meter NISSAN TIIDA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 157 of 5883

BCS-22

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

1: Factory setting

2: If equipped

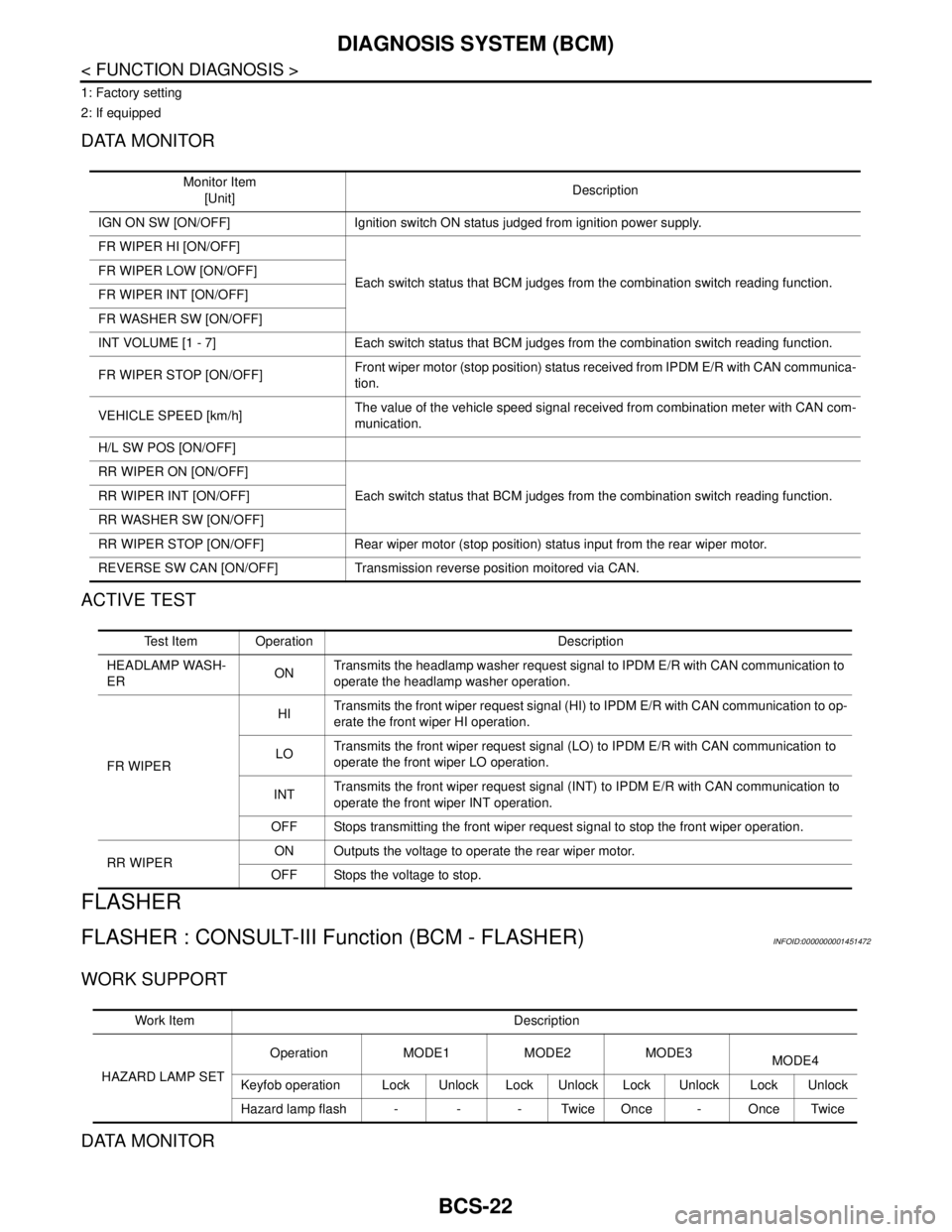

DATA MONITOR

ACTIVE TEST

FLASHER

FLASHER : CONSULT-III Function (BCM - FLASHER)INFOID:0000000001451472

WORK SUPPORT

DATA MONITOR

Monitor Item

[Unit]Description

IGN ON SW [ON/OFF] Ignition switch ON status judged from ignition power supply.

FR WIPER HI [ON/OFF]

Each switch status that BCM judges from the combination switch reading function. FR WIPER LOW [ON/OFF]

FR WIPER INT [ON/OFF]

FR WASHER SW [ON/OFF]

INT VOLUME [1 - 7] Each switch status that BCM judges from the combination switch reading function.

FR WIPER STOP [ON/OFF]Front wiper motor (stop position) status received from IPDM E/R with CAN communica-

tion.

VEHICLE SPEED [km/h]The value of the vehicle speed signal received from combination meter with CAN com-

munication.

H/L SW POS [ON/OFF]

RR WIPER ON [ON/OFF]

Each switch status that BCM judges from the combination switch reading function. RR WIPER INT [ON/OFF]

RR WASHER SW [ON/OFF]

RR WIPER STOP [ON/OFF] Rear wiper motor (stop position) status input from the rear wiper motor.

REVERSE SW CAN [ON/OFF] Transmission reverse position moitored via CAN.

Test Item Operation Description

HEADLAMP WASH-

ERONTransmits the headlamp washer request signal to IPDM E/R with CAN communication to

operate the headlamp washer operation.

FR WIPERHITransmits the front wiper request signal (HI) to IPDM E/R with CAN communication to op-

erate the front wiper HI operation.

LOTransmits the front wiper request signal (LO) to IPDM E/R with CAN communication to

operate the front wiper LO operation.

INTTransmits the front wiper request signal (INT) to IPDM E/R with CAN communication to

operate the front wiper INT operation.

OFF Stops transmitting the front wiper request signal to stop the front wiper operation.

RR WIPERON Outputs the voltage to operate the rear wiper motor.

OFF Stops the voltage to stop.

Work Item Description

HAZARD LAMP SETOperation MODE1 MODE2 MODE3

MODE4

Keyfob operation Lock Unlock Lock Unlock Lock Unlock Lock Unlock

Hazard lamp flash - - - Twice Once - Once Twice

Page 161 of 5883

BCS-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

*: Each lamp switch is in ON position.

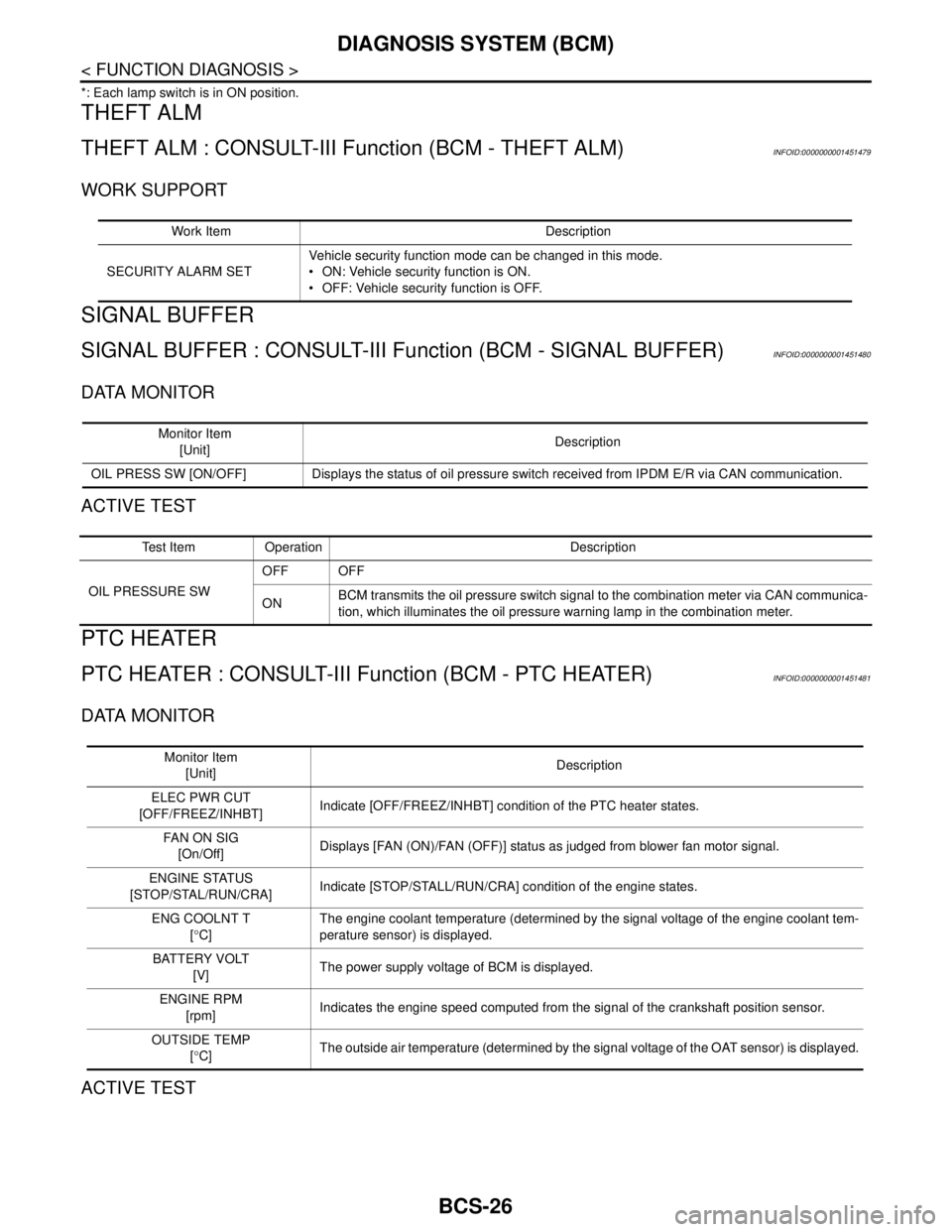

THEFT ALM

THEFT ALM : CONSULT-III Function (BCM - THEFT ALM)INFOID:0000000001451479

WORK SUPPORT

SIGNAL BUFFER

SIGNAL BUFFER : CONSULT-III Function (BCM - SIGNAL BUFFER)INFOID:0000000001451480

DATA MONITOR

ACTIVE TEST

PTC HEATER

PTC HEATER : CONSULT-III Function (BCM - PTC HEATER)INFOID:0000000001451481

DATA MONITOR

ACTIVE TEST

Work Item Description

SECURITY ALARM SETVehicle security function mode can be changed in this mode.

ON: Vehicle security function is ON.

OFF: Vehicle security function is OFF.

Monitor Item

[Unit]Description

OIL PRESS SW [ON/OFF] Displays the status of oil pressure switch received from IPDM E/R via CAN communication.

Test Item Operation Description

OIL PRESSURE SWOFF OFF

ONBCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which illuminates the oil pressure warning lamp in the combination meter.

Monitor Item

[Unit]Description

ELEC PWR CUT

[OFF/FREEZ/INHBT]Indicate [OFF/FREEZ/INHBT] condition of the PTC heater states.

FA N O N S I G

[On/Off]Displays [FAN (ON)/FAN (OFF)] status as judged from blower fan motor signal.

ENGINE STATUS

[STOP/STAL/RUN/CRA]Indicate [STOP/STALL/RUN/CRA] condition of the engine states.

ENG COOLNT T

[°C]The engine coolant temperature (determined by the signal voltage of the engine coolant tem-

perature sensor) is displayed.

BATTERY VOLT

[V]The power supply voltage of BCM is displayed.

ENGINE RPM

[rpm]Indicates the engine speed computed from the signal of the crankshaft position sensor.

OUTSIDE TEMP

[°C]The outside air temperature (determined by the signal voltage of the OAT sensor) is displayed.

Page 163 of 5883

BCS-28

< COMPONENT DIAGNOSIS >

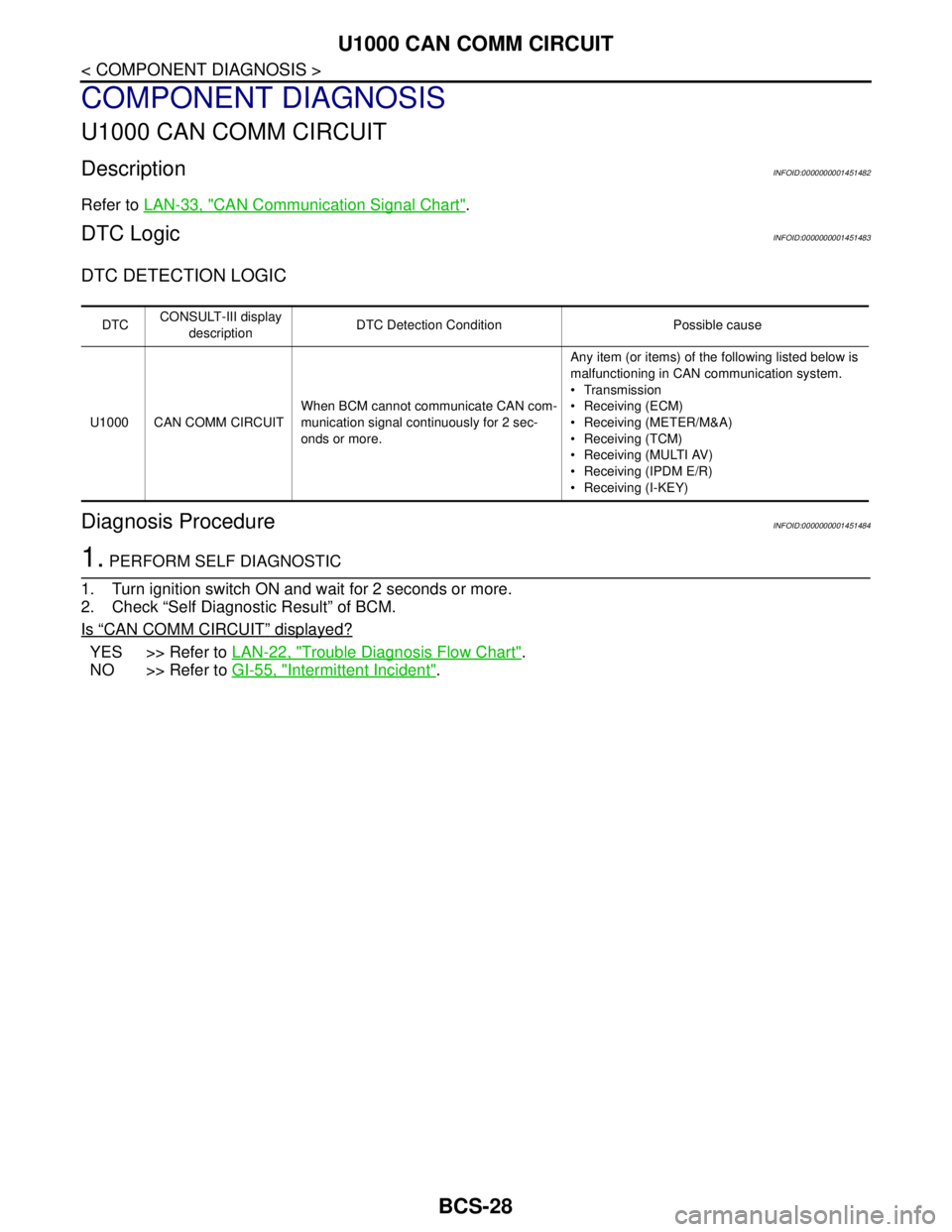

U1000 CAN COMM CIRCUIT

COMPONENT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001451482

Refer to LAN-33, "CAN Communication Signal Chart".

DTC LogicINFOID:0000000001451483

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000001451484

1. PERFORM SELF DIAGNOSTIC

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result” of BCM.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-22, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-55, "

Intermittent Incident".

DTCCONSULT-III display

descriptionDTC Detection Condition Possible cause

U1000 CAN COMM CIRCUITWhen BCM cannot communicate CAN com-

munication signal continuously for 2 sec-

onds or more.Any item (or items) of the following listed below is

malfunctioning in CAN communication system.

Transmission

Receiving (ECM)

Receiving (METER/M&A)

Receiving (TCM)

Receiving (MULTI AV)

Receiving (IPDM E/R)

Receiving (I-KEY)

Page 172 of 5883

BCS

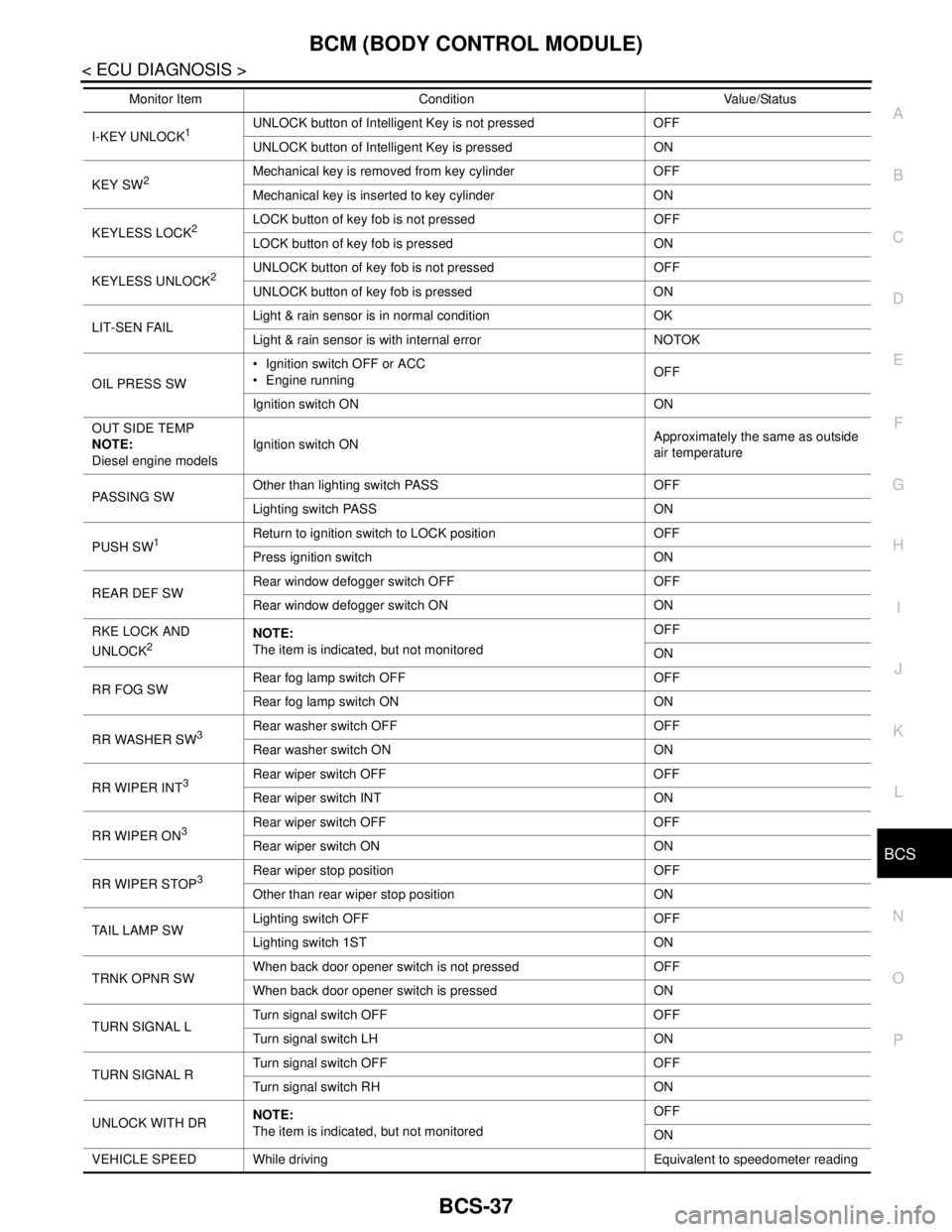

BCM (BODY CONTROL MODULE)

BCS-37

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

I-KEY UNLOCK1UNLOCK button of Intelligent Key is not pressed OFF

UNLOCK button of Intelligent Key is pressed ON

KEY SW

2Mechanical key is removed from key cylinder OFF

Mechanical key is inserted to key cylinder ON

KEYLESS LOCK

2LOCK button of key fob is not pressed OFF

LOCK button of key fob is pressed ON

KEYLESS UNLOCK

2UNLOCK button of key fob is not pressed OFF

UNLOCK button of key fob is pressed ON

LIT-SEN FAILLight & rain sensor is in normal condition OK

Light & rain sensor is with internal error NOTOK

OIL PRESS SW Ignition switch OFF or ACC

Engine runningOFF

Ignition switch ON ON

OUT SIDE TEMP

NOTE:

Diesel engine modelsIgnition switch ONApproximately the same as outside

air temperature

PASSING SWOther than lighting switch PASS OFF

Lighting switch PASS ON

PUSH SW

1Return to ignition switch to LOCK position OFF

Press ignition switch ON

REAR DEF SWRear window defogger switch OFF OFF

Rear window defogger switch ON ON

RKE LOCK AND

UNLOCK

2NOTE:

The item is indicated, but not monitoredOFF

ON

RR FOG SWRear fog lamp switch OFF OFF

Rear fog lamp switch ON ON

RR WASHER SW

3Rear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INT

3Rear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON

3 Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOP

3Rear wiper stop position OFF

Other than rear wiper stop position ON

TAIL LAMP SWLighting switch OFF OFF

Lighting switch 1ST ON

TRNK OPNR SWWhen back door opener switch is not pressed OFF

When back door opener switch is pressed ON

TURN SIGNAL LTurn signal switch OFF OFF

Turn signal switch LH ON

TURN SIGNAL RTurn signal switch OFF OFF

Turn signal switch RH ON

UNLOCK WITH DRNOTE:

The item is indicated, but not monitoredOFF

ON

VEHICLE SPEED While driving Equivalent to speedometer reading Monitor Item Condition Value/Status

Page 196 of 5883

BR-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

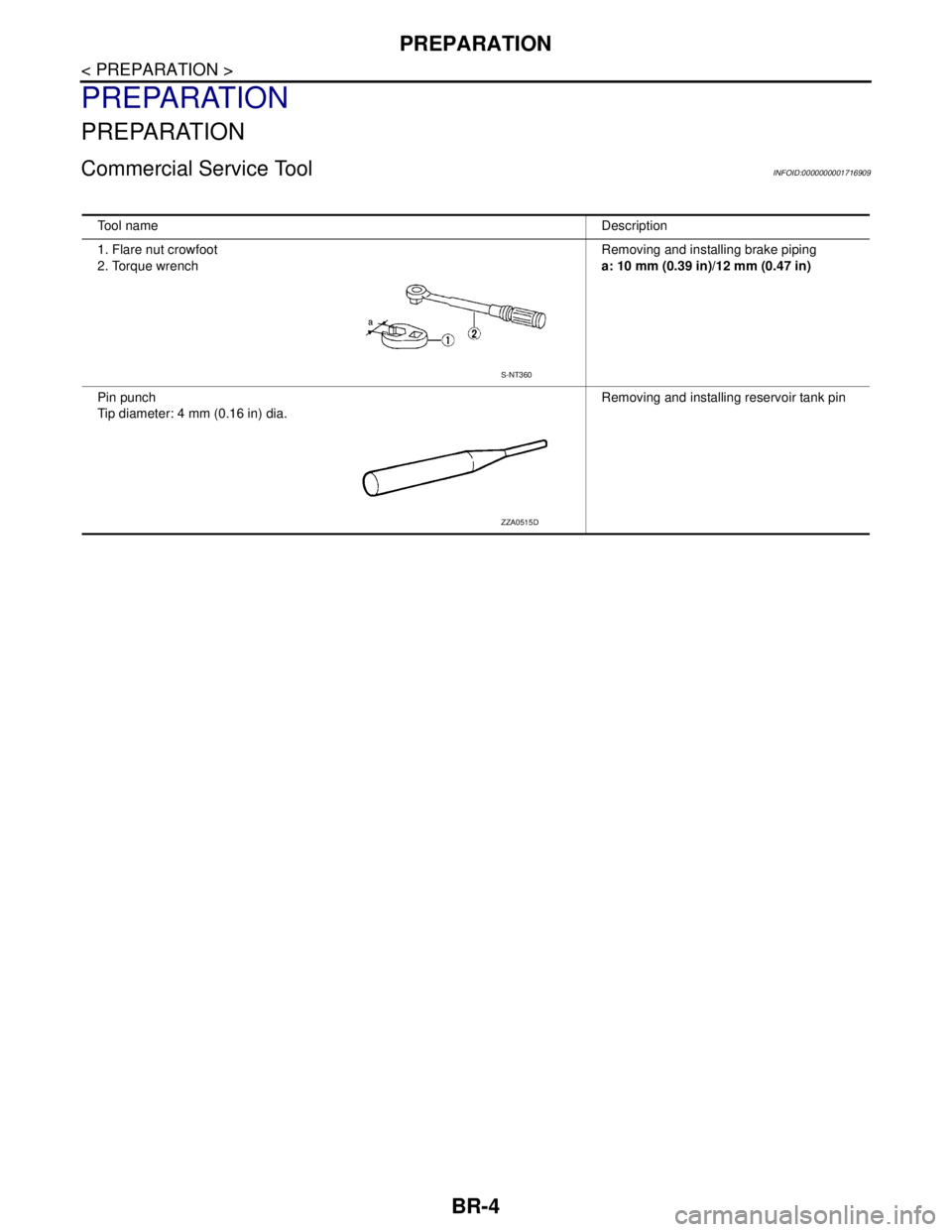

Commercial Service ToolINFOID:0000000001716909

Tool nameDescription

1. Flare nut crowfoot

2. Torque wrenchRemoving and installing brake piping

a: 10 mm (0.39 in)/12 mm (0.47 in)

Pin punch

Tip diameter: 4 mm (0.16 in) dia. Removing and installing reservoir tank pin

S-NT360

ZZA0515D

Page 223 of 5883

![NISSAN TIIDA 2007 Service Owners Guide BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank NISSAN TIIDA 2007 Service Owners Guide BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank](/img/5/57395/w960_57395-222.png)

BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank.

3. Remove master cylinder assembly from vise.

4. Remove reservoir tank and grommet from cylinder body.

5. While pushing primary piston, remove piston stopper through

secondary tank boss hole in the cylinder body.

6. Remove snap ring with pushing primary piston.

CAUTION:

Be careful not to pop out piston.

7. Holding rod of primary piston, remove primary piston assembly,

plate and guide assembly by pulling straight to prevent piston

cup from being caught by the inner wall of cylinder.

8. Remove plate and guide assembly from primary piston.

CAUTION:

Be careful not to damage rod from the inner wall of plate.

9. Tap flange using a soft block such as wood, and carefully pull

secondary piston assembly straight out to prevent cylinder inner

wall from being damaged.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for damage, wear, corrosion, and pin holes. Replace cylinder body if neces-

sary.

ASSEMBLY

CAUTION:

Never use mineral oils such as kerosene or gasoline during the cleaning and assembly processes.

Make sure that there is no foreign material such as dirt and dust on the inner wall of cylinder, piston,

and piston cup. Be careful not to damage parts with a service tool when assembling.

Do not drop parts. If a part is dropped, do not use it.

WFIA0515E

WFIA0516E

BRA0561DWFIA0517E

WFIA0518E

Page 224 of 5883

BR-32

< DISASSEMBLY AND ASSEMBLY >

BRAKE MASTER CYLINDER

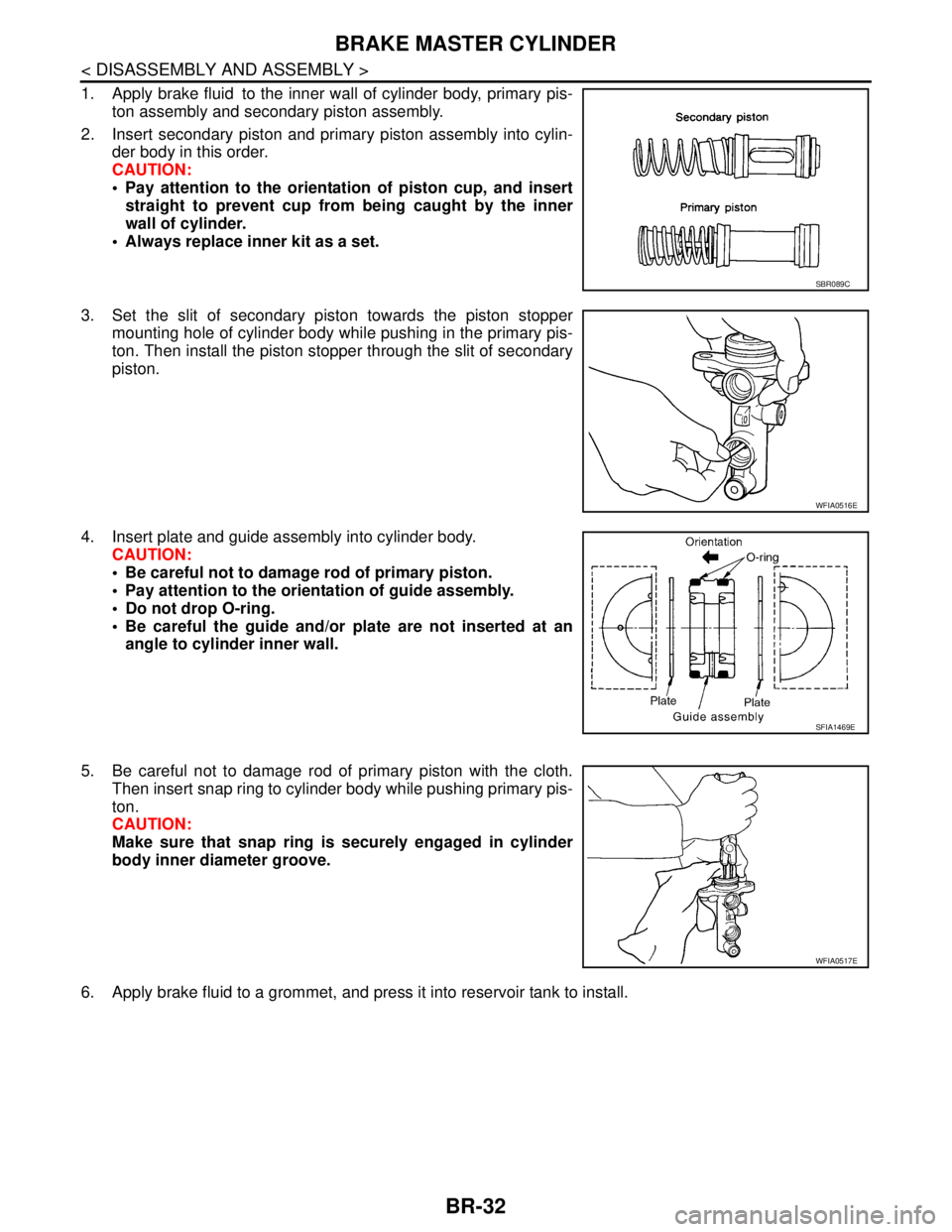

1. Apply brake fluid to the inner wall of cylinder body, primary pis-

ton assembly and secondary piston assembly.

2. Insert secondary piston and primary piston assembly into cylin-

der body in this order.

CAUTION:

Pay attention to the orientation of piston cup, and insert

straight to prevent cup from being caught by the inner

wall of cylinder.

Always replace inner kit as a set.

3. Set the slit of secondary piston towards the piston stopper

mounting hole of cylinder body while pushing in the primary pis-

ton. Then install the piston stopper through the slit of secondary

piston.

4. Insert plate and guide assembly into cylinder body.

CAUTION:

Be careful not to damage rod of primary piston.

Pay attention to the orientation of guide assembly.

Do not drop O-ring.

Be careful the guide and/or plate are not inserted at an

angle to cylinder inner wall.

5. Be careful not to damage rod of primary piston with the cloth.

Then insert snap ring to cylinder body while pushing primary pis-

ton.

CAUTION:

Make sure that snap ring is securely engaged in cylinder

body inner diameter groove.

6. Apply brake fluid to a grommet, and press it into reservoir tank to install.

SBR089C

WFIA0516E

SFIA1469E

WFIA0517E

Page 225 of 5883

BRAKE MASTER CYLINDER

BR-33

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

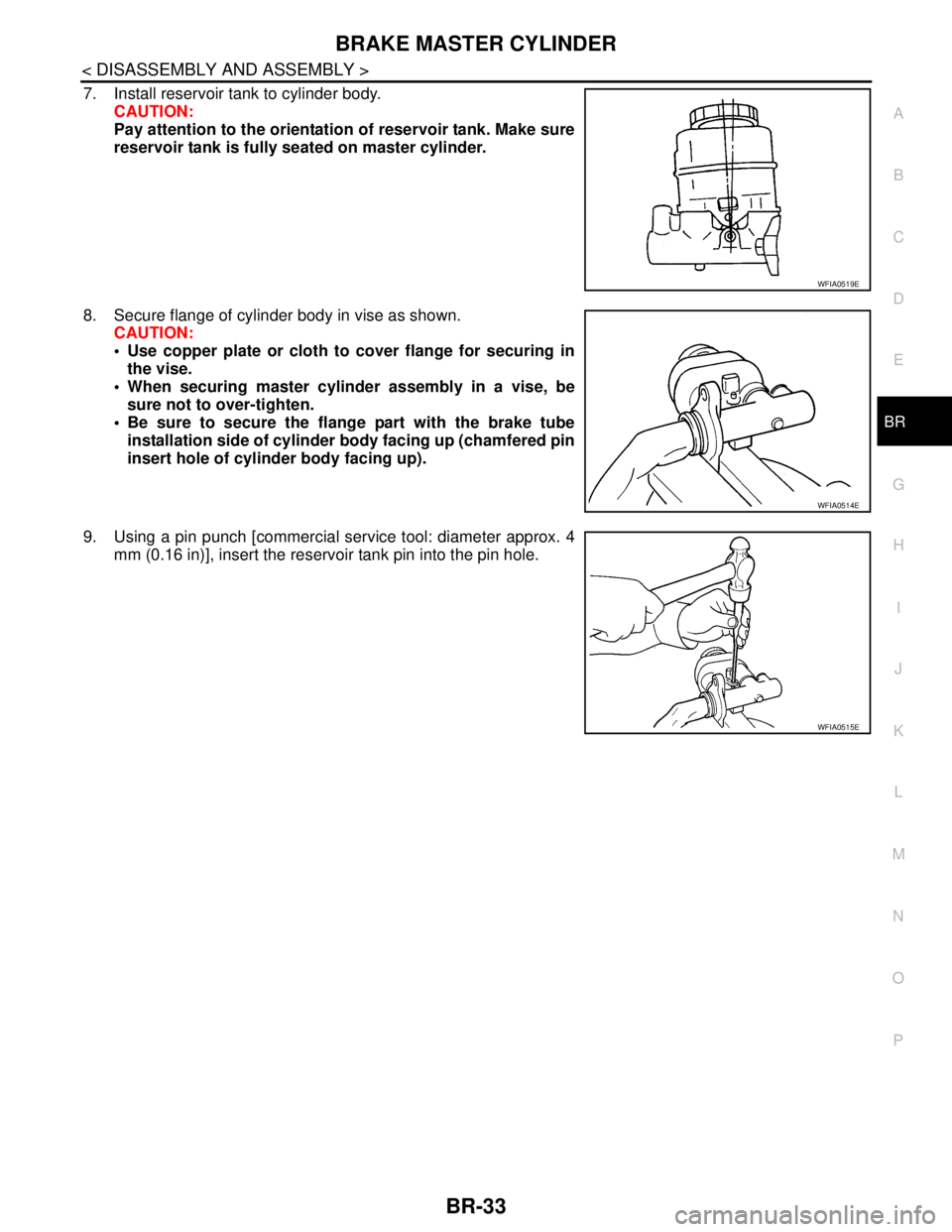

7. Install reservoir tank to cylinder body.

CAUTION:

Pay attention to the orientation of reservoir tank. Make sure

reservoir tank is fully seated on master cylinder.

8. Secure flange of cylinder body in vise as shown.

CAUTION:

Use copper plate or cloth to cover flange for securing in

the vise.

When securing master cylinder assembly in a vise, be

sure not to over-tighten.

Be sure to secure the flange part with the brake tube

installation side of cylinder body facing up (chamfered pin

insert hole of cylinder body facing up).

9. Using a pin punch [commercial service tool: diameter approx. 4

mm (0.16 in)], insert the reservoir tank pin into the pin hole.

WFIA0519E

WFIA0514E

WFIA0515E

Page 228 of 5883

BR-36

< DISASSEMBLY AND ASSEMBLY >

FRONT DISC BRAKE

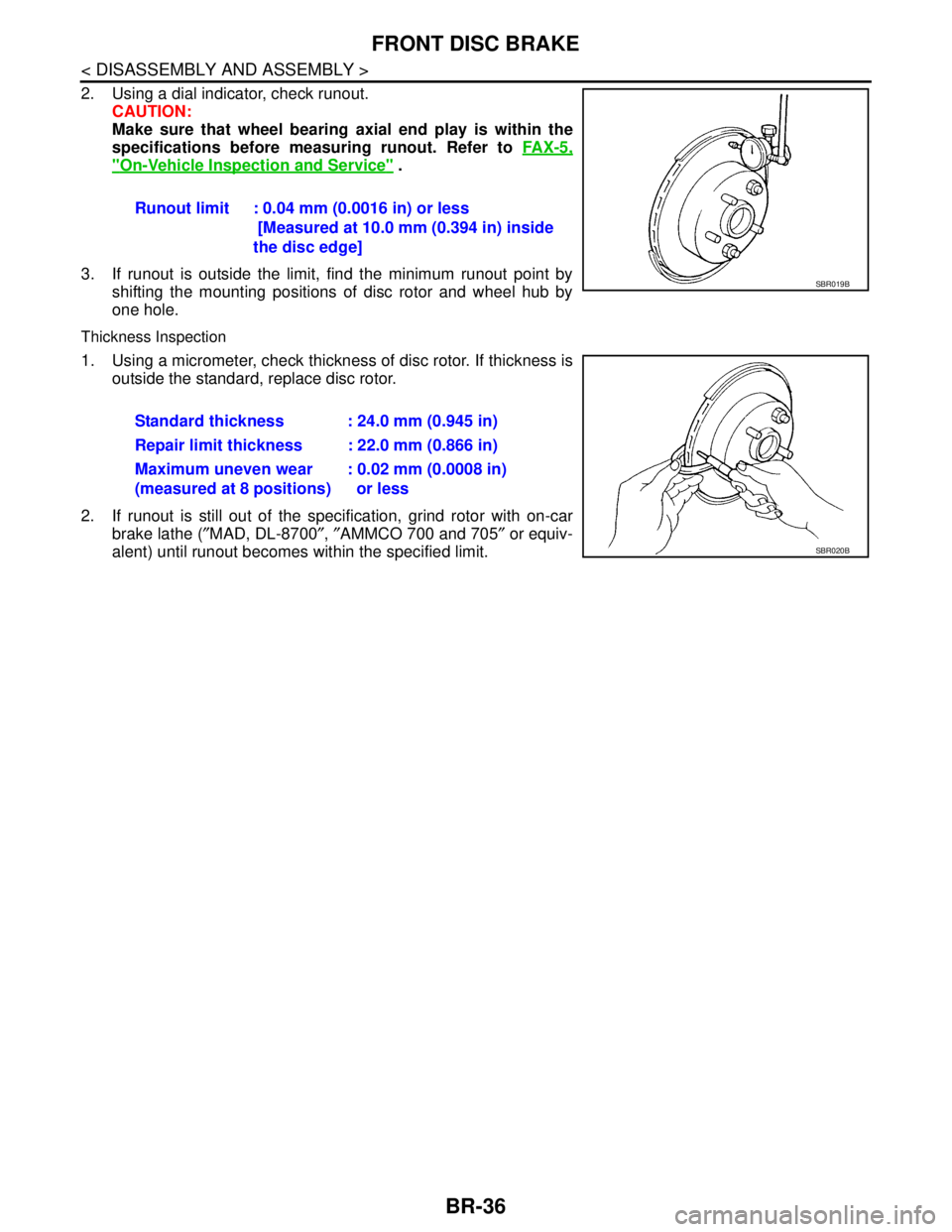

2. Using a dial indicator, check runout.

CAUTION:

Make sure that wheel bearing axial end play is within the

specifications before measuring runout. Refer to FA X - 5 ,

"On-Vehicle Inspection and Service" .

3. If runout is outside the limit, find the minimum runout point by

shifting the mounting positions of disc rotor and wheel hub by

one hole.

Thickness Inspection

1. Using a micrometer, check thickness of disc rotor. If thickness is

outside the standard, replace disc rotor.

2. If runout is still out of the specification, grind rotor with on-car

brake lathe (″MAD, DL-8700″, ″AMMCO 700 and 705″ or equiv-

alent) until runout becomes within the specified limit.Runout limit : 0.04 mm (0.0016 in) or less

[Measured at 10.0 mm (0.394 in) inside

the disc edge]

SBR019B

Standard thickness : 24.0 mm (0.945 in)

Repair limit thickness : 22.0 mm (0.866 in)

Maximum uneven wear

(measured at 8 positions): 0.02 mm (0.0008 in)

or less

SBR020B

Page 231 of 5883

REAR DISC BRAKE

BR-39

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

5. Attach the sliding pin bolt and sliding pin boot to the torque member.

6. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the rear of the pad and to both sides

of the shim, and attach the inner shim and shim cover to the inner pad, and the outer shim and outer shim

cover to the outer pad.

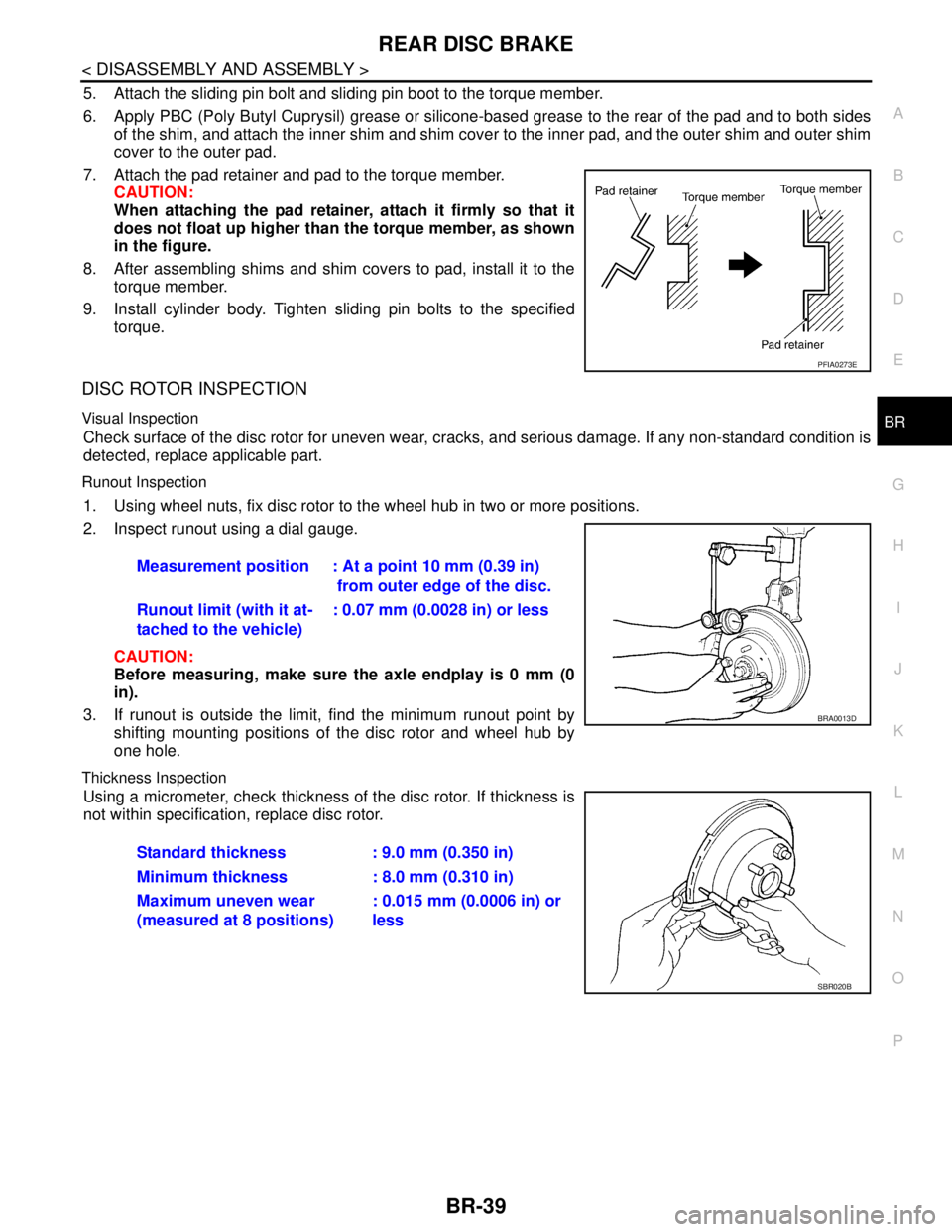

7. Attach the pad retainer and pad to the torque member.

CAUTION:

When attaching the pad retainer, attach it firmly so that it

does not float up higher than the torque member, as shown

in the figure.

8. After assembling shims and shim covers to pad, install it to the

torque member.

9. Install cylinder body. Tighten sliding pin bolts to the specified

torque.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of the disc rotor for uneven wear, cracks, and serious damage. If any non-standard condition is

detected, replace applicable part.

Runout Inspection

1. Using wheel nuts, fix disc rotor to the wheel hub in two or more positions.

2. Inspect runout using a dial gauge.

CAUTION:

Before measuring, make sure the axle endplay is 0 mm (0

in).

3. If runout is outside the limit, find the minimum runout point by

shifting mounting positions of the disc rotor and wheel hub by

one hole.

Thickness Inspection

Using a micrometer, check thickness of the disc rotor. If thickness is

not within specification, replace disc rotor.

PFIA0273E

Measurement position : At a point 10 mm (0.39 in)

from outer edge of the disc.

Runout limit (with it at-

tached to the vehicle): 0.07 mm (0.0028 in) or less

BRA0013D

Standard thickness : 9.0 mm (0.350 in)

Minimum thickness : 8.0 mm (0.310 in)

Maximum uneven wear

(measured at 8 positions): 0.015 mm (0.0006 in) or

less

SBR020B