coolant NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4382 of 5883

MWI

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-75

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

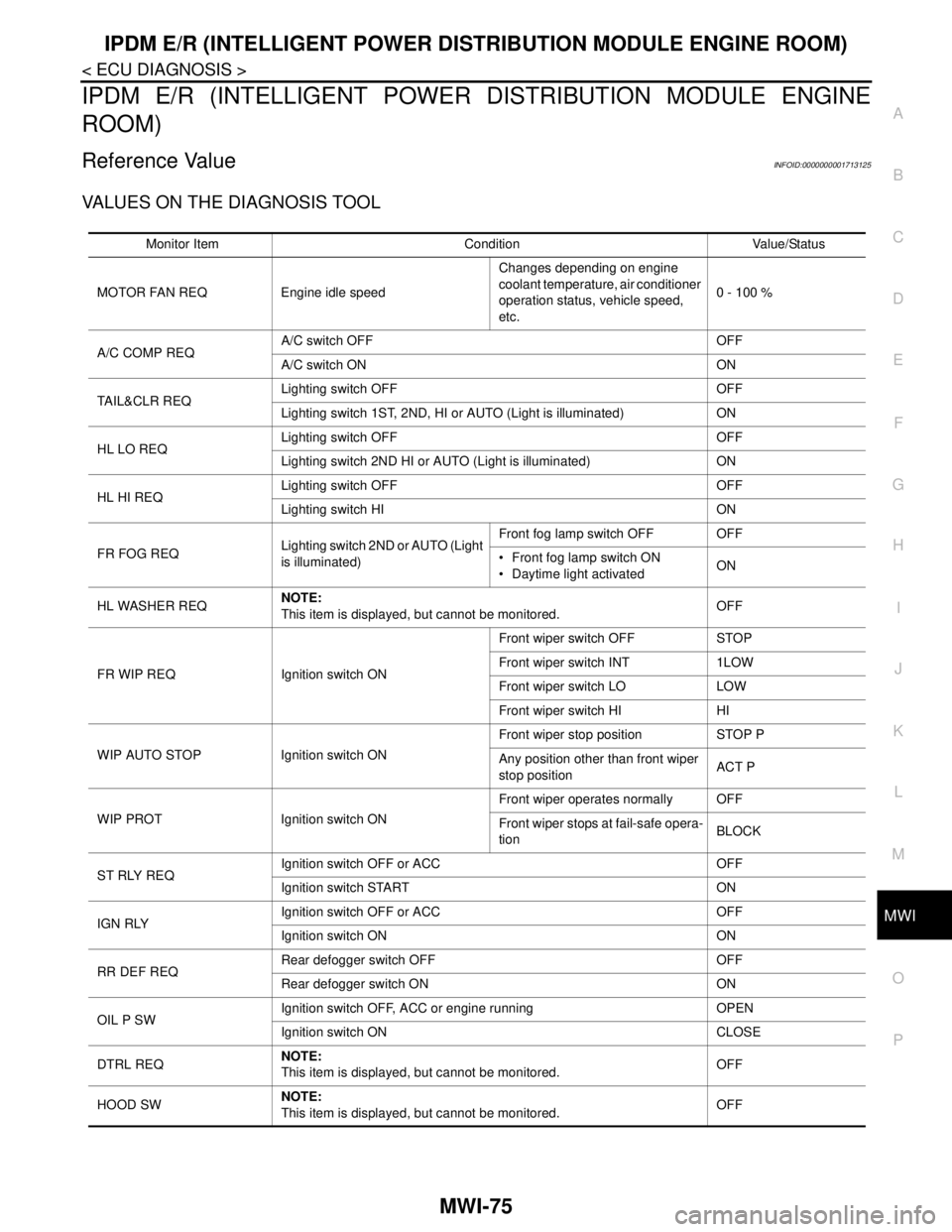

Reference ValueINFOID:0000000001713125

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

MOTOR FAN REQ Engine idle speedChanges depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQA/C switch OFF OFF

A/C switch ON ON

TA I L & C L R R E QLighting switch OFF OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQLighting switch OFF OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQLighting switch OFF OFF

Lighting switch HI ON

FR FOG REQLighting switch 2ND or AUTO (Light

is illuminated)Front fog lamp switch OFF OFF

Front fog lamp switch ON

Daytime light activated ON

HL WASHER REQNOTE:

This item is displayed, but cannot be monitored.OFF

FR WIP REQ Ignition switch ONFront wiper switch OFF STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ONFront wiper stop position STOP P

Any position other than front wiper

stop positionACT P

WIP PROT Ignition switch ONFront wiper operates normally OFF

Front wiper stops at fail-safe opera-

tionBLOCK

ST RLY REQIgnition switch OFF or ACC OFF

Ignition switch START ON

IGN RLYIgnition switch OFF or ACC OFF

Ignition switch ON ON

RR DEF REQRear defogger switch OFF OFF

Rear defogger switch ON ON

OIL P SWIgnition switch OFF, ACC or engine running OPEN

Ignition switch ON CLOSE

DTRL REQNOTE:

This item is displayed, but cannot be monitored.OFF

HOOD SWNOTE:

This item is displayed, but cannot be monitored.OFF

Page 4424 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-10

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000001697589

AUTO ACTIVE TEST

Description

In auto active test mode, the NISSAN TIIDA 2007 Service Repair Manual PCS-10

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000001697589

AUTO ACTIVE TEST

Description

In auto active test mode, the](/img/5/57395/w960_57395-4423.png)

PCS-10

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000001697589

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure low/coolant pressure high warning indicator

Oil pressure gauge

Rear window defogger

Front wipers

Tail, license and parking lamps

Front fog lamps

Headlamps (Hi, Lo)

A/C compressor (magnetic clutch)

Cooling fan

Operation Procedure

1. Close the hood and front door RH, and lift the wiper arms from the windshield (to prevent windshield dam-

age due to wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield before hand.

2. Turn ignition switch OFF.

3. Turn the ignition switch ON and, within 20 seconds, press the front door switch LH 10 times. Then turn the

ignition switch OFF.

4. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

• If auto active test mode cannot be actuated, check door switch system. Refer to DLK-65, "

DRIVER

SIDE : Description" (with Intelligent Key system), DLK-499, "DRIVER SIDE : Description" (without

Intelligent Key system).

Do not start the engine.

Inspection in Auto Active Test Mode

Page 4426 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-12

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN c NISSAN TIIDA 2007 Service Repair Manual PCS-12

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN c](/img/5/57395/w960_57395-4425.png)

PCS-12

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

Symptom Inspection contents Possible cause

Oil pressure low warning indicator does not operatePerform auto active test.

Does the oil pressure low/

coolant temperature high

warning indicator operate?YES IPDM E/R signal input cir-

cuit

ECM signal input circuit

CAN communication signal

between ECM and combi-

nation meter

NO CAN communication signal

between IPDM E/R, BCM

and combination meter

Rear window defogger does not operatePerform auto active test.

Does the rear window defog-

ger operate?YES BCM signal input circuit

NO Harness or connector be-

tween A/C and AV switch

assembly and AV control

unit

CAN communication signal

between BCM and IPDM E/

R

Any of the following components do not operate

Front wipers

Tail lamps

License plate lamps

Parking lamps

Front fog lamps

Headlamps (Hi, Lo)Perform auto active test.

Does the applicable system

operate?YES BCM signal input system

NO Lamp or front wiper motor

malfunction

Lamp or front wiper motor

ground circuit

Harness or connector be-

tween IPDM E/R and appli-

cable system

IPDM E/R (integrated relay

malfunction)

A/C compressor does not operatePerform auto active test.

Does the A/C compressor op-

erate?YES BCM signal input circuit

CAN communication signal

between BCM and ECM

CAN communication signal

between ECM and IPDM E/

R

NO Magnetic clutch malfunction

Harness or connector be-

tween IPDM E/R and mag-

netic clutch

IPDM E/R (integrated relay

malfunction)

Cooling fan does not operatePerform auto active test.

Does the cooling fan operate?YES ECM signal input circuit

CAN communication signal

between ECM and IPDM E/

R

NO Cooling fan motor malfunc-

tion

Harness or connector be-

tween IPDM E/R and cool-

ing fan

IPDM E/R (integrated relay

malfunction)

Page 4431 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-17

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

R NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-17

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

R](/img/5/57395/w960_57395-4430.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-17

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000001697595

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

MOTOR FAN REQ Engine idle speedChanges depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQA/C switch OFF OFF

A/C switch ON ON

TA I L & C L R R E QLighting switch OFF OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQLighting switch OFF OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQLighting switch OFF OFF

Lighting switch HI ON

FR FOG REQLighting switch 2ND or AUTO (Light

is illuminated)Front fog lamp switch OFF OFF

Front fog lamp switch ON

Daytime light activated ON

HL WASHER REQNOTE:

This item is displayed, but cannot be monitored.OFF

FR WIP REQ Ignition switch ONFront wiper switch OFF STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ONFront wiper stop position STOP P

Any position other than front wiper

stop positionACT P

WIP PROT Ignition switch ONFront wiper operates normally OFF

Front wiper stops at fail-safe opera-

tionBLOCK

ST RLY REQIgnition switch OFF or ACC OFF

Ignition switch START ON

IGN RLYIgnition switch OFF or ACC OFF

Ignition switch ON ON

RR DEF REQRear defogger switch OFF OFF

Rear defogger switch ON ON

OIL P SWIgnition switch OFF, ACC or engine running OPEN

Ignition switch ON CLOSE

DTRL REQNOTE:

This item is displayed, but cannot be monitored.OFF

HOOD SWNOTE:

This item is displayed, but cannot be monitored.OFF

Page 4530 of 5883

PRECAUTIONS

RAX-3

< PRECAUTION >

C

E

F

G

H

I

J

K

L

MA

B

RAX

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001724594

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PrecautionINFOID:0000000001724595

When installing each rubber part, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

Use flare nut wrench when removing or installing brake tubes.

After installing removed suspension parts, check wheel align-

ment.

Do not jack up at the trailing arm and lateral link.

Always torque brake lines when installing.

SBR686C

Page 4575 of 5883

PRECAUTIONS

RSU-3

< PRECAUTION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001724583

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Rear SuspensionINFOID:0000000001724584

When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

After installing suspension components, check the wheel alignment.

Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Page 4577 of 5883

REAR SUSPENSION ASSEMBLY

RSU-5

< ON-VEHICLE MAINTENANCE >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

ON-VEHICLE MAINTENANCE

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001724575

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are within specifications.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace it if necessary.

Wheel AlignmentINFOID:0000000001724576

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-5, "

Inspection" .

3. Wheel bearing axial end play. Refer to RAX-5, "

On-Vehicle Inspection and Service" .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

This type of alignment is recommended for any NISSAN vehicle.

The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

The alignment machine itself should be capable of accepting any NISSAN vehicle.

The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

Your alignment machine should be regularly calibrated in order to give correct information.

Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-5, "Wheel

Alignment" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

Use the “Jacking Compensation” method. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

See Instructions in the alignment machine you are using for more information.

CAMBER INSPECTION

Page 4584 of 5883

RSU-12

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Alignment (Unladen*)INFOID:0000000001724581

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*)INFOID:0000000001724582

Unit: mm (in)

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Camber

Degree minute (Decimal degree)Minimum – 2° 01′ (– 2.02°)

Nominal – 1° 31′ (– 1.52°)

Maximum – 1° 01′ (– 1.02°)

Total toe-inDistance (A - B)Minimum – 1.0 mm (– 0.039 in)

Nominal 3.0 mm (0.118 in)

Maximum 7.0 mm (0.276 in)

Angle (A - B)

Degree minute

(Decimal degree)Minimum – 0° 5′ (0.08°)

Nominal 0° 13′ (0.22°)

Maximum 0° 31 (0.52)

Tire sizeP195/65R15

Engine model K9K HR16DE, MR18DE

Front (Hf) 689 (27.13) 692 (27.24)

Rear (Hr) 689 (27.13) 689 (27.13)

LEIA0085E

Page 4978 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-32

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001694433

A/T system has two self-diagnostic systems.

Th NISSAN TIIDA 2007 Service Repair Manual TM-32

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001694433

A/T system has two self-diagnostic systems.

Th](/img/5/57395/w960_57395-4977.png)

TM-32

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001694433

A/T system has two self-diagnostic systems.

The first is emission-related on board diagnostic system (OBD) performed by the TCM in combination with the

ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in the ECM

memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the OD OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with OBD self-diagnostic items. For detail,

refer to TM-35, "

CONSULT-III Function (TRANSMISSION)".

OBD Function for A/T SystemINFOID:0000000001694434

The ECM provides emission-related on board diagnostic (OBD) functions for the A/T system. One function is

to receive a signal from the TCM used with OBD-related parts of the A/T system. The signal is sent to the ECM

when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a diagnos-

tic result by means of the MIL (malfunction indicator lamp) on the instrument panel. Sensors, switches and

solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBDINFOID:0000000001694435

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD Diagnostic Trouble Code (DTC)INFOID:0000000001694436

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

1st trip DTC No. is the same as DTC No.

Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-III screen, not on the GST. For

detail, refer to EC-107, "

CONSULT-III Function".

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

Page 5111 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5110.png)

PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001696268

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001696269

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"