engine overheat NISSAN TIIDA 2007 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4284 of 5883

MA-44

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (K9K)

4. Start engine without closing reservoir tank cap and keep engine racing at 1,500 rpm for about 2-3 minutes.

If necessary, pour engine coolant up to MAX level.

If coolant overflows reservoir tank hole, install filler cap.

Watch engine coolant temperature gauge so as not overheat the engine.

WARNING:

Be careful not to be scaled with hot engine coolant or vacuum pump when operating.

Radiator fan blade can start at any time and cause personal injuries.

5. Turn off the engine and loosen air relief plug until coolant spills from air relief hole.

6. Close the air relief plug and run the engine at 2,000 rpm until the upper hose becomes hot and radiator

fan operates. Leave the engine running approximately 5 minutes at idle speed and check for sound of

coolant flow while running engine from idle up to 3,000 rpm.

Sound may be noticeable at heater water cock.

7. If sound is heard, bleed air from cooling system by repeating steps 4 to 6 until coolant level no longer

drops.

Check the radiator lower hose for any signs of leakage.

8. Turn off the engine and let it cool down.

Cool down using a fan to reduce the time.

9. After cooling period, loosen the air relief plug and check if coolant spills from the air relief hole. if not,

remove the air relief plug until the coolant spills, and then close the relief air plug. Bleed air from cooling

system by repeating steps 6 to 10 until the coolant spills immediately.

10. Check the engine coolant level when engine is cool and refill to MAX level line if the level is lower.

Clean excess coolant from engine.

11. Check that the reservoir tank cap is tightened.

ENGINE COOLANT : FlushingINFOID:0000000001730883

1. Install reservoir tank if removed.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-314, "

Exploded

View".

2. Fill reservoir tank with water until water spills from the air relief hole, then close air relief plug. Reinstall

reservoir tank cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from radiator.

8. Blow compressed air into cooling circuit through the reservoir tank valve hole to drain all the water.

RADIATOR

RADIATOR : Checking Radiator CapINFOID:0000000001730884

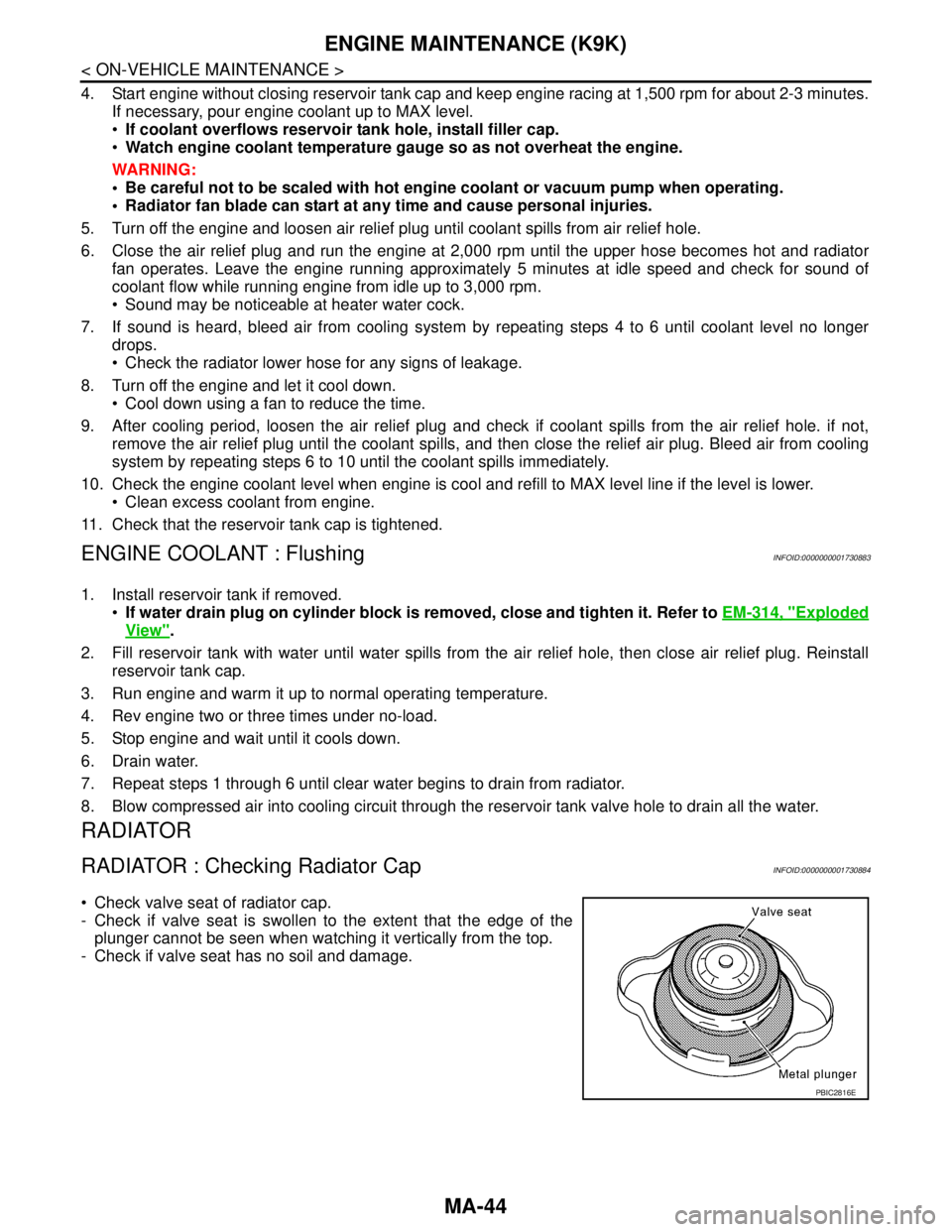

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

PBIC2816E

Page 5084 of 5883

![NISSAN TIIDA 2007 Service Service Manual TM-138

< SYMPTOM DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

SYSTEM SYMPTOM

OD OFF Indicator Lamp Does Not Come On

INFOID:0000000001696242

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds wh NISSAN TIIDA 2007 Service Service Manual TM-138

< SYMPTOM DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

SYSTEM SYMPTOM

OD OFF Indicator Lamp Does Not Come On

INFOID:0000000001696242

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds wh](/img/5/57395/w960_57395-5083.png)

TM-138

< SYMPTOM DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

SYSTEM SYMPTOM

OD OFF Indicator Lamp Does Not Come On

INFOID:0000000001696242

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds when turning ignition switch to ON.

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TM-35, "

CONSULT-III Function (TRANSMISSION)" or TM-350, "Diagnosis

Procedure without CONSULT-III".

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to TM-43, "Description" (type 1) or TM-391, "Description"

(type 2).

NO >> GO TO 2.

2.CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground.

OthersTransaxle overheats.ON vehicle1. A/T fluid levelTM-171

2. Engine idling speedEC-26

3. Accelerator pedal position sensorEC-297

4. Line pressure testTM-178

5. Line pressure solenoid valveTM-81

6. Control valve assemblyTM-191

OFF vehicle7. Oil pumpTM-240

8. Reverse clutchTM-258

9. High clutchTM-262

10. Brake bandTM-287

11. Forward clutchTM-267

12. Overrun clutchTM-267

13. Low & reverse brakeTM-273

14. Torque converterTM-222

ATF shoots out during

operation.

White smoke emitted

from exhaust pipe

during operation.ON vehicle 1. A/T fluid levelTM-171

OFF vehicle2. Reverse clutchTM-258

3. High clutchTM-262

4. Brake bandTM-287

5. Forward clutchTM-267

6. Overrun clutchTM-267

7. Low & reverse brakeTM-273

Unusual smell at A/T

fluid charging pipe.ON vehicle 1. A/T fluid levelTM-171

OFF vehicle2. Torque converterTM-222

3. Oil pumpTM-240

4. Reverse clutchTM-258

5. High clutchTM-262

6. Brake bandTM-287

7. Forward clutchTM-267

8. Overrun clutchTM-267

9. Low & reverse brakeTM-273

Items Symptom Condition Diagnostic item Reference page

Page 5111 of 5883

![NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5110.png)

PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001696268

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001696269

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

Page 5386 of 5883

![NISSAN TIIDA 2007 Service Service Manual TM-440

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

SYSTEM SYMPTOM

OD OFF Indicator Lamp Does Not Come On

INFOID:0000000001714346

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds wh NISSAN TIIDA 2007 Service Service Manual TM-440

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

SYSTEM SYMPTOM

OD OFF Indicator Lamp Does Not Come On

INFOID:0000000001714346

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds wh](/img/5/57395/w960_57395-5385.png)

TM-440

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

SYSTEM SYMPTOM

OD OFF Indicator Lamp Does Not Come On

INFOID:0000000001714346

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds when turning ignition switch to ON.

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to XX-XX, "*****"

or TM-350, "Diagnosis Procedure without CONSULT-III".

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to XX-XX, "*****" (type 1) or XX-XX, "*****" (type 2).

NO >> GO TO 2.

2.CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground.

OthersTransaxle overheats.ON vehicle1. A/T fluid levelXX-XX, "*****"

2. Engine idling speedEC-389

3. Accelerator pedal position sensorEC-583

4. Line pressure testTM-178

5. Line pressure solenoid valveXX-XX, "*****"

6. Control valve assemblyXX-XX, "*****"

OFF vehicle7. Oil pumpXX-XX, "*****"

8. Reverse clutchXX-XX, "*****"

9. High clutchXX-XX, "*****"

10. Brake bandXX-XX, "*****"

11. Forward clutchXX-XX, "*****"

12. Overrun clutchXX-XX, "*****"

13. Low & reverse brakeXX-XX, "*****"

14. Torque converterXX-XX, "*****"

ATF shoots out during

operation.

White smoke emitted

from exhaust pipe

during operation.ON vehicle 1. A/T fluid levelXX-XX, "*****"

OFF vehicle2. Reverse clutchXX-XX, "*****"

3. High clutchXX-XX, "*****"

4. Brake bandXX-XX, "*****"

5. Forward clutchXX-XX, "*****"

6. Overrun clutchXX-XX, "*****"

7. Low & reverse brakeXX-XX, "*****"

Unusual smell at A/T

fluid charging pipe.ON vehicle 1. A/T fluid levelXX-XX, "*****"

OFF vehicle2. Torque converterXX-XX, "*****"

3. Oil pumpXX-XX, "*****"

4. Reverse clutchXX-XX, "*****"

5. High clutchXX-XX, "*****"

6. Brake bandXX-XX, "*****"

7. Forward clutchXX-XX, "*****"

8. Overrun clutchXX-XX, "*****"

9. Low & reverse brakeXX-XX, "*****"

Items Symptom Condition Diagnostic item Reference page

Page 5413 of 5883

![NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5412.png)

PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001723048

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001723049

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"