air conditioning NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 1 of 5883

MODEL C11 SERIES

2007 NISSAN EUROPE S.A.S.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form,

or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Europe

S.A.S., Paris, France.

A GENERAL INFORMATION

B ENGINE

D TRANSMISSION& DRIVELINE

E SUSPENSION F BRAKES

G STEERING H RESTRAINTS

I VENTILATION, HEATER & AIR CONDITIONER

J BODY INTERIOR

K BODY EXTERIOR, DOOR, ROOF & VEHICLE SECURITY

L DRIVER CONTROLS

M ELECTRICAL & POWER CONTROL

N DRIVER INFORMATION & MULTIMEDIA

O CRUISE CONTROL P MAINTENANCEGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

STR Starting System

ACC Accelerator Control System

CL Clutch

TM Transaxle & Transmission

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

ST Steering System

STC Steering Control System

SB Seat Belt

SR SRS Airbag

SRC SRS Airbag Control System

VTL Ventilation System

HA Heater & Air Conditioning System

HAC Heater & Air Conditioning Control System

INT Interior

IP Instrument Panel

SE Seat

DLK Door & Lock

SEC Security Control System

GW Glass & Window System

PWC Power Window Control System

RF Roof

EXT Exterior

MIR Mirrors

EXL Exterior Lighting System

INL Interior Lighting System

WW Wiper & Washer

DEF Defogger

HRN Horn

PWO Power Outlet

BCS Body Control System

LAN LAN System

PCS Power Control System

CHG Charging System

PG Power Supply, Ground & Circuit Elements

MWI Meter, Warning Lanp & Indicator

WCS Warning Chime System

AV Audio, Visual & Navigation System

CCS Cruise Control System Maintenance

MA Maintenance

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM7E00-1C11E0E

Page 1350 of 5883

EC-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

N

O

P

CONTENTS

ENGINE CONTROL SYSTEM

HR16DE (WITH EURO-OBD)

BASIC INSPECTION ...................................

18

DIAGNOSIS AND REPAIR WORKFLOW .........18

Work Flow ...............................................................18

Diagnostic Work Sheet ............................................20

INSPECTION AND ADJUSTMENT ....................22

BASIC INSPECTION .................................................22

BASIC INSPECTION : Special Repair Require-

ment ........................................................................

22

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ........................................................

25

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

25

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

25

IDLE SPEED ..............................................................25

IDLE SPEED : Description ......................................26

IDLE SPEED : Special Repair Requirement ...........26

IGNITION TIMING ......................................................26

IGNITION TIMING : Description ..............................26

IGNITION TIMING : Special Repair Requirement ....26

ACCELERATOR PEDAL RELEASED POSITION

LEARNING ................................................................

26

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Description .........................................

26

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement ..............

26

THROTTLE VALVE CLOSED POSITION LEARN-

ING .............................................................................

27

THROTTLE VALVE CLOSED POSITION

LEARNING : Description .........................................

27

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repair Requirement ..............

27

IDLE AIR VOLUME LEARNING ................................27

IDLE AIR VOLUME LEARNING : Description .........27

IDLE AIR VOLUME LEARNING : Special Repair

Requirement ............................................................

27

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR .......................................................................

29

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ................................................

29

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement .....................

29

FUNCTION DIAGNOSIS ..............................30

ENGINE CONTROL SYSTEM ..........................30

System Diagram .....................................................30

System Description ..................................................31

Component Parts Location ....................................31

Component Description ...........................................36

MULTIPORT FUEL INJECTION SYSTEM .......38

System Diagram .....................................................38

System Description ..................................................38

Component Parts Location ....................................41

Component Description ...........................................46

ELECTRIC IGNITION SYSTEM ........................47

System Diagram .....................................................47

System Description ..................................................47

Component Parts Location ....................................48

Component Description ...........................................53

AIR CONDITIONING CUT CONTROL ..............54

System Diagram ......................................................54

System Description ..................................................54

Component Parts Location ....................................55

Component Description ...........................................60

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ..............................................................

61

System Diagram ......................................................61

System Description ..................................................61

Page 1355 of 5883

EC-6

IDLE AIR VOLUME LEARNING : Special Repair

Requirement ..........................................................

390

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR .....................................................................

392

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ..............................................

392

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement ...................

392

FUNCTION DIAGNOSIS ............................393

ENGINE CONTROL SYSTEM .........................393

System Diagram ...................................................393

System Description ................................................394

Component Parts Location ..................................394

Component Description .........................................399

MULTIPORT FUEL INJECTION SYSTEM ......401

System Diagram ...................................................401

System Description ................................................401

Component Parts Location ..................................404

Component Description .........................................409

ELECTRIC IGNITION SYSTEM .......................410

System Diagram ...................................................410

System Description ................................................410

Component Parts Location ..................................411

Component Description .........................................416

AIR CONDITIONING CUT CONTROL ............417

System Diagram ....................................................417

System Description ................................................417

Component Parts Location ..................................418

Component Description .........................................423

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) .............................................................

424

System Diagram ....................................................424

System Description ................................................424

Component Parts Location ..................................426

Component Description ........................................431

CAN COMMUNICATION .................................432

System Description ................................................432

COOLING FAN CONTROL .............................433

System Diagram ....................................................433

System Description ................................................433

Component Parts Location ..................................435

Component Description .........................................440

EVAPORATIVE EMISSION SYSTEM .............441

System Diagram ....................................................441

System Description ................................................443

Component Parts Location ..................................444

Component Description ........................................449

INTAKE VALVE TIMING CONTROL ...............450

System Diagram ....................................................450

System Description ................................................450

Component Parts Location ..................................451

Component Description ........................................456

DIAGNOSIS SYSTEM (ECM) ...........................457

Diagnosis Description ...........................................457

CONSULT-III Function ..........................................462

COMPONENT DIAGNOSIS ......................469

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ..............................................................

469

Description ............................................................469

Component Function Check .................................469

Diagnosis Procedure .............................................470

POWER SUPPLY AND GROUND CIRCUIT ....477

Diagnosis Procedure .............................................477

U1000, U1001 CAN COMM CIRCUIT ..............481

Description ............................................................481

DTC Logic .............................................................481

Diagnosis Procedure .............................................481

U1010 CONTROL UNIT (CAN) ........................482

Description ............................................................482

DTC Logic .............................................................482

Diagnosis Procedure .............................................482

P0011 IVT CONTROL ......................................483

DTC Logic .............................................................483

Component Function Check .................................484

Diagnosis Procedure .............................................484

Component Inspection ..........................................486

P0102, P0103 MAF SENSOR ..........................487

Description ............................................................487

DTC Logic .............................................................487

Diagnosis Procedure .............................................488

Component Inspection ..........................................489

P0117, P0118 ECT SENSOR ...........................492

Description ............................................................492

DTC Logic .............................................................492

Diagnosis Procedure .............................................493

Component Inspection ..........................................493

P0122, P0123 TP SENSOR ..............................495

Description ............................................................495

DTC Logic .............................................................495

Diagnosis Procedure .............................................495

Component Inspection ..........................................497

Special Repair Requirement .................................497

P0132 HO2S1 ...................................................498

Description ............................................................498

DTC Logic .............................................................498

Diagnosis Procedure .............................................499

Component Inspection ..........................................500

P0134 HO2S1 ...................................................502

Description ............................................................502

DTC Logic .............................................................502

Page 1359 of 5883

EC-10

FUNCTION DIAGNOSIS ............................697

ENGINE CONTROL SYSTEM .........................697

System Diagram ...................................................697

System Description ................................................698

Component Parts Location ..................................698

Component Description .........................................703

MULTIPORT FUEL INJECTION SYSTEM ......705

System Diagram ...................................................705

System Description ................................................705

Component Parts Location ..................................708

Component Description .........................................713

ELECTRIC IGNITION SYSTEM .......................714

System Diagram ...................................................714

System Description ................................................714

Component Parts Location ..................................715

Component Description .........................................720

AIR CONDITIONING CUT CONTROL ............721

System Diagram ....................................................721

System Description ................................................721

Component Parts Location ..................................722

Component Description .........................................727

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) .............................................................

728

System Diagram ....................................................728

System Description ................................................728

Component Parts Location ..................................730

Component Description ........................................735

CAN COMMUNICATION .................................736

System Description ................................................736

COOLING FAN CONTROL .............................737

System Diagram ....................................................737

System Description ................................................737

Component Parts Location ..................................739

Component Description .........................................744

EVAPORATIVE EMISSION SYSTEM .............745

System Diagram ....................................................745

System Description ................................................746

Component Parts Location ..................................747

Component Description ........................................752

INTAKE VALVE TIMING CONTROL ...............753

System Diagram ....................................................753

System Description ................................................753

Component Parts Location ..................................754

Component Description .........................................759

ON BOARD DIAGNOSTIC (OBD) SYSTEM ...760

Diagnosis Description ............................................760

CONSULT-III Function ..........................................772

Diagnosis Tool Function ......................................779

COMPONENT DIAGNOSIS .......................781

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ..............................................................

781

Description ............................................................781

Component Function Check .................................781

Diagnosis Procedure .............................................782

POWER SUPPLY AND GROUND CIRCUIT ....789

Diagnosis Procedure .............................................789

U1000, U1001 CAN COMM CIRCUIT ..............793

Description ............................................................793

DTC Logic .............................................................793

Diagnosis Procedure .............................................793

U1010 CONTROL UNIT (CAN) ........................794

Description ............................................................794

DTC Logic .............................................................794

Diagnosis Procedure .............................................794

P0011 IVT CONTROL ......................................795

DTC Logic .............................................................795

Diagnosis Procedure .............................................796

Component Inspection ..........................................797

P0102, P0103 MAF SENSOR ..........................799

Description ............................................................799

DTC Logic .............................................................799

Diagnosis Procedure .............................................800

Component Inspection ..........................................801

P0112, P0113 IAT SENSOR ............................804

Description ............................................................804

DTC Logic .............................................................804

Diagnosis Procedure .............................................805

Component Inspection ..........................................805

P0117, P0118 ECT SENSOR ...........................807

Description ............................................................807

DTC Logic .............................................................807

Diagnosis Procedure .............................................808

Component Inspection ..........................................808

P0122, P0123 TP SENSOR ..............................810

Description ............................................................810

DTC Logic .............................................................810

Diagnosis Procedure .............................................810

Component Inspection ..........................................812

Special Repair Requirement .................................812

P0132 HO2S1 ...................................................813

Description ............................................................813

DTC Logic .............................................................813

Diagnosis Procedure .............................................814

Component Inspection ..........................................815

P0133 HO2S1 ...................................................817

Description ............................................................817

DTC Logic .............................................................817

Diagnosis Procedure .............................................819

Component Inspection ..........................................820

Page 1376 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

EC-27

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

quirementINFOID:0000000001161131

1.START

1. Make sure that accelerator pedal is fully relea NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

EC-27

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

quirementINFOID:0000000001161131

1.START

1. Make sure that accelerator pedal is fully relea](/img/5/57395/w960_57395-1375.png)

INSPECTION AND ADJUSTMENT

EC-27

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

quirementINFOID:0000000001161131

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

>> END

THROTTLE VALVE CLOSED POSITION LEARNING

THROTTLE VALVE CLOSED POSITION LEARNING : DescriptionINFOID:0000000001161132

Throttle Valve Closed Position Learning is a function of ECM to learn the fully closed position of the throttle

valve by monitoring the throttle position sensor output signal. It must be performed each time harness connec-

tor of electric throttle control actuator or ECM is disconnected.

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement

INFOID:0000000001161133

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

>> END

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING : DescriptionINFOID:0000000001161134

Idle Air Volume Learning is a function of ECM to learn the idle air volume that keeps each engine idle speed

within the specific range. It must be performed under any of the following conditions:

Each time electric throttle control actuator or ECM is replaced.

Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING : Special Repair RequirementINFOID:0000000001161135

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

Battery voltage: More than 12.9V (At idle)

Engine coolant temperature: 70 - 100°C (158 - 212°F)

Park/neutral position switch: ON

Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting switch to the 1st position to light only

small lamps.

Steering wheel: Neutral (Straight-ahead position)

Vehicle speed: Stopped

Transmission: Warmed-up

- For A/T models with CONSULT-III

Drive vehicle until “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indicates less than 0.9V.

- For A/T models without CONSULT-III and M/T models.

Drive vehicle for 10 minutes

Do you have CONSULT-III?

YES >> GO TO 2.

Page 1403 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-54

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000001161150

System DescriptionINFOID:0000000001161151

INPUT/OUT NISSAN TIIDA 2007 Service Repair Manual EC-54

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000001161150

System DescriptionINFOID:0000000001161151

INPUT/OUT](/img/5/57395/w960_57395-1402.png)

EC-54

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000001161150

System DescriptionINFOID:0000000001161151

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

When the accelerator pedal is fully depressed.

When cranking the engine.

At high engine speeds.

When the engine coolant temperature becomes excessively high.

When operating power steering during low engine speed or low vehicle speed.

When engine speed is excessively low.

JMBIA0175GB

Sensor Input Signal to ECM ECM function Actuator

BCM*

1Air conditioner ON signal

Air conditioner

cut controlIPDM E/R

↓

Air conditioner relay

↓

Compressor Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

EPS control unit*

1Power steering operation

Combination meter*

1Vehicle speed

Page 1404 of 5883

![NISSAN TIIDA 2007 Service Repair Manual AIR CONDITIONING CUT CONTROL

EC-55

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

When refrigerant pressure is excessively low or high.

Component Parts LocationINFOID NISSAN TIIDA 2007 Service Repair Manual AIR CONDITIONING CUT CONTROL

EC-55

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

When refrigerant pressure is excessively low or high.

Component Parts LocationINFOID](/img/5/57395/w960_57395-1403.png)

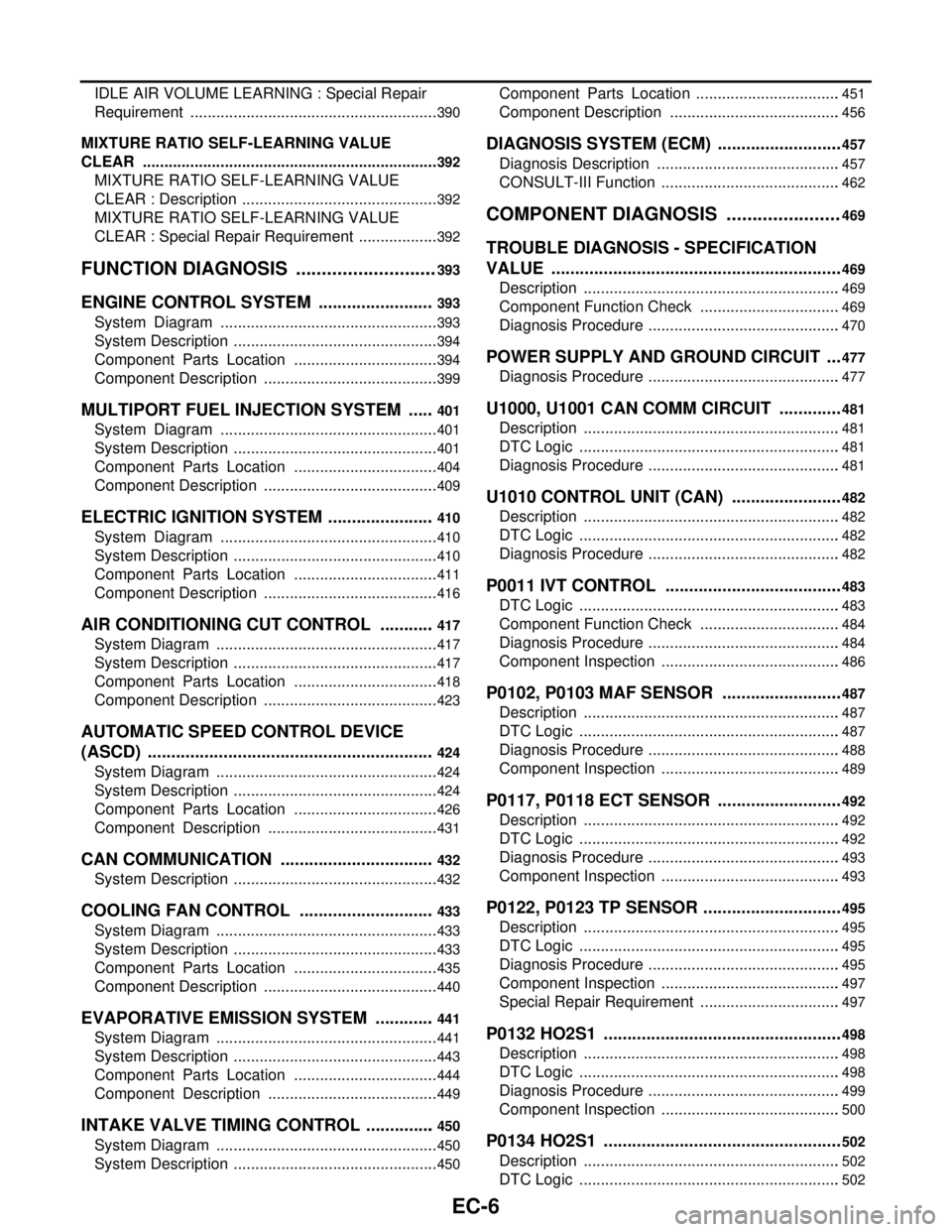

AIR CONDITIONING CUT CONTROL

EC-55

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

When refrigerant pressure is excessively low or high.

Component Parts LocationINFOID:0000000001677954

1. Ignition coil (with power transistor)

and spark plug2. Intake valve timing control solenoid

valve3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air

temperature sensor)11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control

solenoid valve

PBIB2939E

Page 1405 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-56

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor

(with intake air temperature sensor)2. Engine coolant temperature sensor 3. Electric throttle NISSAN TIIDA 2007 Service Repair Manual EC-56

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor

(with intake air temperature sensor)2. Engine coolant temperature sensor 3. Electric throttle](/img/5/57395/w960_57395-1404.png)

EC-56

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor

(with intake air temperature sensor)2. Engine coolant temperature sensor 3. Electric throttle control actuator

4. Camshaft position sensor (PHASE) 5. Ignition coil (with power transistor) 6. Fuel injector

7. EVAP canister purge volume control

solenoid valve

Vehicle front

PBIB2940E

Page 1406 of 5883

![NISSAN TIIDA 2007 Service Repair Manual AIR CONDITIONING CUT CONTROL

EC-57

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. ECM harness connectors 2. ECM 3. IPDM E/R

4. Fuel pump fuse (15A) 5. Intake valve t NISSAN TIIDA 2007 Service Repair Manual AIR CONDITIONING CUT CONTROL

EC-57

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. ECM harness connectors 2. ECM 3. IPDM E/R

4. Fuel pump fuse (15A) 5. Intake valve t](/img/5/57395/w960_57395-1405.png)

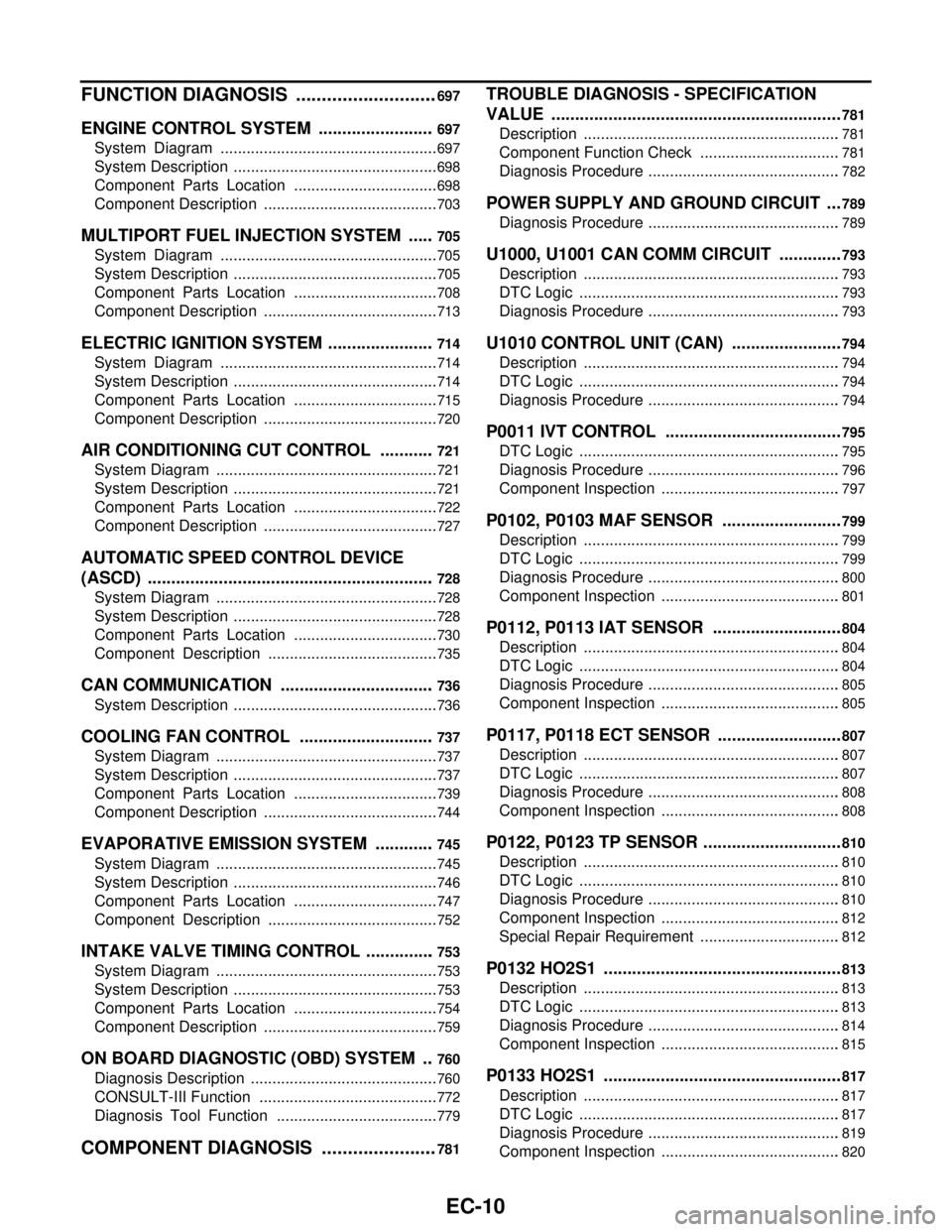

AIR CONDITIONING CUT CONTROL

EC-57

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. ECM harness connectors 2. ECM 3. IPDM E/R

4. Fuel pump fuse (15A) 5. Intake valve timing control solenoid

valve6. Knock sensor

7. Refrigerant pressure sensor 8. PCV valve

Vehicle front

PBIB2941E

Page 1407 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-58

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

1. Exhaust manifold 2. Heated oxygen sensor 1 3. Heated oxygen sensor 2

4. Heated oxygen sensor 2 harness

connector

V NISSAN TIIDA 2007 Service Repair Manual EC-58

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

1. Exhaust manifold 2. Heated oxygen sensor 1 3. Heated oxygen sensor 2

4. Heated oxygen sensor 2 harness

connector

V](/img/5/57395/w960_57395-1406.png)

EC-58

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

AIR CONDITIONING CUT CONTROL

1. Exhaust manifold 2. Heated oxygen sensor 1 3. Heated oxygen sensor 2

4. Heated oxygen sensor 2 harness

connector

Vehicle front

PBIB2942E

PBIB2943E