ECO mode NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 5698 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/C UNIT ASSEMBLY

VTL-37

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696531

NOTE:

A LHD model shown, RHD m NISSAN TIIDA 2007 Service Repair Manual A/C UNIT ASSEMBLY

VTL-37

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696531

NOTE:

A LHD model shown, RHD m](/img/5/57395/w960_57395-5697.png)

A/C UNIT ASSEMBLY

VTL-37

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696531

NOTE:

A LHD model shown, RHD model similar.

REMOVAL

1. Use a recovery/recycling equipment (for HFC-134a) to discharge refrigerant. Refer to HA-29, "HFC-134a

(R-134a) Service Procedure".

2. Drain coolant from cooling system. Refer to CO-11, "

Changing Engine Coolant" (HR16DE), CO-35,

"Changing Engine Coolant" (MR18DE), CO-58, "Draining" (K9K).

3. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

4. Remove lower dash insulator.

5. Remove bolt (A), and then disconnect low-pressure flexible

hose (1) and high-pressure pipe (2) from evaporator.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

6. Remove clamps (A), and then disconnect heater hoses (1) from

heater core.

A. A/C unit assembly bolts B. Steering member bolts C. Steering column nuts

SJIA0648E

SJIA0644E

SJIA0645E

Page 5724 of 5883

WCS

WARNING CHIME SYSTEM

WCS-9

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

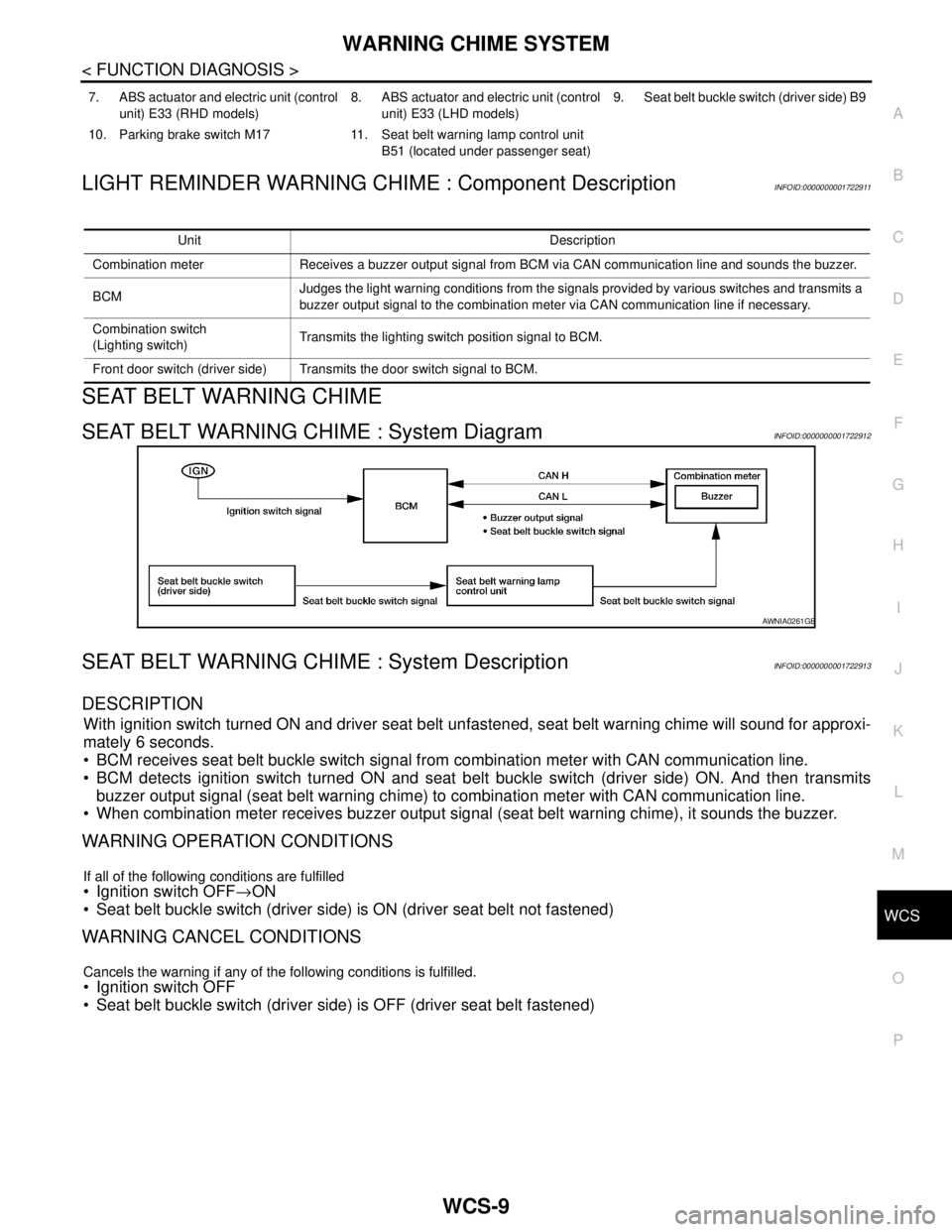

LIGHT REMINDER WARNING CHIME : Component DescriptionINFOID:0000000001722911

SEAT BELT WARNING CHIME

SEAT BELT WARNING CHIME : System DiagramINFOID:0000000001722912

SEAT BELT WARNING CHIME : System DescriptionINFOID:0000000001722913

DESCRIPTION

With ignition switch turned ON and driver seat belt unfastened, seat belt warning chime will sound for approxi-

mately 6 seconds.

BCM receives seat belt buckle switch signal from combination meter with CAN communication line.

BCM detects ignition switch turned ON and seat belt buckle switch (driver side) ON. And then transmits

buzzer output signal (seat belt warning chime) to combination meter with CAN communication line.

When combination meter receives buzzer output signal (seat belt warning chime), it sounds the buzzer.

WARNING OPERATION CONDITIONS

If all of the following conditions are fulfilled

Ignition switch OFF→ON

Seat belt buckle switch (driver side) is ON (driver seat belt not fastened)

WARNING CANCEL CONDITIONS

Cancels the warning if any of the following conditions is fulfilled.

Ignition switch OFF

Seat belt buckle switch (driver side) is OFF (driver seat belt fastened)

7. ABS actuator and electric unit (control

unit) E33 (RHD models)8. ABS actuator and electric unit (control

unit) E33 (LHD models)9. Seat belt buckle switch (driver side) B9

10. Parking brake switch M17 11. Seat belt warning lamp control unit

B51 (located under passenger seat)

Unit Description

Combination meter Receives a buzzer output signal from BCM via CAN communication line and sounds the buzzer.

BCMJudges the light warning conditions from the signals provided by various switches and transmits a

buzzer output signal to the combination meter via CAN communication line if necessary.

Combination switch

(Lighting switch)Transmits the lighting switch position signal to BCM.

Front door switch (driver side) Transmits the door switch signal to BCM.

AWNIA0261GB

Page 5770 of 5883

WCS

COMBINATION METER

WCS-55

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

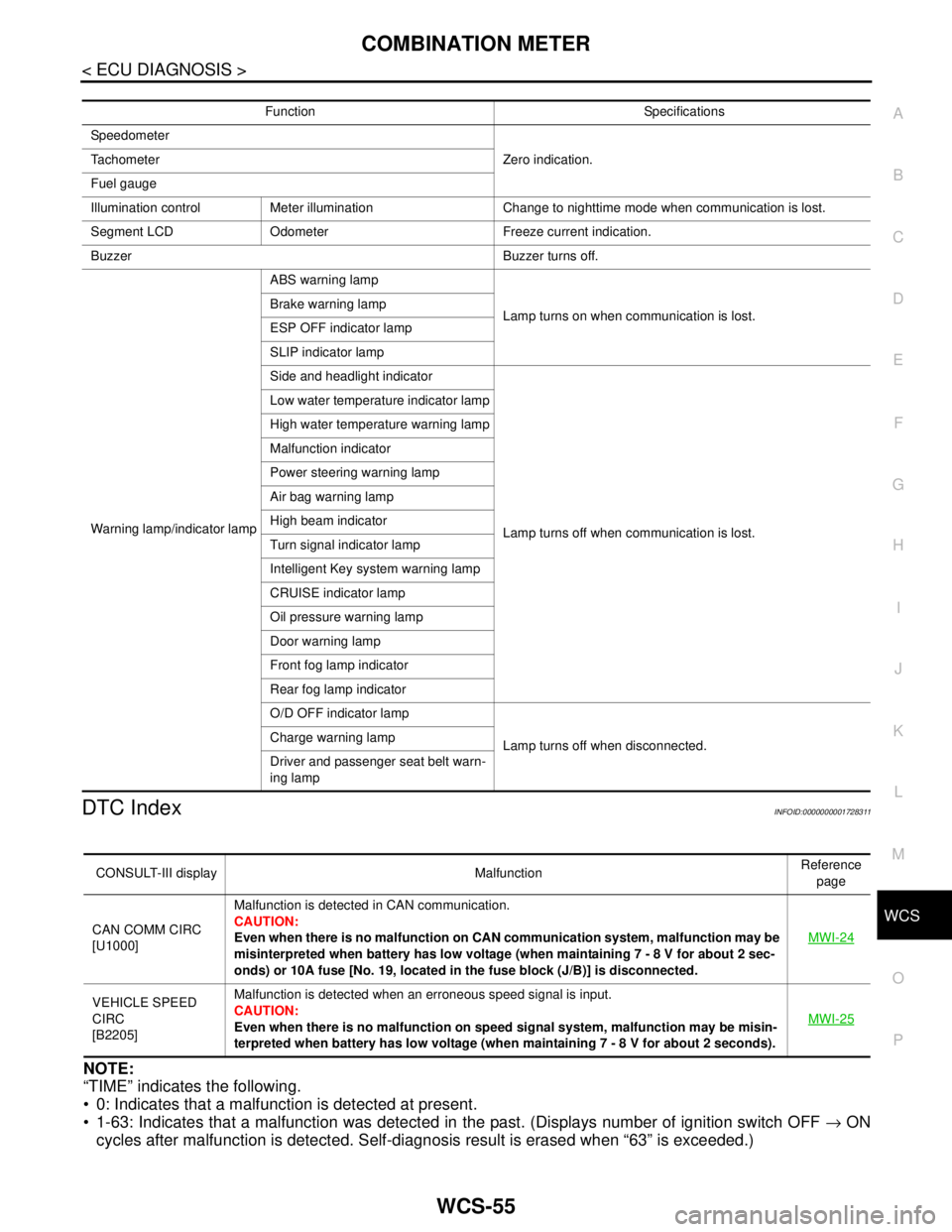

DTC IndexINFOID:0000000001728311

NOTE:

“TIME” indicates the following.

0: Indicates that a malfunction is detected at present.

1-63: Indicates that a malfunction was detected in the past. (Displays number of ignition switch OFF → ON

cycles after malfunction is detected. Self-diagnosis result is erased when “63” is exceeded.)

Function Specifications

Speedometer

Zero indication. Tachometer

Fuel gauge

Illumination control Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer Freeze current indication.

Buzzer Buzzer turns off.

Warning lamp/indicator lampABS warning lamp

Lamp turns on when communication is lost. Brake warning lamp

ESP OFF indicator lamp

SLIP indicator lamp

Side and headlight indicator

Lamp turns off when communication is lost. Low water temperature indicator lamp

High water temperature warning lamp

Malfunction indicator

Power steering warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

Intelligent Key system warning lamp

CRUISE indicator lamp

Oil pressure warning lamp

Door warning lamp

Front fog lamp indicator

Rear fog lamp indicator

O/D OFF indicator lamp

Lamp turns off when disconnected. Charge warning lamp

Driver and passenger seat belt warn-

ing lamp

CONSULT-III display MalfunctionReference

page

CAN COMM CIRC

[U1000]Malfunction is detected in CAN communication.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltage (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 19, located in the fuse block (J/B)] is disconnected.MWI-24

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has low voltage (when maintaining 7 - 8 V for about 2 seconds). MWI-25

Page 5818 of 5883

WW-16

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000001366606

AUTO ACTIVE TEST

Refer to PCS IPDM E/R AUTO ACTIVE TEST.

CONSULT - III Function (IPDM E/R)INFOID:0000000001366607

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC

Refer to PCS-28, "DTCIndex".

DATA MONITOR

Monitor item

ACTIVE TEST

Te s t i t e m

Diagnosis mode Description

ECU Identification Allows confirmation of IPDM E/R part number.

Self Diagnostic Result Displays the diagnosis results judged by IPDM E/R.

Data Monitor Displays the real-time input/output data from IPDM E/R input/output data.

Active Test IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item

[Unit]MAIN

SIGNALSDescription

HL WASHER REQ

[Off/On]Displays the status of the headlamp washer request signal received from BCM via CAN

communication.

FR WIP REQ

[Stop/1LOW/Low/Hi]×Displays the status of the front wiper request signal received from BCM via CAN com-

munication.

WIP AUTO STOP

[STOP P/ACT P]×Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK]×Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

IGN RLY

[Off/On]×Displays the status of the ignition relay judged by IPDM E/R.

IGN ON SW

[Off/On]Displays the status of the ignition switch judged by IPDM E/R.

Test item Operation Description

FRONT WIPEROff OFF

Lo Operates the front wiper relay.

Hi Operates the front wiper relay and front wiper high relay.

HEAD LAMP WASHER On Operates the headlamp washer relay for 1 second.

EXTERNAL LAMPSOff OFF

TAIL Operates the tail lamp relay.

Lo Operates the headlamp low relay.

HiOperates the headlamp low relay and ON/OFF the headlamp high relay at 1 sec-

ond intervals.

Fog Operates the front fog lamp relay.

Page 5854 of 5883

WW-52

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

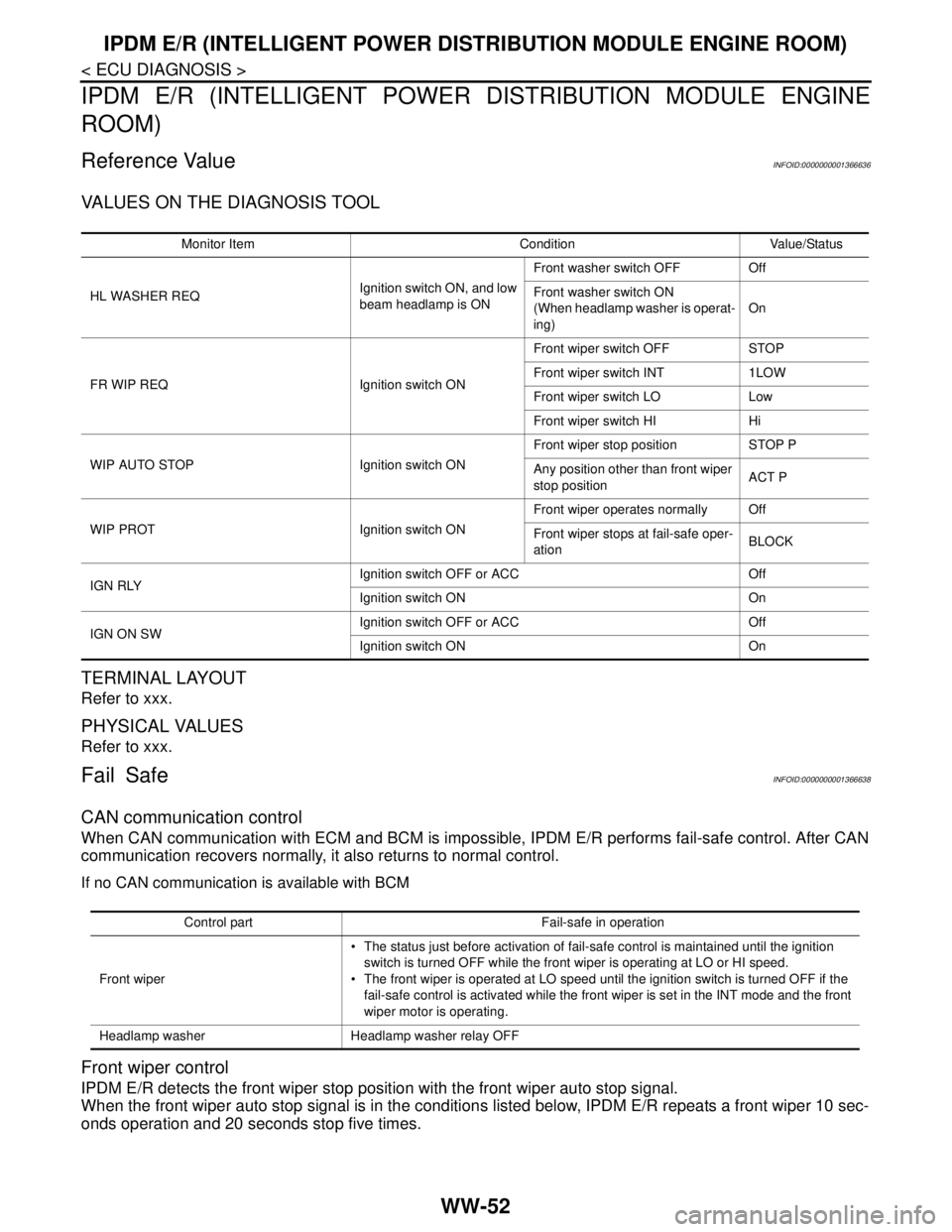

Reference ValueINFOID:0000000001366636

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

Refer to xxx.

PHYSICAL VALUES

Refer to xxx.

Fail SafeINFOID:0000000001366638

CAN communication control

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If no CAN communication is available with BCM

Front wiper control

IPDM E/R detects the front wiper stop position with the front wiper auto stop signal.

When the front wiper auto stop signal is in the conditions listed below, IPDM E/R repeats a front wiper 10 sec-

onds operation and 20 seconds stop five times.

Monitor Item Condition Value/Status

HL WASHER REQIgnition switch ON, and low

beam headlamp is ONFront washer switch OFF Off

Front washer switch ON

(When headlamp washer is operat-

ing)On

FR WIP REQ Ignition switch ONFront wiper switch OFF STOP

Front wiper switch INT 1LOW

Front wiper switch LO Low

Front wiper switch HI Hi

WIP AUTO STOP Ignition switch ONFront wiper stop position STOP P

Any position other than front wiper

stop positionACT P

WIP PROT Ignition switch ONFront wiper operates normally Off

Front wiper stops at fail-safe oper-

ationBLOCK

IGN RLYIgnition switch OFF or ACC Off

Ignition switch ON On

IGN ON SWIgnition switch OFF or ACC Off

Ignition switch ON On

Control part Fail-safe in operation

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The front wiper is operated at LO speed until the ignition switch is turned OFF if the

fail-safe control is activated while the front wiper is set in the INT mode and the front

wiper motor is operating.

Headlamp washer Headlamp washer relay OFF