horn NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 1 of 5883

MODEL C11 SERIES

2007 NISSAN EUROPE S.A.S.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form,

or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Europe

S.A.S., Paris, France.

A GENERAL INFORMATION

B ENGINE

D TRANSMISSION& DRIVELINE

E SUSPENSION F BRAKES

G STEERING H RESTRAINTS

I VENTILATION, HEATER & AIR CONDITIONER

J BODY INTERIOR

K BODY EXTERIOR, DOOR, ROOF & VEHICLE SECURITY

L DRIVER CONTROLS

M ELECTRICAL & POWER CONTROL

N DRIVER INFORMATION & MULTIMEDIA

O CRUISE CONTROL P MAINTENANCEGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

STR Starting System

ACC Accelerator Control System

CL Clutch

TM Transaxle & Transmission

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

ST Steering System

STC Steering Control System

SB Seat Belt

SR SRS Airbag

SRC SRS Airbag Control System

VTL Ventilation System

HA Heater & Air Conditioning System

HAC Heater & Air Conditioning Control System

INT Interior

IP Instrument Panel

SE Seat

DLK Door & Lock

SEC Security Control System

GW Glass & Window System

PWC Power Window Control System

RF Roof

EXT Exterior

MIR Mirrors

EXL Exterior Lighting System

INL Interior Lighting System

WW Wiper & Washer

DEF Defogger

HRN Horn

PWO Power Outlet

BCS Body Control System

LAN LAN System

PCS Power Control System

CHG Charging System

PG Power Supply, Ground & Circuit Elements

MWI Meter, Warning Lanp & Indicator

WCS Warning Chime System

AV Audio, Visual & Navigation System

CCS Cruise Control System Maintenance

MA Maintenance

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM7E00-1C11E0E

Page 495 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001534602

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edg NISSAN TIIDA 2007 Service Repair Manual CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001534602

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edg](/img/5/57395/w960_57395-494.png)

CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001534602

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

Pull negative-pressure valve to open it, and make sure that it is

completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and

closing conditions.

Check radiator cap relief pressure using suitable tool.

- When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative-

pressure valve, or if the open-valve pressure is outside of the stan-

dard values.

Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking RadiatorINFOID:0000000001534603

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

PBIC2816E

SMA967B

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Page 519 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CO-38

< ON-VEHICLE MAINTENANCE >[MR18DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001337842

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edg NISSAN TIIDA 2007 Service Repair Manual CO-38

< ON-VEHICLE MAINTENANCE >[MR18DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001337842

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edg](/img/5/57395/w960_57395-518.png)

CO-38

< ON-VEHICLE MAINTENANCE >[MR18DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001337842

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

Pull negative-pressure valve to open it, and make sure that it is

completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and

closing conditions.

Check radiator cap relief pressure using suitable tool.

- When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative-

pressure valve, or if the open-valve pressure is outside of the stan-

dard values.

Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking RadiatorINFOID:0000000001337843

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

PBIC2816E

SMA967B

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Page 541 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CO-60

< ON-VEHICLE MAINTENANCE >[K9K]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001538671

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge o NISSAN TIIDA 2007 Service Repair Manual CO-60

< ON-VEHICLE MAINTENANCE >[K9K]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001538671

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge o](/img/5/57395/w960_57395-540.png)

CO-60

< ON-VEHICLE MAINTENANCE >[K9K]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000001538671

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

Pull negative-pressure valve to open it, and make sure that it is

completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and

closing conditions.

Check radiator cap relief pressure using suitable tool.

- When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative-

pressure valve, or if the open-valve pressure is outside of the stan-

dard values.

Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking RadiatorINFOID:0000000001538672

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

PBIC2816E

SMA967B

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Page 544 of 5883

![NISSAN TIIDA 2007 Service Repair Manual RADIATOR

CO-63

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

6. Disconnect radiator upper hose, reservoir tank hose and mounting bracket.

7. Disconnect radiator fan motor harness connecto NISSAN TIIDA 2007 Service Repair Manual RADIATOR

CO-63

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

6. Disconnect radiator upper hose, reservoir tank hose and mounting bracket.

7. Disconnect radiator fan motor harness connecto](/img/5/57395/w960_57395-543.png)

RADIATOR

CO-63

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

6. Disconnect radiator upper hose, reservoir tank hose and mounting bracket.

7. Disconnect radiator fan motor harness connectors.

8. Remove radiator core support cover.

9. Remove hood latch.

10. Disconnect horn and ambient temperature sensor harness connectors.

11. Remove radiator core support (upper).

12. Remove cooling fan and shroud assembly.

13. Release charge air cooler from the radiator. Refer to EM-270, "

Exploded View".

14. Remove A/C condenser to radiator bolts.

15. Remove radiator.

CAUTION:

Do not damage or scratch radiator core when removing.

INSTALLATION

Installation is in the reverse order of removal.

Check for engine coolant leaks. Refer to CO-58, "

Inspection".

InspectionINFOID:0000000001381593

INSPECTION AFTER INSTALLATION

Check for engine coolant leaks using rsuitable tools. Refer to CO-58, "Inspection".

Page 3648 of 5883

HRN-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION HRN

A

B

HRN

N

O

P

CONTENTS

HORN

PRECAUTION ...............................................2

PRECAUTION .....................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

COMPONENT DIAGNOSIS ..........................3

HORN .................................................................3

Wiring Diagram .........................................................3

ON-VEHICLE REPAIR ..................................4

HORN .................................................................4

Removal and Installation ..........................................4

Page 3650 of 5883

HORN

HRN-3

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

HRN

N

O

P

COMPONENT DIAGNOSIS

HORN

Wiring DiagramINFOID:0000000001702207

AWMWA0025GB

Page 3651 of 5883

HRN-4

< ON-VEHICLE REPAIR >

HORN

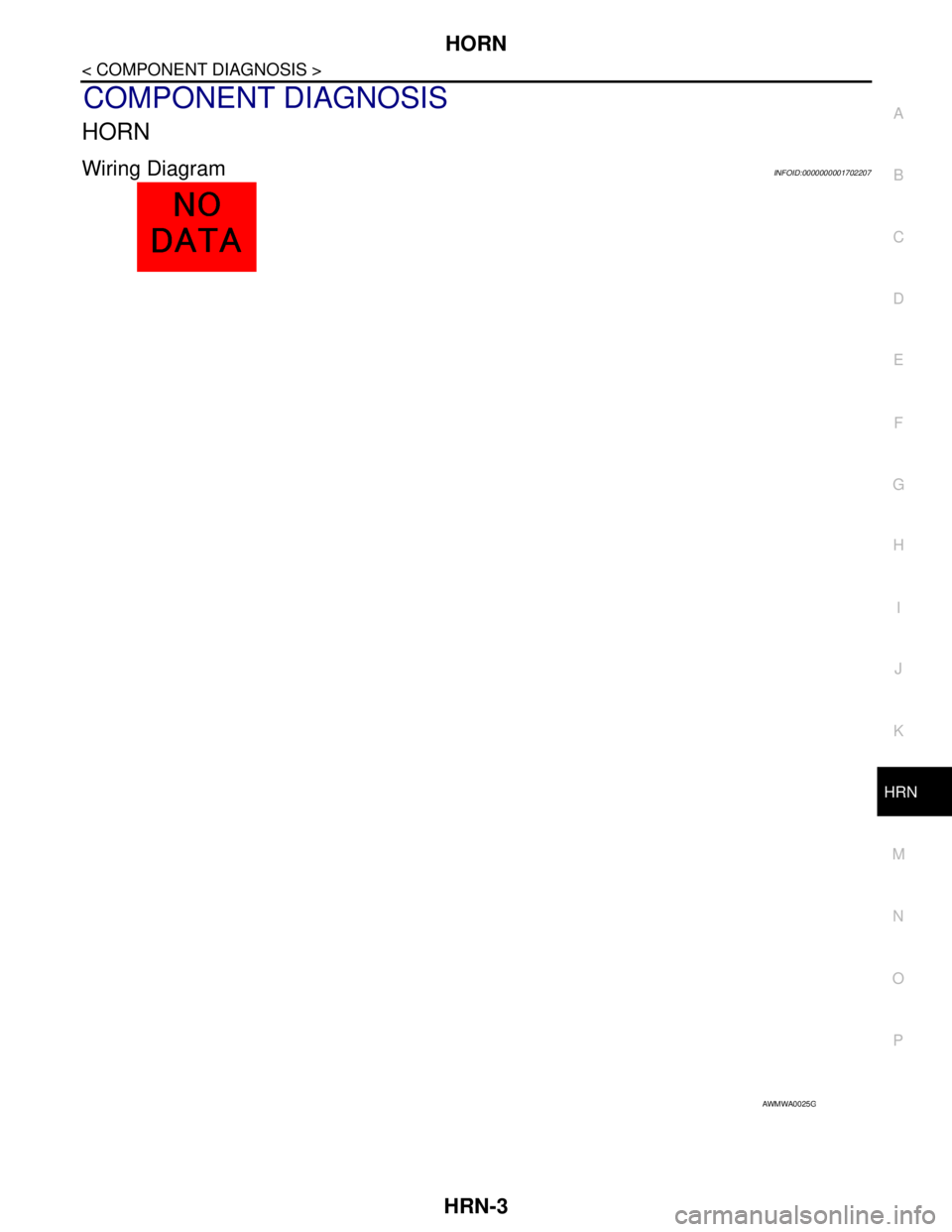

ON-VEHICLE REPAIR

HORN

Removal and InstallationINFOID:0000000001728320

REMOVAL

NOTE:

Front grille, front bumper fascia and front bumper shown removed for clarity.

1. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

2. Disconnect the horn connectors (A).

3. Remove the horn nuts (B), then remove the horns (1) and (2).

INSTALLATION

Installation is in the reverse order of removal.

ALLIA0657ZZ

Page 4265 of 5883

ENGINE MAINTENANCE (HR16DE)

MA-25

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

11. Refill reservoir tank to “MAX” level line with engine coolant.

12. Repeat steps 6 through 11 two or more times with radiator cap installed until engine coolant level no

longer drops.

13. Check cooling system for leaks with engine running.

14. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

15. Repeat step 14 three times.

16. If sound is heard, bleed air from cooling system by repeating steps 6 through 11 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed.

2. Install radiator drain plug.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-100, "

Exploded

View".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-16, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system. Refer to CO-11, "

Changing Engine Coolant".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

RADIATOR

RADIATOR : Checking RadiatorINFOID:0000000001730858

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

FUEL LINES

FUEL LINES : InspectionINFOID:0000000001277610

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

SMA803A

Page 4274 of 5883

MA-34

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (MR18DE)

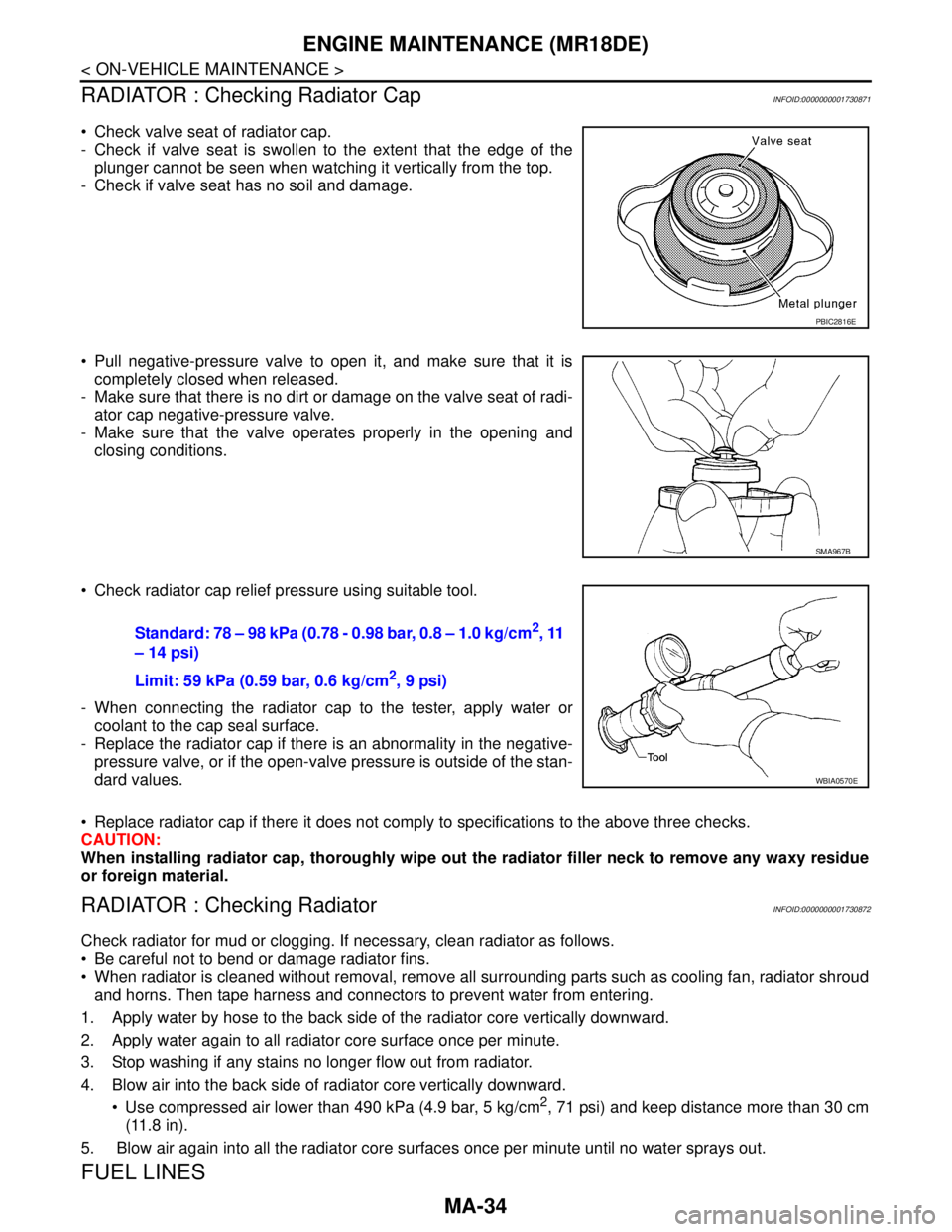

RADIATOR : Checking Radiator Cap

INFOID:0000000001730871

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

Pull negative-pressure valve to open it, and make sure that it is

completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and

closing conditions.

Check radiator cap relief pressure using suitable tool.

- When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative-

pressure valve, or if the open-valve pressure is outside of the stan-

dard values.

Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

RADIATOR : Checking RadiatorINFOID:0000000001730872

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

FUEL LINES

PBIC2816E

SMA967B

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E