brakes NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 2896, PDF Size: 64.73 MB

Page 2340 of 2896

MA-6

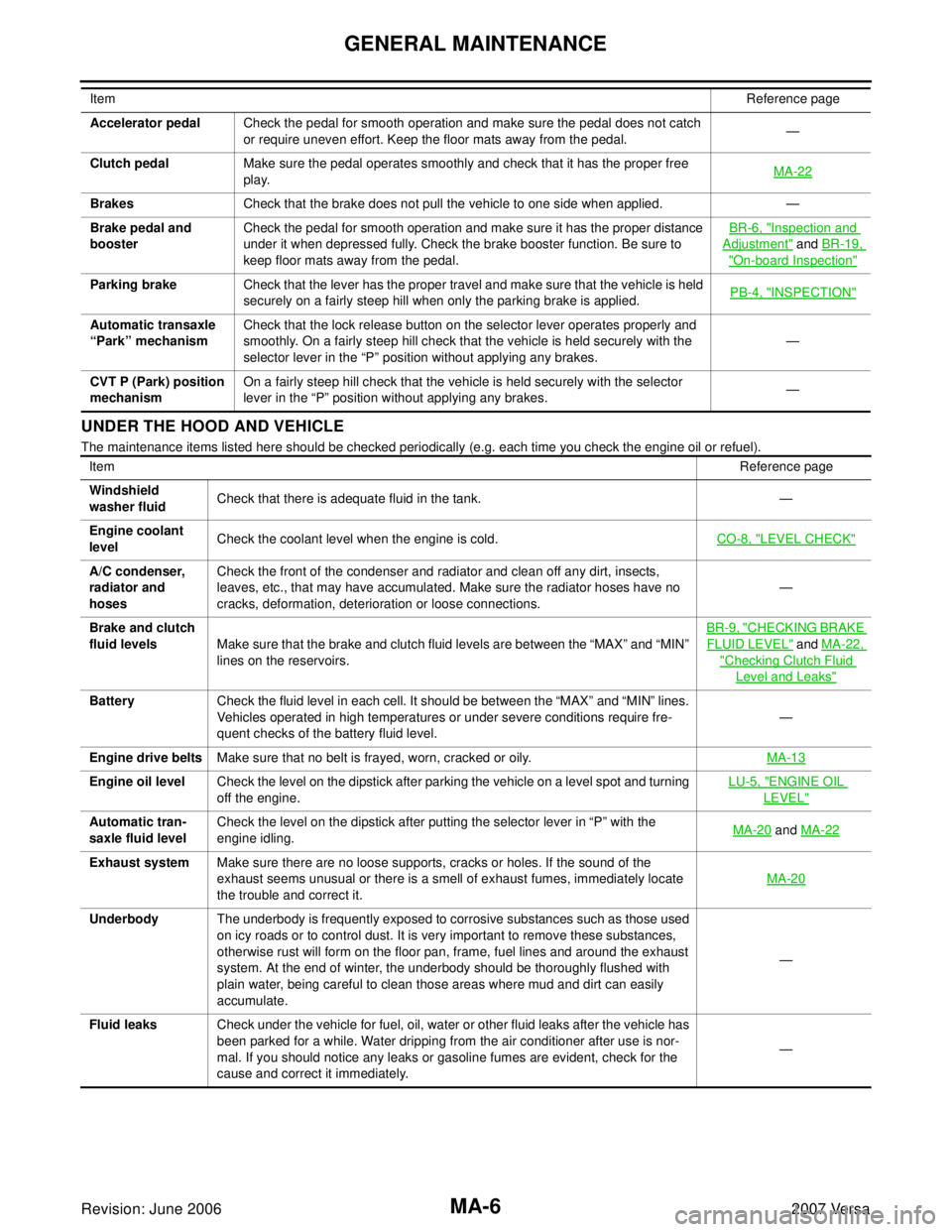

GENERAL MAINTENANCE

Revision: June 20062007 Versa

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).Accelerator pedalCheck the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal.—

Clutch pedalMake sure the pedal operates smoothly and check that it has the proper free

play.MA-22

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

boosterCheck the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep floor mats away from the pedal.BR-6, "

Inspection and

Adjustment" and BR-19,

"On-board Inspection"

Parking brakeCheck that the lever has the proper travel and make sure that the vehicle is held

securely on a fairly steep hill when only the parking brake is applied.PB-4, "INSPECTION"

Automatic transaxle

“Park” mechanismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the “P” position without applying any brakes.—

CVT P (Park) position

mechanismOn a fairly steep hill check that the vehicle is held securely with the selector

lever in the “P” position without applying any brakes.— ItemReference page

ItemReference page

Windshield

washer fluidCheck that there is adequate fluid in the tank. —

Engine coolant

levelCheck the coolant level when the engine is cold.CO-8, "

LEVEL CHECK"

A/C condenser,

radiator and

hosesCheck the front of the condenser and radiator and clean off any dirt, insects,

leaves, etc., that may have accumulated. Make sure the radiator hoses have no

cracks, deformation, deterioration or loose connections.—

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs.BR-9, "

CHECKING BRAKE

FLUID LEVEL" and MA-22,

"Checking Clutch Fluid

Level and Leaks"

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level.—

Engine drive beltsMake sure that no belt is frayed, worn, cracked or oily.MA-13

Engine oil levelCheck the level on the dipstick after parking the vehicle on a level spot and turning

off the engine.LU-5, "ENGINE OIL

LEVEL"

Automatic tran-

saxle fluid levelCheck the level on the dipstick after putting the selector lever in “P” with the

engine idling.MA-20 and MA-22

Exhaust systemMake sure there are no loose supports, cracks or holes. If the sound of the

exhaust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it.MA-20

UnderbodyThe underbody is frequently exposed to corrosive substances such as those used

on icy roads or to control dust. It is very important to remove these substances,

otherwise rust will form on the floor pan, frame, fuel lines and around the exhaust

system. At the end of winter, the underbody should be thoroughly flushed with

plain water, being careful to clean those areas where mud and dirt can easily

accumulate.—

Fluid leaksCheck under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has

been parked for a while. Water dripping from the air conditioner after use is nor-

mal. If you should notice any leaks or gasoline fumes are evident, check for the

cause and correct it immediately.—

Page 2509 of 2896

PB-1

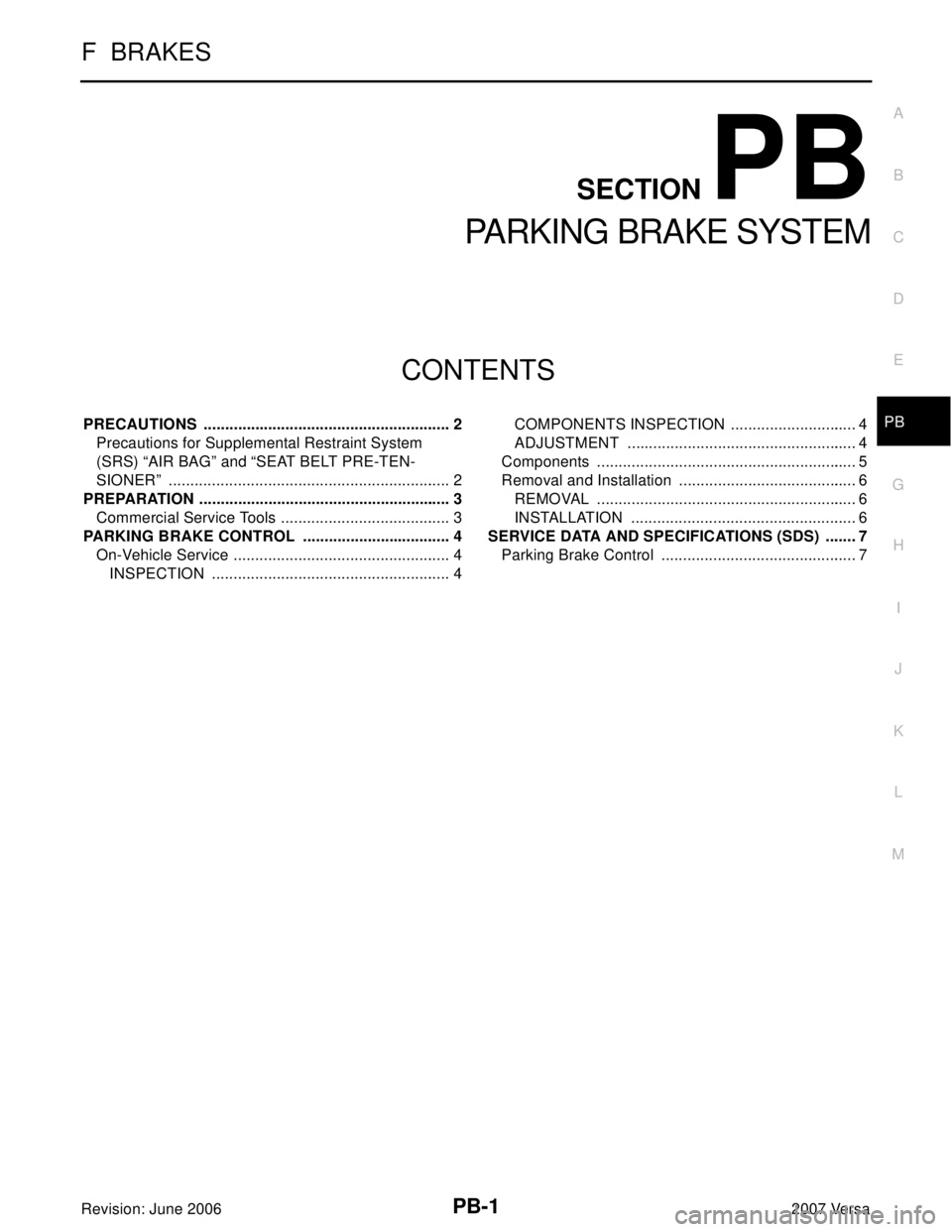

PARKING BRAKE SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION PB

A

B

PB

Revision: June 20062007 Versa PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

PREPARATION ........................................................... 3

Commercial Service Tools ........................................ 3

PARKING BRAKE CONTROL ................................... 4

On-Vehicle Service ................................................... 4

INSPECTION ........................................................ 4COMPONENTS INSPECTION .............................. 4

ADJUSTMENT ...................................................... 4

Components ............................................................. 5

Removal and Installation .......................................... 6

REMOVAL ............................................................. 6

INSTALLATION ..................................................... 6

SERVICE DATA AND SPECIFICATIONS (SDS) ........ 7

Parking Brake Control .............................................. 7

Page 2599 of 2896

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: June 20062007 Versa

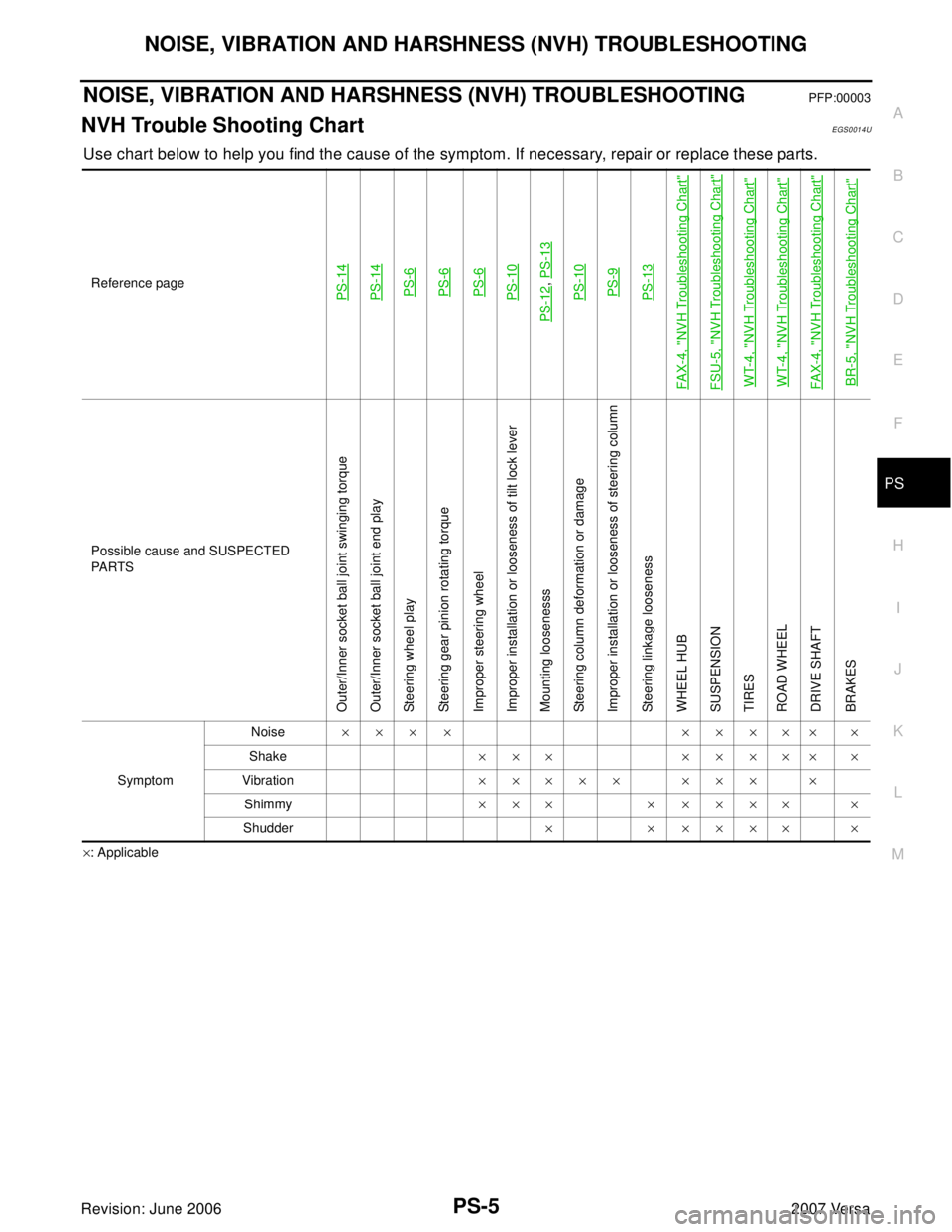

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Trouble Shooting ChartEGS0014U

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

PS-14PS-14PS-6PS-6PS-6PS-10

PS-12

, PS-13PS-10PS-9PS-13

FA X-4, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

FA X-4, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED

PA R T S

Outer/Inner socket ball joint swinging torque

Outer/Inner socket ball joint end play

Steering wheel play

Steering gear pinion rotating torque

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting loosenesss

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

SymptomNoise××× × ××××× ×

Shake××× ××××× ×

Vibration××××× ××× ×

Shimmy××× × ×××× ×

Shudder× × ×××× ×

Page 2615 of 2896

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RAX-3

C

E

F

G

H

I

J

K

L

MA

B

RAX

Revision: June 20062007 Versa

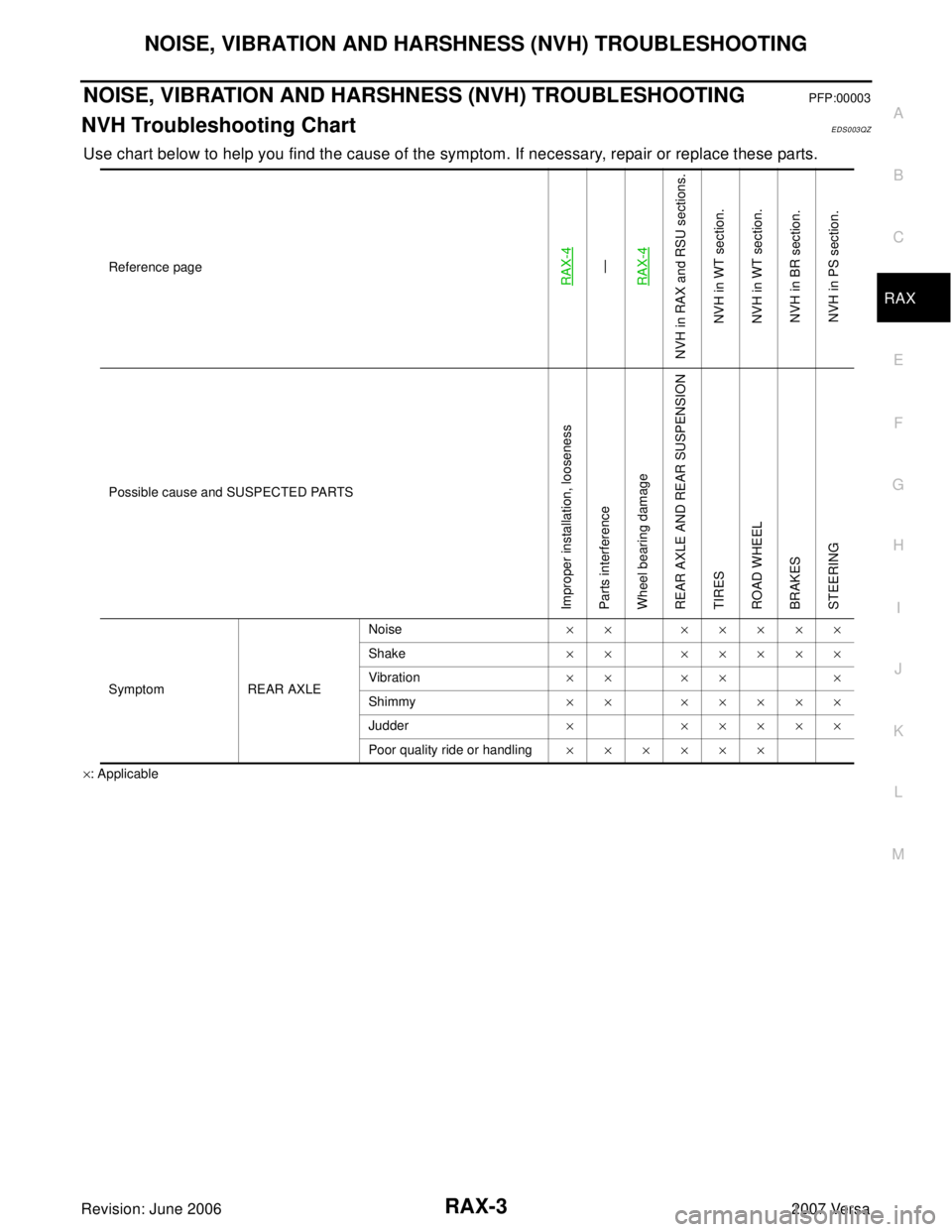

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS003QZ

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RAX-4—

RAX-4

NVH in RAX and RSU sections.

NVH in WT section.

NVH in WT section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Parts interference

Wheel bearing damage

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom REAR AXLENoise×× ×××××

Shake×× ×××××

Vibration×× ×× ×

Shimmy×× ×××××

Judder× ×××××

Poor quality ride or handling××××××

Page 2652 of 2896

RSU-4

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Revision: June 20062007 Versa

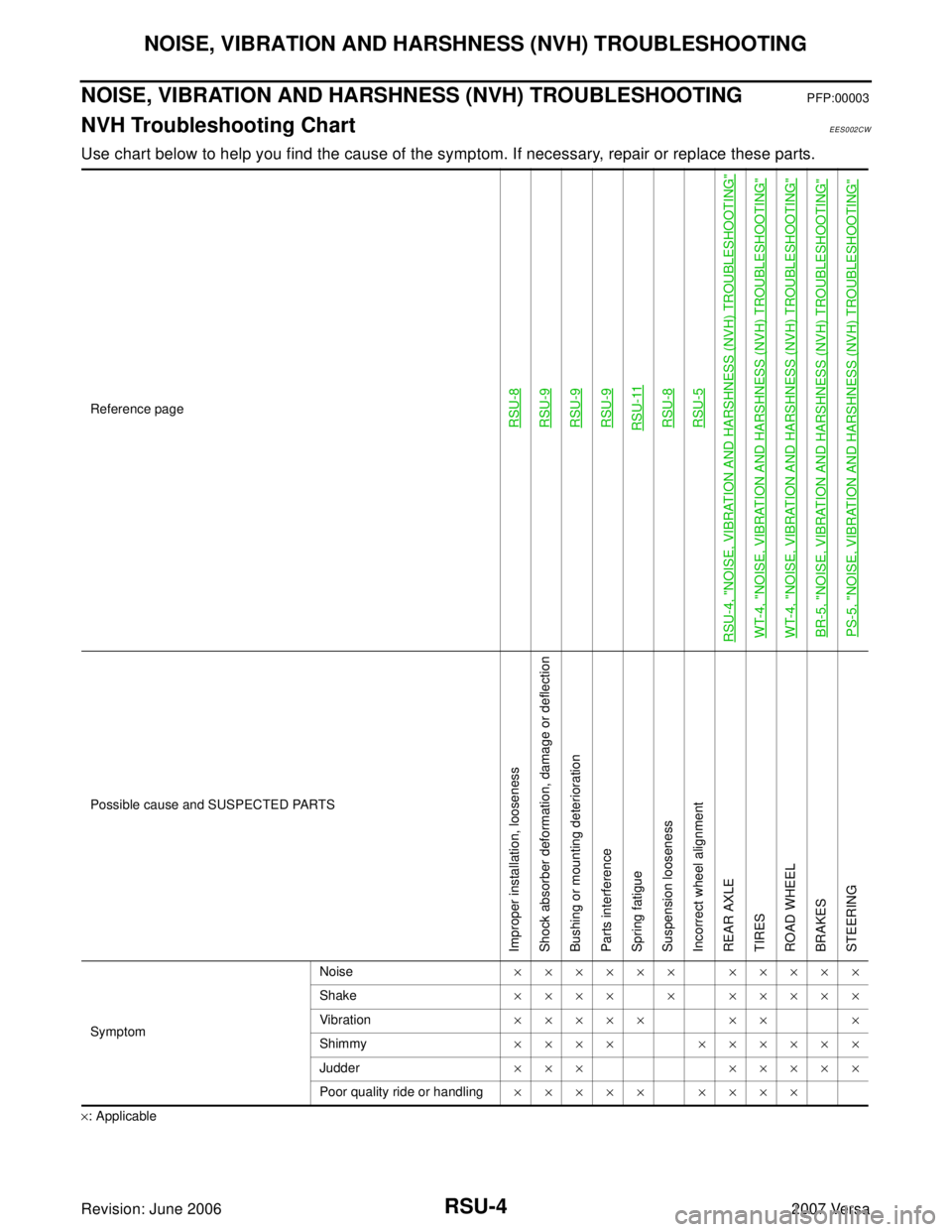

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEES002CW

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RSU-8RSU-9RSU-9RSU-9RSU-11RSU-8RSU-5

RSU-4, "

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

"

WT-4, "

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

"

WT-4, "

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

"

BR-5, "

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

"

PS-5, "

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

REAR AXLE

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomNoise×××××× ×××××

Shake×××× × ×××××

Vib ration××××× ×× ×

Shimmy×××× ××××××

Judder ××× ×××××

Poor quality ride or handling××××× ××××

Page 2671 of 2896

SEAT BELTS

SB-9

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: June 20062007 Versa

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are of the Emergency Locking Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors

except the driver's seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted partially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors using the following test(s) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull it forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts, indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If

NG, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WA RN ING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be paved and dry. DO NOT perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten driver's seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event the retractor does not

lock, apply brakes firmly and make a very hard stop.

During the stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.