trunk NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 18 of 1833

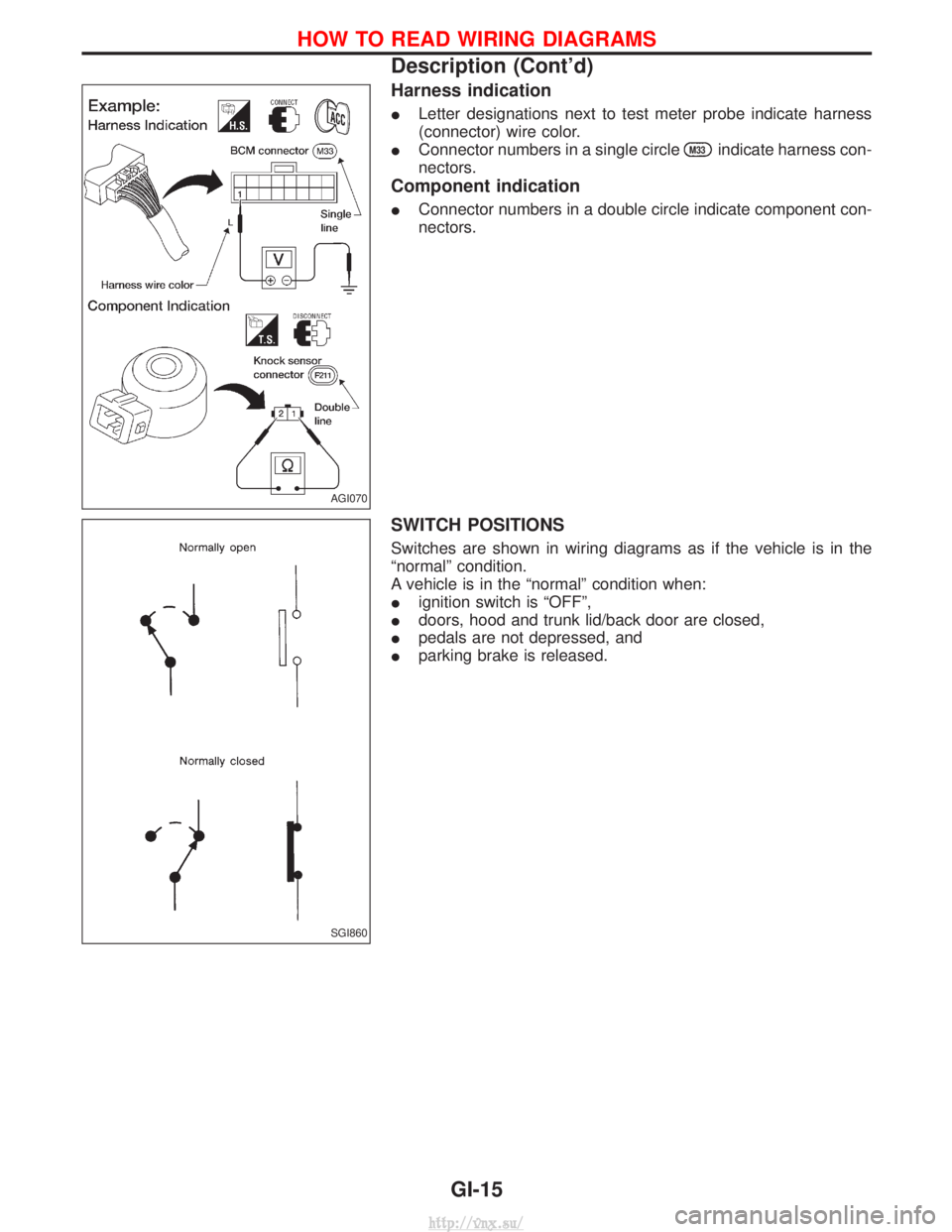

Harness indication

ILetter designations next to test meter probe indicate harness

(connector) wire color.

I Connector numbers in a single circle

M33indicate harness con-

nectors.

Component indication

I Connector numbers in a double circle indicate component con-

nectors.

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the

ªnormalº condition.

A vehicle is in the ªnormalº condition when:

Iignition switch is ªOFFº,

I doors, hood and trunk lid/back door are closed,

I pedals are not depressed, and

I parking brake is released.

AGI070

SGI860

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-15

http://vnx.su/

Page 45 of 1833

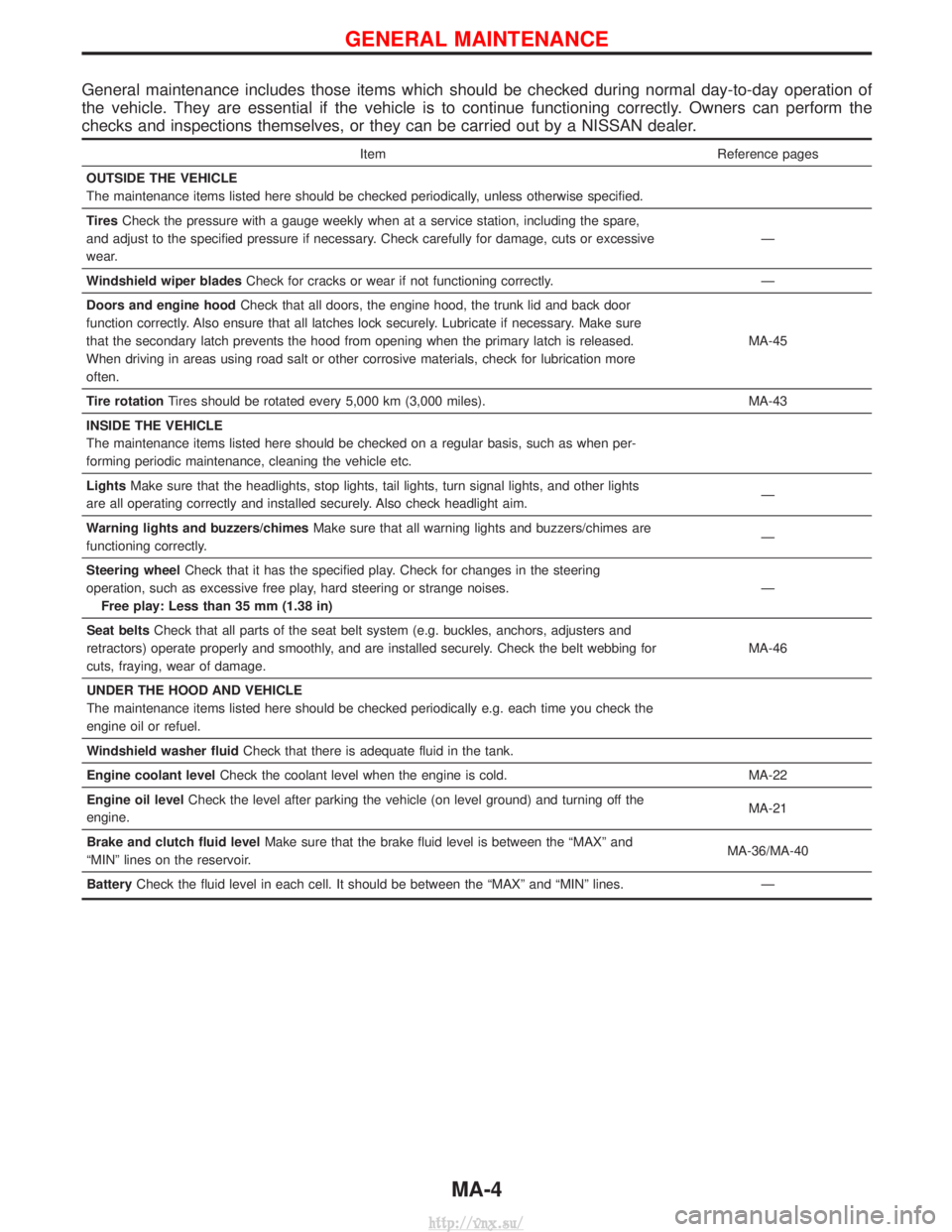

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 88 of 1833

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut lower in engine

compartment, etc.

Panel edge

Back door lid opening, sun roof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel,

etc.

Parts contact

Waist moulding, windshield moulding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-47

http://vnx.su/

Page 1712 of 1833

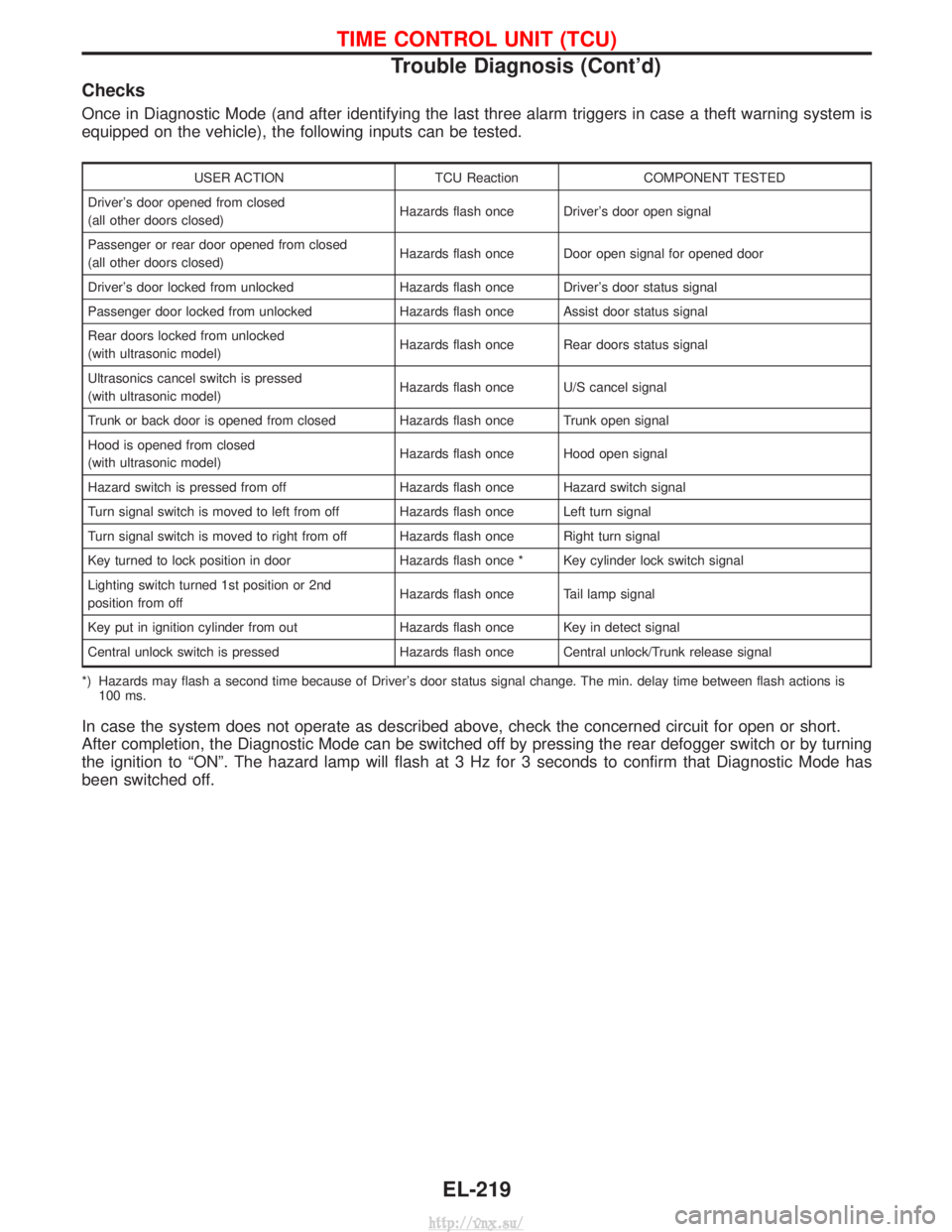

Checks

Once in Diagnostic Mode (and after identifying the last three alarm triggers in case a theft warning system is

equipped on the vehicle), the following inputs can be tested.

USER ACTIONTCU ReactionCOMPONENT TESTED

Driver's door opened from closed

(all other doors closed) Hazards flash once Driver's door open signal

Passenger or rear door opened from closed

(all other doors closed) Hazards flash once Door open signal for opened door

Driver's door locked from unlocked Hazards flash once Driver's door status signal

Passenger door locked from unlocked Hazards flash once Assist door status signal

Rear doors locked from unlocked

(with ultrasonic model) Hazards flash once Rear doors status signal

Ultrasonics cancel switch is pressed

(with ultrasonic model) Hazards flash once U/S cancel signal

Trunk or back door is opened from closed Hazards flash once Trunk open signal

Hood is opened from closed

(with ultrasonic model) Hazards flash once Hood open signal

Hazard switch is pressed from off Hazards flash once Hazard switch signal

Turn signal switch is moved to left from off Hazards flash once Left turn signal

Turn signal switch is moved to right from off Hazards flash once Right turn signal

Key turned to lock position in door Hazards flash once * Key cylinder lock switch signal

Lighting switch turned 1st position or 2nd

position from off Hazards flash once Tail lamp signal

Key put in ignition cylinder from out Hazards flash once Key in detect signal

Central unlock switch is pressed Hazards flash once Central unlock/Trunk release signal

*) Hazards may flash a second time because of Driver's door status signal change. The min. delay time between flash actions is 100 ms.

In case the system does not operate as described above, check the concerned circuit for open or short.

After completion, the Diagnostic Mode can be switched off by pressing the rear defogger switch or by turning

the ignition to ªONº. The hazard lamp will flash at 3 Hz for 3 seconds to confirm that Diagnostic Mode has

been switched off.

TIME CONTROL UNIT (TCU)

Trouble Diagnosis (Cont'd)

EL-219

http://vnx.su/

Page 1757 of 1833

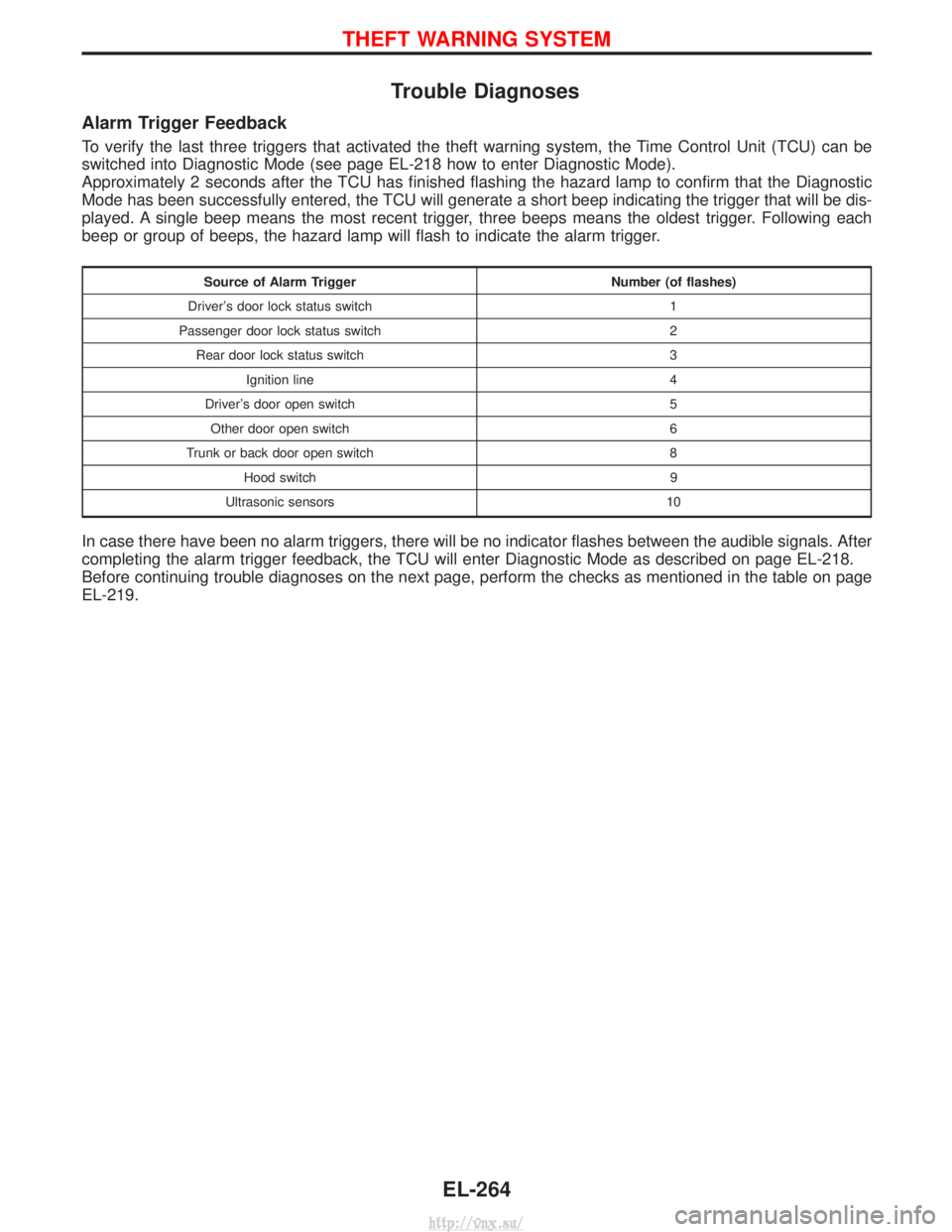

Trouble Diagnoses

Alarm Trigger Feedback

To verify the last three triggers that activated the theft warning system, the Time Control Unit (TCU) can be

switched into Diagnostic Mode (see page EL-218 how to enter Diagnostic Mode).

Approximately 2 seconds after the TCU has finished flashing the hazard lamp to confirm that the Diagnostic

Mode has been successfully entered, the TCU will generate a short beep indicating the trigger that will be dis-

played. A single beep means the most recent trigger, three beeps means the oldest trigger. Following each

beep or group of beeps, the hazard lamp will flash to indicate the alarm trigger.

Source of Alarm TriggerNumber (of flashes)

Driver's door lock status switch 1

Passenger door lock status switch 2

Rear door lock status switch 3

Ignition line 4

Driver's door open switch 5

Other door open switch 6

Trunk or back door open switch 8

Hood switch 9

Ultrasonic sensors 10

In case there have been no alarm triggers, there will be no indicator flashes between the audible signals. After

completing the alarm trigger feedback, the TCU will enter Diagnostic Mode as described on page EL-218.

Before continuing trouble diagnoses on the next page, perform the checks as mentioned in the table on page

EL-219.

THEFT WARNING SYSTEM

EL-264

http://vnx.su/

Page 1758 of 1833

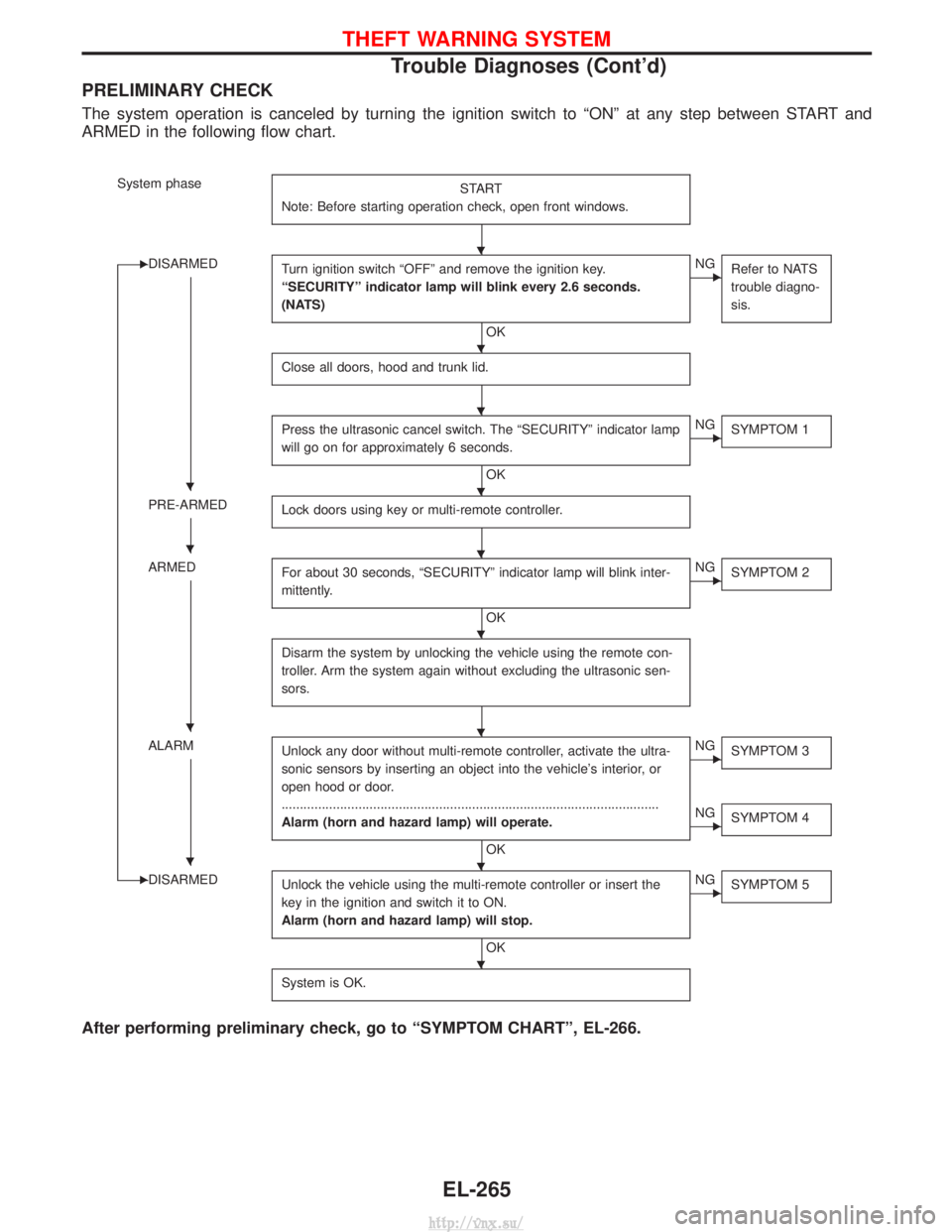

PRELIMINARY CHECK

The system operation is canceled by turning the ignition switch to ªONº at any step between START and

ARMED in the following flow chart.

System phaseSTART

Note: Before starting operation check, open front windows.

EDISARMED Turn ignition switch ªOFFº and remove the ignition key.

ªSECURITYº indicator lamp will blink every 2.6 seconds.

(NATS)

OK

ENGRefer to NATS

trouble diagno-

sis.

Close all doors, hood and trunk lid.

Press the ultrasonic cancel switch. The ªSECURITYº indicator lamp

will go on for approximately 6 seconds.

OK

ENGSYMPTOM 1

PRE-ARMED Lock doors using key or multi-remote controller.

ARMEDFor about 30 seconds, ªSECURITYº indicator lamp will blink inter-

mittently.

OK

ENGSYMPTOM 2

Disarm the system by unlocking the vehicle using the remote con-

troller. Arm the system again without excluding the ultrasonic sen-

sors.

ALARM Unlock any door without multi-remote controller, activate the ultra-

sonic sensors by inserting an object into the vehicle's interior, or

open hood or door.

........................................................................\

...............................

Alarm (horn and hazard lamp) will operate.

OK

ENGSYMPTOM 3

ENGSYMPTOM 4

EDISARMED Unlock the vehicle using the multi-remote controller or insert the

key in the ignition and switch it to ON.

Alarm (horn and hazard lamp) will stop.

OK

ENGSYMPTOM 5

System is OK.

After performing preliminary check, go to ªSYMPTOM CHARTº, EL-266.

H

H

H

HH

HH

H

HH

HH

H

THEFT WARNING SYSTEM

Trouble Diagnoses (Cont'd)

EL-265

http://vnx.su/

Page 1832 of 1833

T

Tachometer .....................................................EL-86

Tail lamp ..........................................................EL-49

TAIL/L - Wiring diagram ..................................EL-49

TCM circuit diagram ..........................................AT-7

TCM inspection table ......................................AT-46

TDC Pulse Signal .........................................EC-173

Temperature control cable and linkageadjustment ..................................................HA-63

THEFT - Wiring diagram...............................EL-248

Theft warning system ...........EL-243, 244, 247, 264

Thermo control amp. ......................................HA-61

Thermostat................................................LC-12, 31

Third (3rd) seat ...............................................BT-39

THLCNT - Wiring diagram ...........................EC-458

Three way catalyst precautions.........................GI-5

Throttle control solenoid valve .....................EC-458

Throttle position switch ...................................AT-62

Tie-rod .......................................................ST-19, 21

Tie-rod ball joints.............................................ST-20

Tightening torque of standard bolts.................GI-37

Time control system .....................EL-216, 218, 220

Timing chain ...................................................EM-26

Timing gear ....................................................EM-38

Tire rotation ....................................................MA-43

Tooth contact diff. .....................................PD-27, 52

Torque converter clutch solenoid valve ..AT-74, 146

Torsion bar spring .......................................FA-4, 30

Tow truck towing ..............................................GI-32

Towing point.....................................................GI-33

Transaxle fluid replacement.....................MA-36, 37

Transfer case ..............................................TF-9, 12

Transfer fluid replacement (Part time 4WD model) .........................................MA-36, 37

Transfer oil replacement ..........................MA-36, 38

Transmission case (M/T)..........................MT-10, 14

TRANSMT - Wiring diagram ...........................EL-98

Tread-FR&RR (Dimensions)............................GI-25

Trim...............................................BT-18, 19, 20, 21

Trunk room trim...............................................BT-47

Turbocharger ..................................................EM-14

Turbocharger charge air cooler......................EM-11

Turbocharger precautions..................................GI-5

TURN - Wiring diagram ..................................EL-62

Turn signal lamp .......................................EL-61, 62

U

Under body .....................................................BT-53

Upper link (front susp.) ...................................FA-33 V

Vacuum hose (brake system) ........................BR-20

Vacuum hose drawing (Engine

control)................................................EC-18, 327

Vacuum pump .............................EM-24, BR-24, 26

Valve clearance..............................................EM-35

Valve clearance adjustment.....................MA-20, 28

Valve guide ....................................................EM-59

Valve lifter ......................................................EM-32

Valve seat ......................................................EM-60

Valve spring ...................................................EM-61

Variable nozzle turbocharger control solenoid valve ...........................................EC-289

Vehicle identification number...........................GI-28

Vehicle speed sensor (VSS) ..................EC-99, 420

Ventilator door control rod adjustment ...........HA-61

Viscosity number (SAE)...........................MA-17, 18

VNT - Wiring diagram ..................................EC-291

VSS - Wiring diagram ..................................EC-101

W

WARN - Wiring diagram........................EL-100, 111

Warning chime ........................................EL-99, 111

Warning lamps ........................................EL-99, 100

Washer, front .................................................EL-112

Washer, rear ..................................................EL-114

Water cock control rod adjustment ................HA-63

Water pump ..............................................LC-11, 29

Water temperature gauge ...............................EL-86

Weatherstrip - See Exterior ............................BT-21

Wheel alignment (front) ....................................FA-8

Wheel balance ...............................................MA-43

Wheel bearing (front axle) ................................FA-6

Wheel bearing (rear) ..................................RA-5, 16

Wheel hub (front) ........................................FA-4, 18

Wheel sensors (ABS)...............................BR-39, 43

Wheel size .......................................................GI-30

WINDOW - Wiring diagram ..........................EL-159

Window, back door .........................................BT-47

Window, door ..................................................BT-42

Window, rear side .....................................BT-42, 43

Window, side - See Rear side window ...........BT-43

Windshield.......................................................BT-42

WIP/R - Wiring diagram ................................EL-114

WIPER - Wiring diagram .......................EL-112, 118

Wiper and washer .................................EL-112, 116

Wiper, front ....................................................EL-112

Wiper, rear.....................................................EL-114

Wiring Diagram (Cell code) list .....................EL-326

ALPHABETICAL INDEX

IDX-7

http://vnx.su/