light system NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 5401 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SYSTEM SYMPTOM

TM-455

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

O NISSAN TIIDA 2007 Service Repair Manual SYSTEM SYMPTOM

TM-455

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

O](/img/5/57395/w960_57395-5400.png)

SYSTEM SYMPTOM

TM-455

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)INFOID:0000000001714360

SYMPTOM:

Engine speed does not smoothly return to idle when A/T shifts from D

4 to D3 on “Cruise Test — Part

1”.

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to XX-XX, "*****"

or TM-38, "Diagnosis Procedure without CONSULT-III".

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to XX-XX, "*****" or XX-XX, "*****".

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to XX-XX, "*****"

(type 1) or XX-XX, "*****" (type 2).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to TM-213, "

Component".

2. Check A/T fluid condition. Refer to TM-171, "

Checking A/T Fluid".

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to TM-191, "

Control Valve Assembly and Accumulators".

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to TM-222, "

Disassembly".

4. Check the following items:

- Overrun clutch assembly. Refer to TM-267, "

Forward and Overrun Clutches".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to TM-191, "

Control Valve Assembly and Accumulators".

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again. Refer to TM-183, "

Cruise Test - Part 1".

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

Page 5411 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-465

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSION NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-465

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSION](/img/5/57395/w960_57395-5410.png)

PRECAUTIONS

TM-465

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001723044

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001723045

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precaution for On Board Diagnosis (OBD) System of A/T and Engine (For Type1 Only)

INFOID:0000000001723046

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 5441 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SHIFT CONTROL SYSTEM

TM-495

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. Remove the plate (1) from the control device assembly.

: Vehicle front

8. Remove the lock pl NISSAN TIIDA 2007 Service Repair Manual SHIFT CONTROL SYSTEM

TM-495

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. Remove the plate (1) from the control device assembly.

: Vehicle front

8. Remove the lock pl](/img/5/57395/w960_57395-5440.png)

SHIFT CONTROL SYSTEM

TM-495

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. Remove the plate (1) from the control device assembly.

: Vehicle front

8. Remove the lock plate (1) from the control cable (2).

: Vehicle front

9. Remove the control cable (2) from the control device assembly.

10. Insert flat-bladed screwdrivers at points (A) and (B) as shown,

and press both tabs (E) and (F) at the front (C) and rear (D)

slightly toward the center of the control device assembly to

remove the control device assembly from the underside of the

vehicle.

: Vehicle front

INSTALLATION

Installation is in the reverse order of removal.

SCIA6967E

SCIA6968E

SCIA6970E

Page 5442 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-496

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

SHIFT CONTROL SYSTEM

When installing the control cable (1) to the control device assembly

(2), make sure that the control cable (1) is fully press NISSAN TIIDA 2007 Service Repair Manual TM-496

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

SHIFT CONTROL SYSTEM

When installing the control cable (1) to the control device assembly

(2), make sure that the control cable (1) is fully press](/img/5/57395/w960_57395-5441.png)

TM-496

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

SHIFT CONTROL SYSTEM

When installing the control cable (1) to the control device assembly

(2), make sure that the control cable (1) is fully pressed in with the

ribbed surface (A) facing downward from the vehicle.

: Vehicle front

After installation is completed, adjust and check the A/T position.

Refer to TM-497, "

Adjustment of A/T Position" and TM-497,

"Checking of A/T Position".

Control Device Disassembly and AssemblyINFOID:0000000001731422

DISASSEMBLY

NOTE:

Refer to TM-493, "

Control Device Removal and Installation" to disassemble.

1. Remove selector lever knob from control device assembly. Refer to TM-496, "

Selector Lever Knob

Removal and Installation".

2. Remove position lamp from position indicator plate (1).

3. Insert a flat-bladed screwdriver to (A) (at 4 locations) as shown,

and bend each hook slightly to raise position indicator plate (1)

and remove from control device assembly (2).

4. Remove bracket from control device assembly (2).

5. Remove A/T device harness connector from control device

assembly (2).

6. Release tabs (A) on shift lock solenoid and park position switch

assembly from hooks (B) on control device assembly to shift

lock solenoid and park position switch assembly.

ASSEMBLY

Assemble in the reverse order of disassembly.

Selector Lever Knob Removal and InstallationINFOID:0000000001731423

REMOVAL

CAUTION:

Make sure that parking brake is applied before removal/installation.

SCIA6253E

SCIA6969E

SCIA6977E

Page 5716 of 5883

WCS

WCS-1

DRIVER INFORMATION & MULTIMEDIA

C

D

E

F

G

H

I

J

K

L

MB

SECTION WCS

A

O

P

CONTENTS

WARNING CHIME SYSTEM

BASIC INSPECTION ....................................3

DIAGNOSIS AND REPAIR WORKFLOW ..........3

Work Flow .................................................................3

FUNCTION DIAGNOSIS ...............................4

WARNING CHIME SYSTEM ...............................4

WARNING CHIME SYSTEM .......................................4

WARNING CHIME SYSTEM : System Diagram .......4

WARNING CHIME SYSTEM : System Description

......

4

WARNING CHIME SYSTEM : Component Parts

Location .....................................................................

5

WARNING CHIME SYSTEM : Component De-

scription .....................................................................

6

LIGHT REMINDER WARNING CHIME .......................6

LIGHT REMINDER WARNING CHIME : System

Diagram .....................................................................

6

LIGHT REMINDER WARNING CHIME : System

Description ................................................................

6

LIGHT REMINDER WARNING CHIME : Compo-

nent Parts Location ...................................................

8

LIGHT REMINDER WARNING CHIME : Compo-

nent Description ........................................................

9

SEAT BELT WARNING CHIME ..................................9

SEAT BELT WARNING CHIME : System Diagram

......

9

SEAT BELT WARNING CHIME : System Descrip-

tion ............................................................................

9

SEAT BELT WARNING CHIME : Component

Parts Location .........................................................

10

SEAT BELT WARNING CHIME : Component De-

scription ...................................................................

11

KEY WARNING CHIME (WITH INTELLIGENT

KEY) ...........................................................................

11

KEY WARNING CHIME (WITH INTELLIGENT

KEY) : System Diagram ..........................................

11

KEY WARNING CHIME (WITH INTELLIGENT

KEY) : System Description ......................................

11

KEY WARNING CHIME (WITH INTELLIGENT

KEY) : Component Parts Location ...........................

12

KEY WARNING CHIME (WITH INTELLIGENT

KEY) : Component Description ................................

13

KEY WARNING CHIME (WITHOUT INTELLIGENT

KEY) ...........................................................................

13

KEY WARNING CHIME (WITHOUT INTELLI-

GENT KEY) : System Diagram ................................

13

KEY WARNING CHIME (WITHOUT INTELLI-

GENT KEY) : System Description ...........................

13

KEY WARNING CHIME (WITHOUT INTELLI-

GENT KEY) : Component Parts Location ................

14

KEY WARNING CHIME (WITHOUT INTELLI-

GENT KEY) : Component Description .....................

15

PARKING BRAKE RELEASE WARNING CHIME ....15

PARKING BRAKE RELEASE WARNING CHIME

: System Diagram ....................................................

15

PARKING BRAKE RELEASE WARNING CHIME

: System Description ................................................

15

PARKING BRAKE RELEASE WARNING CHIME

: Component Parts Location ....................................

16

PARKING BRAKE RELEASE WARNING CHIME

: Component Description .........................................

17

DIAGNOSIS SYSTEM (METER) .......................18

CONSULT-III Function (METER/M&A) ....................18

DIAGNOSIS SYSTEM (BCM) ...........................20

BUZZER .....................................................................20

BUZZER : CONSULT-III Function (BCM - BUZZ-

ER) ..........................................................................

20

COMPONENT DIAGNOSIS .........................21

POWER SUPPLY AND GROUND CIRCUIT ....21

COMBINATION METER ............................................21

COMBINATION METER : Diagnosis Procedure .....21

Page 5717 of 5883

WCS-2

BCM (BODY CONTROL MODULE) .........................21

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ...............................................................

21

METER BUZZER CIRCUIT ................................23

Description ..............................................................23

Component Function Check ...................................23

Diagnosis Procedure .............................................23

SEAT BELT BUCKLE SWITCH SIGNAL CIR-

CUIT ...................................................................

24

Description ..............................................................24

Component Function Check .................................24

Diagnosis Procedure .............................................24

Component Inspection ............................................25

KEY SWITCH SIGNAL CIRCUIT (WITH IN-

TELLIGENT KEY) ..............................................

26

Description ..............................................................26

Component Function Check .................................26

Diagnosis Procedure .............................................26

Component Inspection ............................................27

KEY SWITCH SIGNAL CIRCUIT (WITHOUT

INTELLIGENT KEY) ..........................................

28

Description ..............................................................28

Component Function Check .................................28

Diagnosis Procedure .............................................28

Component Inspection ............................................29

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ...................................................................

30

Description ..............................................................30

Component Function Check ...................................30

Diagnosis Procedure ..............................................30

Component Inspection ............................................30

WARNING CHIME SYSTEM .............................31

Wiring Diagram .......................................................31

ECU DIAGNOSIS ........................................37

COMBINATION METER ....................................37

Reference Value .....................................................37

Wiring Diagram .......................................................40

Fail Safe ..................................................................54

DTC Index ...............................................................55

BCM (BODY CONTROL MODULE) ..................56

Reference Value .....................................................56

Terminal Layout ......................................................59

Physical Values .......................................................59

Wiring Diagram .......................................................71

DTC Inspection Priority Chart ...............................74

DTC Index ..............................................................75

SYMPTOM DIAGNOSIS ............................76

THE LIGHT REMINDER WARNING DOES

NOT SOUND ......................................................

76

Description ..............................................................76

Diagnosis Procedure ...............................................76

THE SEAT BELT WARNING CONTINUES

SOUNDING, OR DOES NOT SOUND ...............

77

Description ..............................................................77

Diagnosis Procedure ...............................................77

THE KEY WARNING DOES NOT SOUND .......78

Description ..............................................................78

Diagnosis Procedure ...............................................78

THE PARKING BRAKE RELEASE WARNING

CONTINUES SOUNDING, OR DOES NOT

SOUND ..............................................................

79

Description ..............................................................79

Diagnosis Procedure ...............................................79

PRECAUTION ............................................80

PRECAUTIONS .................................................80

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" ....................

80

Page 5719 of 5883

WCS-4

< FUNCTION DIAGNOSIS >

WARNING CHIME SYSTEM

FUNCTION DIAGNOSIS

WARNING CHIME SYSTEM

WARNING CHIME SYSTEM

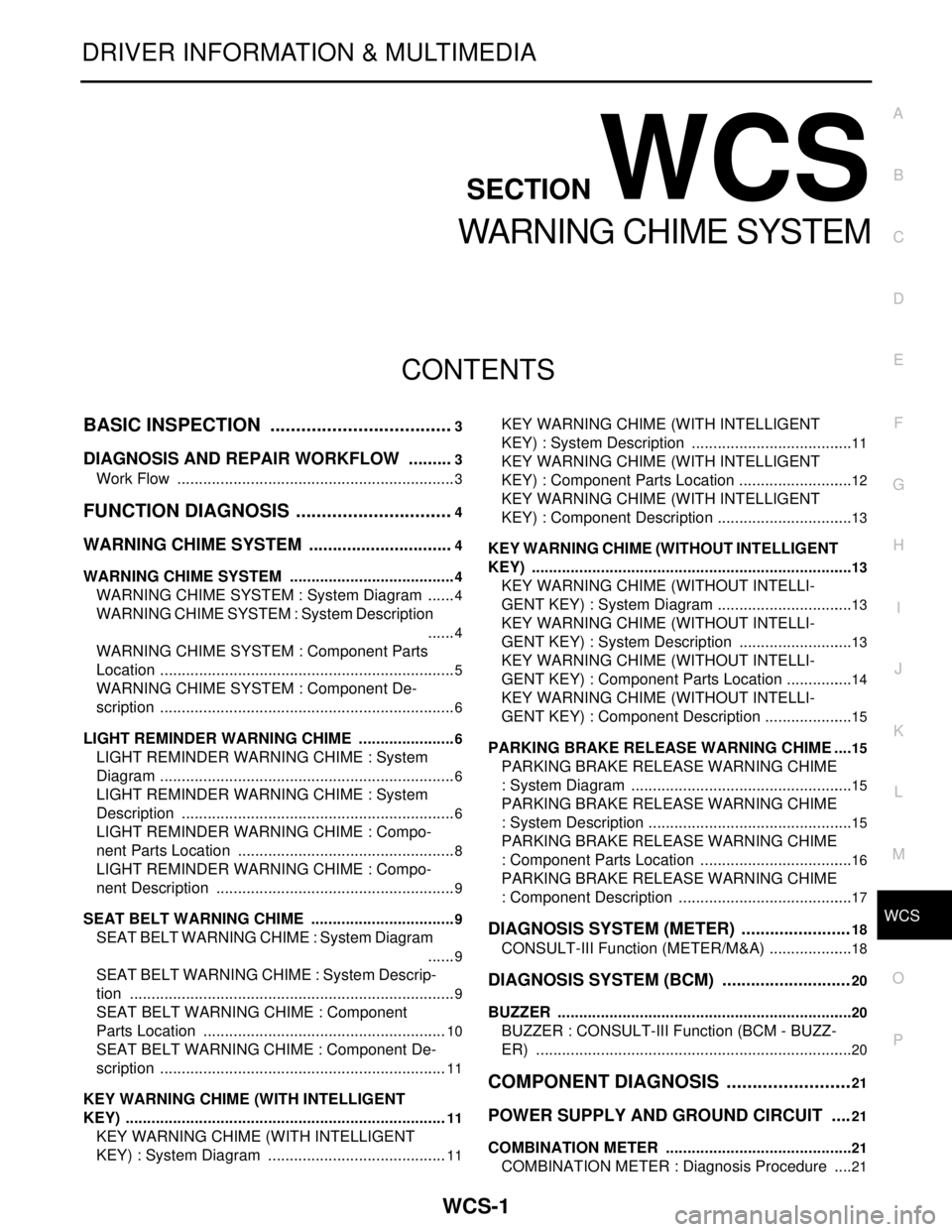

WARNING CHIME SYSTEM : System DiagramINFOID:0000000001722904

WARNING CHIME SYSTEM : System DescriptionINFOID:0000000001722905

COMBINATION METER

The buzzer for warning chime system is installed in the combination meter.

The buzzer sounds when the combination meter receives a buzzer output signal from each unit.

BCM

BCM receives signals from various units and transmits a buzzer output signal to the combination meter with

CAN communication line if it judges that the warning buzzer should be activated.

BCM warning function list

AWNIA0258GB

Warning functions Signal name

Light reminder warning chime Lighting switch position signal

Door switch signal

Seat belt warning chime Seat belt buckle switch signal

Key warning chime Key switch signal

Door switch signal

Page 5720 of 5883

WCS

WARNING CHIME SYSTEM

WCS-5

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

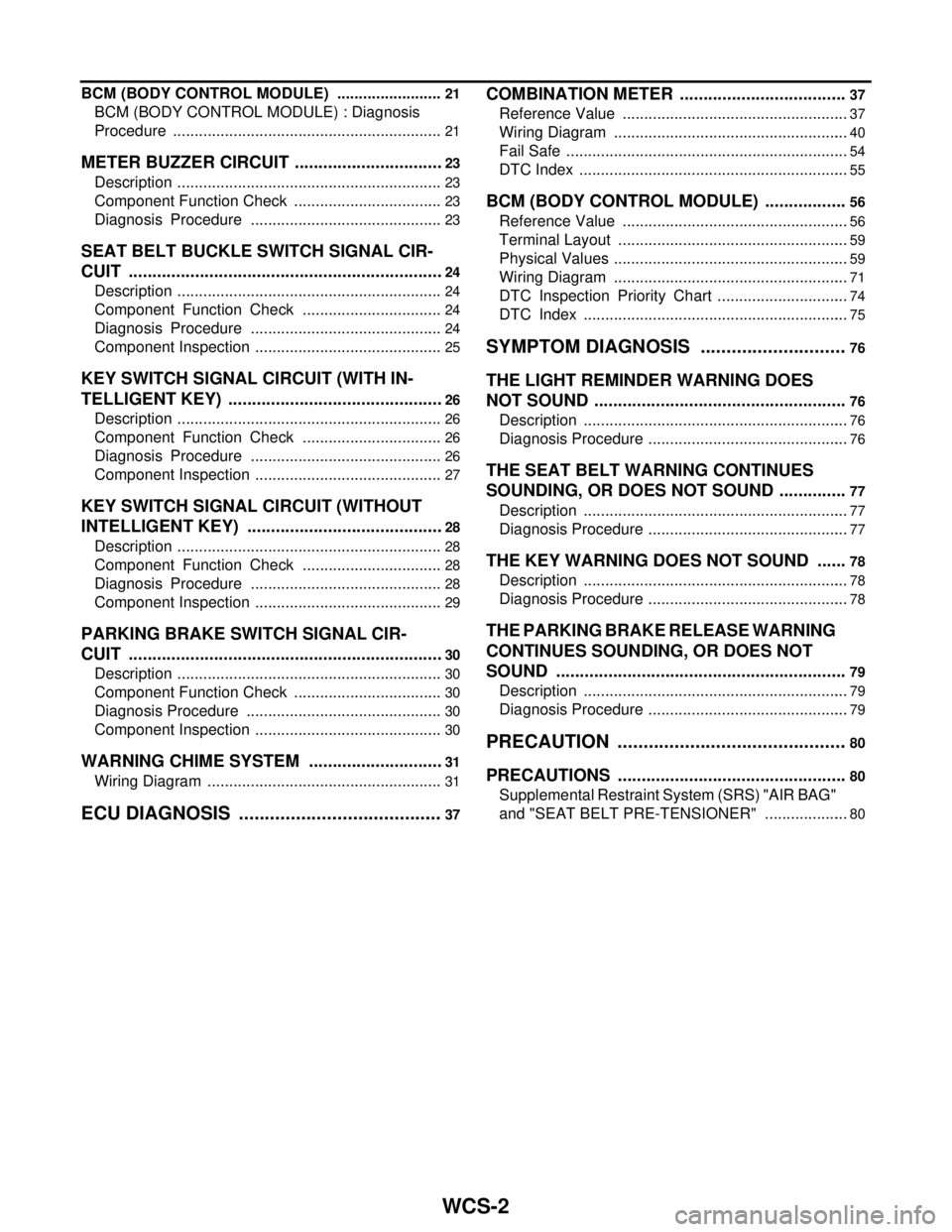

WARNING CHIME SYSTEM : Component Parts LocationINFOID:0000000001722906

AWNIA0259ZZ

1. Combination meter M24 2. BCM M18 (view with glove box re-

moved)3. Key switch and key lock solenoid M27

(without Intelligent Key)

4. Key switch and ignition knob switch

M32 (with Intelligent Key)5. Combination switch (lighting switch)

M286. Front door switch (driver side) B9

Page 5721 of 5883

WCS-6

< FUNCTION DIAGNOSIS >

WARNING CHIME SYSTEM

WARNING CHIME SYSTEM : Component Description

INFOID:0000000001722907

LIGHT REMINDER WARNING CHIME

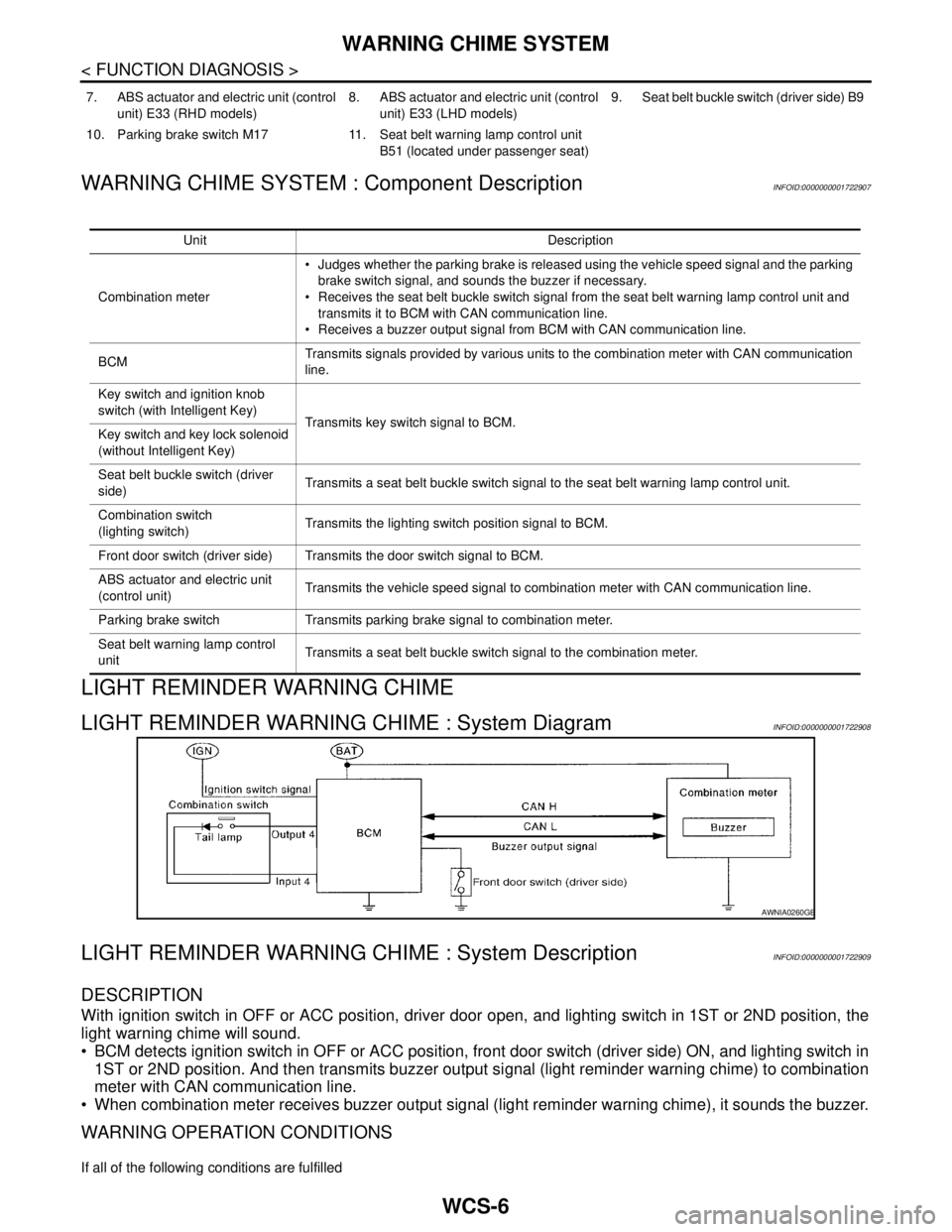

LIGHT REMINDER WARNING CHIME : System DiagramINFOID:0000000001722908

LIGHT REMINDER WARNING CHIME : System DescriptionINFOID:0000000001722909

DESCRIPTION

With ignition switch in OFF or ACC position, driver door open, and lighting switch in 1ST or 2ND position, the

light warning chime will sound.

BCM detects ignition switch in OFF or ACC position, front door switch (driver side) ON, and lighting switch in

1ST or 2ND position. And then transmits buzzer output signal (light reminder warning chime) to combination

meter with CAN communication line.

When combination meter receives buzzer output signal (light reminder warning chime), it sounds the buzzer.

WARNING OPERATION CONDITIONS

If all of the following conditions are fulfilled

7. ABS actuator and electric unit (control

unit) E33 (RHD models)8. ABS actuator and electric unit (control

unit) E33 (LHD models)9. Seat belt buckle switch (driver side) B9

10. Parking brake switch M17 11. Seat belt warning lamp control unit

B51 (located under passenger seat)

Unit Description

Combination meter Judges whether the parking brake is released using the vehicle speed signal and the parking

brake switch signal, and sounds the buzzer if necessary.

Receives the seat belt buckle switch signal from the seat belt warning lamp control unit and

transmits it to BCM with CAN communication line.

Receives a buzzer output signal from BCM with CAN communication line.

BCMTransmits signals provided by various units to the combination meter with CAN communication

line.

Key switch and ignition knob

switch (with Intelligent Key)

Transmits key switch signal to BCM.

Key switch and key lock solenoid

(without Intelligent Key)

Seat belt buckle switch (driver

side)Transmits a seat belt buckle switch signal to the seat belt warning lamp control unit.

Combination switch

(lighting switch)Transmits the lighting switch position signal to BCM.

Front door switch (driver side) Transmits the door switch signal to BCM.

ABS actuator and electric unit

(control unit)Transmits the vehicle speed signal to combination meter with CAN communication line.

Parking brake switch Transmits parking brake signal to combination meter.

Seat belt warning lamp control

unitTransmits a seat belt buckle switch signal to the combination meter.

AWNIA0260GB

Page 5722 of 5883

WCS

WARNING CHIME SYSTEM

WCS-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

Lighting switch is at 1st or 2nd position

Ignition switch is at OFF or ACC

Front door switch (driver side) is ON

WARNING CANCEL CONDITIONS

Warning is canceled if any of the following conditions is fulfilled. Lighting switch OFF

Ignition switch ON

Front door switch (driver side) is OFF