engine overheat NISSAN TIIDA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2375 of 5883

![NISSAN TIIDA 2007 Service Owners Guide EC-1026

< SYMPTOM DIAGNOSIS >[MR18DE]

ENGINE CONTROL SYSTEM

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR NISSAN TIIDA 2007 Service Owners Guide EC-1026

< SYMPTOM DIAGNOSIS >[MR18DE]

ENGINE CONTROL SYSTEM

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR](/img/5/57395/w960_57395-2374.png)

EC-1026

< SYMPTOM DIAGNOSIS >[MR18DE]

ENGINE CONTROL SYSTEM

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code A

AAB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FL-10

Fuel piping 555 55 5EM-162

Va p o r l o c k—

Valve deposit

5 555 55 5—

Poor fuel (Heavy weight gasoline,

Low octane)—

Air Air duct

55555 5EM-154

Air cleanerEM-154

Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator)

555 5EM-156

Electric throttle control actuator

Air leakage from intake manifold/

Collector/Gasket

Cranking Battery

111111

11PG-6

Generator circuitCHG-29

Starter circuit 3STR-24

Signal plate 6EM-219

PNP switch 4TM-665

Engine Cylinder head

55555 55 5EM-198

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-200

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nismTiming chain

55555 55 5EM-177

CamshaftEM-186

Intake valve timing controlEM-177

Intake valve

3EM-198

Exhaust valve

Page 2376 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ENGINE CONTROL SYSTEM

EC-1027

< SYMPTOM DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5 NISSAN TIIDA 2007 Service Owners Guide ENGINE CONTROL SYSTEM

EC-1027

< SYMPTOM DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5](/img/5/57395/w960_57395-2375.png)

ENGINE CONTROL SYSTEM

EC-1027

< SYMPTOM DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5EX-5

, EX-9

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil cooler

55555 55 5EM-166

,

LU-18

, LU-

19

Oil level (Low)/Filthy oilLU-15

Cooling Radiator/Hose/Radiator filler cap

55555 55 45CO-40

Thermostat 5CO-45

Water pumpCO-44

Water galleryCO-28

Cooling fan

5CO-43

Coolant level (Low)/Contaminat-

ed coolantCO-35

NATS (NISSAN Anti-Theft System) 1 1SEC-7

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code A

AAB AC AD AE AF AG AH AJ AK AL AM HA

Page 2453 of 5883

![NISSAN TIIDA 2007 Service Owners Guide EC-1104

< FUNCTION DIAGNOSIS >[K9K]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000001162547

The ECM controls the display on the instrument panel NISSAN TIIDA 2007 Service Owners Guide EC-1104

< FUNCTION DIAGNOSIS >[K9K]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000001162547

The ECM controls the display on the instrument panel](/img/5/57395/w960_57395-2452.png)

EC-1104

< FUNCTION DIAGNOSIS >[K9K]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000001162547

The ECM controls the display on the instrument panel of certain information relating to the operation of the

engine.

Four functions are involved here: The OBD malfunction indicator [MI (Yellow)] for the EOBD (European On

Board Diagnostics), the pre/post heating, the engine coolant temperature and engine malfunction [MI (Red)].

These four functions are represented by four lights given out by the ECM

GLOW LAMP

This lamp indicates that the glow control system has been activated.

ENGINE COOLANT TEMPERATURE LIGHT

This light is used as an indicator of engine overheating.

In the event of overheating, it is up to the driver whether to stop the vehicle or not.

MALFUNCTION INDICATOR

The OBD malfunction indicator [MI (Yellow)] is used to alert the driver to the existence of engine control sys-

tem malfunctions involving excessive pollution or if the EOBD system is deactivated.

The ECM makes a request for lighting of the MI (Yellow) only where there is a malfunction present at the end

of three consecutive cycles.

The 3-second visual check upon powering up (automatic test procedure controlled by the IPDM E/R) is per-

formed by the ECM.

In the event of a confirmed OBD malfunction by lighting of the MI, no flashing of the light must be observed fol-

lowing the lighting test.

DTCs Causing MI to Light

ENGINE WARNING LIGHT

In the event of an engine malfunction, the ECM may request the display of an engine warning light [MI (Red)].

HOW TO ERASE DTC, 1ST TRIP DTC AND 2ND TRIP DTC

With CONSULT-III

The emission related diagnostic information in the ECM can be erased by selecting “ALL ERASE” in the

“Description” of “FINAL CHECK” mode with CONSULT-III.

MI OPERATION CHART

Some malfunction must switch on MI to warn driver, that his engine emissions exceed OBD thresholds (Euro 3

x 2.5).

The rule is to switch on MI after 3 consecutive driving cycles (engine start + engine stop + power latch) with a

present OBD malfunction.

To switch off the MI (without CONSULT-III), vehicle has to drive 3 consecutive cycles without present OBD

malfunction.

Ignition switch OFF → ON transition, MI remains switched on in pre-drive check mode until engine start.If MI

does not switch off whereas engine is running, there is at least one present OBD malfunction.

DTC Description Reference page

P0201 Cylinder 1 fuel injector control circuitEC-1142

P0202 Cylinder 2 fuel injector control circuitEC-1142

P0203 Cylinder 3 fuel injector control circuitEC-1142

P0204 Cylinder 4 fuel injector control circuitEC-1142

P0409 EGR Volume control valve control position sensor circuitEC-1158

P0606 ECMEC-1178

P2413 EGR volume control valveEC-1202

Page 2604 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ENGINE CONTROL SYSTEM SYMPTOMS

EC-1255

< SYMPTOM DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001162698

NOTE:

Only consu NISSAN TIIDA 2007 Service Owners Guide ENGINE CONTROL SYSTEM SYMPTOMS

EC-1255

< SYMPTOM DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001162698

NOTE:

Only consu](/img/5/57395/w960_57395-2603.png)

ENGINE CONTROL SYSTEM SYMPTOMS

EC-1255

< SYMPTOM DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001162698

NOTE:

Only consult this customer complaint after a complete check using the CONSULT-III.

Symptom Trouble diagnosis Reference page

No communication with the ECM CHART 1EC-1256, "

Diag-

nosis Procedure"

Starting malfunctionEngine does not start or starts with difficulty CHART 2EC-1257, "

Diag-

nosis Procedure"

Starting difficult with cold engine CHART 3EC-1259, "Diag-

nosis Procedure"

Impossible to shut off engine CHART 4EC-1261, "Diag-

nosis Procedure"

Idle speed malfunctionEngine Idle speed too high CHART 5EC-1262, "

Diag-

nosis Procedure"

Engine Idle speed too low or unstable CHART 6EC-1263, "Diag-

nosis Procedure"

Behavior while drivingEngine stalling CHART 7EC-1265, "

Diag-

nosis Procedure"

No or very little acceleration, increase in engine speed CHART 8EC-1267, "Diag-

nosis Procedure"

Engine bucking CHART 9EC-1270, "Diag-

nosis Procedure"

Erratic acceleration CHART 10EC-1272, "Diag-

nosis Procedure"

No engine braking CHART 11EC-1274, "Diag-

nosis Procedure"

Loss of power CHART 12EC-1275, "Diag-

nosis Procedure"

Too much power CHART 13EC-1278, "Diag-

nosis Procedure"

Overspeed at idle speed or on releasing brake CHART 14EC-1280, "Diag-

nosis Procedure"

Excessive consumption CHART 15EC-1281, "Diag-

nosis Procedure"

Engine knock CHART 16EC-1283, "Diag-

nosis Procedure"

Engine overheating CHART 17EC-1285, "Diag-

nosis Procedure"

Noise, odors or smokeEngine smokes when started CHART 18EC-1286, "

Diag-

nosis Procedure"

Engine emits blue smoke CHART 19EC-1287, "Diag-

nosis Procedure"

Engine smokes when revved CHART 20EC-1289, "Diag-

nosis Procedure"

Engine emits white smoke (especially when starting) CHART 21EC-1290, "Diag-

nosis Procedure"

Emission control not satisfactory CHART 22EC-1291, "Diag-

nosis Procedure"

Page 2634 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ENGINE OVERHEATING

EC-1285

< SYMPTOM DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ENGINE OVERHEATING

DescriptionINFOID:0000000001162731

CHART 17: ENGINE OVERHEATING

Diagnosis ProcedureINFOID:00000 NISSAN TIIDA 2007 Service Owners Guide ENGINE OVERHEATING

EC-1285

< SYMPTOM DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ENGINE OVERHEATING

DescriptionINFOID:0000000001162731

CHART 17: ENGINE OVERHEATING

Diagnosis ProcedureINFOID:00000](/img/5/57395/w960_57395-2633.png)

ENGINE OVERHEATING

EC-1285

< SYMPTOM DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ENGINE OVERHEATING

DescriptionINFOID:0000000001162731

CHART 17: ENGINE OVERHEATING

Diagnosis ProcedureINFOID:0000000001162732

1.CHECK COOLING SYSTEM

Check the cooling system. Refer to CO-53, "

Troubleshooting Chart".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace.

2.CHECK ECM POWER SUPPLY AND GROUND CIRCUIT

Check ECM power supply and ground circuit. Refer to EC-1106, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.CHECK WIRING HARNESS

Visually check the condition of the engine wiring harness.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness or connector.

4.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check engine coolant temperature sensor. Refer to EC-1133, "

Component Inspection".

Is the inspection result normal?

Yes >> GO TO 5.

No >> Repair or replace.

5.CHECK COOLING FAN OPERATION

Check cooling fan operation. Refer to EC-1211, "

Component Function Check".

Is the inspection result normal?

YES >>INSPECTION END

NO >> Repair or replace.

Page 3411 of 5883

![NISSAN TIIDA 2007 Service Owners Guide HAC-78

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

INSUFFICIENT COOLING

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too Hig NISSAN TIIDA 2007 Service Owners Guide HAC-78

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

INSUFFICIENT COOLING

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too Hig](/img/5/57395/w960_57395-3410.png)

HAC-78

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

INSUFFICIENT COOLING

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Both High- and Low-pressure Sides are Too Low

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too high.Pressure is reduced soon af-

ter water is splashed on con-

denser.Excessive refrigerant charge in refrig-

eration cycle.Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. Clean condenser.

Check and repair cooling

fan if necessary.

Low-pressure pipe is not

cold.

When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2 , 28 psi). It then de-

creases gradually thereaf-

ter.Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction.Check and repair each en-

gine cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Plates are sometimes cov-

ered with frost. Excessive liquid refrigerant on low-

pressure side.

Excessive refrigerant discharge

flow.

Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment.Replace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high

and low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. Check and repair or re-

place malfunctioning

parts.

Check oil for contami-

nation.

AC360A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low

and low-pressure side is too

high.High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

AC356A

Page 3523 of 5883

![NISSAN TIIDA 2007 Service Owners Guide HAC-190

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker abo NISSAN TIIDA 2007 Service Owners Guide HAC-190

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker abo](/img/5/57395/w960_57395-3522.png)

HAC-190

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too high.Pressure is reduced soon af-

ter water is splashed on con-

denser.Excessive refrigerant charge in refrig-

eration cycle.Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. Clean condenser.

Check and repair cooling

fan if necessary.

Low-pressure pipe is not

cold.

When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2, 28 psi). It then de-

creases gradually thereaf-

ter.Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction.Check and repair each en-

gine cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Plates are sometimes cov-

ered with frost. Excessive liquid refrigerant on low-

pressure side.

Excessive refrigerant discharge

flow.

Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment.Replace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high

and low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. Check and repair or re-

place malfunctioning

parts.

Check oil for contami-

nation.

AC360A

Page 3637 of 5883

![NISSAN TIIDA 2007 Service Owners Guide HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above NISSAN TIIDA 2007 Service Owners Guide HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above](/img/5/57395/w960_57395-3636.png)

HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too high.Pressure is reduced soon af-

ter water is splashed on con-

denser.Excessive refrigerant charge in refrig-

eration cycle.Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. Clean condenser.

Check and repair cooling

fan if necessary.

Low-pressure pipe is not

cold.

When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2, 28 psi). It then de-

creases gradually thereaf-

ter.Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction.Check and repair each en-

gine cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Plates are sometimes cov-

ered with frost. Excessive liquid refrigerant on low-

pressure side.

Excessive refrigerant discharge

flow.

Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment.Replace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high

and low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. Check and repair or re-

place malfunctioning

parts.

Check oil for contami-

nation.

AC360A

Page 4264 of 5883

MA-24

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

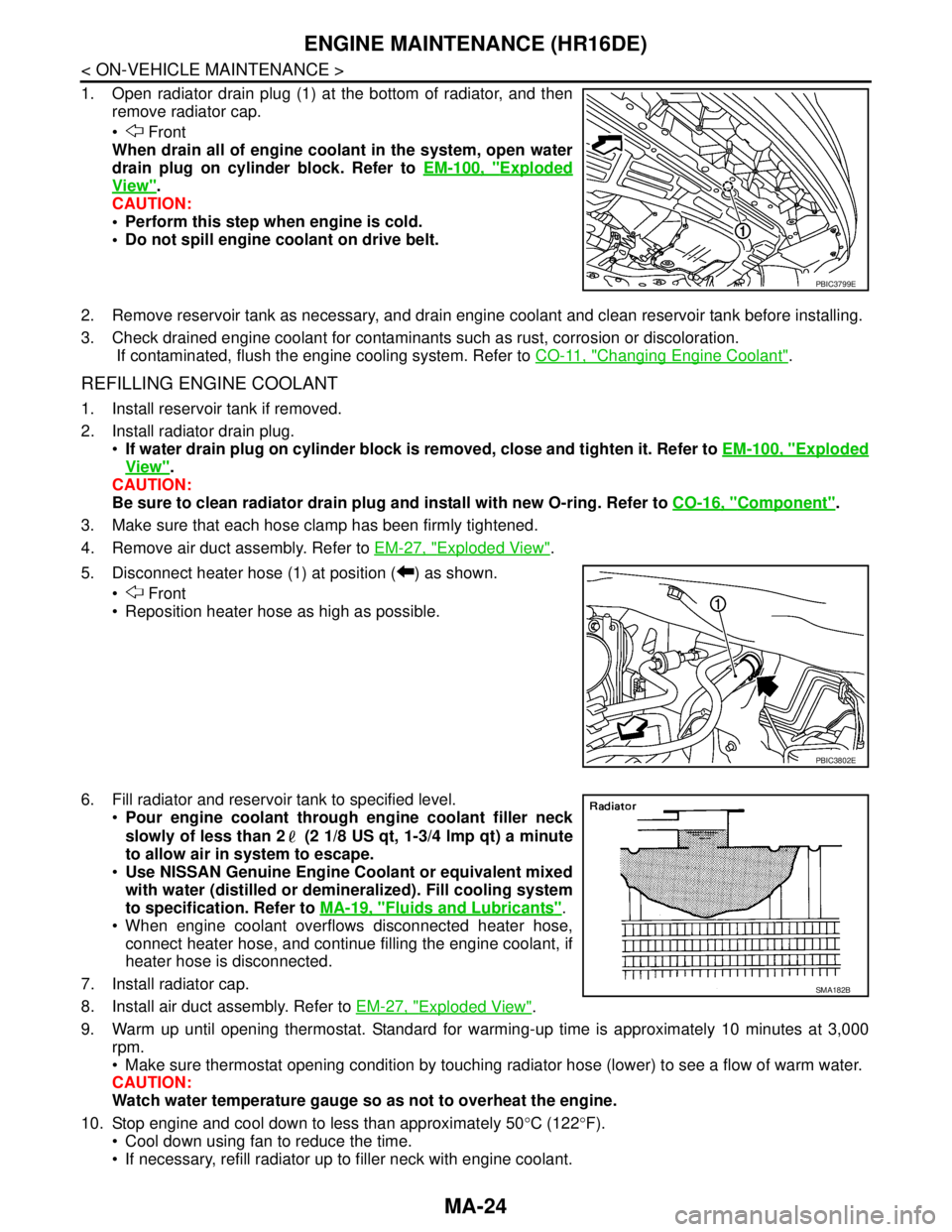

1. Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

Front

When drain all of engine coolant in the system, open water

drain plug on cylinder block. Refer to EM-100, "

Exploded

View".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to CO-11, "

Changing Engine Coolant".

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed.

2. Install radiator drain plug.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-100, "

Exploded

View".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-16, "

Component".

3. Make sure that each hose clamp has been firmly tightened.

4. Remove air duct assembly. Refer to EM-27, "

Exploded View".

5. Disconnect heater hose (1) at position ( ) as shown.

Front

Reposition heater hose as high as possible.

6. Fill radiator and reservoir tank to specified level.

Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2 1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use NISSAN Genuine Engine Coolant or equivalent mixed

with water (distilled or demineralized). Fill cooling system

to specification. Refer to MA-19, "

Fluids and Lubricants".

When engine coolant overflows disconnected heater hose,

connect heater hose, and continue filling the engine coolant, if

heater hose is disconnected.

7. Install radiator cap.

8. Install air duct assembly. Refer to EM-27, "

Exploded View".

9. Warm up until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat the engine.

10. Stop engine and cool down to less than approximately 50°C (122°F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

PBIC3799E

PBIC3802E

SMA182B

Page 4273 of 5883

ENGINE MAINTENANCE (MR18DE)

MA-33

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

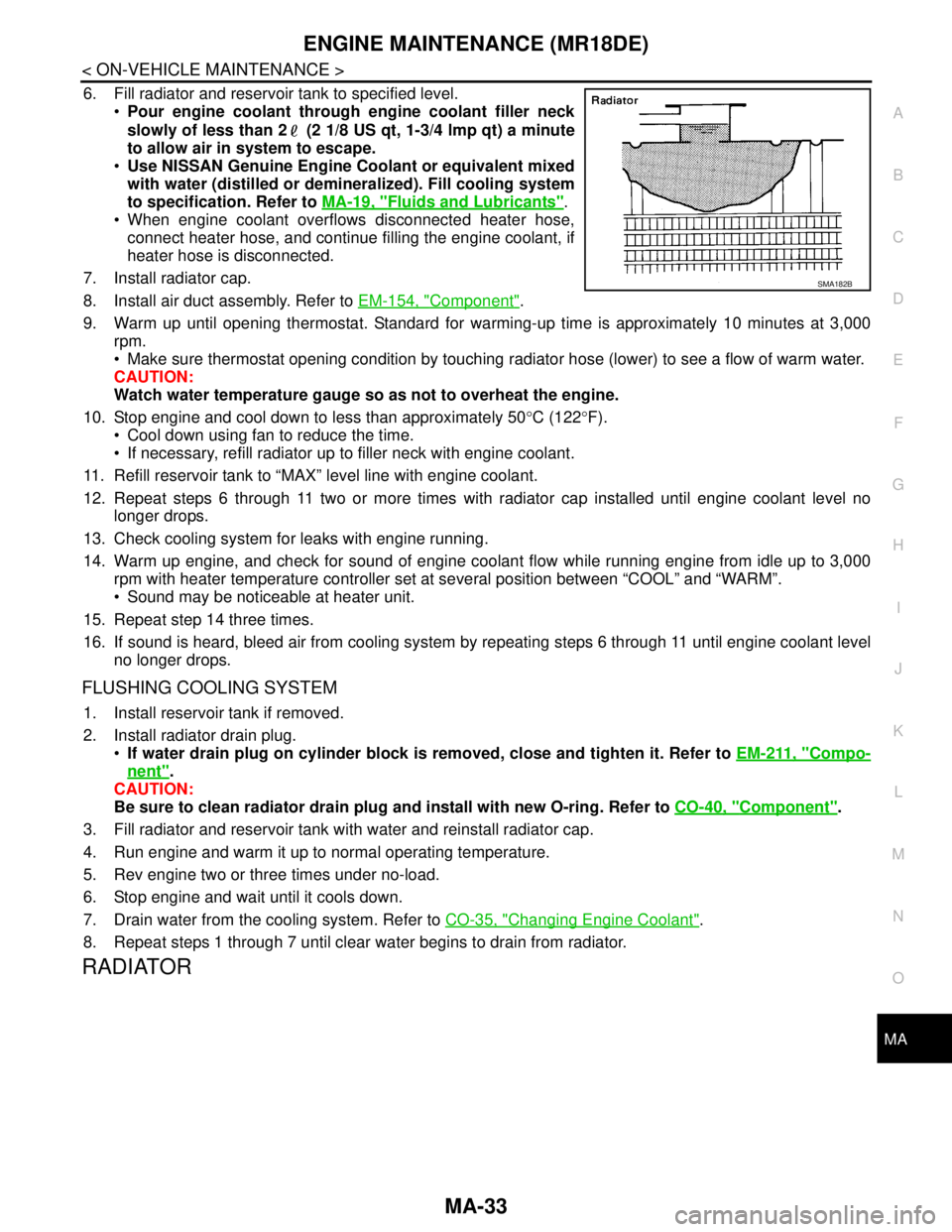

OA

6. Fill radiator and reservoir tank to specified level.

Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2 1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use NISSAN Genuine Engine Coolant or equivalent mixed

with water (distilled or demineralized). Fill cooling system

to specification. Refer to MA-19, "

Fluids and Lubricants".

When engine coolant overflows disconnected heater hose,

connect heater hose, and continue filling the engine coolant, if

heater hose is disconnected.

7. Install radiator cap.

8. Install air duct assembly. Refer to EM-154, "

Component".

9. Warm up until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat the engine.

10. Stop engine and cool down to less than approximately 50°C (122°F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

11. Refill reservoir tank to “MAX” level line with engine coolant.

12. Repeat steps 6 through 11 two or more times with radiator cap installed until engine coolant level no

longer drops.

13. Check cooling system for leaks with engine running.

14. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

15. Repeat step 14 three times.

16. If sound is heard, bleed air from cooling system by repeating steps 6 through 11 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed.

2. Install radiator drain plug.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-211, "

Compo-

nent".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-40, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system. Refer to CO-35, "

Changing Engine Coolant".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

RADIATOR

SMA182B