reverse light NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2843 of 5883

![NISSAN TIIDA 2007 Service User Guide EM-196

< ON-VEHICLE REPAIR >[MR18DE]

OIL SEAL

Drive belt; Refer to EM-142, "Component".

Crankshaft pulley; Refer to EM-176, "

Component".

2. Remove front oil seal using a suitable tool.

CAUTION:

B NISSAN TIIDA 2007 Service User Guide EM-196

< ON-VEHICLE REPAIR >[MR18DE]

OIL SEAL

Drive belt; Refer to EM-142, "Component".

Crankshaft pulley; Refer to EM-176, "

Component".

2. Remove front oil seal using a suitable tool.

CAUTION:

B](/img/5/57395/w960_57395-2842.png)

EM-196

< ON-VEHICLE REPAIR >[MR18DE]

OIL SEAL

Drive belt; Refer to EM-142, "Component".

Crankshaft pulley; Refer to EM-176, "

Component".

2. Remove front oil seal using a suitable tool.

CAUTION:

Be careful not to damage front cover and crankshaft.

INSTALLATION

1. Apply new engine oil to new front oil seal joint surface and seal lip.

2. Install front oil seal so that each seal lip is oriented as shown in

the figure.

Install front oil seal (2) using a suitable tool with outer diameter

57 mm (2.24 in) and inner diameter 45 mm (1.77 in) (A) to the

dimension as shown.

CAUTION:

Be careful not to damage front cover and crankshaft.

Press-fit oil seal straight to avoid causing burrs or tilt-

ing.

Do not touch grease applied on oil seal lip.

3. Installation of the remaining components is in the reverse order of removal.

Removal and Installation of Rear Oil SealINFOID:0000000001337802

REMOVAL

1. Remove transaxle assembly. Refer to TM-681, "Removal and Installation".

2. Remove clutch cover and clutch disk. Refer to CL-13, "

Removal and Installation".

3. Remove flywheel. Refer to EM-211, "

Component".

4. Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

1. Apply the liquid gasket lightly to entire outside area of new rear oil seal.

Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-27, "

Recommended Chemical Prod-

ucts and Sealants".

A : Dust seal lip

B : Oil seal lip

: Engine outside

: Engine inside

PBIC3485J

Within 0.3 mm (0.012 in) toward engine front

Within 0.5 mm (0.020 in) toward engine rear

PBIC3729E

Page 2861 of 5883

![NISSAN TIIDA 2007 Service User Guide EM-214

< DISASSEMBLY AND ASSEMBLY >[MR18DE]

ENGINE UNIT

16. Heat piston to 60° to 70°C (140° to 158°F) using a suitable tool

(A).

17. Push out piston pin using a suitable tool of an outer diameter NISSAN TIIDA 2007 Service User Guide EM-214

< DISASSEMBLY AND ASSEMBLY >[MR18DE]

ENGINE UNIT

16. Heat piston to 60° to 70°C (140° to 158°F) using a suitable tool

(A).

17. Push out piston pin using a suitable tool of an outer diameter](/img/5/57395/w960_57395-2860.png)

EM-214

< DISASSEMBLY AND ASSEMBLY >[MR18DE]

ENGINE UNIT

16. Heat piston to 60° to 70°C (140° to 158°F) using a suitable tool

(A).

17. Push out piston pin using a suitable tool of an outer diameter

approximately 18 mm (0.71 in).

18. Loosen main bearing cap bolts in reverse order as shown, and

remove them.

NOTE:

Before loosening main bearing cap bolts, measure crankshaft

end play. Refer to EM-219, "

Inspection After Disassembly".

19. Remove main bearing caps.

Tap main bearing caps lightly using a suitable tool for removal.

CAUTION:

Be careful not to damage the mounting surface.

20. Remove crankshaft.

CAUTION:

Be careful not to damage or deform signal plate (1)

mounted on rear end of crankshaft (A).

When setting crankshaft on a flat floor surface, use a

block of wood to avoid interference between signal plate

and the floor surface.

Never remove signal plate unless it is necessary to do so.

21. Pull rear oil seal out from rear end of crankshaft.

22. Remove main bearings and thrust bearings from cylinder block

and main bearing caps.

CAUTION:

Identify installation positions, and store them without mix-

ing them up.

ASSEMBLY

1. Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

PBIC3231J

PBIC0262E

: Engine front

PBIC3235J

PBIC3234J

Page 2935 of 5883

![NISSAN TIIDA 2007 Service User Guide EM-288

< ON-VEHICLE REPAIR >[K9K]

HIGH PRESSURE SUPPLY PUMP

15. Plug all the holes of the injection circuit.

16. Remove the three mounting bolts from the high pressure supply pump then remove it.

INST NISSAN TIIDA 2007 Service User Guide EM-288

< ON-VEHICLE REPAIR >[K9K]

HIGH PRESSURE SUPPLY PUMP

15. Plug all the holes of the injection circuit.

16. Remove the three mounting bolts from the high pressure supply pump then remove it.

INST](/img/5/57395/w960_57395-2934.png)

EM-288

< ON-VEHICLE REPAIR >[K9K]

HIGH PRESSURE SUPPLY PUMP

15. Plug all the holes of the injection circuit.

16. Remove the three mounting bolts from the high pressure supply pump then remove it.

INSTALLATION

1. Install the pump then position the mounting bolts without tightening them.

2. Before fitting the new injection tube, lightly lubricate the nut threads with the oil from the sachet provided

in the new parts kit.

3. Install the injection tubes according to the following:

remove the protective plugs.

insert the injection tube olive into the taper of the high pressure pump outlet.

insert the injection tube olive into the taper of the high pressure rail inlet.

4. Finger tighten the nuts of the injection tube starting with the one located on the rail side.

5. Tighten the bolts on the high pressure pump.

6. Tighten the injection tube nut.

7. Install the high pressure supply pump protector.

CAUTION:

When installing the high pressure supply pump protector, follow the steps below.

Be sure rubber spacer (1) is touching bolt head of high

pressure supply pump (4) as shown.

Tighten bolt (2) while holding protector towards the high

pressure supply pump.

Tighten nut (3).

Be sure rubber spacer (1) is touching bolt head of high

pressure supply pump (4).

8. Installation is in the reverse order to removal.

9. Test the sealing of the high pressure supply pump after it has been repaired (refer to EM-253, "

Precaution

for Diesel Equipment"). : 21.0 N·m (2.1 kg-m, 15 ft-lb)

: 24.0 N·m (2.4 kg-m, 18 ft-lb)

E1BIA0117ZZ

: 21.0 N·m (2.1 kg-m, 15 ft-lb)

: 21.0 N·m (2.1 kg-m, 15 ft-lb)

E1BIA0118ZZ

Page 3088 of 5883

FRONT FOG LAMP

EXL-87

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

FRONT FOG LAMP

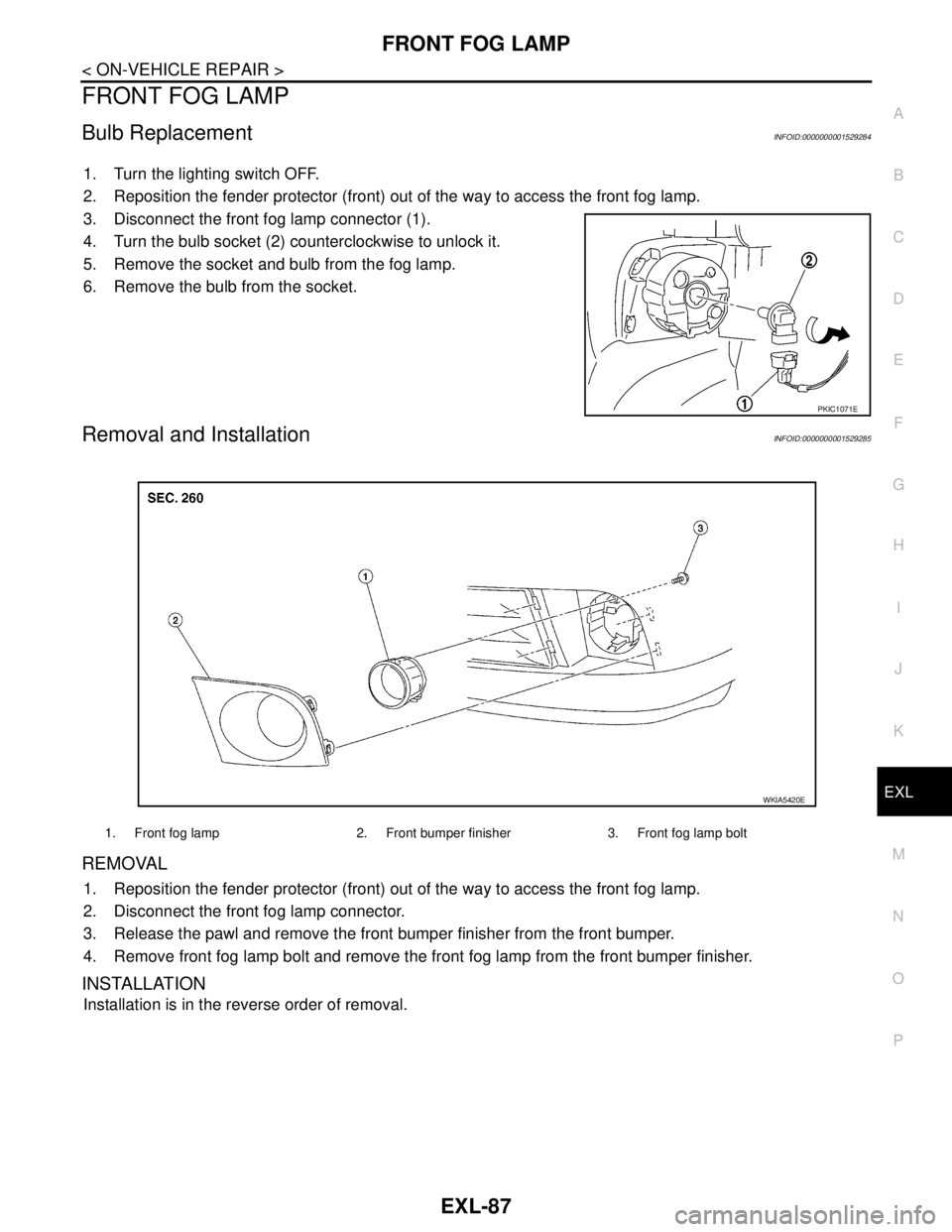

Bulb ReplacementINFOID:0000000001529284

1. Turn the lighting switch OFF.

2. Reposition the fender protector (front) out of the way to access the front fog lamp.

3. Disconnect the front fog lamp connector (1).

4. Turn the bulb socket (2) counterclockwise to unlock it.

5. Remove the socket and bulb from the fog lamp.

6. Remove the bulb from the socket.

Removal and InstallationINFOID:0000000001529285

REMOVAL

1. Reposition the fender protector (front) out of the way to access the front fog lamp.

2. Disconnect the front fog lamp connector.

3. Release the pawl and remove the front bumper finisher from the front bumper.

4. Remove front fog lamp bolt and remove the front fog lamp from the front bumper finisher.

INSTALLATION

Installation is in the reverse order of removal.

PKIC1071E

1. Front fog lamp 2. Front bumper finisher 3. Front fog lamp bolt

WKIA5420E

Page 3092 of 5883

AUTO LIGHT SYSTEM

EXL-91

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

AUTO LIGHT SYSTEM

Removal and Installation of Light and Rain SensorINFOID:0000000001530408

REMOVAL

1. Remove the rear view mirror. Refer to MIR-9, "Removal and Installation".

2. Disconnect the light and rain sensor connector.

3. Remove the light and rain sensor.

INSTALLATION

Installation is in the reverse order of removal.

Page 3102 of 5883

LIGHTING & TURN SIGNAL SWITCH

EXL-101

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

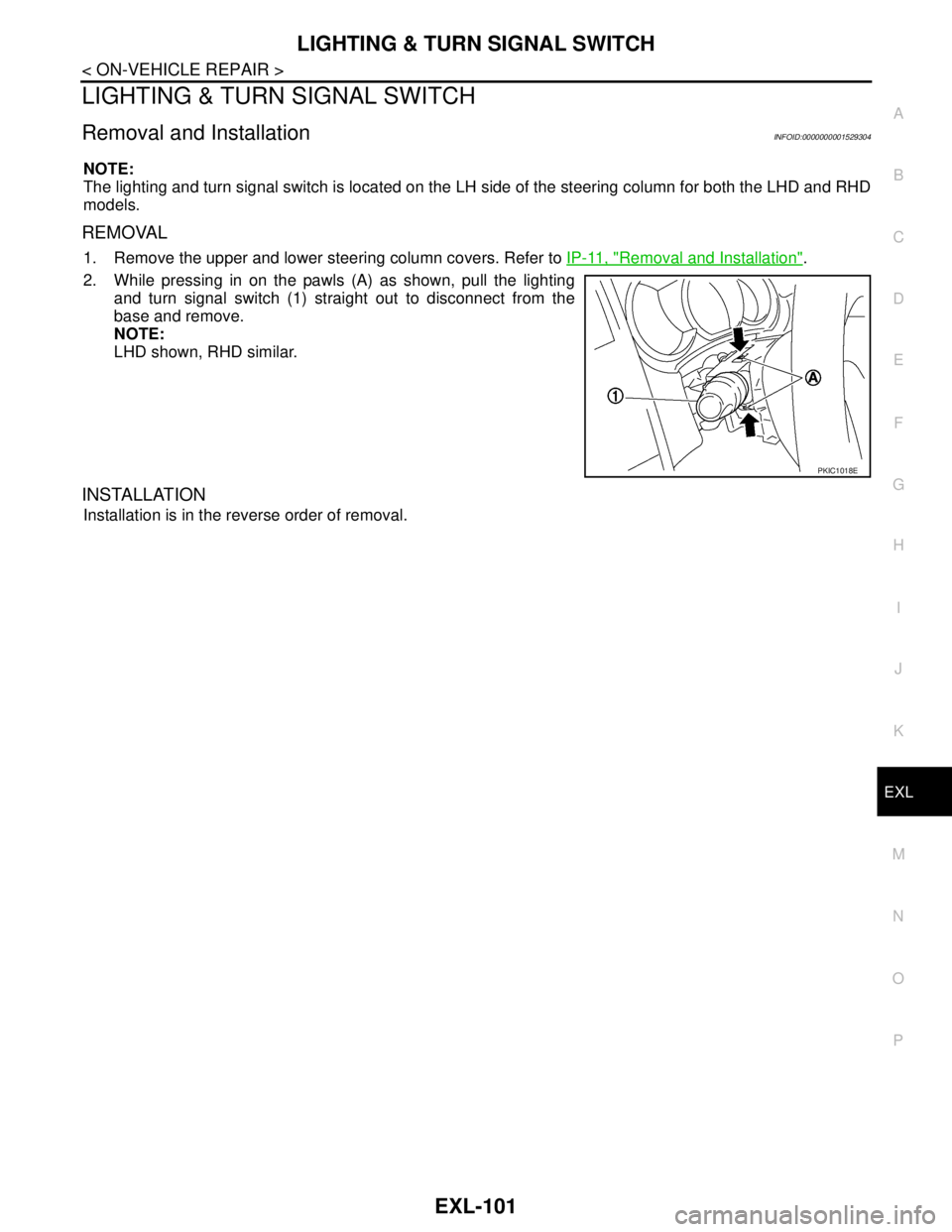

LIGHTING & TURN SIGNAL SWITCH

Removal and InstallationINFOID:0000000001529304

NOTE:

The lighting and turn signal switch is located on the LH side of the steering column for both the LHD and RHD

models.

REMOVAL

1. Remove the upper and lower steering column covers. Refer to IP-11, "Removal and Installation".

2. While pressing in on the pawls (A) as shown, pull the lighting

and turn signal switch (1) straight out to disconnect from the

base and remove.

NOTE:

LHD shown, RHD similar.

INSTALLATION

Installation is in the reverse order of removal.

PKIC1018E

Page 3146 of 5883

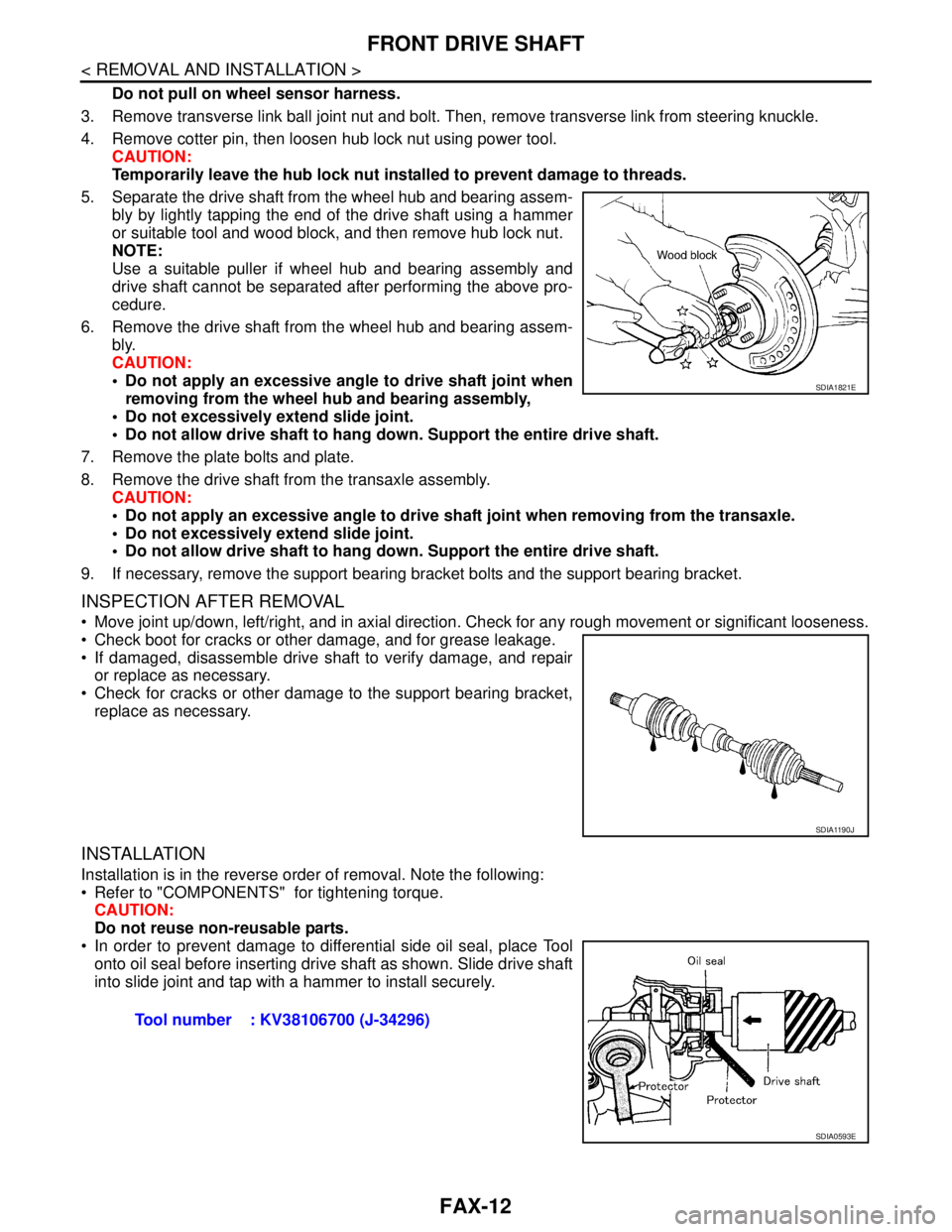

FAX-12

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool.

CAUTION:

Temporarily leave the hub lock nut installed to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem-

bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem-

bly.

CAUTION:

Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

Do not excessively extend slide joint.

Do not allow drive shaft to hang down. Support the entire drive shaft.

7. Remove the plate bolts and plate.

8. Remove the drive shaft from the transaxle assembly.

CAUTION:

Do not apply an excessive angle to drive shaft joint when removing from the transaxle.

Do not excessively extend slide joint.

Do not allow drive shaft to hang down. Support the entire drive shaft.

9. If necessary, remove the support bearing bracket bolts and the support bearing bracket.

INSPECTION AFTER REMOVAL

Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

Check boot for cracks or other damage, and for grease leakage.

If damaged, disassemble drive shaft to verify damage, and repair

or replace as necessary.

Check for cracks or other damage to the support bearing bracket,

replace as necessary.

INSTALLATION

Installation is in the reverse order of removal. Note the following:

Refer to "COMPONENTS" for tightening torque.

CAUTION:

Do not reuse non-reusable parts.

In order to prevent damage to differential side oil seal, place Tool

onto oil seal before inserting drive shaft as shown. Slide drive shaft

into slide joint and tap with a hammer to install securely.

SDIA1821E

SDIA1190J

Tool number : KV38106700 (J-34296)

SDIA0593E

Page 3276 of 5883

FRONT DOOR GLASS AND REGULATOR

GW-17

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

GW

N

O

P

Removal and installation of the door glass.

Removal and installation of the door glass run.

Initialization

After installing each component to the vehicle, follow the steps below.

1. Disconnect the battery negative cable or disconnect power window switch's harness connector tempo-

rarily, then reconnect after at least 1 minute.

2. Turn ignition switch ON.

3. Open the window to its full width by operating the power window switch. (Exclude this procedure if the

window is already fully opened).

4. Move the power window switch in the up direction (auto close position) and hold. Keep holding the switch

even when window is completely closed, and then release after 3 seconds have passed.

5. Inspection of the anti-pinch system function.

NOTE:

Initialization may be cancelled with continuous opening and closing operation. In this case, initialize the

system.

INSPECT THE FUNCTION OF THE ANTI-PINCH SYSTEM

1. Fully open the door glass.

2. Place a wooden piece (wooden hammer handle, etc.) near the fully closed position.

3. Carry out fully closing operation with auto up switch.

Check that the glass reverses without pinching the wooden piece, is lowered approx.150 mm (5.91 in) or for

2 seconds and then stops.

The glass should not be raised with power window main switch while it is reversing or lowering.

CAUTION:

Use care to avoid being pinched during the inspection. Do not use a hand, etc. in place of the

wooden piece during the inspection.

Check that auto up function is normal before inspection, following the system initialization.

FITTING INSPECTION

Make sure the glass is securely fit into the glass run groove.

Lower the glass slightly [approx. 10 to 20 mm (0.39 to 0.79 in)] and make sure the clearance to the sash is

parallel. If the clearance between the glass and sash is not parallel, loosen the regulator bolts, guide rail

bolts, and the glass and guide rail bolts to correct the glass position.

Make sure the system is normal with raising and lowering the glass.

Page 3282 of 5883

REAR DOOR GLASS AND REGULATOR

GW-23

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

GW

N

O

P

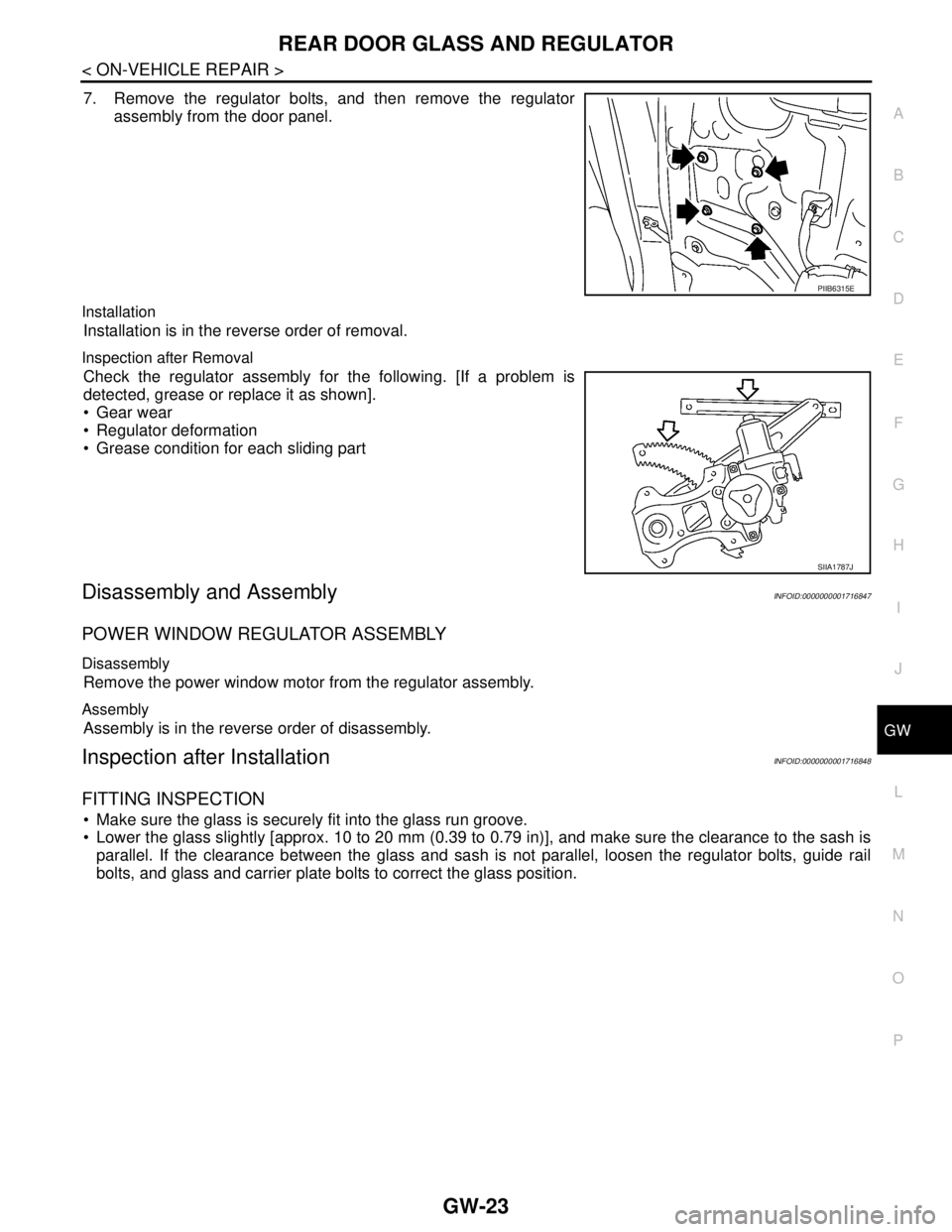

7. Remove the regulator bolts, and then remove the regulator

assembly from the door panel.

Installation

Installation is in the reverse order of removal.

Inspection after Removal

Check the regulator assembly for the following. [If a problem is

detected, grease or replace it as shown].

Gear wear

Regulator deformation

Grease condition for each sliding part

Disassembly and AssemblyINFOID:0000000001716847

POWER WINDOW REGULATOR ASSEMBLY

Disassembly

Remove the power window motor from the regulator assembly.

Assembly

Assembly is in the reverse order of disassembly.

Inspection after InstallationINFOID:0000000001716848

FITTING INSPECTION

Make sure the glass is securely fit into the glass run groove.

Lower the glass slightly [approx. 10 to 20 mm (0.39 to 0.79 in)], and make sure the clearance to the sash is

parallel. If the clearance between the glass and sash is not parallel, loosen the regulator bolts, guide rail

bolts, and glass and carrier plate bolts to correct the glass position.

PIIB6315E

SIIA1787J

Page 3731 of 5883

IP-16

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

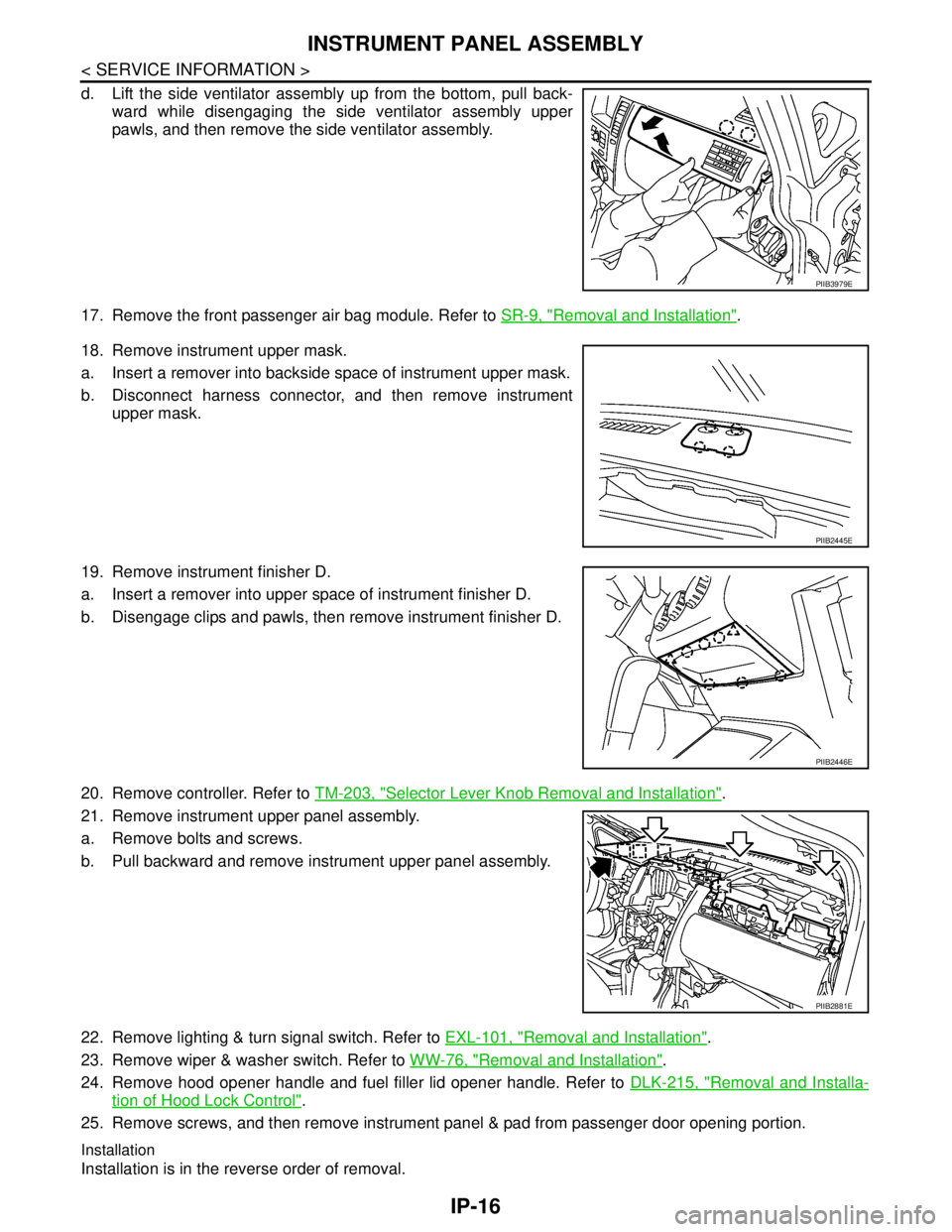

d. Lift the side ventilator assembly up from the bottom, pull back-

ward while disengaging the side ventilator assembly upper

pawls, and then remove the side ventilator assembly.

17. Remove the front passenger air bag module. Refer to SR-9, "

Removal and Installation".

18. Remove instrument upper mask.

a. Insert a remover into backside space of instrument upper mask.

b. Disconnect harness connector, and then remove instrument

upper mask.

19. Remove instrument finisher D.

a. Insert a remover into upper space of instrument finisher D.

b. Disengage clips and pawls, then remove instrument finisher D.

20. Remove controller. Refer to TM-203, "

Selector Lever Knob Removal and Installation".

21. Remove instrument upper panel assembly.

a. Remove bolts and screws.

b. Pull backward and remove instrument upper panel assembly.

22. Remove lighting & turn signal switch. Refer to EXL-101, "

Removal and Installation".

23. Remove wiper & washer switch. Refer to WW-76, "

Removal and Installation".

24. Remove hood opener handle and fuel filler lid opener handle. Refer to DLK-215, "

Removal and Installa-

tion of Hood Lock Control".

25. Remove screws, and then remove instrument panel & pad from passenger door opening portion.

Installation

Installation is in the reverse order of removal.

PIIB3979E

PIIB2445E

PIIB2446E

PIIB2881E