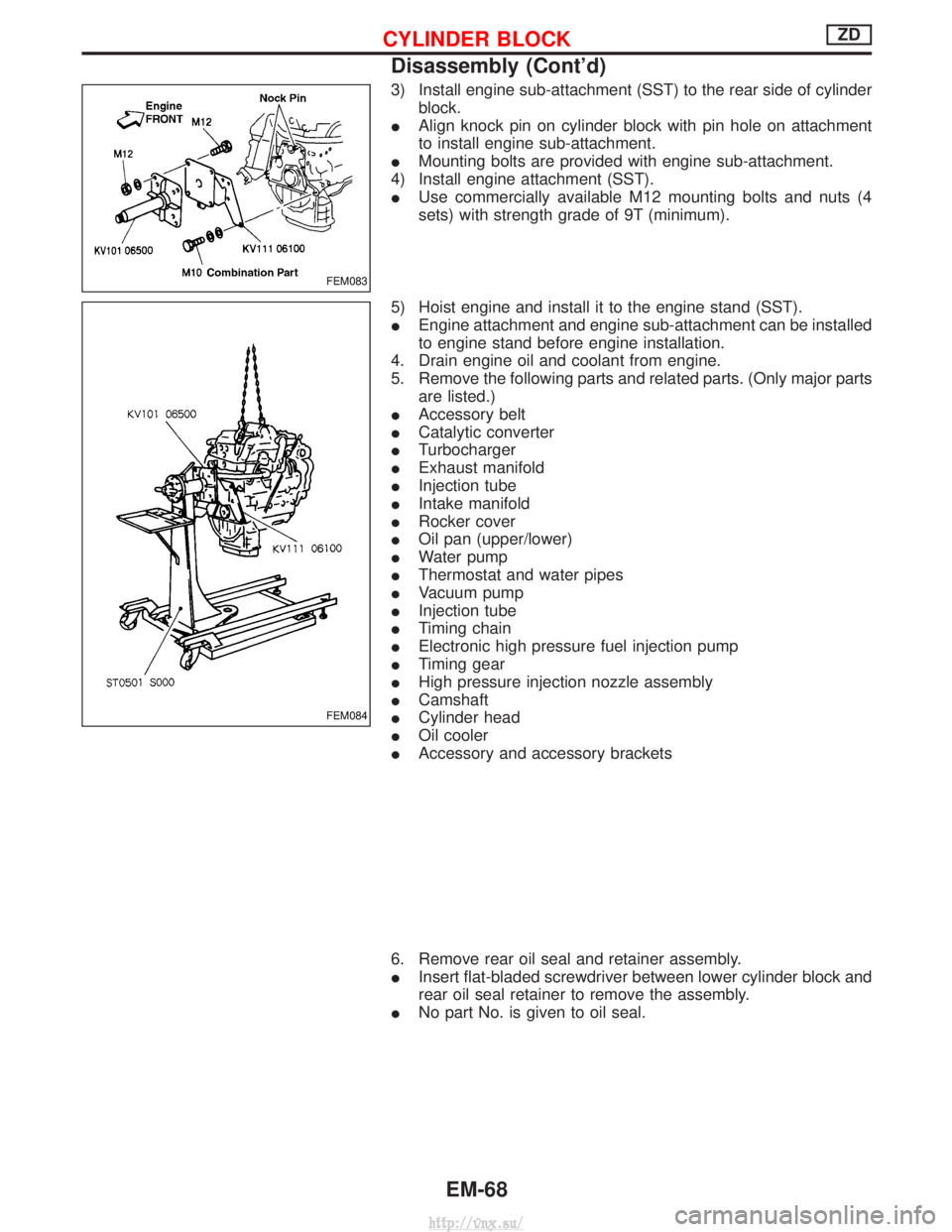

3) Install engine sub-attachment (SST) to the rear side of cylinderblock.

I Align knock pin on cylinder block with pin hole on attachment

to install engine sub-attachment.

I Mounting bolts are provided with engine sub-attachment.

4) Install engine attachment (SST).

I Use commercially available M12 mounting bolts and nuts (4

sets) with strength grade of 9T (minimum).

5) Hoist engine and install it to the engine stand (SST).

I Engine attachment and engine sub-attachment can be installed

to engine stand before engine installation.

4. Drain engine oil and coolant from engine.

5. Remove the following parts and related parts. (Only major parts are listed.)

I Accessory belt

I Catalytic converter

I Turbocharger

I Exhaust manifold

I Injection tube

I Intake manifold

I Rocker cover

I Oil pan (upper/lower)

I Water pump

I Thermostat and water pipes

I Vacuum pump

I Injection tube

I Timing chain

I Electronic high pressure fuel injection pump

I Timing gear

I High pressure injection nozzle assembly

I Camshaft

I Cylinder head

I Oil cooler

I Accessory and accessory brackets

6. Remove rear oil seal and retainer assembly.

I Insert flat-bladed screwdriver between lower cylinder block and

rear oil seal retainer to remove the assembly.

I No part No. is given to oil seal.

FEM083

FEM084

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-68

http://vnx.su/

Page 216 of 1833

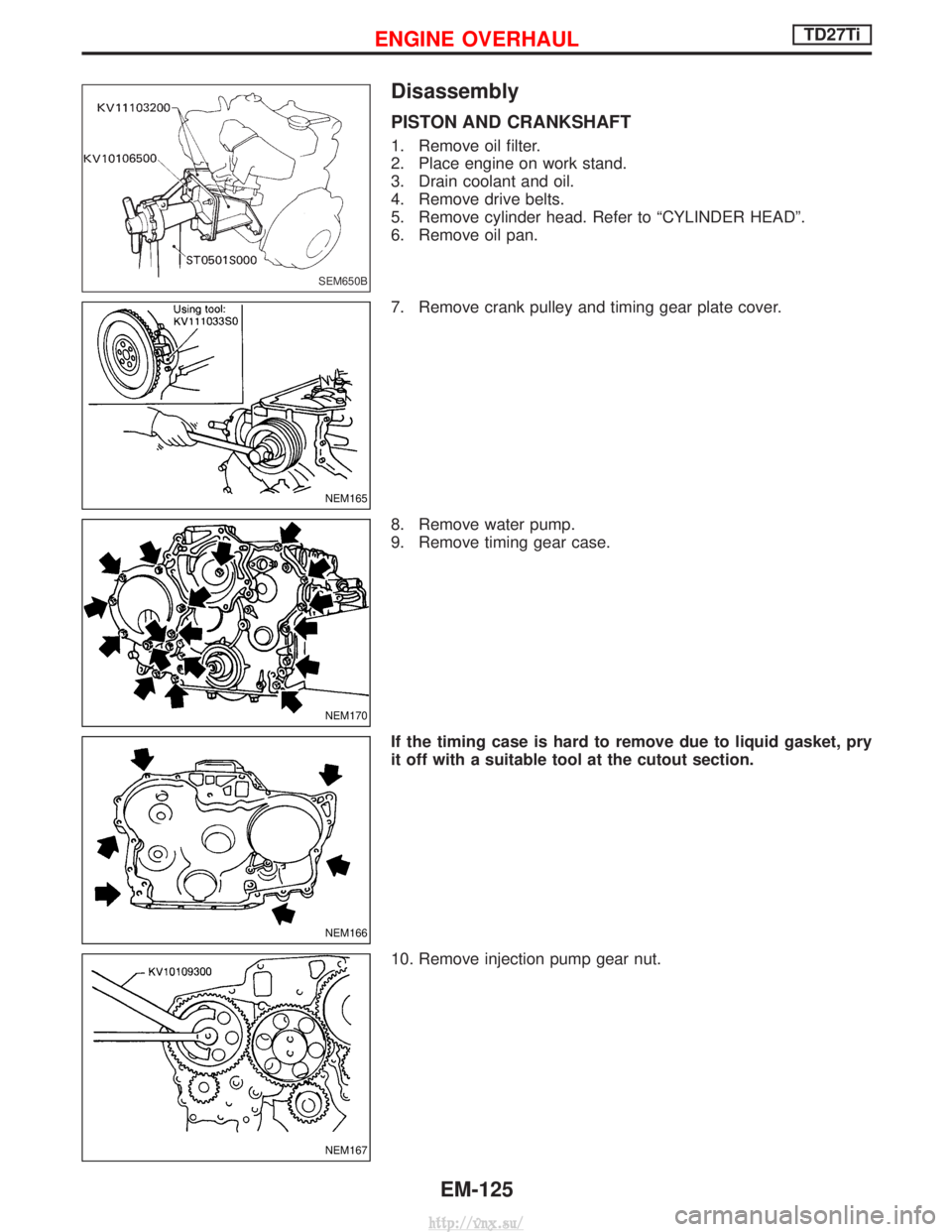

Disassembly

PISTON AND CRANKSHAFT

1. Remove oil filter.

2. Place engine on work stand.

3. Drain coolant and oil.

4. Remove drive belts.

5. Remove cylinder head. Refer to ªCYLINDER HEADº.

6. Remove oil pan.

7. Remove crank pulley and timing gear plate cover.

8. Remove water pump.

9. Remove timing gear case.

If the timing case is hard to remove due to liquid gasket, pry

it off with a suitable tool at the cutout section.

10. Remove injection pump gear nut.

SEM650B

NEM165

NEM170

NEM166

NEM167

ENGINE OVERHAULTD27Ti

EM-125

http://vnx.su/

Page 252 of 1833

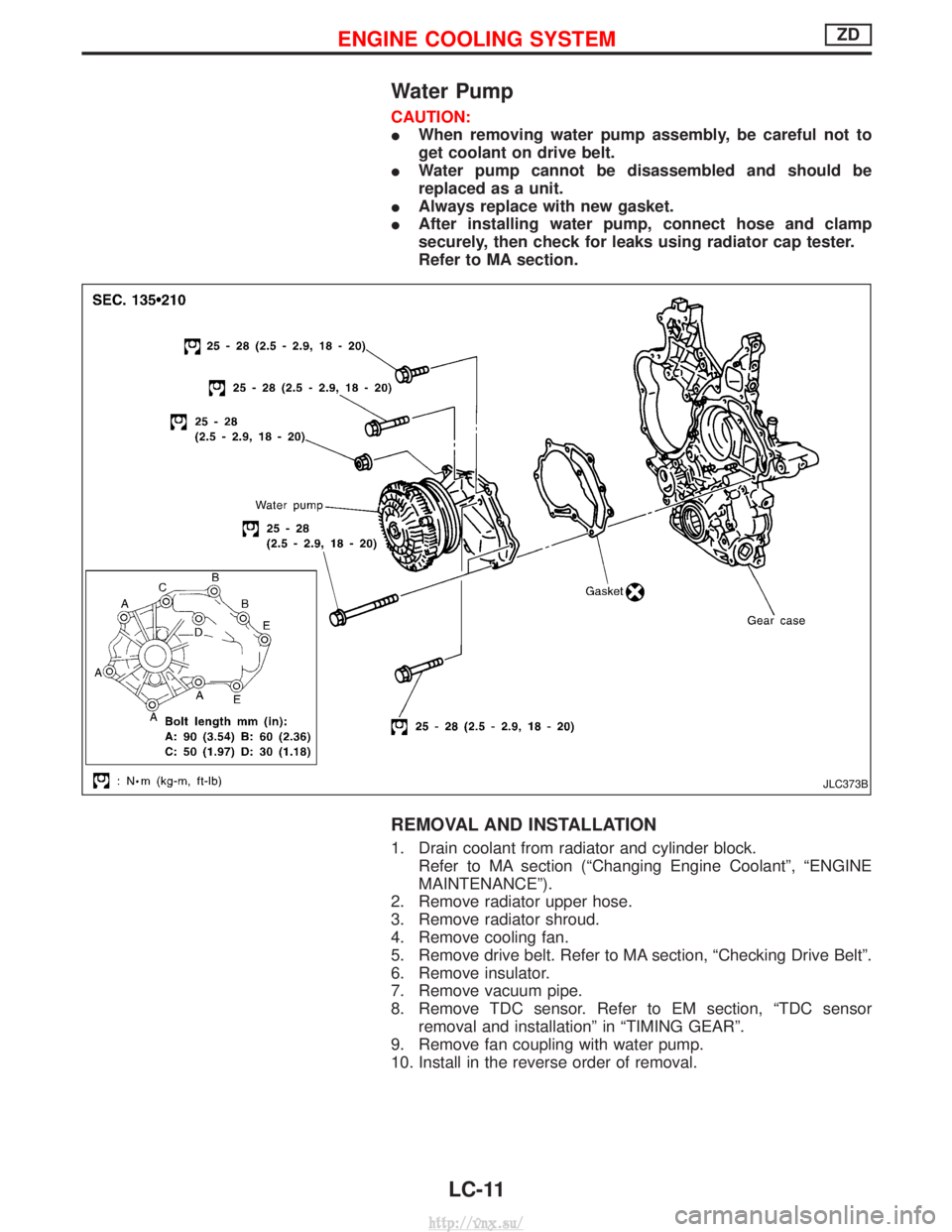

Water Pump

CAUTION:

IWhen removing water pump assembly, be careful not to

get coolant on drive belt.

I Water pump cannot be disassembled and should be

replaced as a unit.

I Always replace with new gasket.

I After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

Refer to MA section.

REMOVAL AND INSTALLATION

1. Drain coolant from radiator and cylinder block.

Refer to MA section (ªChanging Engine Coolantº, ªENGINE

MAINTENANCEº).

2. Remove radiator upper hose.

3. Remove radiator shroud.

4. Remove cooling fan.

5. Remove drive belt. Refer to MA section, ªChecking Drive Beltº.

6. Remove insulator.

7. Remove vacuum pipe.

8. Remove TDC sensor. Refer to EM section, ªTDC sensor removal and installationº in ªTIMING GEARº.

9. Remove fan coupling with water pump.

10. Install in the reverse order of removal.

JLC373B

ENGINE COOLING SYSTEMZD

LC-11

http://vnx.su/

Page 1829 of 1833

F

Fan switch ......................................................HA-60

F/FOG - Wiring diagram .................................EL-55

Final drive disassembly............................PD-15, 37

Final drive pre-inspection .........................PD-15, 37

Final drive removal and installation ...............PD-15

Finisher, interior - See Trim ............................BT-18

Finisher, rear panel .........................................BT-18

Floor trim .........................................................BT-18

Fluid temperature sensor (A/T) .....................AT-146

Fluids .............................................MA-5, 17, 20, 36

Flywheel (clutch) .......................................CL-11, 12

Flywheel runout..............................................EM-94

Fog lamp, front .........................................EL-55, 57

Fog lamp, rear ................................................EL-58

Fork rod (M/T) ................................................MT-13

Forward clutch...............................................AT-162

Front axle ....................................................FA-4, 13

Front bumper ....................................................BT-6

Front case (Transfer) ..................................TF-9, 23

Front combination lamp removal andinstallation .....................................................BT-6

Front disc brake .............................................BR-27

Front door .......................................................BT-10

Front Door Trim...............................................BT-19

Front drive shaft (Transfer) .........................TF-9, 19

Front final drive disassembly (4WD) ..............PD-14

Front final drive removal and installa- tion (4WD) ............................................PD-12, 13

Front fog lamp ..........................................EL-55, 57

Front passenger air bag .................................RS-19

Front seat ........................................................BT-34

Front seat belt ..................................................RS-4

Front seat belt pre-tensioner ..........................RS-14

Front side air bag ...........................................RS-20

Front suspension ........................................FA-4, 29

Fuel cut control (at no load & high engine speed).....................................EC-22, 334

Fuel cut solenoid valve ................................EC-399

Fuel cut system ............................................EC-237

Fuel filler lid.......................................................BT-8

Fuel filter replacement...................MA-5, 20, 23, 33

Fuel gauge..................................FE-3, 6, EL-86, 98

Fuel injection system .............................EC-20, 329

Fuel injection timing feed back (Elec- tronic Fuel Injection Pump) ......................EC-197

Fuel precautions ................................................GI-6

Fuel pump and gauge ..............................FE-3, 6, 7

Fuel system ..................................................FE-3, 6

Fuel tank .......................................................FE-3, 6

Fuel temperature sensor ......................EC-123, 395

Fuse ................................................................EL-19

Fuse and fusible link box .............................Foldout

Fuse block ....................................................Foldout

Fusible link ......................................................EL-19 GGarage jack and safety stand .........................GI-31

Gauges .....................................................EL-82, 85

Gear components (M/T) ........MT-11, 14, 16, 21, 23

Generator - See Alternator .............................SC-27

GLOW - Wiring diagram...............................EC-246

Glow control system ....................EC-244, 334, 412

Glow plug .............................................EC-244, 413

Glow relay ............................................EC-246, 419

Grease .........................................MA-17, 39, 40, 44

Ground distribution..........................................EL-20

H

Harness connector ............................................EL-5

Harness connector inspection .........................GI-19

Harness layout ....EL-280, 281, 282, 298, 310, 312,320, 321, 322, 323, 324

Hazard warning lamp................................EL-61, 62

Headlamp ......EL-28, 32, 33, 34, 41, 42, 43, 46, 47

Headlamp aiming control .............EL-41, 42, 43, 46

Headlamp washer .........................................EL-118

Headlining - See Roof trim .............................BT-20

Heat up switch..............................................EC-265

Heated seat .......................................BT-36, EL-151

HEATER - Wiring diagram .............................HA-41

HEATUP - Wiring diagram ...........................EC-266

Height (Dimensions) ........................................GI-10

HFC134a (R134a) system precaution .............HA-3

HFC134a (R134a) system service procedure....................................................HA-15

HFC134a (R134a) system service tools ........HA-11

High clutch ....................................................AT-160

H/LAMP - Wiring diagram ............EL-28, 34, 43, 62

Hood..................................................................BT-6

Hood lock system .............................................BT-6

Horn ..............................................................EL-122

HORN - Wiring diagram................................EL-122

How to erase DTC for OBD system ......EC-33, 344

HSEAT - Wiring diagram...............................EL-151

I

Identification .....................................................HA-2

Identification plate .....................................GI-28, 29

Idle speed...............................................EC-50, 361

Idle speed inspection ...............................MA-20, 26

ILL - Wiring diagram .......................................EL-68

Illumination ................................................EL-67, 68

Injection nozzle ......................................EC-24, 336

Injection nozzle inspection ..................MA-5, 20, 25

Injection timing control valve ........................EC-403

INJPMP - Wiring diagram ...EC-126, 169, 176, 183, 190, 200, 240

Instrument panel .............................................BT-16

INT/L - Wiring diagram....................................EL-74

ALPHABETICAL INDEX

IDX-4

http://vnx.su/