tire pressure NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 49 of 5883

![NISSAN TIIDA 2007 Service Repair Manual AV-44

< FUNCTION DIAGNOSIS >[AUDIO WITH NAVIGATION]

DIAGNOSIS SYSTEM (NAVI CONTROL UNIT)

Select “SPEAKER TEST” to display the Speaker Diagnosis screen.

Press “START and NEXT” to generate a tes NISSAN TIIDA 2007 Service Repair Manual AV-44

< FUNCTION DIAGNOSIS >[AUDIO WITH NAVIGATION]

DIAGNOSIS SYSTEM (NAVI CONTROL UNIT)

Select “SPEAKER TEST” to display the Speaker Diagnosis screen.

Press “START and NEXT” to generate a tes](/img/5/57395/w960_57395-48.png)

AV-44

< FUNCTION DIAGNOSIS >[AUDIO WITH NAVIGATION]

DIAGNOSIS SYSTEM (NAVI CONTROL UNIT)

Select “SPEAKER TEST” to display the Speaker Diagnosis screen.

Press “START and NEXT” to generate a test tone in a speaker.

Press “Start” to generate a test tone in the next speaker. Press

“Stop” to stop the test tones.

NOTE:

The frequency of test tone emitted from each speaker is as follows.

Navigation

STEERING ANGLE ADJUSTMENT

The steering angle output value detected with the gyroscope is

adjusted.

SPEED CALIBRATION

During normal driving, distance error caused by tire wear and tire

pressure change is automatically adjusted for by the automatic dis-

tance correction function. This function, on the other hand, is for

immediate adjustment, in cases such as driving with tire chain fitted

on tires.

ERROR HISTORY

The diagnostic results of “Self-diagnosis” determine if any malfunction occurred between selecting “Self-diag-

nosis” and displaying “Self-diagnostic Results”.

The trouble diagnosis result will be judged normal if an error occurred before the ignition switch was turned

ON and does not occur again until “Self-diagnosis” is completed. Therefore, errors in the past which cannot be

found by “Self-diagnosis”, must be found by checking the “Error record”.

The error history shows the error occurrence frequency in past. The frequency of occurrence is displayed by 2

types: the count down type and the count up type. Select either type according to the error item.

In “Error History” of models with NAVI, time and place that the selected error last occurred are displayed. Be

careful about the following.

The correct date of occurrence may not be able to be displayed if there is a malfunction with the GPS

antenna circuit board in the NAVI control unit.

Place of the error occurrence is represented by the position of the current location mark at the time an error

occurred. If current location mark has deviated from the correct position, then the place of the error occur-

rence cannot be located correctly.Tweeter : 3 kHz

Front door speaker : 300 Hz

Rear door speaker : 1 kHz

SKIB4686E

SKIB3684E

SKIB3685E

Page 122 of 5883

![NISSAN TIIDA 2007 Service Repair Manual AV

NORMAL OPERATING CONDITION

AV-117

< SYMPTOM DIAGNOSIS >[AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

THE CURRENT POSITION MARK SHOWS A POSITION THAT IS COMPLETELY INCORRECT.

In the following NISSAN TIIDA 2007 Service Repair Manual AV

NORMAL OPERATING CONDITION

AV-117

< SYMPTOM DIAGNOSIS >[AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

THE CURRENT POSITION MARK SHOWS A POSITION THAT IS COMPLETELY INCORRECT.

In the following](/img/5/57395/w960_57395-121.png)

AV

NORMAL OPERATING CONDITION

AV-117

< SYMPTOM DIAGNOSIS >[AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

THE CURRENT POSITION MARK SHOWS A POSITION THAT IS COMPLETELY INCORRECT.

In the following cases, the current location mark may be displayed in a completely incorrect location. If so, per-

form position/direction correction.

When location correction has not been done

- It may shift to a completely unexpected location and not return unless location correction is performed if

GPS satellite reception is poor and the current location mark slips out of place. The position will be corrected

if a GPS signal can be received.

When vehicle is traveled by ferry, or when vehicle is towed.

- Because calculation of the current location cannot be done when traveling with the ignition OFF, for example

when traveling by ferry or when being towed, the location before travel is displayed. The location will be cor-

rected if the precise location can be detected with GPS.

Ve h i c l eUse of tire chains

The vehicle mark may deviate from

the correct road.Drive the vehicle for a while. Adjust

it with the distance adjustment func-

tion if distance still deviates. (Re-

cover the original value if tire chains

are removed.)

Use of tires other than the specified sizeReplace all tires with the specified

size tire.

Malfunctioning air pressure of tireAdjust all tires to the specified air

pressure.

Replace tireDrive the vehicle for a while. It ad-

justs with the distance adjustment

function if the distance is still not in

the correct location.

Driving man-

nerJust after the engine is startedThe vehicle can be shown in the in-

correct direction and may deviate

from the correct location if vehicle is

driven off just after the engine is

started when gyroscope (angular

speed sensor) correction is not com-

pleted.Wait for a short while before driving

after starting the engine.

Continuous driving without stoppingDirection errors may accumulate,

and the current location mark may

deviate from the correct road when

driving long distances without stop-

ping.Stop and adjust orientation.

Abusive drivingSpinning the wheels or engaging in

other kinds of abusive driving may

result in the system being unable

perform correct detection, and may

cause the vehicle mark to deviate

from the correct road.Perform location correction and, if

necessary, direction correction if af-

ter traveling about 10 km/h (6 MPH)

the correct location has not been re-

stored.

Position cor-

rection

methodPosition correction accuracy

Accuracy may be reduced when cor-

rect road cannot be found, particu-

larly in places where there are many

roads if accuracy of location settings

is poor.From the roads displayed on the

screen, input a position within an

accuracy of 1mm (0.04 in).

CAUTION:

When correcting, use the most

detailed map possible.

Direction when location is corrected

Accuracy may be reduced after-

wards if accuracy of location set-

tings during correction is poor.Perform direction correction. Cause (condition) Driving condition Remarks (correction, etc.)

SEL701V

SEL702V

Page 221 of 5883

REAR DISC BRAKE

BR-29

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

3. Drain brake fluid. Refer to BR-8, "Bleeding Brake System".

4. Remove connecting bolt and torque member bolts using power tool, and remove cylinder body.

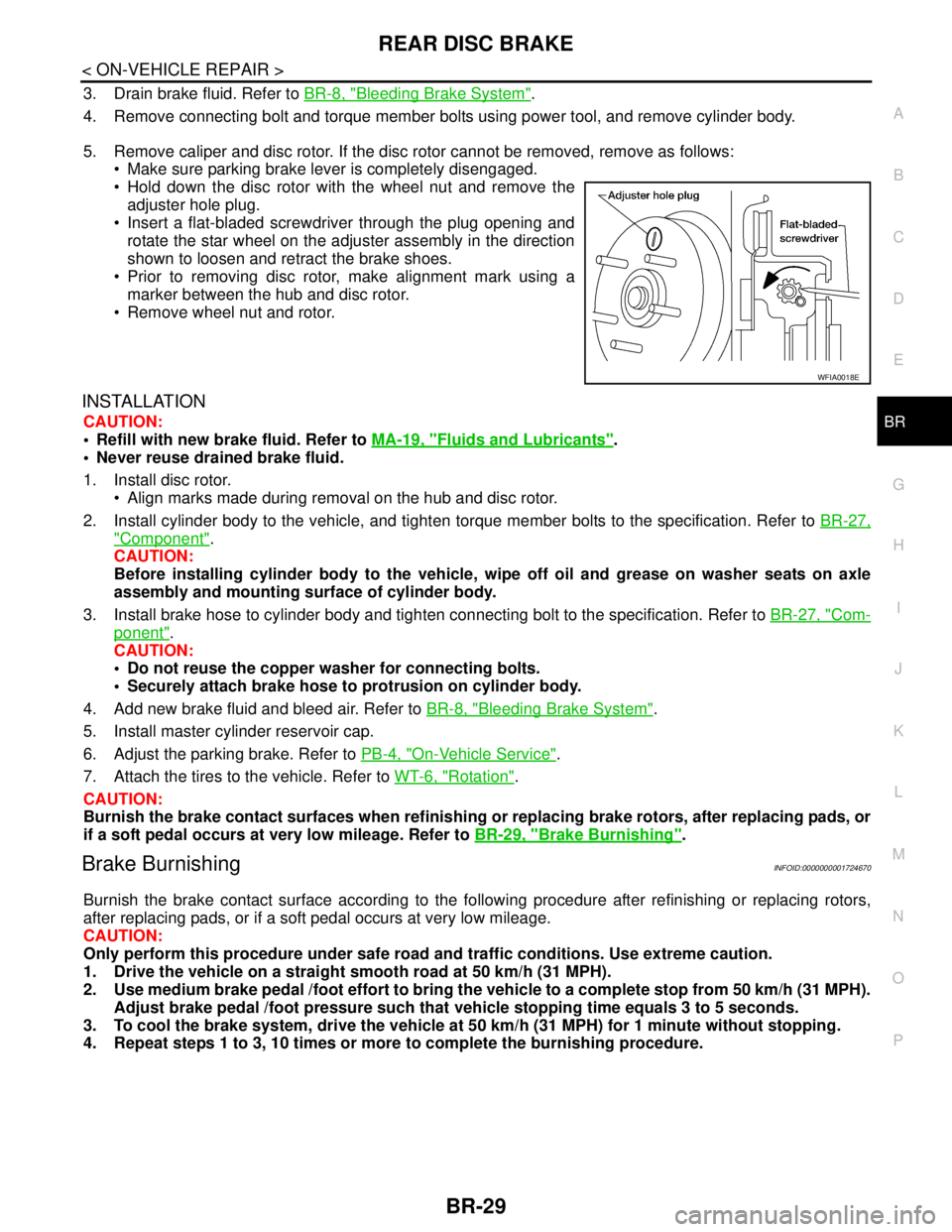

5. Remove caliper and disc rotor. If the disc rotor cannot be removed, remove as follows:

Make sure parking brake lever is completely disengaged.

Hold down the disc rotor with the wheel nut and remove the

adjuster hole plug.

Insert a flat-bladed screwdriver through the plug opening and

rotate the star wheel on the adjuster assembly in the direction

shown to loosen and retract the brake shoes.

Prior to removing disc rotor, make alignment mark using a

marker between the hub and disc rotor.

Remove wheel nut and rotor.

INSTALLATION

CAUTION:

Refill with new brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

1. Install disc rotor.

Align marks made during removal on the hub and disc rotor.

2. Install cylinder body to the vehicle, and tighten torque member bolts to the specification. Refer to BR-27,

"Component".

CAUTION:

Before installing cylinder body to the vehicle, wipe off oil and grease on washer seats on axle

assembly and mounting surface of cylinder body.

3. Install brake hose to cylinder body and tighten connecting bolt to the specification. Refer to BR-27, "

Com-

ponent".

CAUTION:

Do not reuse the copper washer for connecting bolts.

Securely attach brake hose to protrusion on cylinder body.

4. Add new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System".

5. Install master cylinder reservoir cap.

6. Adjust the parking brake. Refer to PB-4, "

On-Vehicle Service".

7. Attach the tires to the vehicle. Refer to WT-6, "

Rotation".

CAUTION:

Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing pads, or

if a soft pedal occurs at very low mileage. Refer to BR-29, "

Brake Burnishing".

Brake BurnishingINFOID:0000000001724670

Burnish the brake contact surface according to the following procedure after refinishing or replacing rotors,

after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31 MPH).

2. Use medium brake pedal /foot effort to bring the vehicle to a complete stop from 50 km/h (31 MPH).

Adjust brake pedal /foot pressure such that vehicle stopping time equals 3 to 5 seconds.

3. To cool the brake system, drive the vehicle at 50 km/h (31 MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3, 10 times or more to complete the burnishing procedure.

WFIA0018E

Page 264 of 5883

![NISSAN TIIDA 2007 Service Repair Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-31

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS NISSAN TIIDA 2007 Service Repair Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-31

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS](/img/5/57395/w960_57395-263.png)

C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-31

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-83, "

Removal and Installation".

3.CHECK TIRES

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FAX-7, "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11.

Is the inspection result normal?

YES >> Replace the ABS actuator and electric unit (control unit). Refer to BRC-85, "Removal and Installa-

tion".

NO >> Repair the circuit.Continuity should not exist.

WFIA0343E

Wheel sensorABS actuator and

electric unit (control unit)Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E181

Ye s 46 2

Front RH34

E1171

33 2

Rear LH37

C112

36 1

Rear RH42

C102

43 1

Page 267 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-34

< COMPONENT DIAGNOSIS >[ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate a NISSAN TIIDA 2007 Service Repair Manual BRC-34

< COMPONENT DIAGNOSIS >[ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate a](/img/5/57395/w960_57395-266.png)

BRC-34

< COMPONENT DIAGNOSIS >[ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch.

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-83, "

Removal and Installation".

3.CHECK TIRES

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-5, "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FA X - 7 , "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11. Continuity should not exist.

WFIA0343E

Page 275 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-42

< COMPONENT DIAGNOSIS >[ABS]

C1115 WHEEL SENSOR

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO NISSAN TIIDA 2007 Service Repair Manual BRC-42

< COMPONENT DIAGNOSIS >[ABS]

C1115 WHEEL SENSOR

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO](/img/5/57395/w960_57395-274.png)

BRC-42

< COMPONENT DIAGNOSIS >[ABS]

C1115 WHEEL SENSOR

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-6, "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FA X - 7 , "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11.

Is the inspection result normal?

YES >> Replace the ABS actuator and electric unit (control unit). Refer to BRC-85, "Removal and Installa-

tion".

NO >> Repair the circuit.

Component InspectionINFOID:0000000001731255

1.CHECK DATA MONITOR

On “DATA MONITOR”, select “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR”, and “RR RH SEN-

SOR”, and check the vehicle speed.Continuity should not exist.

WFIA0343E

Wheel sensorABS actuator and

electric unit (control unit)Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E181

Ye s 46 2

Front RH34

E1171

33 2

Rear LH37

C112

36 1

Rear RH42

C102

43 1

Wheel sensor Vehicle speed (DATA MONITOR)

Page 299 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-66

< ECU DIAGNOSIS >[ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

NOTE:

1: Confirm tire pressure is normal.

2: Only 4WD models.

3: On and off timing for warning lamp and indicator lamp NISSAN TIIDA 2007 Service Repair Manual BRC-66

< ECU DIAGNOSIS >[ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

NOTE:

1: Confirm tire pressure is normal.

2: Only 4WD models.

3: On and off timing for warning lamp and indicator lamp](/img/5/57395/w960_57395-298.png)

BRC-66

< ECU DIAGNOSIS >[ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

NOTE:

1: Confirm tire pressure is normal.

2: Only 4WD models.

3: On and off timing for warning lamp and indicator lamp.

- ABS warning lamp: Refer to BRC-60, "

Description".

- Brake warning lamp: Refer to BRC-61, "

Description".

- VDC OFF indicator lamp: Refer to XX-XX, "*****"

.

- SLIP indicator lamp: Refer to XX-XX, "*****"

.

TERMINAL LAYOUT

DELTA S SEN Value detected by delta stroke sensorWhen brake pedal is depressed 1.05 - 1.80 mm

When brake pedal is released 0.00 mm (+0.6/-0.4)

RELEASE SWITCH

NO Active booster signal statusWhen brake pedal is depressed ON

When brake pedal is released OFF

RELEASE SWITCH

NC Active booster signal statusWhen brake pedal is depressed OFF

When brake pedal is released ON Monitor item Display contentData monitor

ConditionReference value in

normal operation

AWFIA0032ZZ

Page 312 of 5883

![NISSAN TIIDA 2007 Service Repair Manual NORMAL OPERATING CONDITION

BRC-79

< SYMPTOM DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000001731350

Symptom Result

Slight vibrations are felt on NISSAN TIIDA 2007 Service Repair Manual NORMAL OPERATING CONDITION

BRC-79

< SYMPTOM DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000001731350

Symptom Result

Slight vibrations are felt on](/img/5/57395/w960_57395-311.png)

NORMAL OPERATING CONDITION

BRC-79

< SYMPTOM DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000001731350

Symptom Result

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC, TCS or ABS is acti-

vated.

This is a normal condi-

tion due to the VDC,

TCS or ABS activation. Stopping distance is longer than that of vehicles without ABS when the vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

The brake pedal moves and generates noises, when TCS or VDC is activated due to rapid acceleration or

sharp turn.

The brake pedal vibrates and motor operation noises occur from the engine room, after the engine starts and

just after the vehicle starts.This is normal, and it is

caused by the ABS op-

eration check.

Depending on the road conditions, the driver may experience a sluggish feel. This is normal, because

TCS places the highest

priority on the optimum

traction (stability). TCS may activate momentarily if wheel speed changes when driving over location where friction coefficient

varies, when downshifting, or when fully depressing accelerator pedal.

The ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp may turn ON when the vehicle is

subject to strong shaking or large vibration, such as when the vehicle is rotating on a turntable or located on

a ship while the engine is running. In this case, restart the

engine on a normal

road. If the normal con-

dition is restored, there

is no malfunction. At

that time, erase the self-

diagnosis memory. VDC may not operate normally or the ABS warning lamp, VDC OFF indicator lamp, and SLIP indicator lamp

may illuminate, when running on a special road that is extremely slanted (e.g. bank in a circuit course).

A malfunction may occur in the yaw rate/side/decel G sensor system, when the vehicle turns sharply, such

as during a spin turn, axle turn, or drift driving, while the VDC function is off (VDC OFF indicator lamp illumi-

nated).

The vehicle speed will not increase even though the accelerator pedal is depressed, when inspecting the

speedometer on a 2-wheel chassis dynamometer. Normal (Deactivate the

VDC/TCS function be-

fore performing an in-

spection on a chassis

dynamometer.)

VDC OFF indicator lamp and SLIP indicator lamp may simultaneously turn on when low tire pressure warn-

ing lamp turns on.This is not a VDC sys-

tem error but results

from characteristic

change of tire.

Page 344 of 5883

![NISSAN TIIDA 2007 Service Repair Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-111

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on NISSAN TIIDA 2007 Service Repair Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-111

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on](/img/5/57395/w960_57395-343.png)

C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-111

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-182, "

Removal and Installation".

3.CHECK TIRES

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FA X - 5 , "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FAX-7, "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11.

Is the inspection result normal?

YES >> Replace the ABS actuator and electric unit (control unit). Refer to BRC-184, "Removal and Instal-

lation".

NO >> Repair the circuit.Continuity should not exist.

WFIA0343E

Wheel sensorABS actuator and

electric unit (control unit)Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E181

Ye s 46 2

Front RH34

E1171

33 2

Rear LH37

C112

36 1

Rear RH42

C102

43 1

Page 347 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-114

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appr NISSAN TIIDA 2007 Service Repair Manual BRC-114

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appr](/img/5/57395/w960_57395-346.png)

BRC-114

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch.

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-182, "

Removal and Installation".

3.CHECK TIRES

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-5, "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FA X - 7 , "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11. Continuity should not exist.

WFIA0343E