turn signal relay NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 297 of 1833

Fuel Injection Timing Control System

DESCRIPTION

The target fuel injection timing in accordance with the engine speed and the fuel injection amount are recorded

as a map in the ECM beforehand. The ECM and the injection pump control unit exchange signals and per-

form feedback control for optimum injection timing in accordance with the map.

Air Conditioning Cut Control

DESCRIPTION

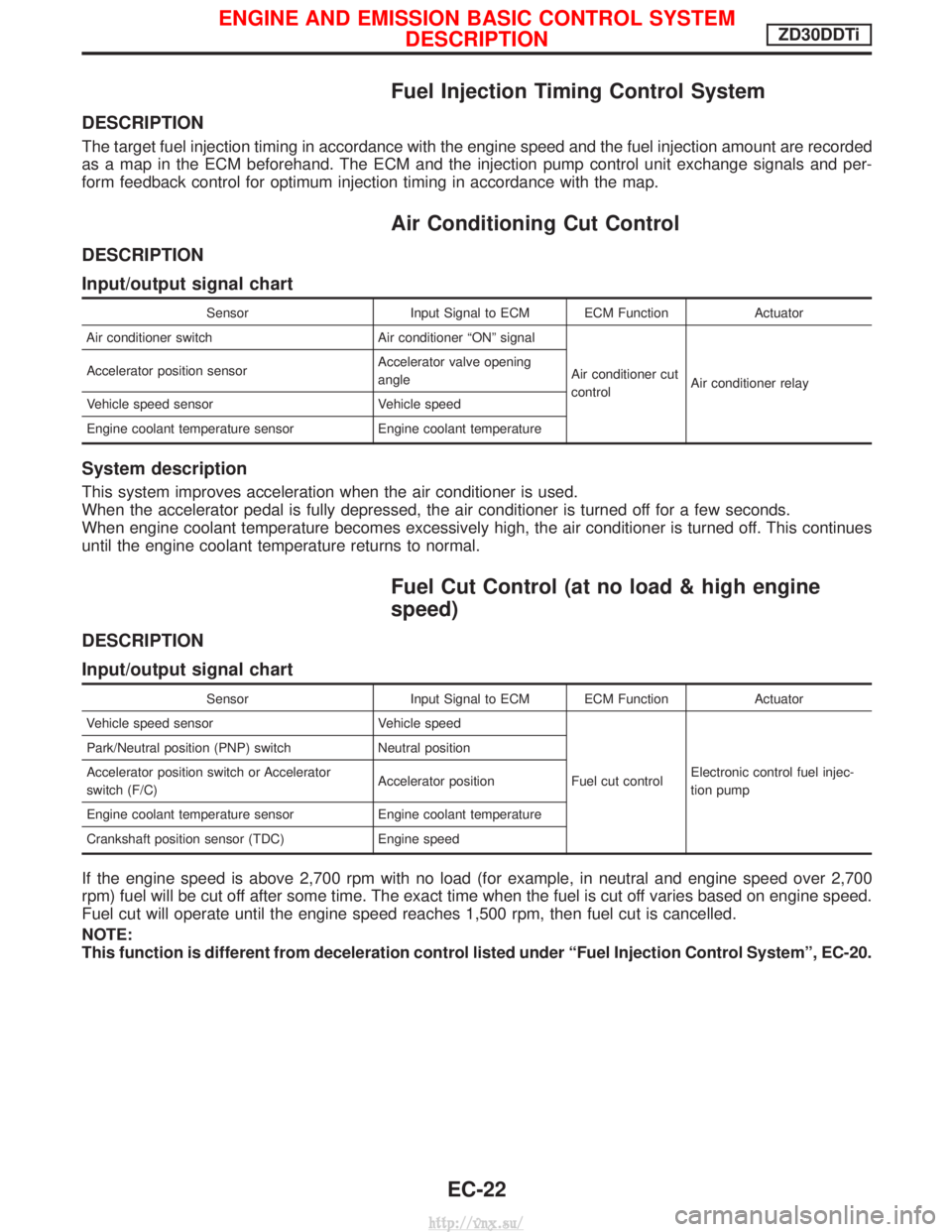

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner cut

controlAir conditioner relay

Accelerator position sensor

Accelerator valve opening

angle

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System description

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This continues

until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTION

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel injec-

tion pump

Park/Neutral position (PNP) switch

Neutral position

Accelerator position switch or Accelerator

switch (F/C) Accelerator position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,700 rpm with no load (for example, in neutral and engine speed over 2,700

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº, EC-20.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-22

http://vnx.su/

Page 345 of 1833

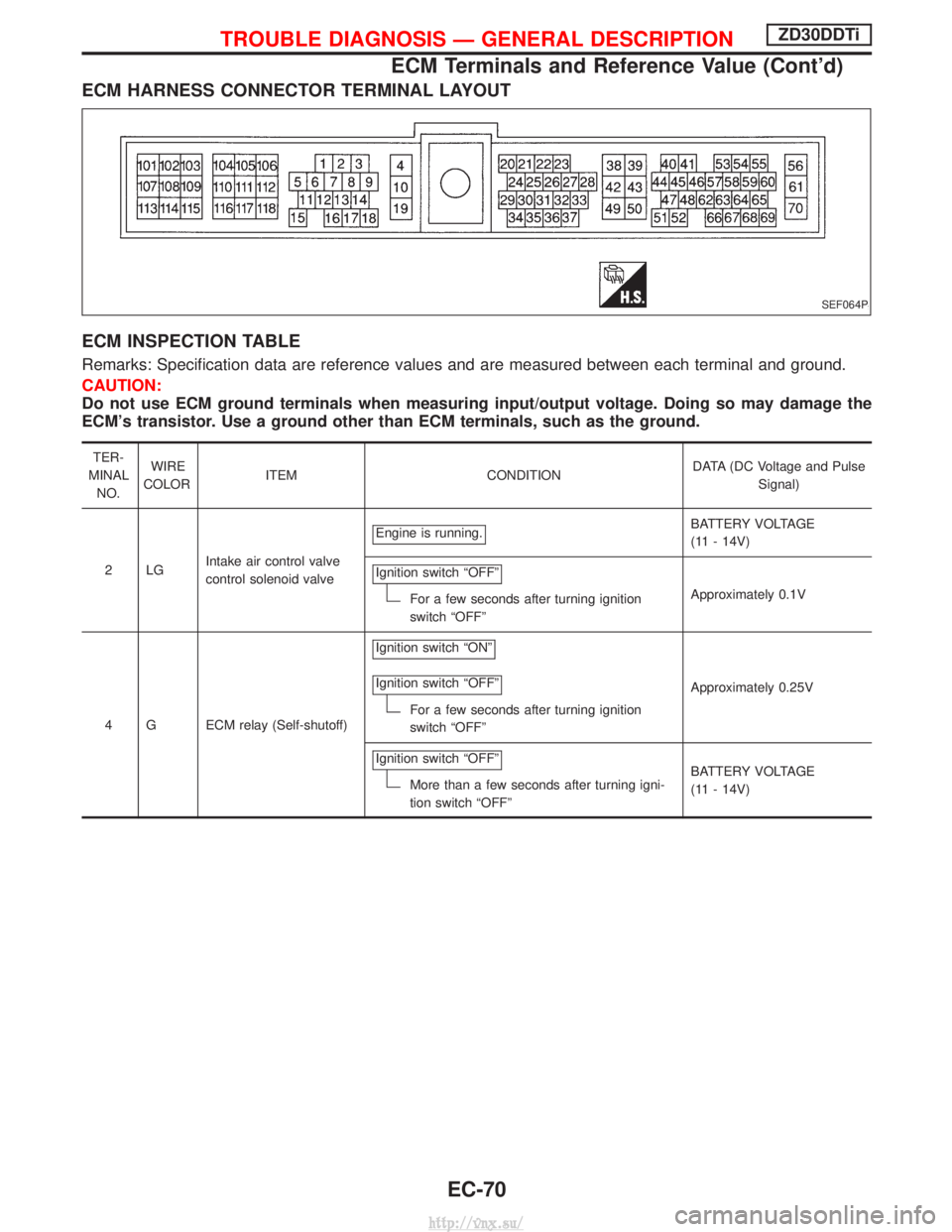

ECM HARNESS CONNECTOR TERMINAL LAYOUT

ECM INSPECTION TABLE

Remarks: Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

2LG Intake air control valve

control solenoid valve Engine is running.

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªOFFº

For a few seconds after turning ignition

switch ªOFFº Approximately 0.1V

4 G ECM relay (Self-shutoff) Ignition switch ªONº

Ignition switch ªOFFº

For a few seconds after turning ignition

switch ªOFFº

Approximately 0.25V

Ignition switch ªOFFº

More than a few seconds after turning igni-

tion switch ªOFFº BATTERY VOLTAGE

(11 - 14V)

SEF064P

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-70

http://vnx.su/

Page 391 of 1833

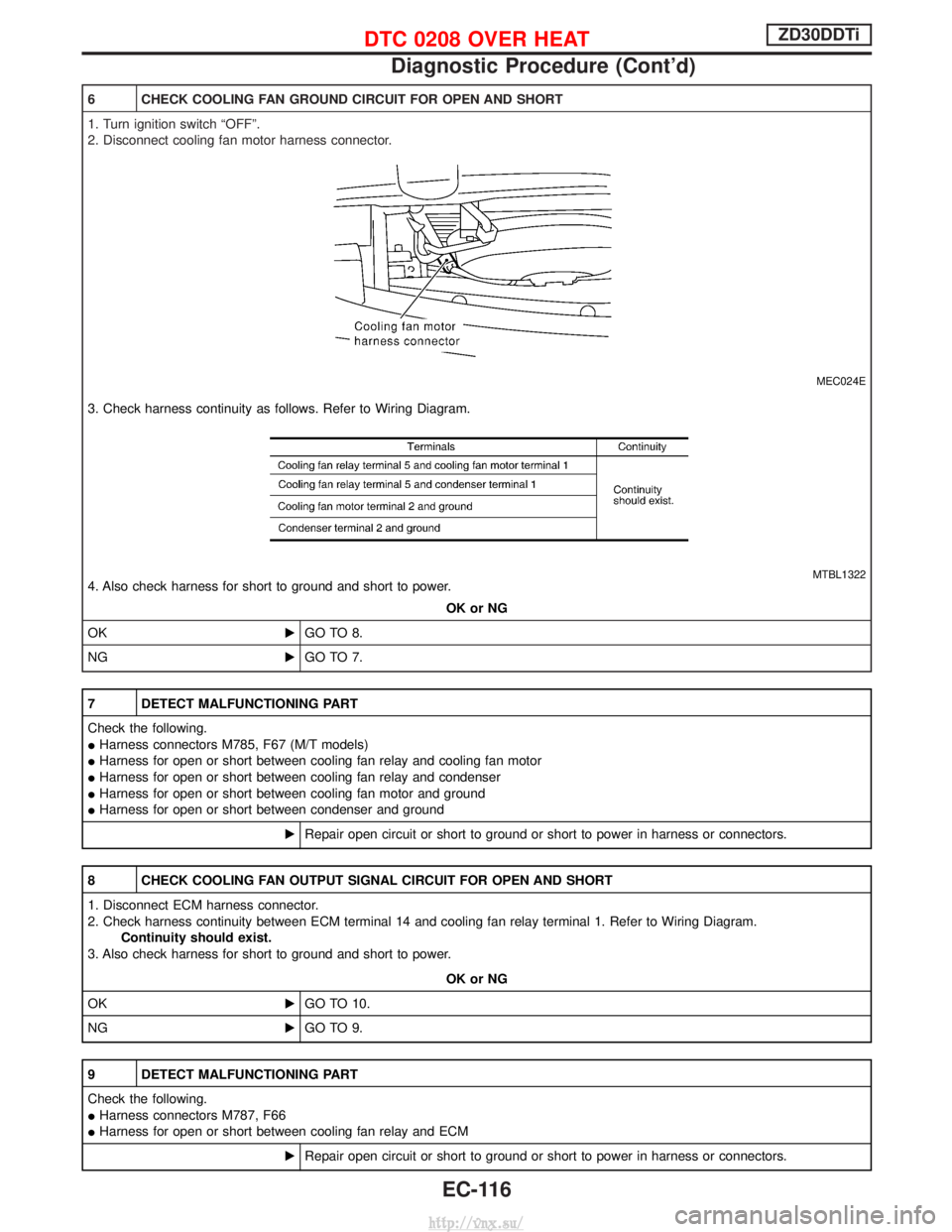

6 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor harness connector.

MEC024E

3. Check harness continuity as follows. Refer to Wiring Diagram.

MTBL13224. Also check harness for short to ground and short to power.OK or NG

OK EGO TO 8.

NG EGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M785, F67 (M/T models)

I Harness for open or short between cooling fan relay and cooling fan motor

I Harness for open or short between cooling fan relay and condenser

I Harness for open or short between cooling fan motor and ground

I Harness for open or short between condenser and ground

ERepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 14 and cooling fan relay terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 10.

NG EGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66

I Harness for open or short between cooling fan relay and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-116

http://vnx.su/

Page 489 of 1833

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

4 G ECM relay (Self-shutoff) Ignition switch ªONº

Ignition switch ªOFFº

For a few seconds after turning ignition switch

ªOFFº

Approximately 0.25V

Ignition switch ªOFFº

More than a few seconds after turning ignition

switch ªOFFº BATTERY VOLTAGE

(11 - 14V)

38 B/W Ignition switch Ignition switch ªOFFº

0V

Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

56

61

11 6 B/W

B/W

B/W

Power supply for ECM Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible Cause)

I An irregular voltage signal from the ECM relay is sent to ECM. IHarness or connectors

(ECM relay circuit is open or shorted.)

I ECM relay

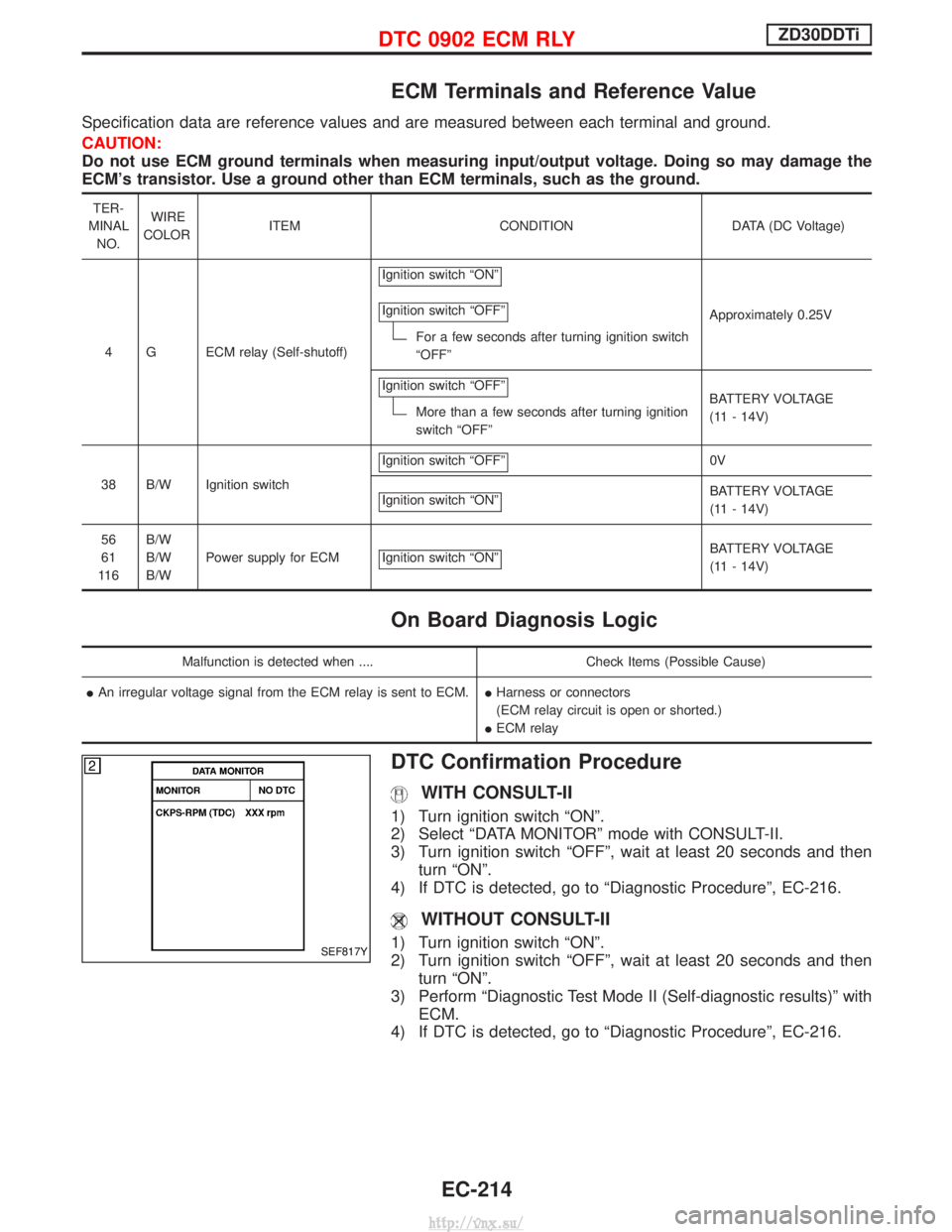

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-216.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº.

2) Turn ignition switch ªOFFº, wait at least 20 seconds and then turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-216.SEF817Y

DTC 0902 ECM RLYZD30DDTi

EC-214

http://vnx.su/

Page 491 of 1833

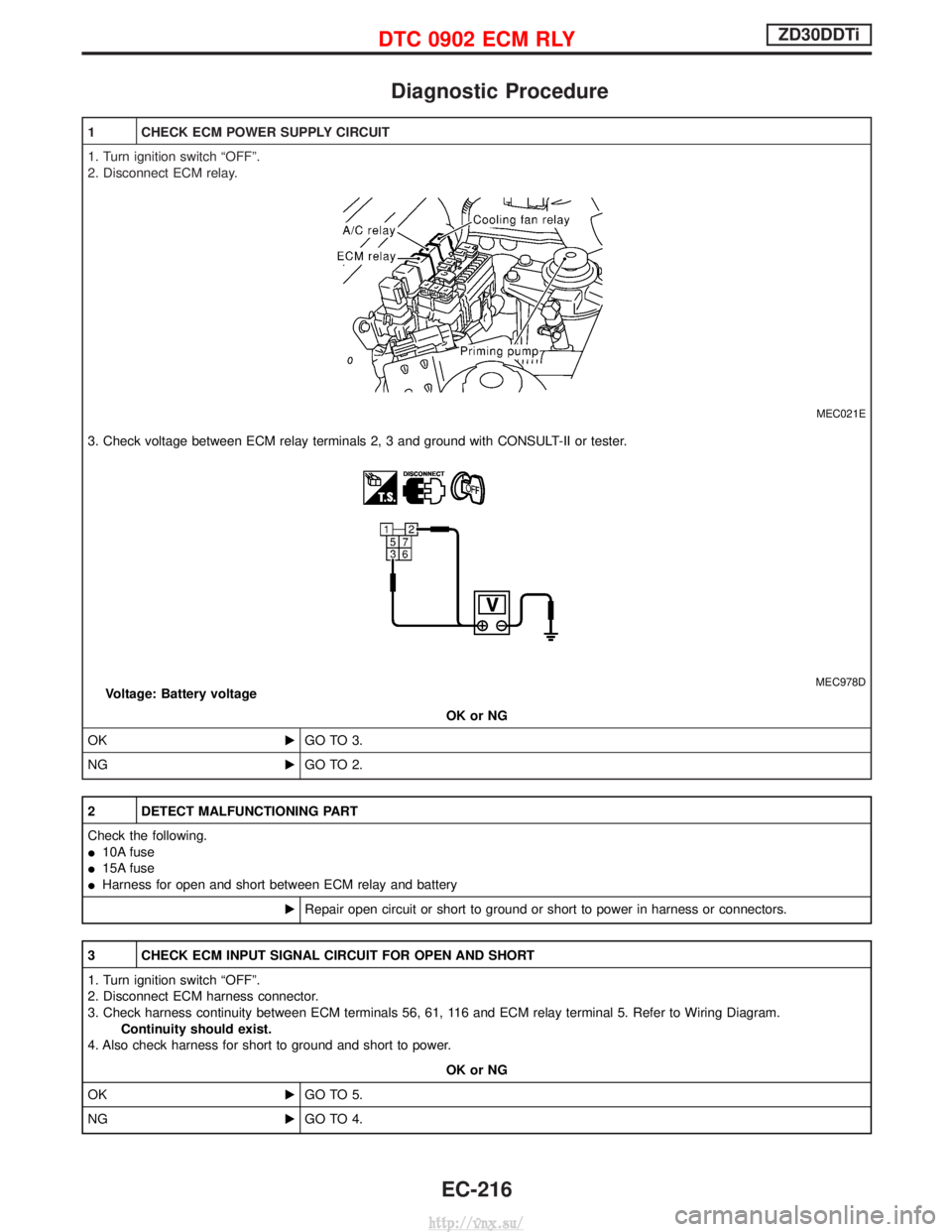

Diagnostic Procedure

1 CHECK ECM POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

MEC021E

3. Check voltage between ECM relay terminals 2, 3 and ground with CONSULT-II or tester.

MEC978DVoltage: Battery voltageOK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

I10A fuse

I 15A fuse

I Harness for open and short between ECM relay and battery

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECM INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 56, 61, 116 and ECM relay terminal 5. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0902 ECM RLYZD30DDTi

EC-216

http://vnx.su/

Page 509 of 1833

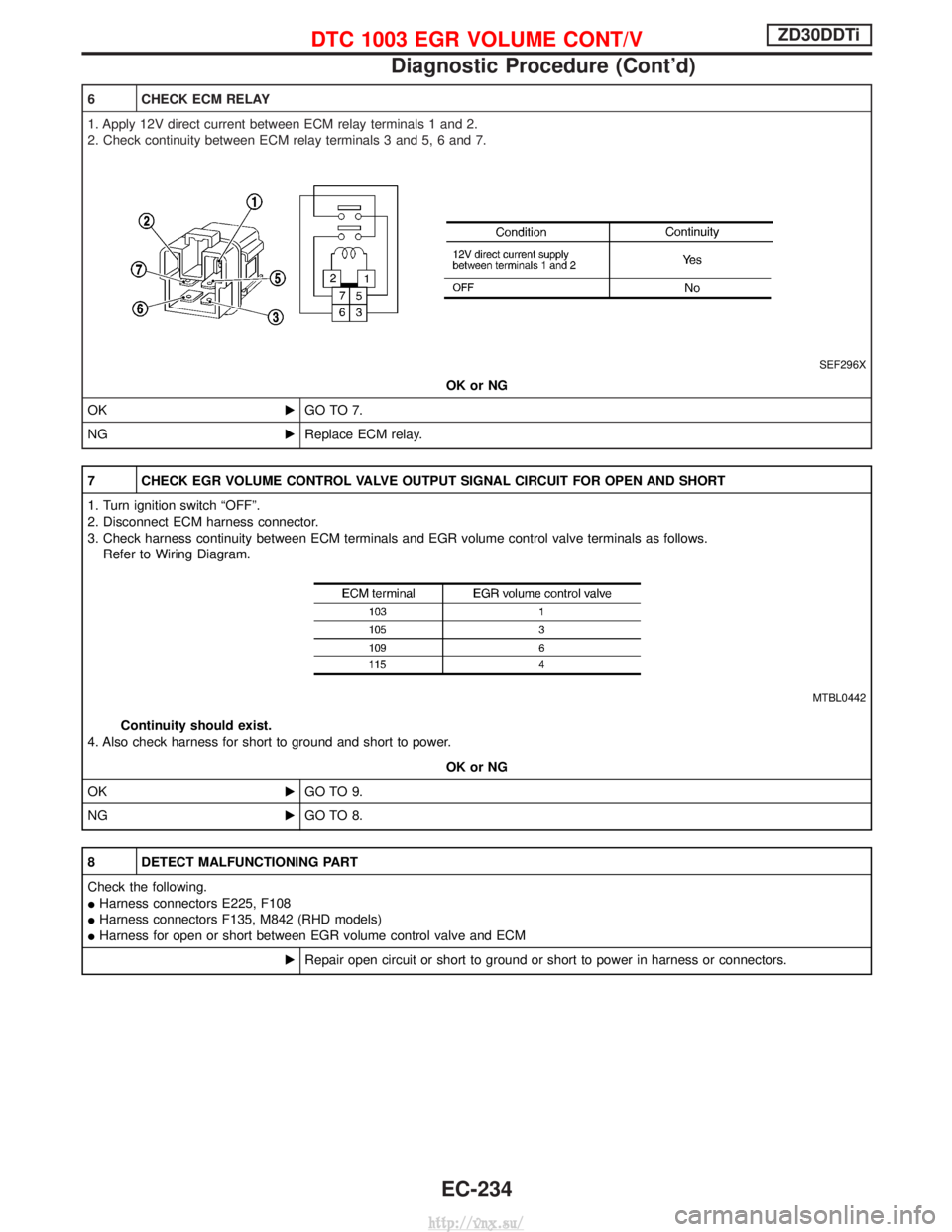

6 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between ECM relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK EGO TO 7.

NG EReplace ECM relay.

7 CHECK EGR VOLUME CONTROL VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals and EGR volume control valve terminals as follows.

Refer to Wiring Diagram.

MTBL0442

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 9.

NG EGO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between EGR volume control valve and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 1003 EGR VOLUME CONT/VZD30DDTi

Diagnostic Procedure (Cont'd)

EC-234

http://vnx.su/

Page 519 of 1833

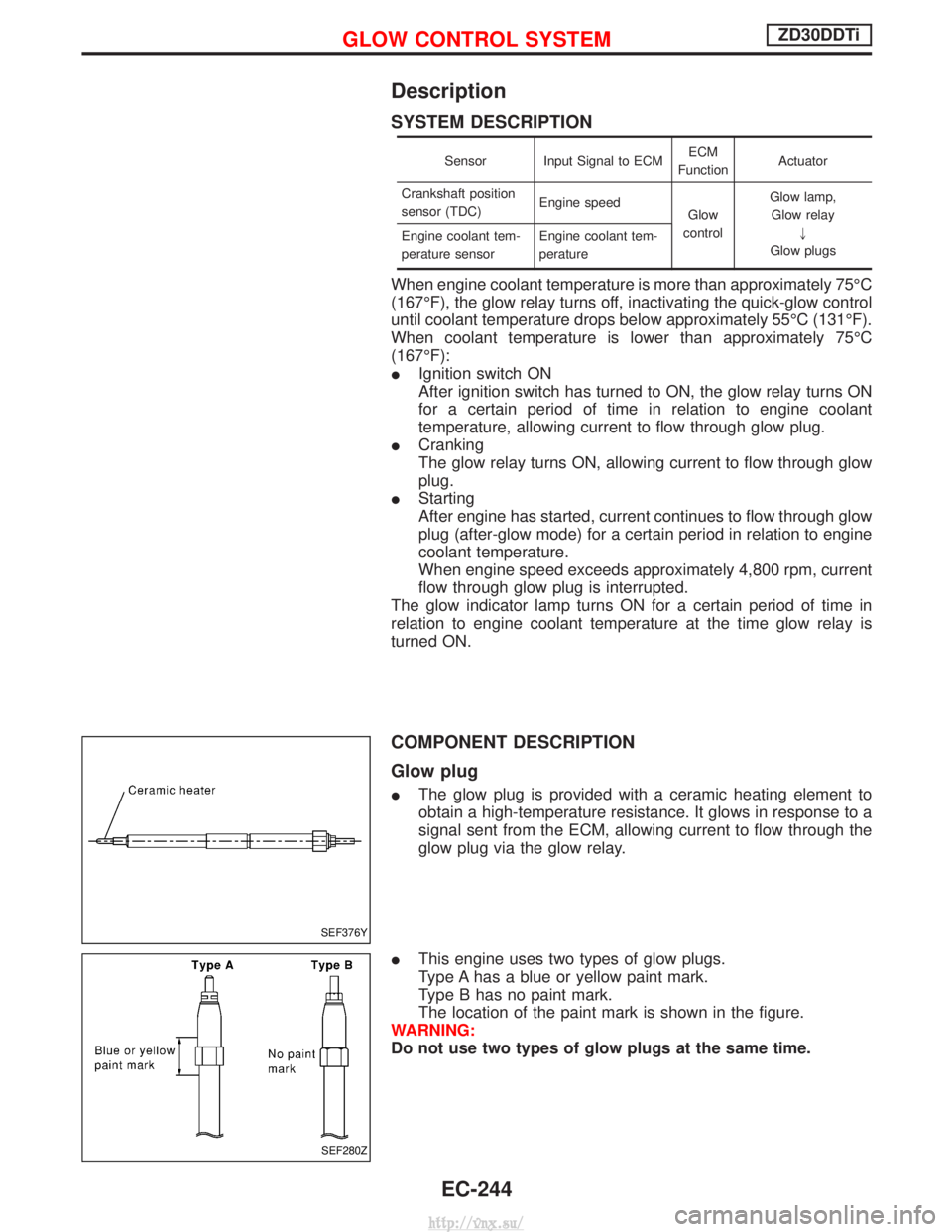

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

Function Actuator

Crankshaft position

sensor (TDC) Engine speed

Glow

control Glow lamp,

Glow relay "

Glow plugs

Engine coolant tem-

perature sensor Engine coolant tem-

perature

When engine coolant temperature is more than approximately 75ÉC

(167ÉF), the glow relay turns off, inactivating the quick-glow control

until coolant temperature drops below approximately 55ÉC (131ÉF).

When coolant temperature is lower than approximately 75ÉC

(167ÉF):

I

Ignition switch ON

After ignition switch has turned to ON, the glow relay turns ON

for a certain period of time in relation to engine coolant

temperature, allowing current to flow through glow plug.

I Cranking

The glow relay turns ON, allowing current to flow through glow

plug.

I Starting

After engine has started, current continues to flow through glow

plug (after-glow mode) for a certain period in relation to engine

coolant temperature.

When engine speed exceeds approximately 4,800 rpm, current

flow through glow plug is interrupted.

The glow indicator lamp turns ON for a certain period of time in

relation to engine coolant temperature at the time glow relay is

turned ON.

COMPONENT DESCRIPTION

Glow plug

I The glow plug is provided with a ceramic heating element to

obtain a high-temperature resistance. It glows in response to a

signal sent from the ECM, allowing current to flow through the

glow plug via the glow relay.

I This engine uses two types of glow plugs.

Type A has a blue or yellow paint mark.

Type B has no paint mark.

The location of the paint mark is shown in the figure.

WARNING:

Do not use two types of glow plugs at the same time.

SEF376Y

SEF280Z

GLOW CONTROL SYSTEMZD30DDTi

EC-244

http://vnx.su/

Page 525 of 1833

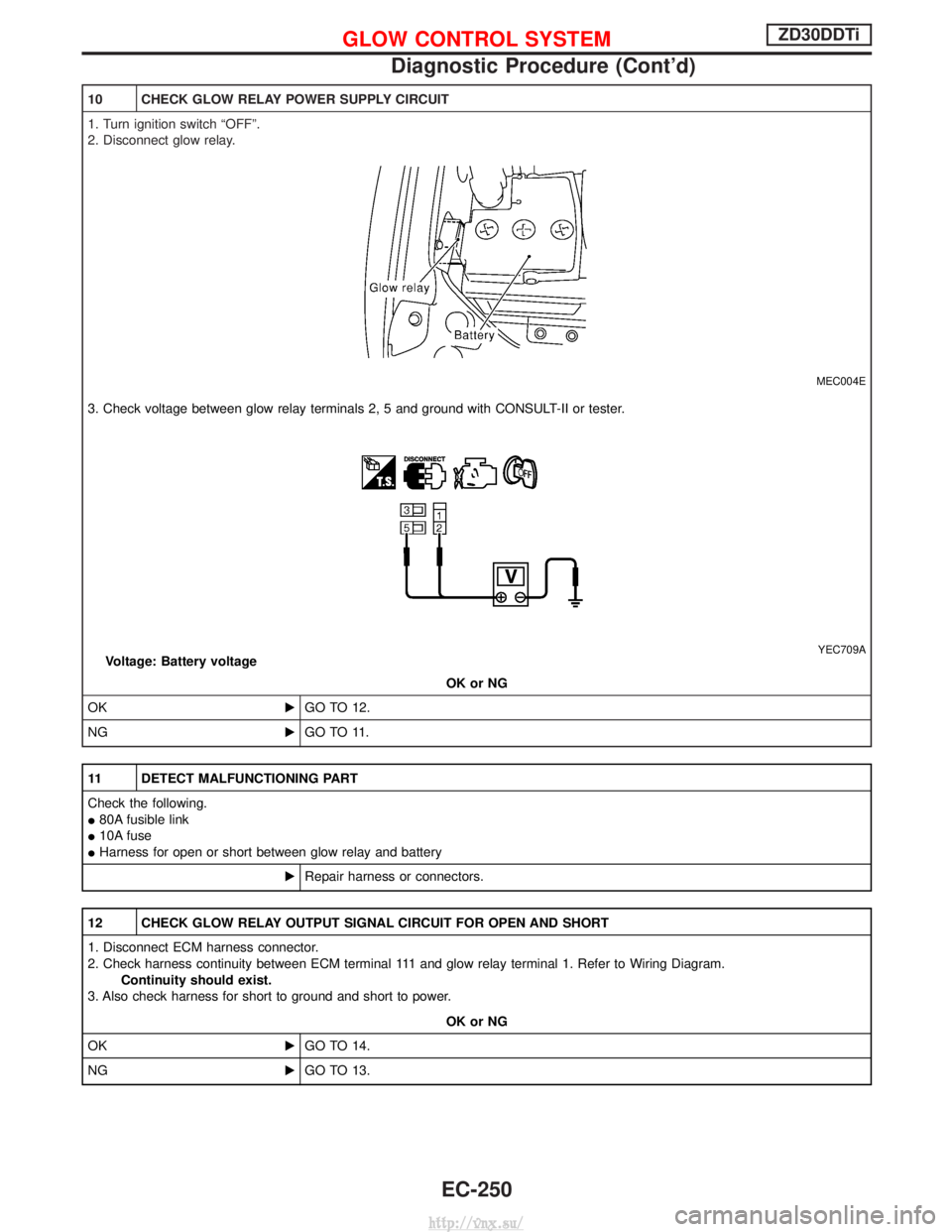

10 CHECK GLOW RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect glow relay.

MEC004E

3. Check voltage between glow relay terminals 2, 5 and ground with CONSULT-II or tester.

YEC709AVoltage: Battery voltageOK or NG

OK EGO TO 12.

NG EGO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

I80A fusible link

I 10A fuse

I Harness for open or short between glow relay and battery

ERepair harness or connectors.

12 CHECK GLOW RELAY OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 111 and glow relay terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 14.

NG EGO TO 13.

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-250

http://vnx.su/

Page 538 of 1833

6 CHECK PARK/NEUTRAL POSITION SWITCH

Refer to AT section, ªPark/neutral position switchº.OK or NG

OK EGO TO 11.

NG EReplace PNP switch.

7 CHECK PNP RELAY GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between PNP relay terminals 1, 6 and engine ground.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK EGO TO 8.

NG ERepair open circuit or short to power in harness or connectors.

8 CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 22 and PNP relay terminal 7.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground or short to power.

OK or NG

OK EGO TO 10.

NG EGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F93, M788 (LHD models)

I Harness for open or short between ECM and PNP relay

ERepair open circuit or short to ground or short to power in harness or connectors.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-263

http://vnx.su/

Page 562 of 1833

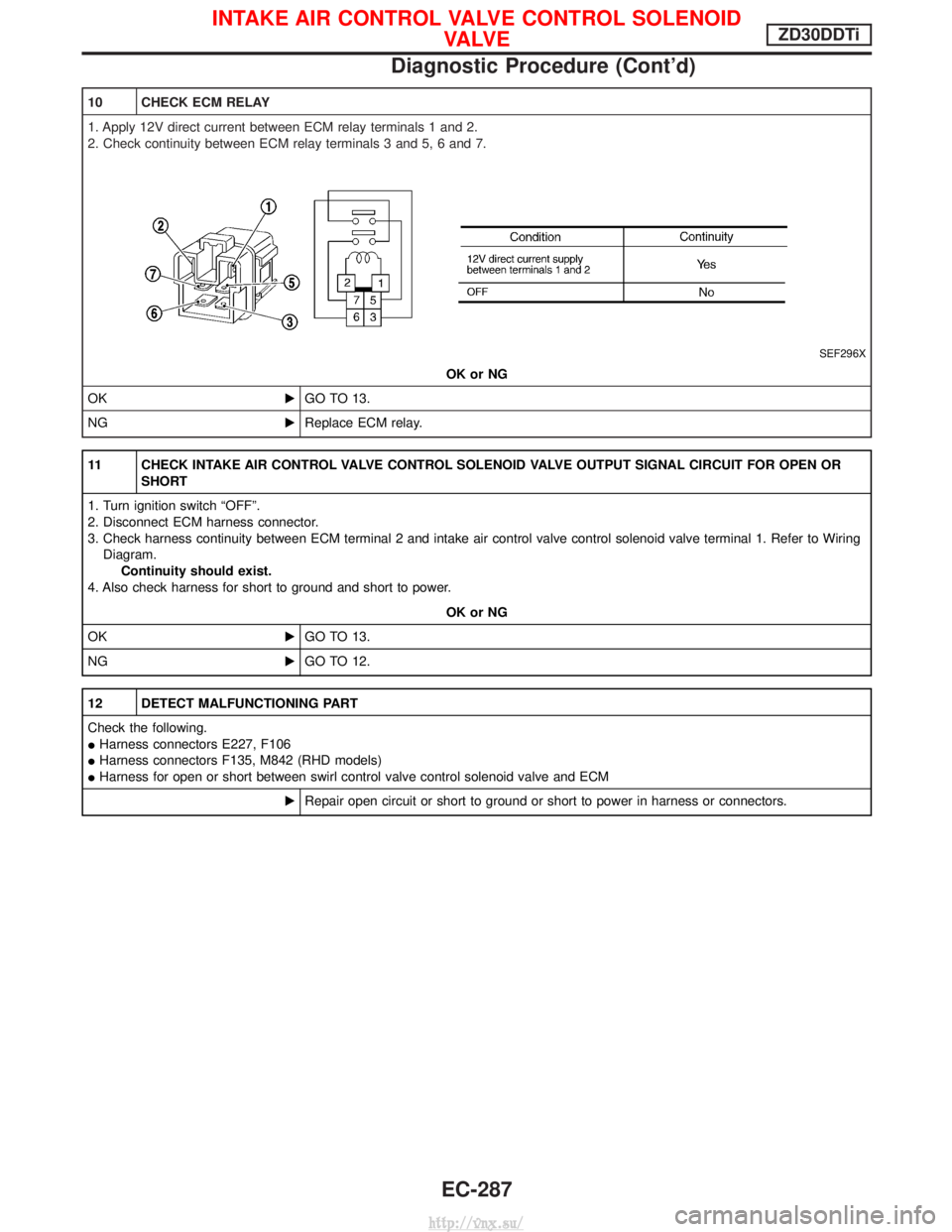

10 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between ECM relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK EGO TO 13.

NG EReplace ECM relay.

11 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN OR

SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 2 and intake air control valve control solenoid valve terminal 1. Refer to Wiring Diagram. Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 13.

NG EGO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E227, F106

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between swirl control valve control solenoid valve and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

INTAKE AIR CONTROL VALVE CONTROL SOLENOID

VA LV EZD30DDTi

Diagnostic Procedure (Cont'd)

EC-287

http://vnx.su/