EC Engine Control System NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 5406 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-460

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

SYSTEM SYMPTOM

- Servo piston assembly

- Brake band

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refe NISSAN TIIDA 2007 Service Repair Manual TM-460

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

SYSTEM SYMPTOM

- Servo piston assembly

- Brake band

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refe](/img/5/57395/w960_57395-5405.png)

TM-460

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

SYSTEM SYMPTOM

- Servo piston assembly

- Brake band

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer to TM-186, "

Cruise Test - Part 3".

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signals. Refer to TM-22, "

Input/Output Signal of TCM".

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Vehicle Does Not Decelerate by Engine BrakeINFOID:0000000001714364

SYMPTOM:

Vehicle does not decelerate by engine brake when shifting from 2

2 (12) to 11“Cruise Test — Part 3”.

Vehicle does not decelerate by engine brake when OD OFF (OD OFF indicator lamp is on) on “Cruise

Test — Part 3”.

Vehicle does not decelerate by engine brake when shifting A/T from “D” to “2” position on “Cruise

Test — Part 3”.

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to XX-XX, "*****"

or TM-38, "Diagnosis Procedure without CONSULT-III".

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to XX-XX, "*****" (type 1) or XX-XX, "*****" (type 2).

NO >> GO TO 2.

2.CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II.

3. Read out “OVERDRIVE SW”.

Check the signal of the overdrive control switch is indicated properly.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

SAT778B

Item nameOverdrive control switch

ConditionDisplay value

OVERDRIVE SWDepressed ON

Released OFF

Page 5407 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SYSTEM SYMPTOM

TM-461

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

2. Check voltage between A/T device harness connector terminal

and ground.

OK or NG

OK (With CONSULT- NISSAN TIIDA 2007 Service Repair Manual SYSTEM SYMPTOM

TM-461

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

2. Check voltage between A/T device harness connector terminal

and ground.

OK or NG

OK (With CONSULT-](/img/5/57395/w960_57395-5406.png)

SYSTEM SYMPTOM

TM-461

< SYMPTOM DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

2. Check voltage between A/T device harness connector terminal

and ground.

OK or NG

OK (With CONSULT-II)>>GO TO 3.

OK (Without CONSULT-II)>>GO TO 4.

NG >> Check overdrive control switch circuit. Refer to XX-XX, "*****"

(type 1) or XX-XX, "*****" (type 2).

3.CHECK PNP SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving

selector lever to each position.

OK or NG

OK >> GO TO 5

NG >> Check PNP switch circuit. Refer to TM-46, "

Component Inspection".

4.CHECK PNP SWITCH CIRCUIT

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

Item Connector TerminalOverdrive

control switch

ConditionJudge-

ment

standard

(Approx.)

A/T device harness

connector (Overdrive

control switch)M38 1 - GroundReleasedBattery

voltage

Depressed 0V

SCIA5336E

Monitor item Condition Display value

PN POSI SWWhen setting selector lever to “N” or “P” posi-

tion.ON

When setting selector lever to other positions. OFF

R POSITION SWWhen setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SWWhen setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SWWhen setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SWWhen setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

SAT701J

Page 5411 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-465

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSION NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-465

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSION](/img/5/57395/w960_57395-5410.png)

PRECAUTIONS

TM-465

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001723044

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001723045

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precaution for On Board Diagnosis (OBD) System of A/T and Engine (For Type1 Only)

INFOID:0000000001723046

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 5443 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SHIFT CONTROL SYSTEM

TM-497

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

1. Place the selector lever knob (1) in “N” position.

2. Slide knob cover (2) downward.

3. NISSAN TIIDA 2007 Service Repair Manual SHIFT CONTROL SYSTEM

TM-497

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

1. Place the selector lever knob (1) in “N” position.

2. Slide knob cover (2) downward.

3.](/img/5/57395/w960_57395-5442.png)

SHIFT CONTROL SYSTEM

TM-497

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

1. Place the selector lever knob (1) in “N” position.

2. Slide knob cover (2) downward.

3. Pull out lock pin (3) from selector lever knob (1).

4. Remove selector lever knob (1) and knob cover (2) as a set from

selector lever.

CAUTION:

Do not push selector button.

INSTALLATION

1. Insert lock pin (1) to selector lever knob (2).

2. Install knob cover (3) to selector lever knob (2).

3. Place the selector lever in “N” position.

4. Install selector lever knob over selector lever until a click is felt.

CAUTION:

Do not tilt selector lever knob when installing. Install it

straight, and do not tap or apply any shock to install it.

Do not push selector button.

Adjustment of A/T PositionINFOID:0000000001731424

Move selector lever from “P” position to “1” position. You should be able to feel the detents in each position. If

the detents cannot be felt or if the position indicator is improperly aligned, the control cable needs adjustment.

CAUTION:

Make sure that parking brake is applied before adjustment.

1. Remove the air duct assembly. Refer to EM-27, "

Removal and Installation".

2. Remove the control cable nut (A) and control cable (1) and

place the manual lever (2) in the "P' position.

3. Place selector lever in “P” position.

4. Hold control cable (1) at the end and pull it with a force of 9.8 N

(approximately 1 kg, 2.2 lb). Release the control cable and tem-

porarily tighten control cable nut (A).

5. Tighten control cable nut (A) to the specified torque.

CAUTION:

Secure manual lever when tightening nut.

6. Move selector lever from “P” to “1” position again. Make sure that selector lever moves smoothly.

7. Check A/T position. Refer to TM-497, "

Checking of A/T Position".

8. Install air duct assembly. Refer to EM-27, "

Removal and Installation".

Checking of A/T PositionINFOID:0000000001731425

1. Place selector lever in “P” position, and turn ignition switch ON (Do not start engine).

2. Make sure selector lever can be shifted to other than “P” position when brake pedal is depressed. Also

make sure selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move selector lever and check for excessive effort, sticking, noise or rattle.

4. Confirm selector lever stops at each position with the feel of engagement when it is moved through all the

positions. Check whether or not the actual position selector lever is in matches the position shown by the

shift position indicator and the transaxle.

SCIA6971E

SCIA6972E

Control cable nut : Refer to TM-493, "Control De-

vice Removal and Installation".WCIA0635E

Page 5444 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-498

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

SHIFT CONTROL SYSTEM

5. The method of operating selector lever to individual positions

correctly should be as shown.

(A): Press selector button to NISSAN TIIDA 2007 Service Repair Manual TM-498

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

SHIFT CONTROL SYSTEM

5. The method of operating selector lever to individual positions

correctly should be as shown.

(A): Press selector button to](/img/5/57395/w960_57395-5443.png)

TM-498

< ON-VEHICLE REPAIR >[TYPE 2 (4AT: RE4F03B)]

SHIFT CONTROL SYSTEM

5. The method of operating selector lever to individual positions

correctly should be as shown.

(A): Press selector button to operate selector lever, while

depressing the brake pedal.

(B): Press selector button to operate selector lever.

(C): Selector lever can be operated without pressing selector

button.

6. Confirm back-up lamps illuminate only when selector lever is

placed in “R” position. Confirm back-up lamps do not illuminate

when selector lever is in “P” or “N” position even if it is pushed

toward “R” position without pressing selector button.

7. Confirm engine can only be started with selector lever in “P” and

“N” positions.

8. Make sure A/T is locked completely in “P” position.

WCIA0636E

Page 5699 of 5883

![NISSAN TIIDA 2007 Service Repair Manual VTL-38

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

A/C UNIT ASSEMBLY

7. Remove console box assembly. Refer to IP-11, "Removal and Installation" .

8. Remove instrument stay nuts (A) and harness clamp NISSAN TIIDA 2007 Service Repair Manual VTL-38

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

A/C UNIT ASSEMBLY

7. Remove console box assembly. Refer to IP-11, "Removal and Installation" .

8. Remove instrument stay nuts (A) and harness clamp](/img/5/57395/w960_57395-5698.png)

VTL-38

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

A/C UNIT ASSEMBLY

7. Remove console box assembly. Refer to IP-11, "Removal and Installation" .

8. Remove instrument stay nuts (A) and harness clamps (B), and

then remove instrument stay (1).

9. Disconnect thermo control amp. connector (1).

10. Remove instrument panel and pad. Refer to IP-11, "

Removal and Installation".

11. Remove side ventilator ducts. Refer to VTL-48, "

Removal and Installation".

12. Remove center ventilator ducts. Refer to VTL-48, "

Removal and Installation".

13. Remove side kicking plates. Refer to INT-20, "

Removal and Installation".

14. Disconnect the fuel filler door cable and the rear hatch door cable.

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

Fill the cooling system. Refer to CO-11, "

Changing Engine Coolant" (HR16DE), CO-35, "Changing Engine

Coolant" (MR18DE), CO-58, "Refilling" (K9K).

Recharge the refrigerant.

CAUTION:

Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks.

SJIA0646E

SJIA0647E

A/C unit assembly bolt : 6.9 N·m (0.7 kg-m, 61 in-lb)

Steering member bolt : 12 N·m (1.25 kg-m, 9 ft-lb)

Steering column nut : Refer to ST-9, "

Removal and Installation".

Page 5772 of 5883

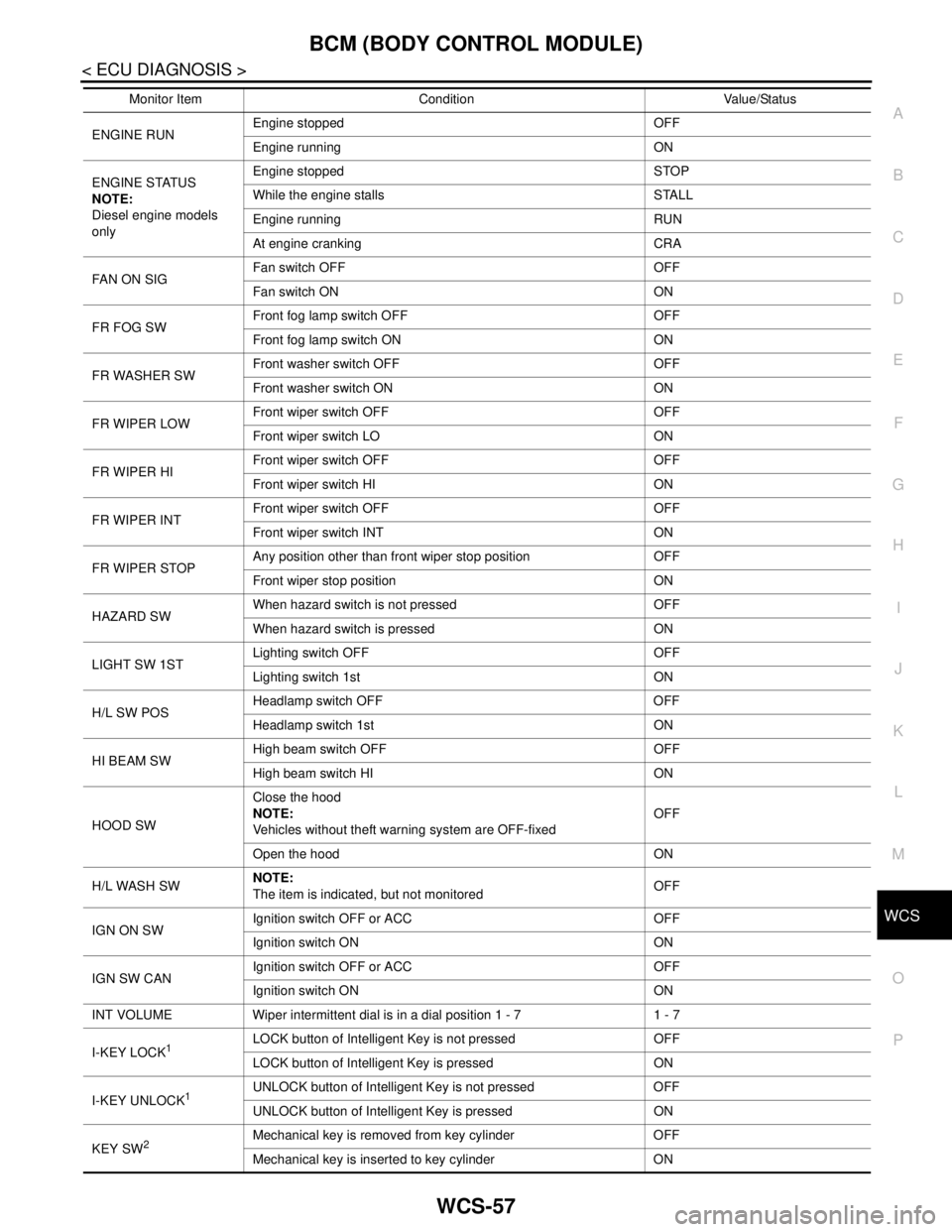

WCS

BCM (BODY CONTROL MODULE)

WCS-57

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

ENGINE RUNEngine stopped OFF

Engine running ON

ENGINE STATUS

NOTE:

Diesel engine models

onlyEngine stopped STOP

While the engine stalls STALL

Engine running RUN

At engine cranking CRA

FA N O N S IGFan switch OFF OFF

Fan switch ON ON

FR FOG SWFront fog lamp switch OFF OFF

Front fog lamp switch ON ON

FR WASHER SWFront washer switch OFF OFF

Front washer switch ON ON

FR WIPER LOWFront wiper switch OFF OFF

Front wiper switch LO ON

FR WIPER HIFront wiper switch OFF OFF

Front wiper switch HI ON

FR WIPER INTFront wiper switch OFF OFF

Front wiper switch INT ON

FR WIPER STOPAny position other than front wiper stop position OFF

Front wiper stop position ON

HAZARD SWWhen hazard switch is not pressed OFF

When hazard switch is pressed ON

LIGHT SW 1STLighting switch OFF OFF

Lighting switch 1st ON

H/L SW POSHeadlamp switch OFF OFF

Headlamp switch 1st ON

HI BEAM SWHigh beam switch OFF OFF

High beam switch HI ON

HOOD SWClose the hood

NOTE:

Vehicles without theft warning system are OFF-fixedOFF

Open the hood ON

H/L WASH SWNOTE:

The item is indicated, but not monitoredOFF

IGN ON SWIgnition switch OFF or ACC OFF

Ignition switch ON ON

IGN SW CANIgnition switch OFF or ACC OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK

1LOCK button of Intelligent Key is not pressed OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK

1UNLOCK button of Intelligent Key is not pressed OFF

UNLOCK button of Intelligent Key is pressed ON

KEY SW

2Mechanical key is removed from key cylinder OFF

Mechanical key is inserted to key cylinder ON Monitor Item Condition Value/Status

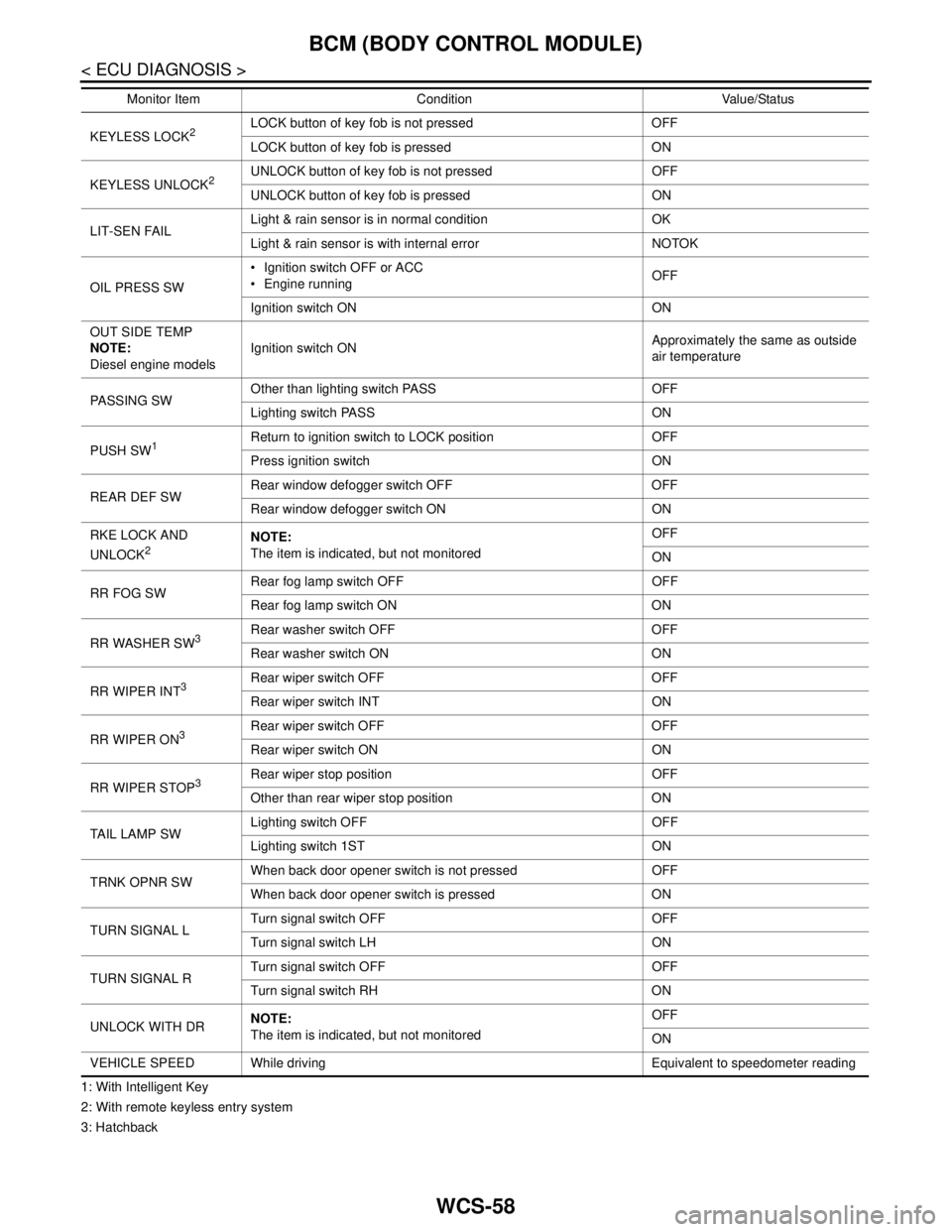

Page 5773 of 5883

WCS-58

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

1: With Intelligent Key

2: With remote keyless entry system

3: HatchbackKEYLESS LOCK

2LOCK button of key fob is not pressed OFF

LOCK button of key fob is pressed ON

KEYLESS UNLOCK

2UNLOCK button of key fob is not pressed OFF

UNLOCK button of key fob is pressed ON

LIT-SEN FAILLight & rain sensor is in normal condition OK

Light & rain sensor is with internal error NOTOK

OIL PRESS SW Ignition switch OFF or ACC

Engine runningOFF

Ignition switch ON ON

OUT SIDE TEMP

NOTE:

Diesel engine modelsIgnition switch ONApproximately the same as outside

air temperature

PASSING SWOther than lighting switch PASS OFF

Lighting switch PASS ON

PUSH SW

1Return to ignition switch to LOCK position OFF

Press ignition switch ON

REAR DEF SWRear window defogger switch OFF OFF

Rear window defogger switch ON ON

RKE LOCK AND

UNLOCK

2NOTE:

The item is indicated, but not monitoredOFF

ON

RR FOG SWRear fog lamp switch OFF OFF

Rear fog lamp switch ON ON

RR WASHER SW

3Rear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INT

3Rear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON

3 Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOP

3Rear wiper stop position OFF

Other than rear wiper stop position ON

TAIL LAMP SWLighting switch OFF OFF

Lighting switch 1ST ON

TRNK OPNR SWWhen back door opener switch is not pressed OFF

When back door opener switch is pressed ON

TURN SIGNAL LTurn signal switch OFF OFF

Turn signal switch LH ON

TURN SIGNAL RTurn signal switch OFF OFF

Turn signal switch RH ON

UNLOCK WITH DRNOTE:

The item is indicated, but not monitoredOFF

ON

VEHICLE SPEED While driving Equivalent to speedometer reading Monitor Item Condition Value/Status

Page 5804 of 5883

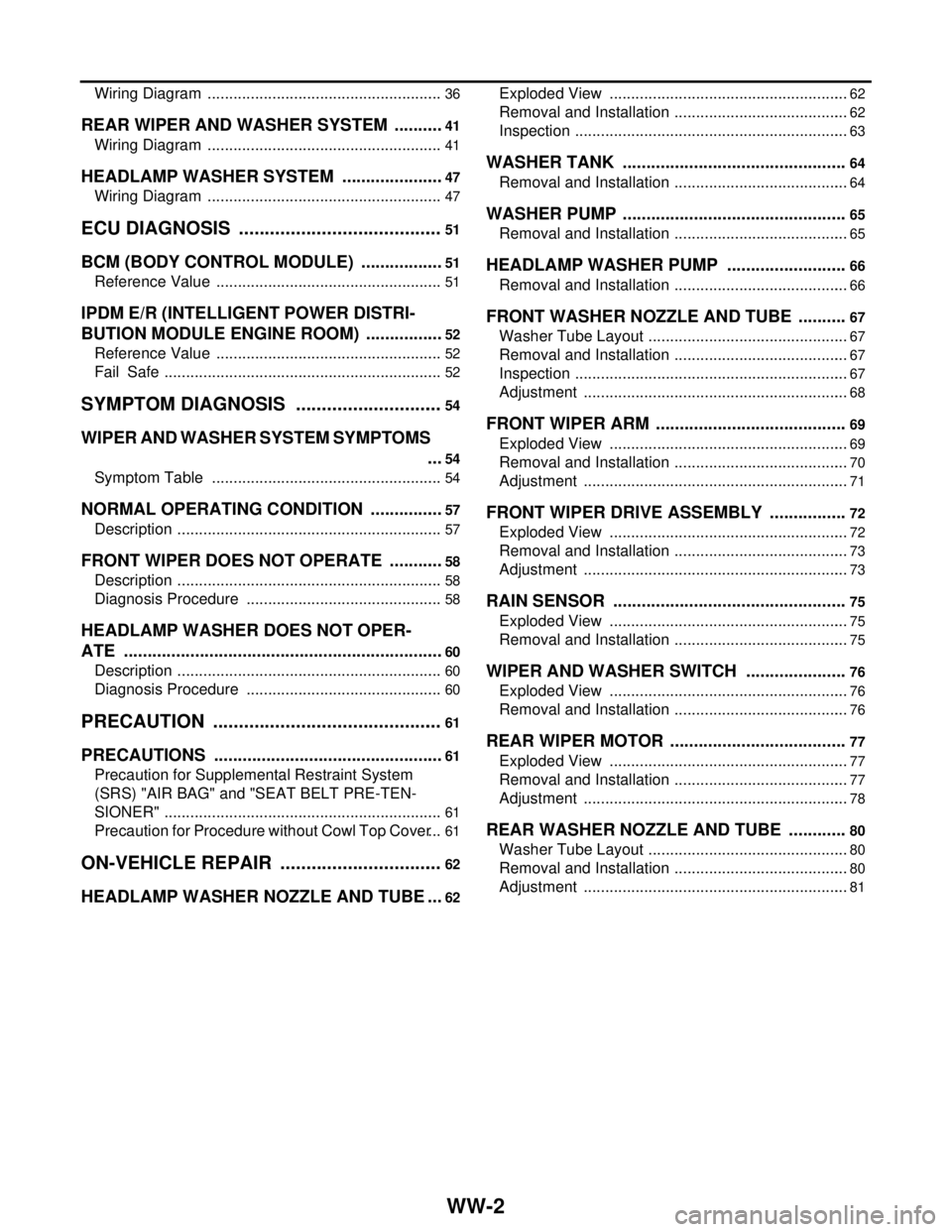

WW-2

Wiring Diagram .......................................................36

REAR WIPER AND WASHER SYSTEM ...........41

Wiring Diagram .......................................................41

HEADLAMP WASHER SYSTEM ......................47

Wiring Diagram .......................................................47

ECU DIAGNOSIS ........................................51

BCM (BODY CONTROL MODULE) ..................51

Reference Value .....................................................51

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

52

Reference Value .....................................................52

Fail Safe .................................................................52

SYMPTOM DIAGNOSIS .............................54

WIPER AND WASHER SYSTEM SYMPTOMS

...

54

Symptom Table ......................................................54

NORMAL OPERATING CONDITION ................57

Description ..............................................................57

FRONT WIPER DOES NOT OPERATE ............58

Description ..............................................................58

Diagnosis Procedure ..............................................58

HEADLAMP WASHER DOES NOT OPER-

ATE ....................................................................

60

Description ..............................................................60

Diagnosis Procedure ..............................................60

PRECAUTION .............................................61

PRECAUTIONS .................................................61

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

61

Precaution for Procedure without Cowl Top Cover ...61

ON-VEHICLE REPAIR ................................62

HEADLAMP WASHER NOZZLE AND TUBE ...62

Exploded View ........................................................62

Removal and Installation .........................................62

Inspection ................................................................63

WASHER TANK ................................................64

Removal and Installation .........................................64

WASHER PUMP ................................................65

Removal and Installation .........................................65

HEADLAMP WASHER PUMP ..........................66

Removal and Installation .........................................66

FRONT WASHER NOZZLE AND TUBE ...........67

Washer Tube Layout ...............................................67

Removal and Installation .........................................67

Inspection ................................................................67

Adjustment ..............................................................68

FRONT WIPER ARM .........................................69

Exploded View ........................................................69

Removal and Installation .........................................70

Adjustment ..............................................................71

FRONT WIPER DRIVE ASSEMBLY .................72

Exploded View ........................................................72

Removal and Installation .........................................73

Adjustment ..............................................................73

RAIN SENSOR ..................................................75

Exploded View ........................................................75

Removal and Installation .........................................75

WIPER AND WASHER SWITCH ......................76

Exploded View ........................................................76

Removal and Installation .........................................76

REAR WIPER MOTOR ......................................77

Exploded View ........................................................77

Removal and Installation .........................................77

Adjustment ..............................................................78

REAR WASHER NOZZLE AND TUBE .............80

Washer Tube Layout ...............................................80

Removal and Installation .........................................80

Adjustment ..............................................................81