ignition NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 5833 of 5883

REAR WIPER AUTO STOP SIGNAL CIRCUIT

WW-31

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

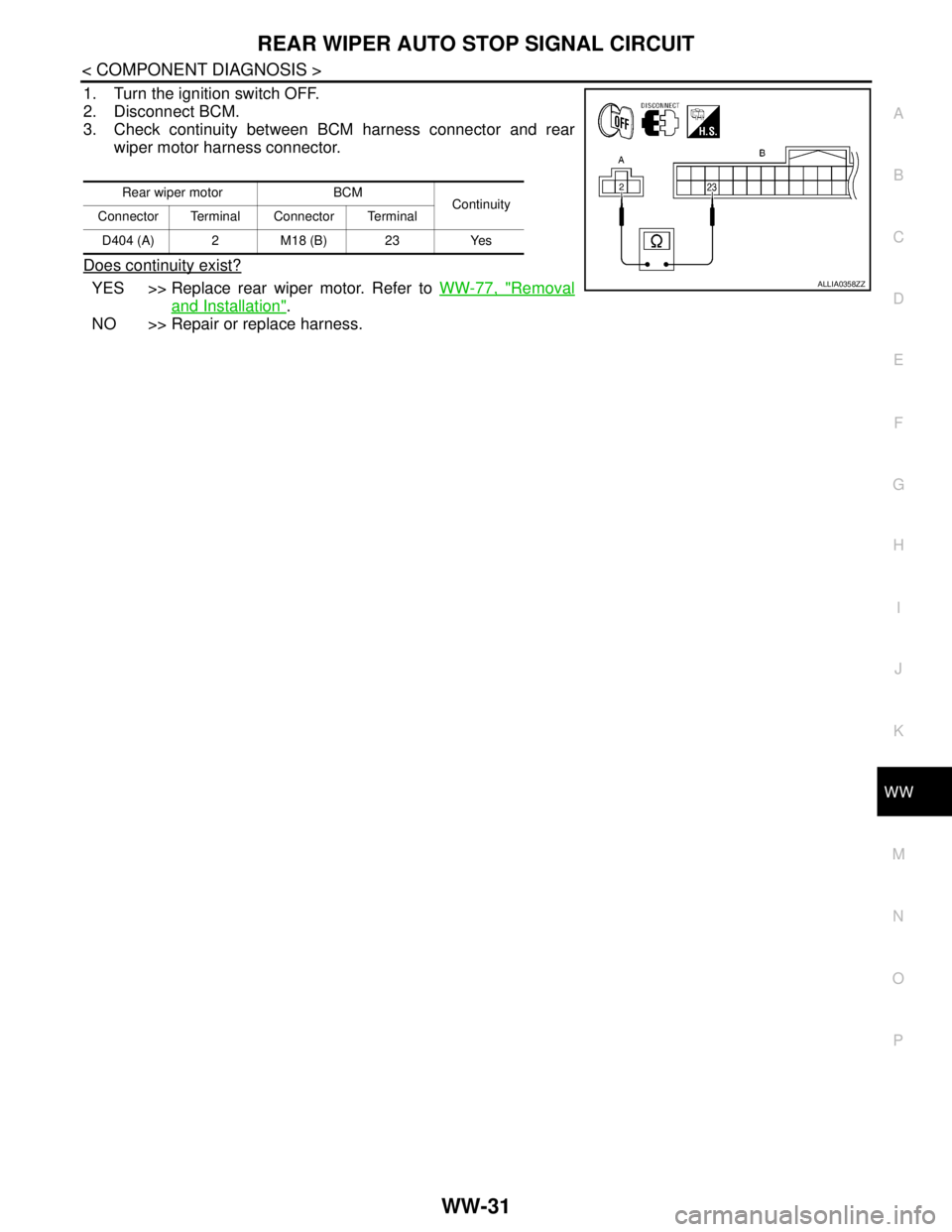

1. Turn the ignition switch OFF.

2. Disconnect BCM.

3. Check continuity between BCM harness connector and rear

wiper motor harness connector.

Does continuity exist?

YES >> Replace rear wiper motor. Refer to WW-77, "Removal

and Installation".

NO >> Repair or replace harness.

Rear wiper motor BCM

Continuity

Connector Terminal Connector Terminal

D404 (A) 2 M18 (B) 23 Yes

ALLIA0358ZZ

Page 5834 of 5883

WW-32

< COMPONENT DIAGNOSIS >

HEADLAMP WASHER RELAY

HEADLAMP WASHER RELAY

Component InspectionINFOID:0000000001366625

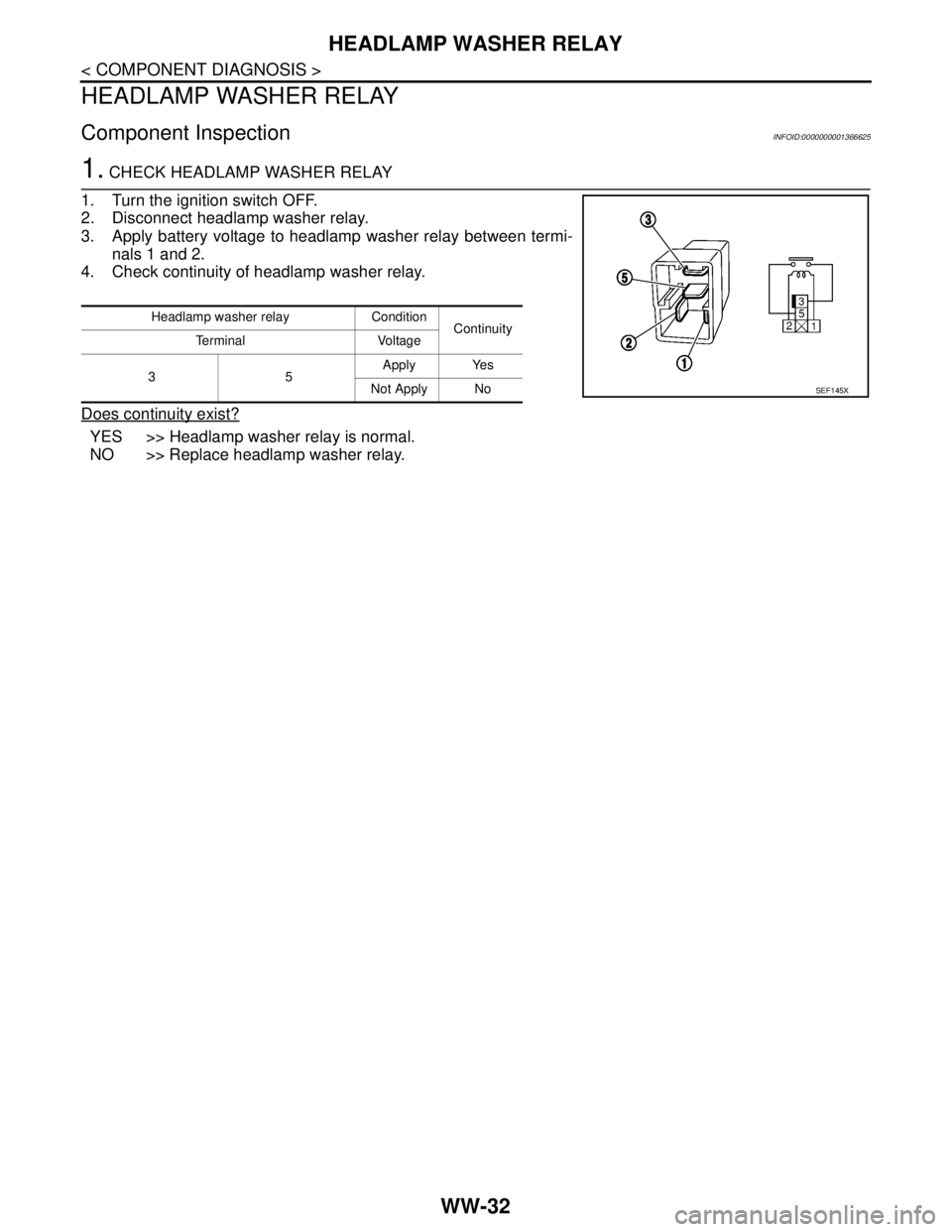

1. CHECK HEADLAMP WASHER RELAY

1. Turn the ignition switch OFF.

2. Disconnect headlamp washer relay.

3. Apply battery voltage to headlamp washer relay between termi-

nals 1 and 2.

4. Check continuity of headlamp washer relay.

Does continuity exist?

YES >> Headlamp washer relay is normal.

NO >> Replace headlamp washer relay.

Headlamp washer relay Condition

Continuity

Terminal Voltage

35Apply Yes

Not Apply No

SEF145X

Page 5835 of 5883

HEADLAMP WASHER CIRCUIT

WW-33

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

HEADLAMP WASHER CIRCUIT

Component Function CheckINFOID:0000000001366626

1. CHECK HEADLAMP WASHER OPERATION

CONSULT-III ACTIVE TEST

1. Select "HEAD LAMP WASHER" of IPDM E/R active test item.

2. While operating the test item, check headlamp washer operation.

Is the headlamp washer operation normally?

YES >> Headlamp washer circuit is normal.

NO >> Refer to WW-33, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001366627

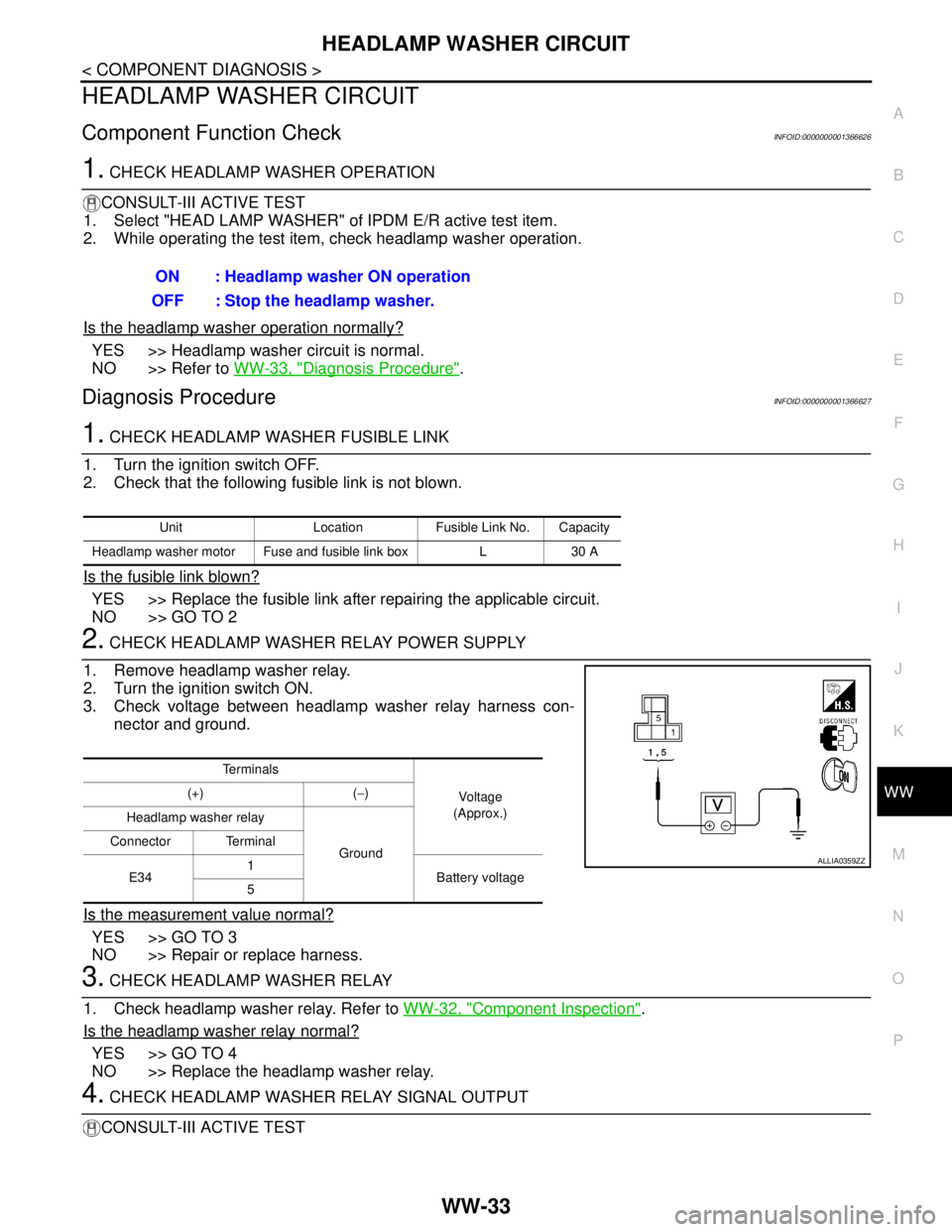

1. CHECK HEADLAMP WASHER FUSIBLE LINK

1. Turn the ignition switch OFF.

2. Check that the following fusible link is not blown.

Is the fusible link blown?

YES >> Replace the fusible link after repairing the applicable circuit.

NO >> GO TO 2

2. CHECK HEADLAMP WASHER RELAY POWER SUPPLY

1. Remove headlamp washer relay.

2. Turn the ignition switch ON.

3. Check voltage between headlamp washer relay harness con-

nector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK HEADLAMP WASHER RELAY

1. Check headlamp washer relay. Refer to WW-32, "

Component Inspection".

Is the headlamp washer relay normal?

YES >> GO TO 4

NO >> Replace the headlamp washer relay.

4. CHECK HEADLAMP WASHER RELAY SIGNAL OUTPUT

CONSULT-III ACTIVE TESTON : Headlamp washer ON operation

OFF : Stop the headlamp washer.

Unit Location Fusible Link No. Capacity

Headlamp washer motor Fuse and fusible link box L 30 A

Te r m i n a l s

Vo l ta g e

(Approx.) (+) (−)

Headlamp washer relay

Ground Connector Terminal

E341

Battery voltage

5

ALLIA0359ZZ

Page 5836 of 5883

WW-34

< COMPONENT DIAGNOSIS >

HEADLAMP WASHER CIRCUIT

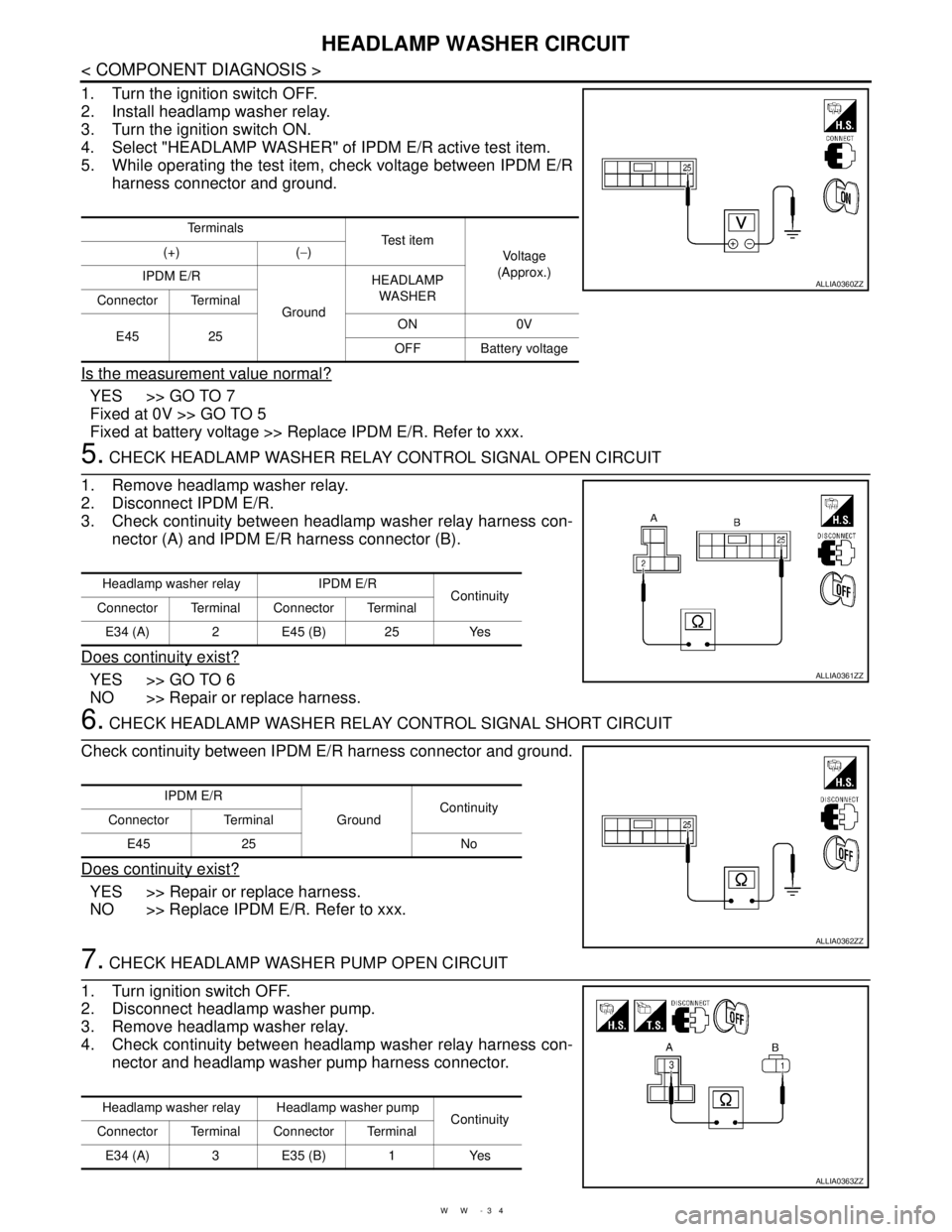

1. Turn the ignition switch OFF.

2. Install headlamp washer relay.

3. Turn the ignition switch ON.

4. Select "HEADLAMP WASHER" of IPDM E/R active test item.

5. While operating the test item, check voltage between IPDM E/R

harness connector and ground.

Is the measurement value normal?

YES >> GO TO 7

Fixed at 0V >> GO TO 5

Fixed at battery voltage >> Replace IPDM E/R. Refer to xxx.

5. CHECK HEADLAMP WASHER RELAY CONTROL SIGNAL OPEN CIRCUIT

1. Remove headlamp washer relay.

2. Disconnect IPDM E/R.

3. Check continuity between headlamp washer relay harness con-

nector (A) and IPDM E/R harness connector (B).

Does continuity exist?

YES >> GO TO 6

NO >> Repair or replace harness.

6. CHECK HEADLAMP WASHER RELAY CONTROL SIGNAL SHORT CIRCUIT

Check continuity between IPDM E/R harness connector and ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace IPDM E/R. Refer to xxx.

7. CHECK HEADLAMP WASHER PUMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect headlamp washer pump.

3. Remove headlamp washer relay.

4. Check continuity between headlamp washer relay harness con-

nector and headlamp washer pump harness connector.

Te r m i n a l s

Te s t i t e m

Vo l ta g e

(Approx.) (+) (−)

IPDM E/R

GroundHEADLAMP

WASHER

Connector Terminal

E45 25ON 0V

OFF Battery voltage

ALLIA0360ZZ

Headlamp washer relay IPDM E/R

Continuity

Connector Terminal Connector Terminal

E34 (A) 2 E45 (B) 25 Yes

ALLIA0361ZZ

IPDM E/R

GroundContinuity

Connector Terminal

E45 25 No

ALLIA0362ZZ

Headlamp washer relay Headlamp washer pump

Continuity

Connector Terminal Connector Terminal

E34 (A) 3 E35 (B) 1 Yes

ALLIA0363ZZ

Page 5853 of 5883

BCM (BODY CONTROL MODULE)

WW-51

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

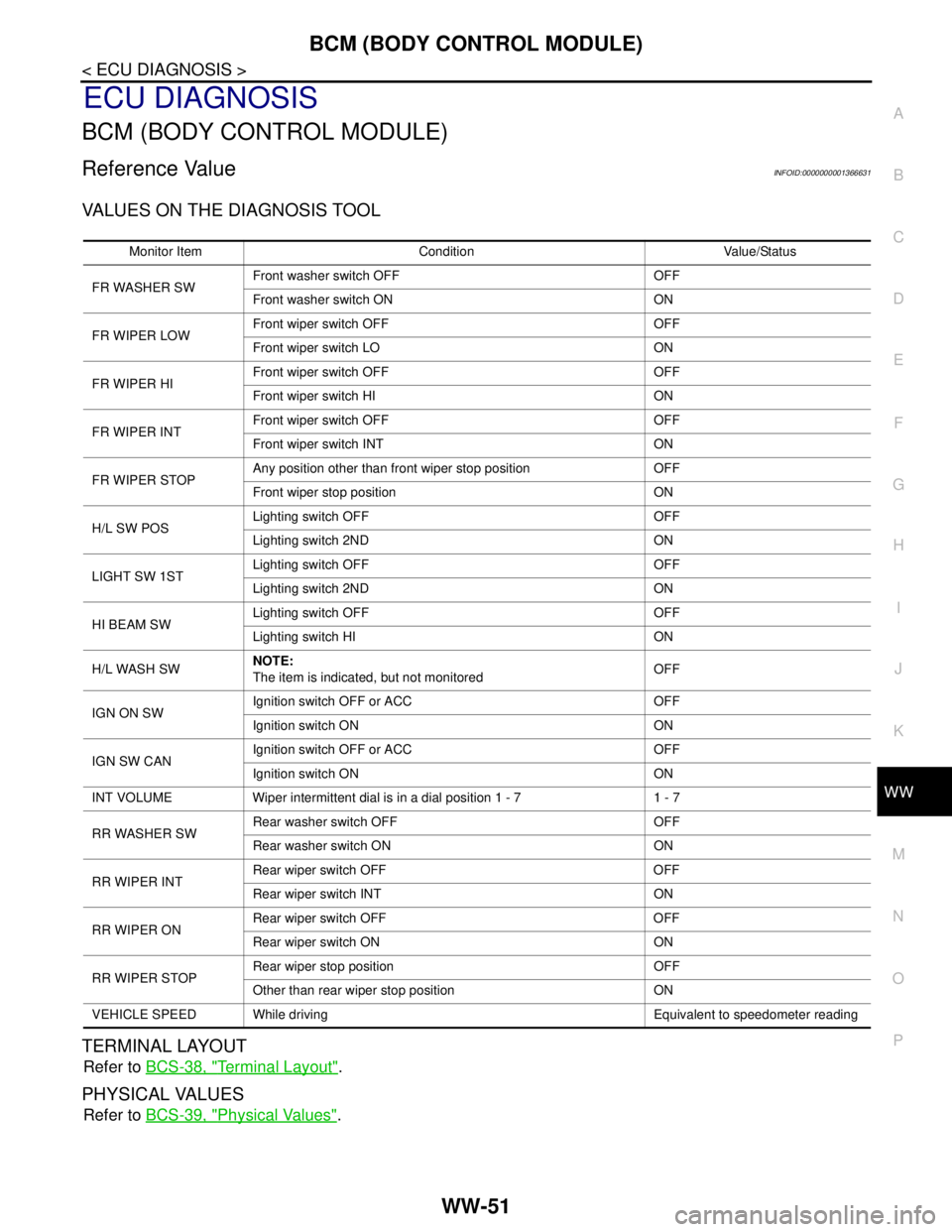

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000001366631

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

Refer to BCS-38, "Terminal Layout".

PHYSICAL VALUES

Refer to BCS-39, "Physical Values".

Monitor Item Condition Value/Status

FR WASHER SWFront washer switch OFF OFF

Front washer switch ON ON

FR WIPER LOWFront wiper switch OFF OFF

Front wiper switch LO ON

FR WIPER HIFront wiper switch OFF OFF

Front wiper switch HI ON

FR WIPER INTFront wiper switch OFF OFF

Front wiper switch INT ON

FR WIPER STOPAny position other than front wiper stop position OFF

Front wiper stop position ON

H/L SW POSLighting switch OFF OFF

Lighting switch 2ND ON

LIGHT SW 1STLighting switch OFF OFF

Lighting switch 2ND ON

HI BEAM SWLighting switch OFF OFF

Lighting switch HI ON

H/L WASH SWNOTE:

The item is indicated, but not monitoredOFF

IGN ON SWIgnition switch OFF or ACC OFF

Ignition switch ON ON

IGN SW CANIgnition switch OFF or ACC OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

RR WASHER SWRear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INTRear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOPRear wiper stop position OFF

Other than rear wiper stop position ON

VEHICLE SPEED While driving Equivalent to speedometer reading

Page 5854 of 5883

WW-52

< ECU DIAGNOSIS >

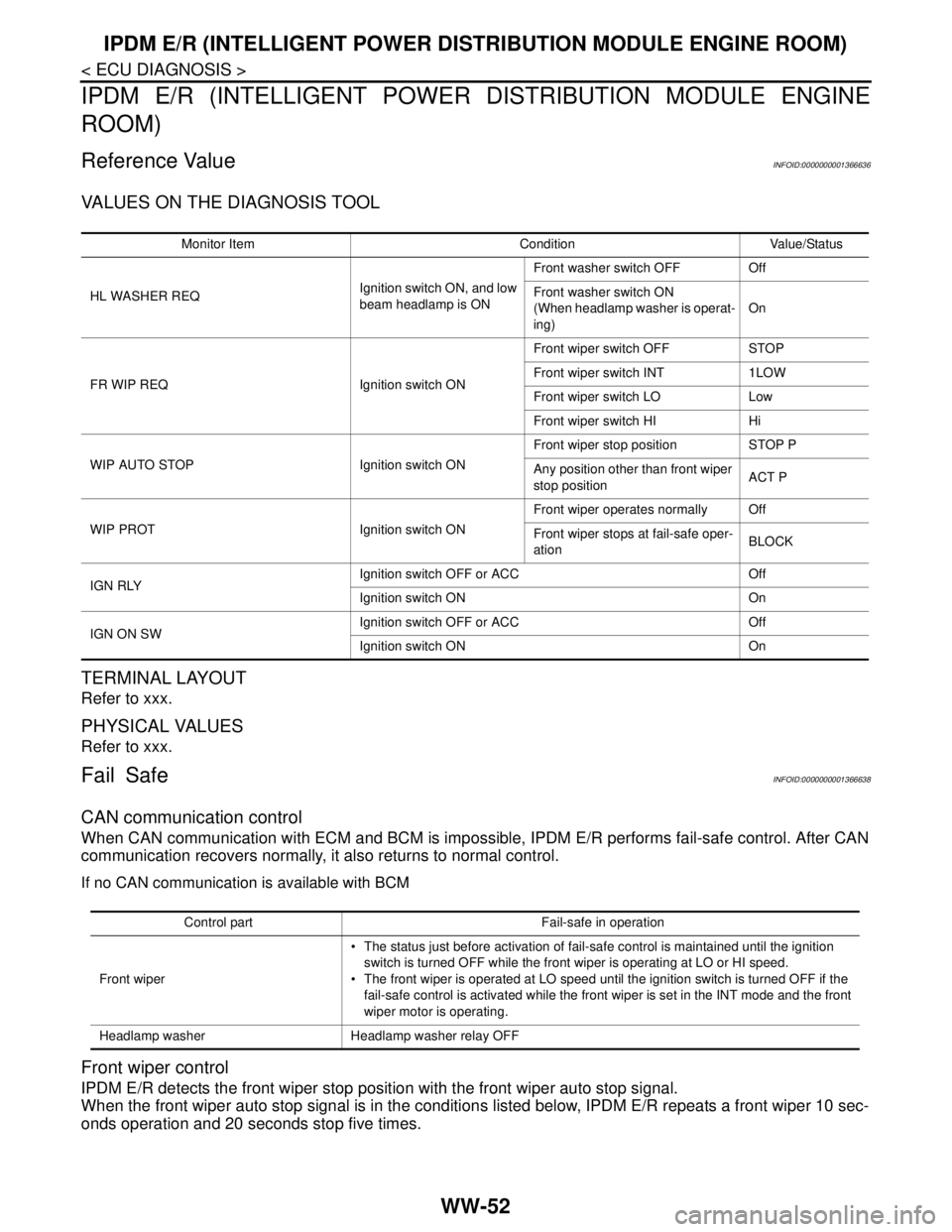

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000001366636

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

Refer to xxx.

PHYSICAL VALUES

Refer to xxx.

Fail SafeINFOID:0000000001366638

CAN communication control

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If no CAN communication is available with BCM

Front wiper control

IPDM E/R detects the front wiper stop position with the front wiper auto stop signal.

When the front wiper auto stop signal is in the conditions listed below, IPDM E/R repeats a front wiper 10 sec-

onds operation and 20 seconds stop five times.

Monitor Item Condition Value/Status

HL WASHER REQIgnition switch ON, and low

beam headlamp is ONFront washer switch OFF Off

Front washer switch ON

(When headlamp washer is operat-

ing)On

FR WIP REQ Ignition switch ONFront wiper switch OFF STOP

Front wiper switch INT 1LOW

Front wiper switch LO Low

Front wiper switch HI Hi

WIP AUTO STOP Ignition switch ONFront wiper stop position STOP P

Any position other than front wiper

stop positionACT P

WIP PROT Ignition switch ONFront wiper operates normally Off

Front wiper stops at fail-safe oper-

ationBLOCK

IGN RLYIgnition switch OFF or ACC Off

Ignition switch ON On

IGN ON SWIgnition switch OFF or ACC Off

Ignition switch ON On

Control part Fail-safe in operation

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The front wiper is operated at LO speed until the ignition switch is turned OFF if the

fail-safe control is activated while the front wiper is set in the INT mode and the front

wiper motor is operating.

Headlamp washer Headlamp washer relay OFF

Page 5855 of 5883

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

WW-53

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

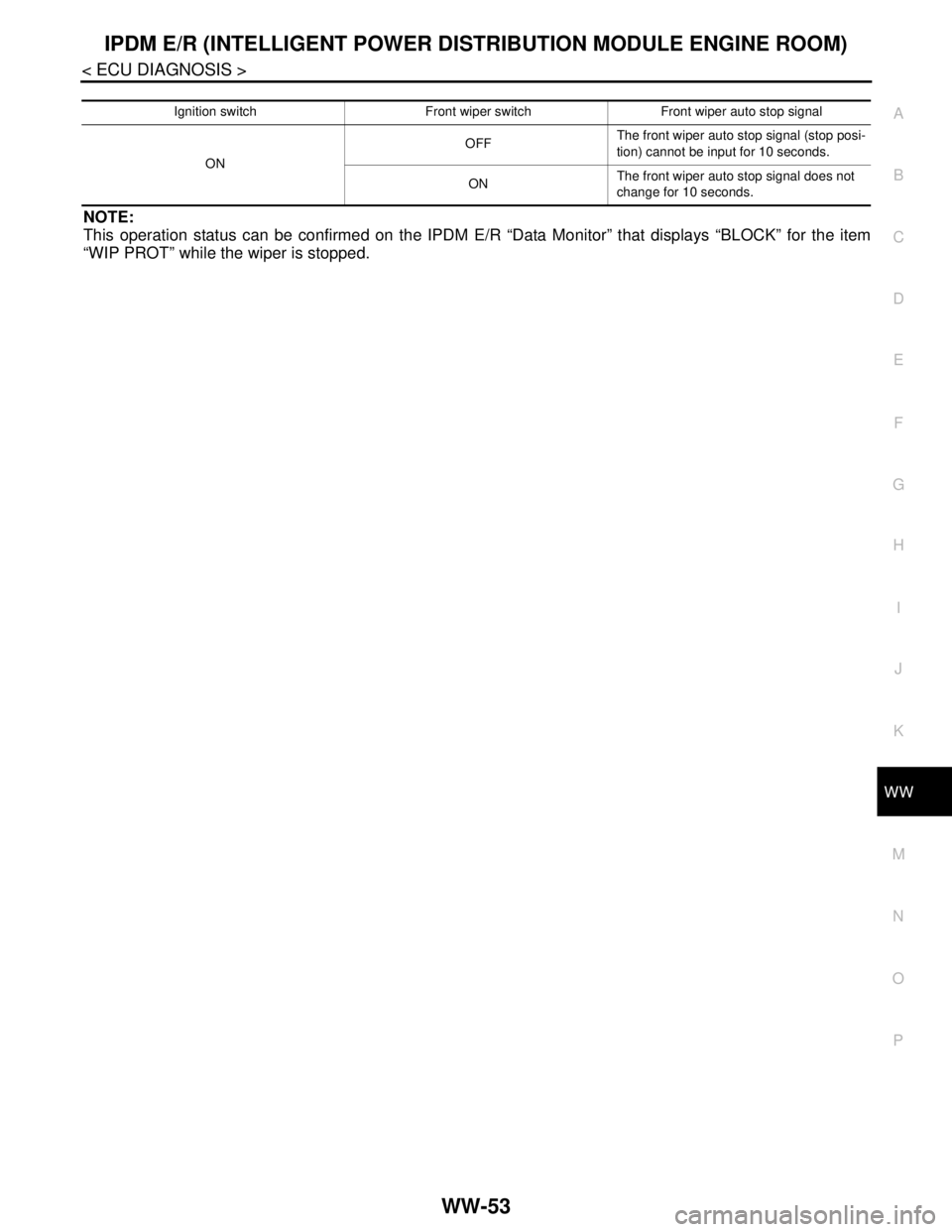

NOTE:

This operation status can be confirmed on the IPDM E/R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

Ignition switch Front wiper switch Front wiper auto stop signal

ONOFFThe front wiper auto stop signal (stop posi-

tion) cannot be input for 10 seconds.

ONThe front wiper auto stop signal does not

change for 10 seconds.

Page 5858 of 5883

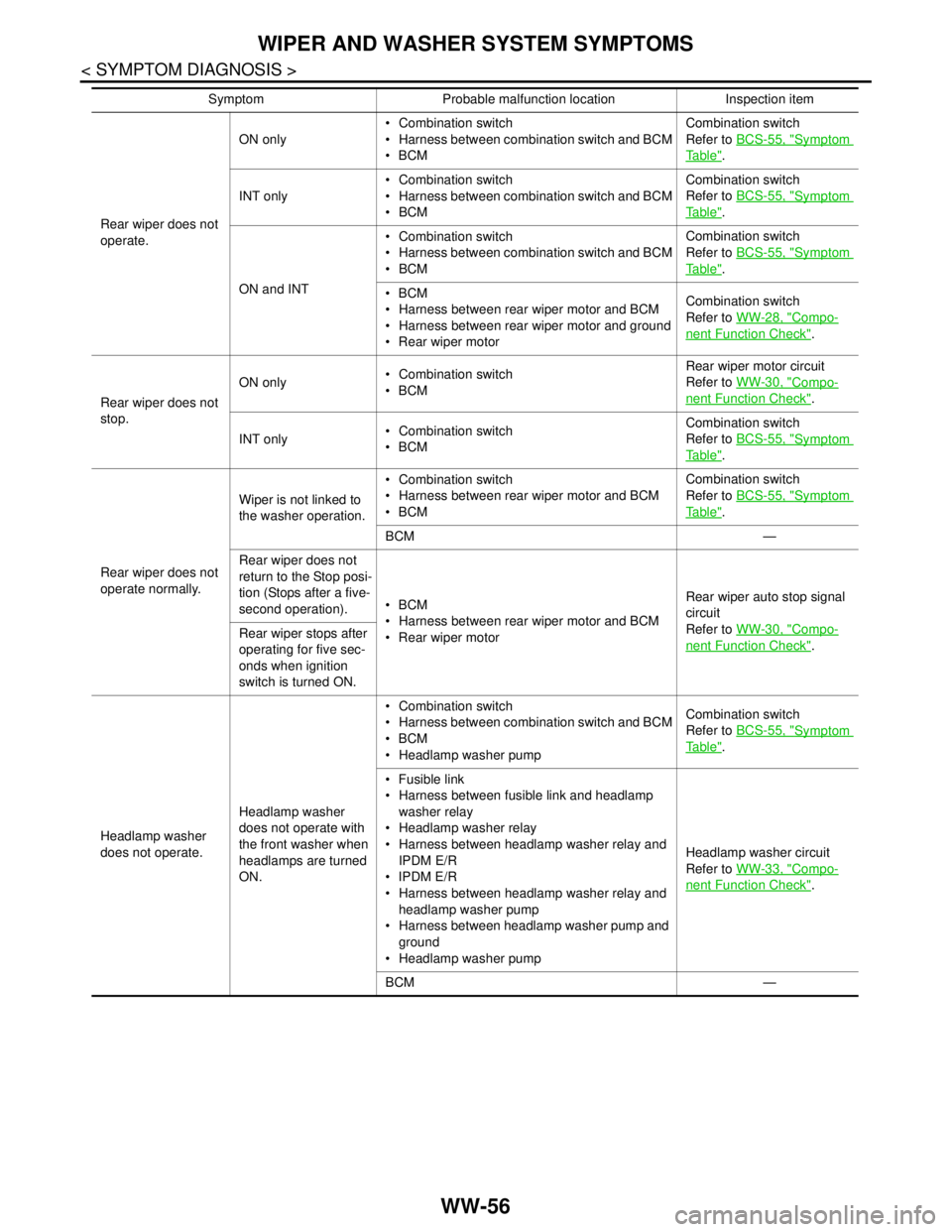

WW-56

< SYMPTOM DIAGNOSIS >

WIPER AND WASHER SYSTEM SYMPTOMS

Rear wiper does not

operate.ON only Combination switch

Harness between combination switch and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

INT only Combination switch

Harness between combination switch and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

ON and INT Combination switch

Harness between combination switch and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

BCM

Harness between rear wiper motor and BCM

Harness between rear wiper motor and ground

Rear wiper motorCombination switch

Refer to WW-28, "

Compo-

nent Function Check".

Rear wiper does not

stop.ON only Combination switch

BCMRear wiper motor circuit

Refer to WW-30, "

Compo-

nent Function Check".

INT only Combination switch

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

Rear wiper does not

operate normally.Wiper is not linked to

the washer operation. Combination switch

Harness between rear wiper motor and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

BCM —

Rear wiper does not

return to the Stop posi-

tion (Stops after a five-

second operation).BCM

Harness between rear wiper motor and BCM

Rear wiper motorRear wiper auto stop signal

circuit

Refer to WW-30, "

Compo-

nent Function Check". Rear wiper stops after

operating for five sec-

onds when ignition

switch is turned ON.

Headlamp washer

does not operate.Headlamp washer

does not operate with

the front washer when

headlamps are turned

ON. Combination switch

Harness between combination switch and BCM

BCM

Headlamp washer pumpCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

Fusible link

Harness between fusible link and headlamp

washer relay

Headlamp washer relay

Harness between headlamp washer relay and

IPDM E/R

IPDM E/R

Harness between headlamp washer relay and

headlamp washer pump

Harness between headlamp washer pump and

ground

Headlamp washer pumpHeadlamp washer circuit

Refer to WW-33, "

Compo-

nent Function Check".

BCM — Symptom Probable malfunction location Inspection item

Page 5860 of 5883

WW-58

< SYMPTOM DIAGNOSIS >

FRONT WIPER DOES NOT OPERATE

FRONT WIPER DOES NOT OPERATE

DescriptionINFOID:0000000001366642

The front wiper does not operate under any operation conditions.

Diagnosis ProcedureINFOID:0000000001366643

1. CHECK WIPER RELAY OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-10, "

Diagnosis Description".

2. Check that the front wiper operates at the LO/HI operation.

CONSULT-III ACTIVE TEST

1. Select "FRONT WIPER" of IPDM E/R active test item.

2. While operating the test item, check front wiper operation.

Is front wiper operation normal?

YES >> GO TO 5

NO >> GO TO 2

2. CHECK FRONT WIPER MOTOR FUSE

1. Turn the ignition switch OFF.

2. Check that the following fuse is not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 3

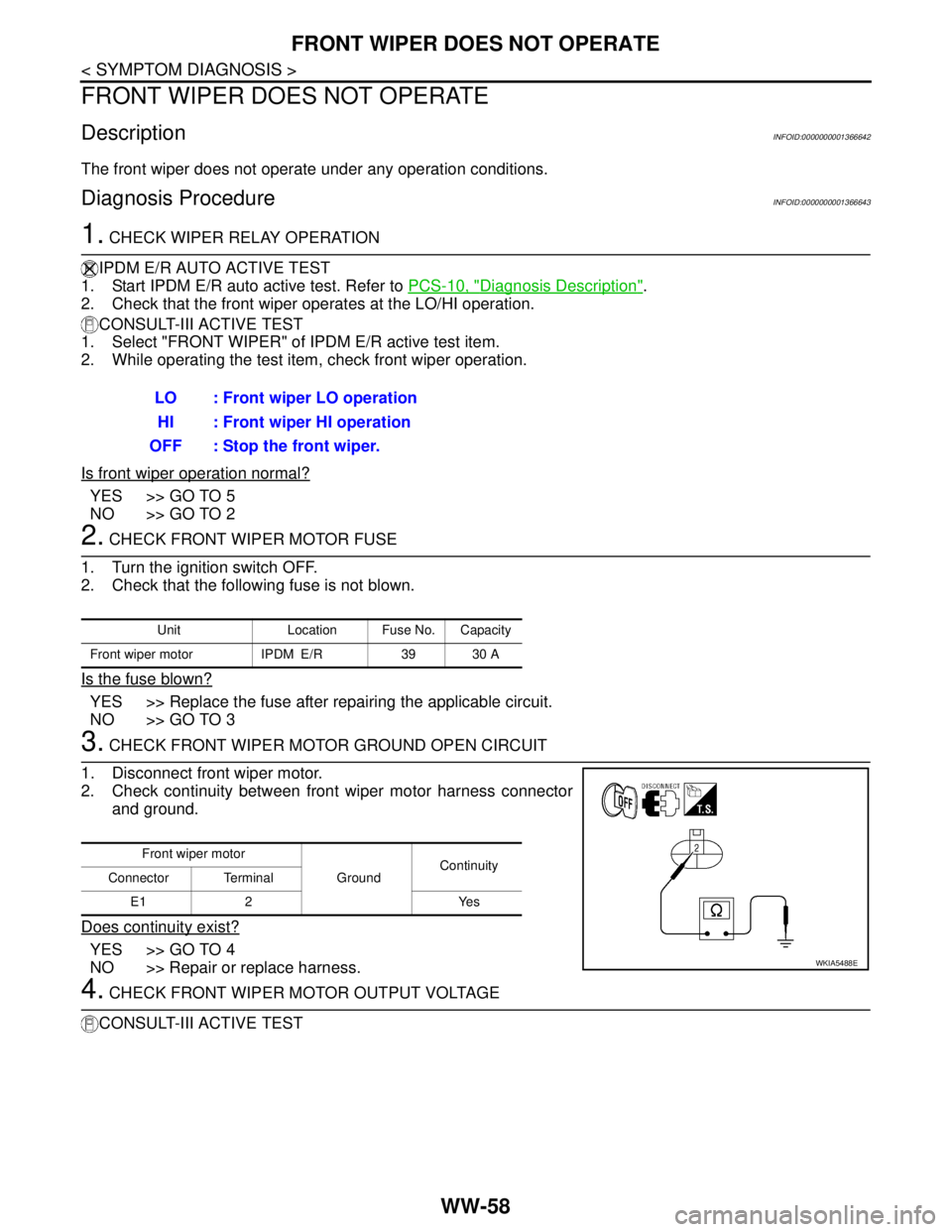

3. CHECK FRONT WIPER MOTOR GROUND OPEN CIRCUIT

1. Disconnect front wiper motor.

2. Check continuity between front wiper motor harness connector

and ground.

Does continuity exist?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK FRONT WIPER MOTOR OUTPUT VOLTAGE

CONSULT-III ACTIVE TESTLO : Front wiper LO operation

HI : Front wiper HI operation

OFF : Stop the front wiper.

Unit Location Fuse No. Capacity

Front wiper motor IPDM E/R 39 30 A

Front wiper motor

GroundContinuity

Connector Terminal

E1 2 Yes

WKIA5488E

Page 5861 of 5883

FRONT WIPER DOES NOT OPERATE

WW-59

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

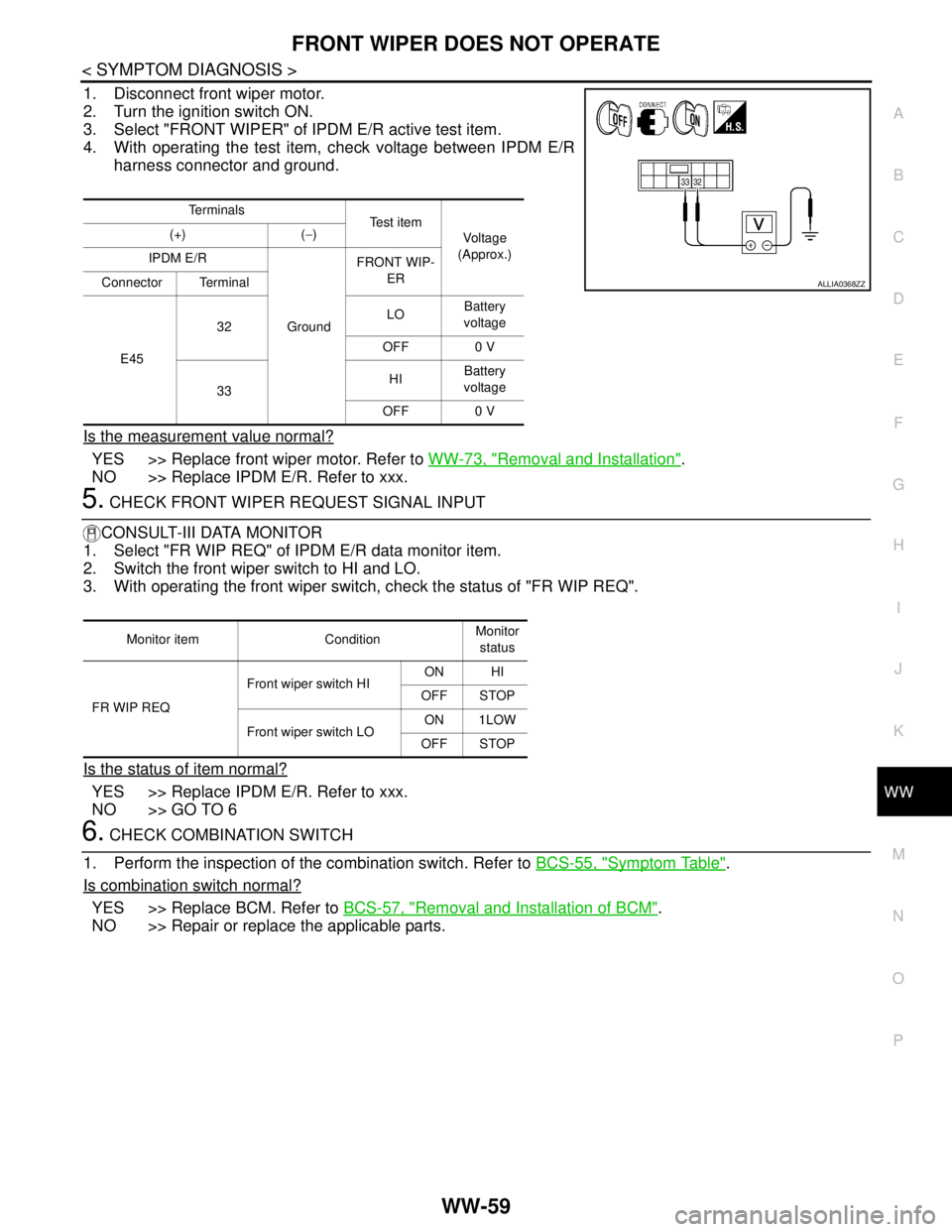

1. Disconnect front wiper motor.

2. Turn the ignition switch ON.

3. Select "FRONT WIPER" of IPDM E/R active test item.

4. With operating the test item, check voltage between IPDM E/R

harness connector and ground.

Is the measurement value normal?

YES >> Replace front wiper motor. Refer to WW-73, "Removal and Installation".

NO >> Replace IPDM E/R. Refer to xxx.

5. CHECK FRONT WIPER REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "FR WIP REQ" of IPDM E/R data monitor item.

2. Switch the front wiper switch to HI and LO.

3. With operating the front wiper switch, check the status of "FR WIP REQ".

Is the status of item normal?

YES >> Replace IPDM E/R. Refer to xxx.

NO >> GO TO 6

6. CHECK COMBINATION SWITCH

1. Perform the inspection of the combination switch. Refer to BCS-55, "

Symptom Table".

Is combination switch normal?

YES >> Replace BCM. Refer to BCS-57, "Removal and Installation of BCM".

NO >> Repair or replace the applicable parts.

Te r m i n a l s

Te s t i t e m

Voltage

(Approx.) (+) (−)

IPDM E/R

GroundFRONT WIP-

ER

Connector Terminal

E4532LOBattery

voltage

OFF 0 V

33HIBattery

voltage

OFF 0 V

ALLIA0368ZZ

Monitor item ConditionMonitor

status

FR WIP REQFront wiper switch HION HI

OFF STOP

Front wiper switch LOON 1LOW

OFF STOP