window NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 1338 of 1833

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS ...............................................................2

Service Notice..............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............2

CLIP AND FASTENER ....................................................3

Description ...................................................................3

CHASSIS AND BODY MAINTENANCE .........................5

Checking Body Corrosion ............................................5

BODY FRONT END .........................................................6

Removal and Installation .............................................6

BODY REAR END AND OPENER ..................................8

Removal and Installation .............................................8

DOOR ........................................................................\

.....10

Removal and Installation ...........................................10

INSTRUMENT PANEL ASSEMBLY ..............................16

Removal and Installation ...........................................16

SIDE AND FLOOR TRIM ..............................................18

Removal and Installation ...........................................18

DOOR TRIM ...................................................................19

Removal and Installation ...........................................19 ROOF TRIM

...................................................................20

Removal and Installation ...........................................20

EXTERIOR .....................................................................21

Removal and Installation ...........................................21

FRONT SEAT .................................................................34

Removal and Installation ...........................................34

Heated Seat ...............................................................36

Active Head Restraint ................................................36

SECOND SEAT ..............................................................37

Removal and Installation ...........................................37

THIRD SEAT ..................................................................39

Removal and Installation ...........................................39

SUNROOF ......................................................................40

Removal and Installation ...........................................40

WINDSHIELD AND WINDOWS ....................................42

Removal and Installation ...........................................42

DOOR MIRROR .............................................................48

Removal and Installation ...........................................48

BODY (ALIGNMENT) ....................................................49

Alignment ...................................................................49

http://vnx.su/

Page 1379 of 1833

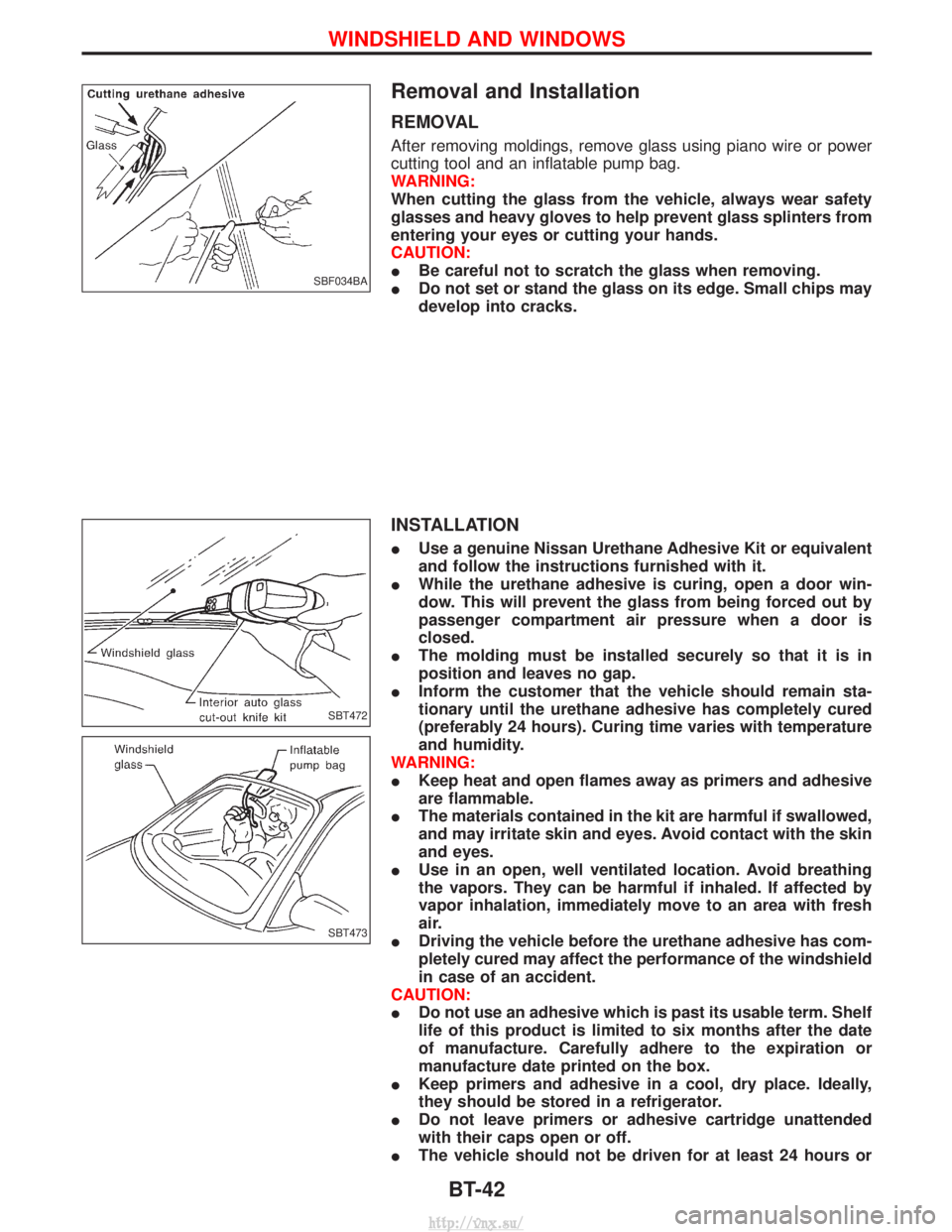

Removal and Installation

REMOVAL

After removing moldings, remove glass using piano wire or power

cutting tool and an inflatable pump bag.

WARNING:

When cutting the glass from the vehicle, always wear safety

glasses and heavy gloves to help prevent glass splinters from

entering your eyes or cutting your hands.

CAUTION:

IBe careful not to scratch the glass when removing.

I Do not set or stand the glass on its edge. Small chips may

develop into cracks.

INSTALLATION

IUse a genuine Nissan Urethane Adhesive Kit or equivalent

and follow the instructions furnished with it.

I While the urethane adhesive is curing, open a door win-

dow. This will prevent the glass from being forced out by

passenger compartment air pressure when a door is

closed.

I The molding must be installed securely so that it is in

position and leaves no gap.

I Inform the customer that the vehicle should remain sta-

tionary until the urethane adhesive has completely cured

(preferably 24 hours). Curing time varies with temperature

and humidity.

WARNING:

I Keep heat and open flames away as primers and adhesive

are flammable.

I The materials contained in the kit are harmful if swallowed,

and may irritate skin and eyes. Avoid contact with the skin

and eyes.

I Use in an open, well ventilated location. Avoid breathing

the vapors. They can be harmful if inhaled. If affected by

vapor inhalation, immediately move to an area with fresh

air.

I Driving the vehicle before the urethane adhesive has com-

pletely cured may affect the performance of the windshield

in case of an accident.

CAUTION:

I Do not use an adhesive which is past its usable term. Shelf

life of this product is limited to six months after the date

of manufacture. Carefully adhere to the expiration or

manufacture date printed on the box.

I Keep primers and adhesive in a cool, dry place. Ideally,

they should be stored in a refrigerator.

I Do not leave primers or adhesive cartridge unattended

with their caps open or off.

I The vehicle should not be driven for at least 24 hours or

SBF034BA

SBT472

SBT473

WINDSHIELD AND WINDOWS

BT-42

http://vnx.su/

Page 1380 of 1833

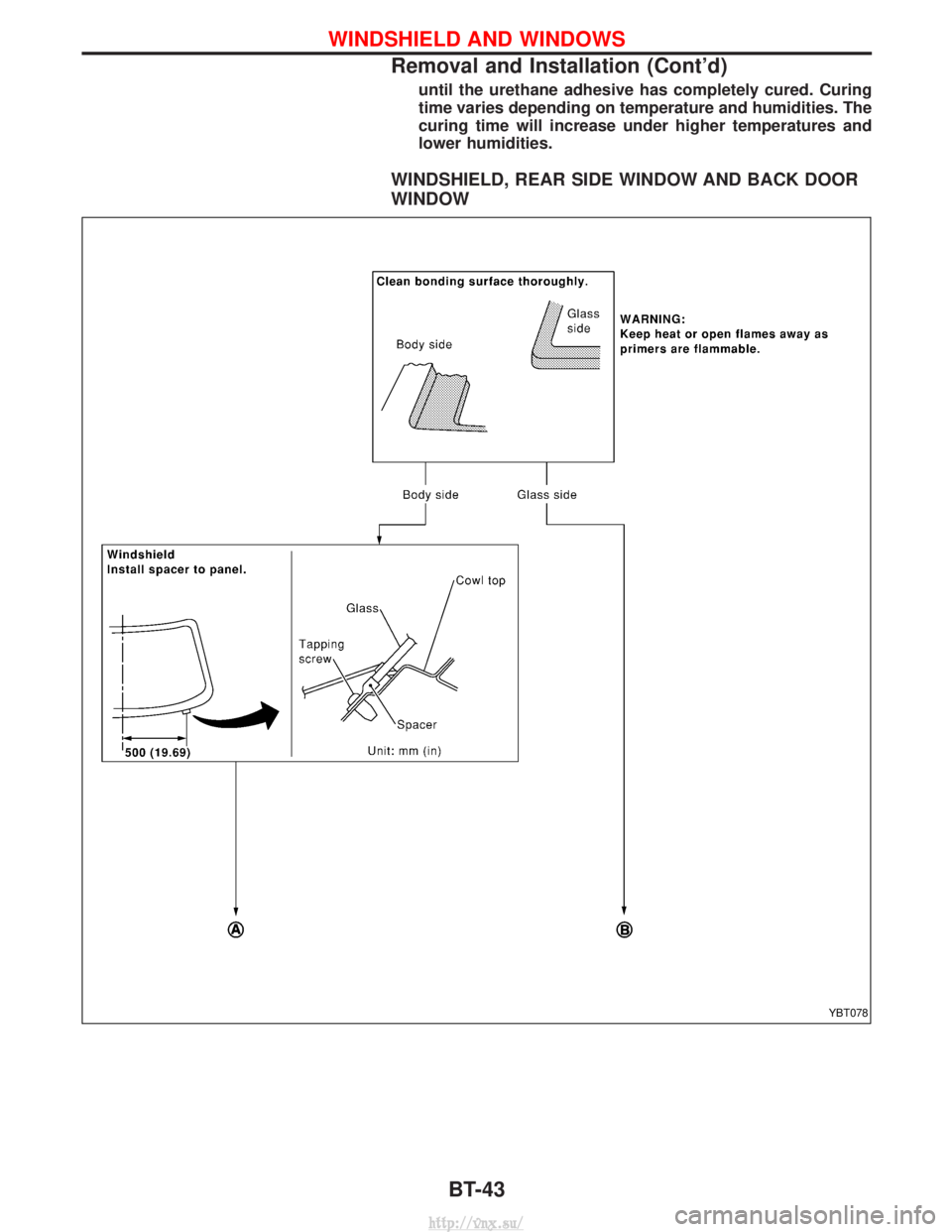

until the urethane adhesive has completely cured. Curing

time varies depending on temperature and humidities. The

curing time will increase under higher temperatures and

lower humidities.

WINDSHIELD, REAR SIDE WINDOW AND BACK DOOR

WINDOW

YBT078

WINDSHIELD AND WINDOWS

Removal and Installation (Cont'd)BT-43

http://vnx.su/

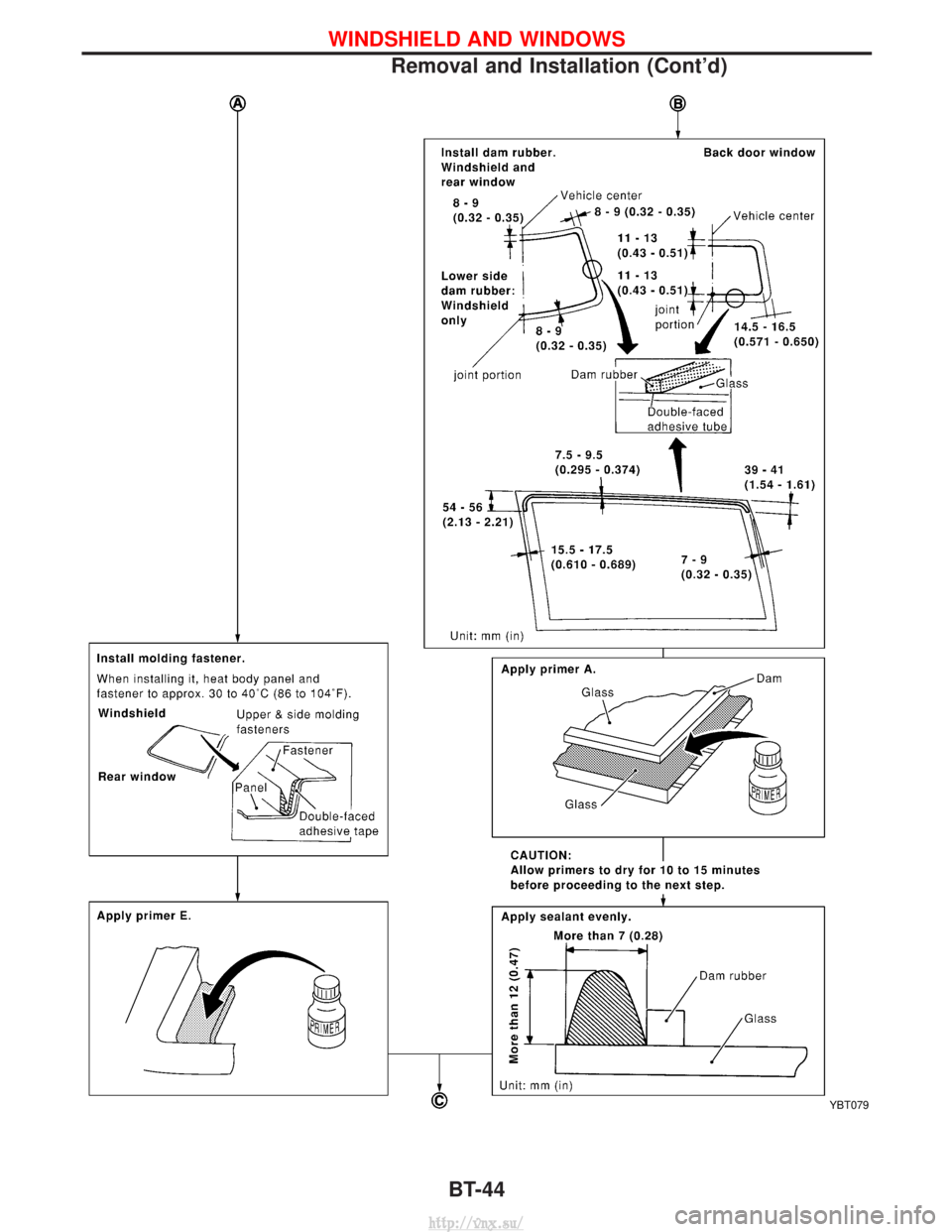

Page 1381 of 1833

YBT079

WINDSHIELD AND WINDOWS

Removal and Installation (Cont'd)BT-44

http://vnx.su/

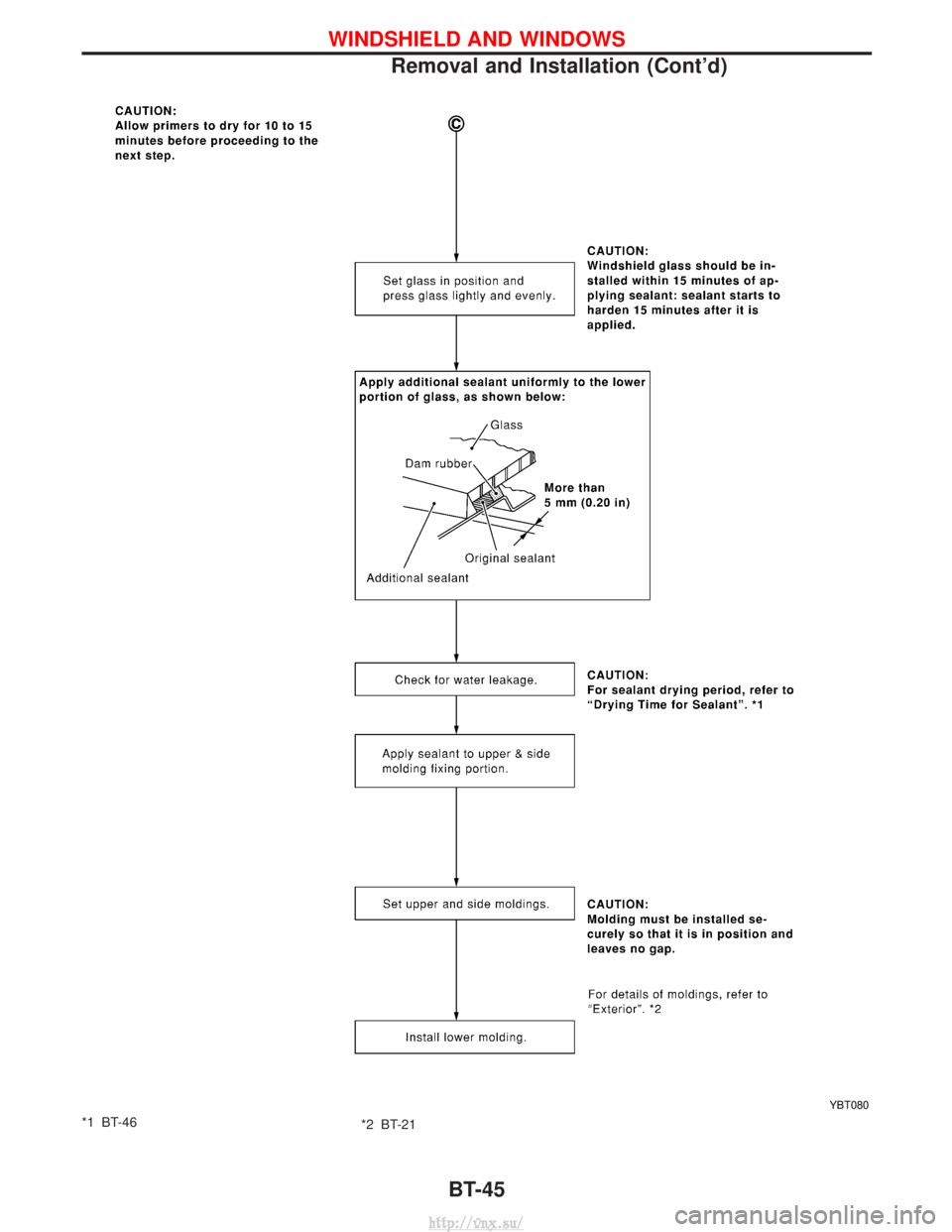

Page 1382 of 1833

*1 BT-46*2 BT-21

YBT080

WINDSHIELD AND WINDOWS

Removal and Installation (Cont'd)

BT-45

http://vnx.su/

Page 1383 of 1833

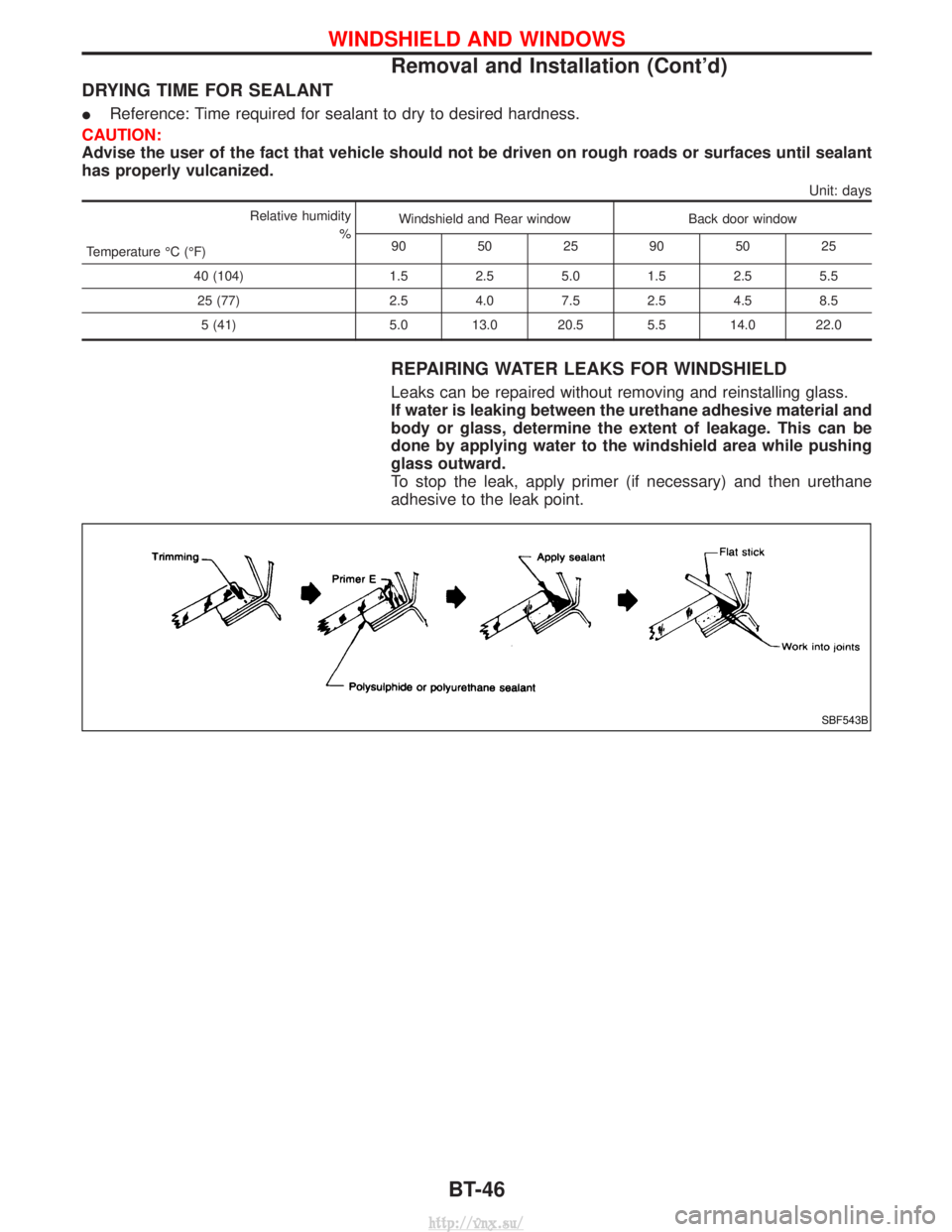

DRYING TIME FOR SEALANT

IReference: Time required for sealant to dry to desired hardness.

CAUTION:

Advise the user of the fact that vehicle should not be driven on rough roads or surfaces until sealant

has properly vulcanized.

Unit: days

Relative humidity

%

Temperature ÉC (ÉF) Windshield and Rear window

Back door window

90 5025905025

40 (104) 1.52.55.01.52.55.5

25 (77) 2.54.07.52.54.58.5

5 (41) 5.0 13.0 20.5 5.5 14.0 22.0

REPAIRING WATER LEAKS FOR WINDSHIELD

Leaks can be repaired without removing and reinstalling glass.

If water is leaking between the urethane adhesive material and

body or glass, determine the extent of leakage. This can be

done by applying water to the windshield area while pushing

glass outward.

To stop the leak, apply primer (if necessary) and then urethane

adhesive to the leak point.

SBF543B

WINDSHIELD AND WINDOWS

Removal and Installation (Cont'd)

BT-46

http://vnx.su/

Page 1384 of 1833

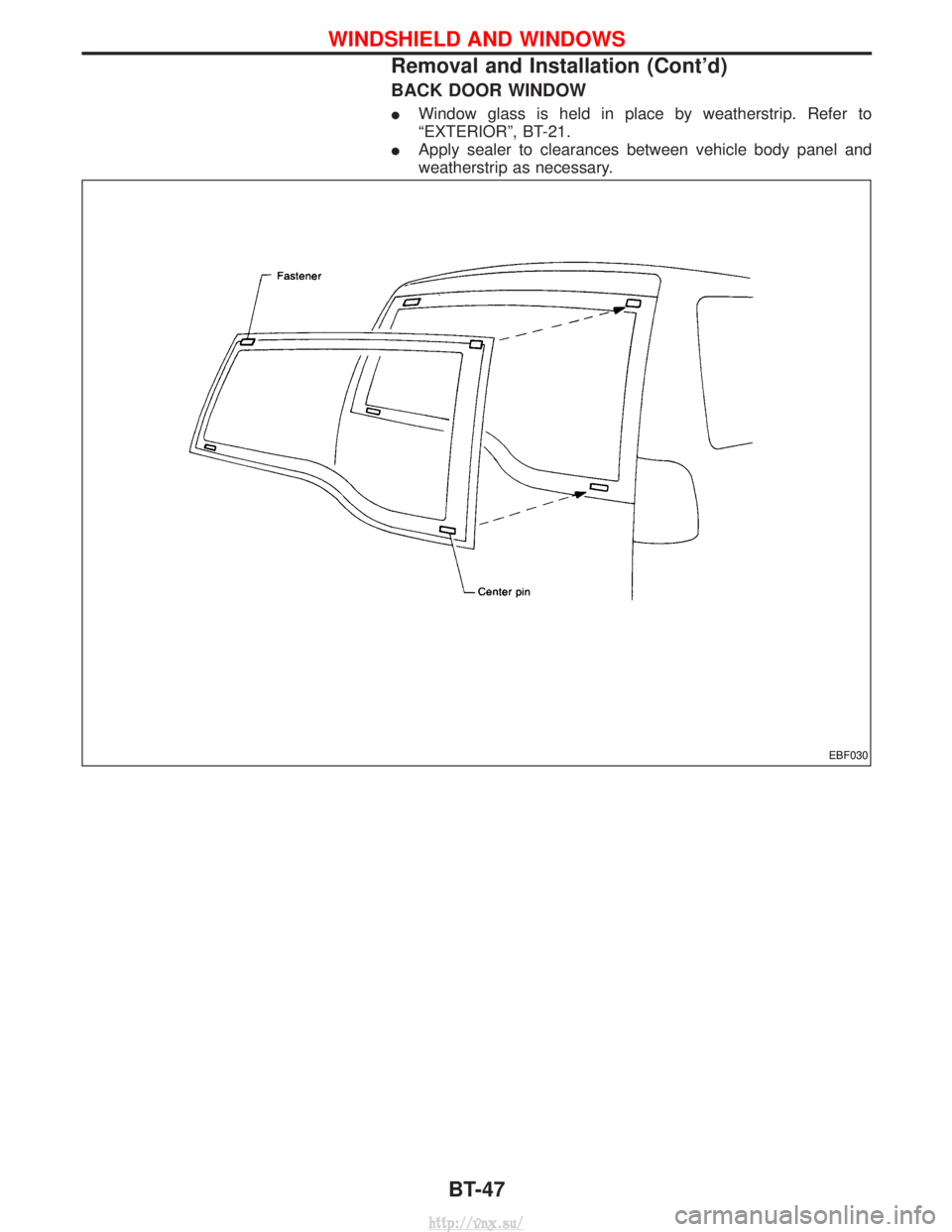

BACK DOOR WINDOW

IWindow glass is held in place by weatherstrip. Refer to

ªEXTERIORº, BT-21.

I Apply sealer to clearances between vehicle body panel and

weatherstrip as necessary.

EBF030

WINDSHIELD AND WINDOWS

Removal and Installation (Cont'd)

BT-47

http://vnx.su/

Page 1428 of 1833

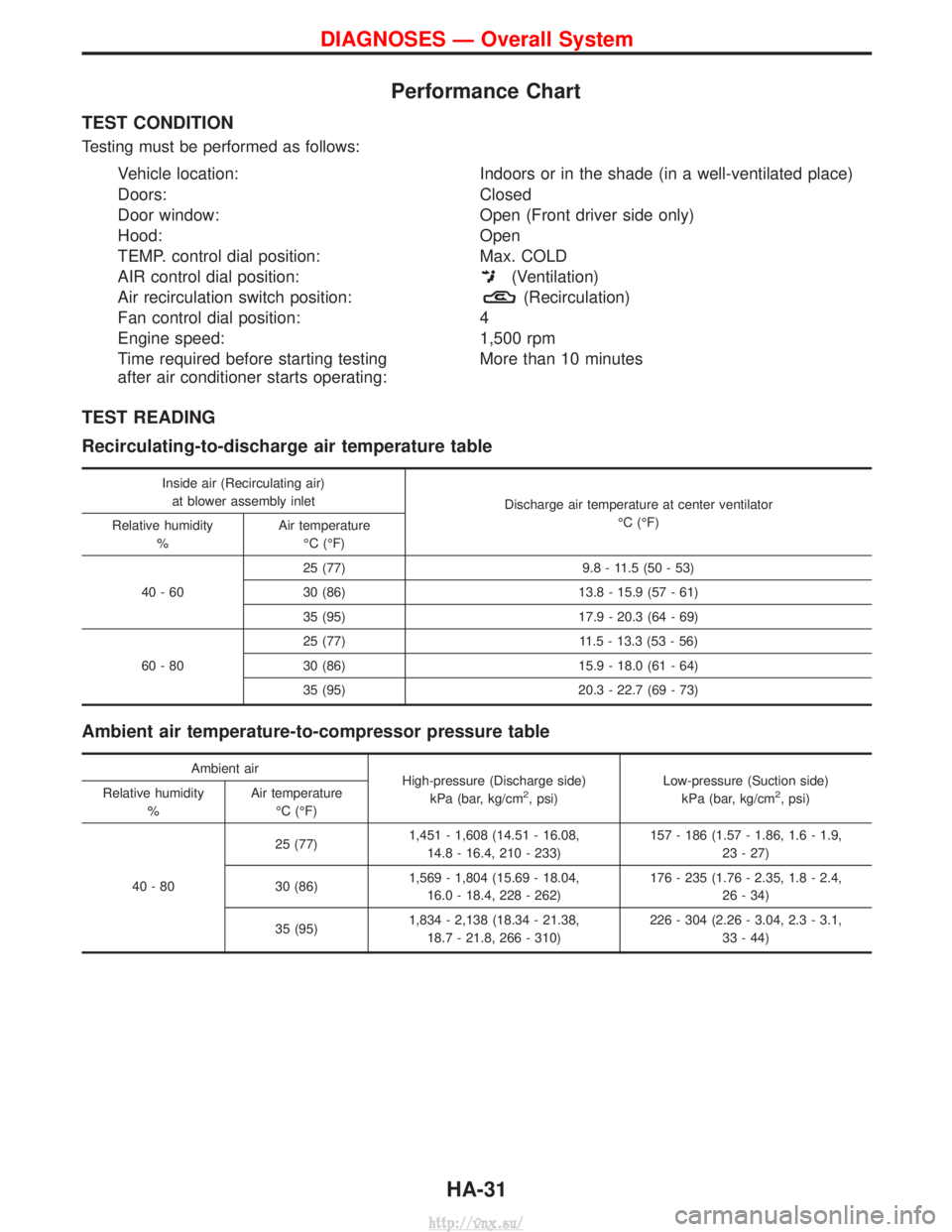

Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location:Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open (Front driver side only)

Hood: Open

TEMP. control dial position: Max. COLD

AIR control dial position:

(Ventilation)

Air recirculation switch position:

(Recirculation)

Fan control dial position: 4

Engine speed: 1,500 rpm

Time required before starting testing

after air conditioner starts operating: More than 10 minutes

TEST READING

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

% Air temperature

ÉC (ÉF)

40-60 25 (77) 9.8 - 11.5 (50 - 53)

30 (86) 13.8 - 15.9 (57 - 61)

35 (95) 17.9 - 20.3 (64 - 69)

60-80 25 (77) 11.5 - 13.3 (53 - 56)

30 (86) 15.9 - 18.0 (61 - 64)

35 (95) 20.3 - 22.7 (69 - 73)

Ambient air temperature-to-compressor pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi) Low-pressure (Suction side)

kPa (bar, kg/cm2, psi)

Relative humidity

% Air temperature

ÉC (ÉF)

40-80 25 (77)

1,451 - 1,608 (14.51 - 16.08,

14.8 - 16.4, 210 - 233) 157 - 186 (1.57 - 1.86, 1.6 - 1.9,

23 - 27)

30 (86) 1,569 - 1,804 (15.69 - 18.04,

16.0 - 18.4, 228 - 262) 176 - 235 (1.76 - 2.35, 1.8 - 2.4,

26 - 34)

35 (95) 1,834 - 2,138 (18.34 - 21.38,

18.7 - 21.8, 266 - 310) 226 - 304 (2.26 - 3.04, 2.3 - 3.1,

33 - 44)

DIAGNOSES Ð Overall System

HA-31

http://vnx.su/

Page 1495 of 1833

Oil Pressure Switch Check ...................................... 110

Wiring Diagram - CHIME - ...................................... 111

WIPER AND WASHER ................................................ 112

Wiring Diagram - WIPER - ...................................... 112

Wiring Diagram - WIP/R -........................................ 114

Installation ................................................................ 116

Washer Nozzle Adjustment ..................................... 117

Check Valve ............................................................. 117

Wiring Diagram - HLC - ........................................... 118

HORN, CIGARETTE LIGHTER AND CLOCK ............122

Wiring Diagram - HORN - .......................................122

Wiring Diagram - CIGAR -.......................................123

Wiring Diagram - CLOCK -......................................124

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER .................................................125

System Description ..................................................125

Wiring Diagram - DEF - ...........................................126

Trouble Diagnoses...................................................128

Filament Check ........................................................132

Filament Repair .......................................................133

AUDIO ........................................................................\

..134

System Description ..................................................134

Schematic ................................................................136

Wiring Diagram - AUDIO - .......................................138

Wiring Diagram - REMOTE -...................................145

Trouble Diagnoses...................................................147

Inspection.................................................................149

Location of Roof Mounted Antenna .........................150

HEATED SEAT ............................................................151

Wiring Diagram - HSEAT - ......................................151

SUNROOF ....................................................................153

Wiring Diagram - SROOF - .....................................153

DOOR MIRROR ...........................................................154

Wiring Diagram - MIRROR - ...................................154

POWER WINDOW .......................................................156

System Description ..................................................156

Schematic ................................................................158

Wiring Diagram - WINDOW - ..................................159

Trouble Diagnoses...................................................162

POWER DOOR LOCK .................................................163

System Description ..................................................163

Schematic ................................................................164

Wiring Diagram - D/LOCK -.....................................166

Trouble Diagnoses...................................................171

POWER DOOR LOCK - SUPER LOCK - ...................179

Component Parts Location ......................................179

System Description ..................................................180

Schematic ................................................................182 Wiring Diagram - S/LOCK - .....................................184

Trouble Diagnoses...................................................192

MULTI-REMOTE CONTROL SYSTEM .......................202

System Description ..................................................202

Schematic ................................................................204

Wiring Diagram - MULTI - .......................................205

Trouble Diagnoses...................................................213

ID Code Entry Procedure ........................................215

TIME CONTROL UNIT (TCU) .....................................216

System Description ..................................................216

Trouble Diagnosis ....................................................218

Schematic ................................................................220

NATS (Nissan Anti-Theft System) .............................222

System Description ..................................................222

System Composition ................................................223

Component Parts Location ......................................224

Wiring Diagram - NATS -.........................................225

CONSULT-II .............................................................229

Trouble Diagnoses...................................................231

How to Replace NATS IMMU ..................................242

THEFT WARNING SYSTEM .......................................243

Components Parts and Harness Connector

Location ...................................................................243

System Description ..................................................244

Theft Warning System/Schematic ...........................247

Wiring Diagram - THEFT -.......................................248

Trouble Diagnoses...................................................264

LOCATION OF ELECTRICAL UNITS .........................275

Engine Compartment ...............................................275

Passenger Compartment/LHD Models ....................276

Passenger Compartment/RHD Models ...................278

HARNESS LAYOUT ....................................................280

How to Read Harness Layout .................................280

Outline......................................................................281

Main Harness...........................................................282

EFC Harness ...........................................................298

Engine Harness .......................................................310

Body Harness ..........................................................312

Chassis Harness......................................................320

Room Lamp Harness...............................................321

Tailgate Harness ......................................................322

Door Harness (LH side)...........................................323

Door Harness (RH side) ..........................................324

BULB SPECIFICATIONS ............................................325

Headlamps ...............................................................325

Exterior Lamps.........................................................325

Interior Lamps ..........................................................325

WIRING DIAGRAM CODES (CELL CODES) .............326

CONTENTS(Cont'd)

EL-2

http://vnx.su/