automatic transmission fluid NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2582 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ECM

EC-1233

< ECU DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O Test Condition: Engine at Idle

Order Function Parameter Display and notes Trouble diagnosis

1 Fan speed request*FAN ASSEMBLY INACTIVE NISSAN TIIDA 2007 Service Repair Manual ECM

EC-1233

< ECU DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O Test Condition: Engine at Idle

Order Function Parameter Display and notes Trouble diagnosis

1 Fan speed request*FAN ASSEMBLY INACTIVE](/img/5/57395/w960_57395-2581.png)

ECM

EC-1233

< ECU DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O Test Condition: Engine at Idle

Order Function Parameter Display and notes Trouble diagnosis

1 Fan speed request*FAN ASSEMBLY INACTIVE

NONE. FAN UNIT LOW -

FAN UNIT HIGH -

2Compressor

engagement requestDMND LNK COMPThe ECM requests the IPDM E/R

(via CAN communication line) to

start the compressor

ACTIVE: The CAN communica-

tion should not be suspected on

the Automatic Transmission,

IPDM E/R or Intelligent Key unit

or BCM system.

The Intelligent Key unit or BCM

should request the ECM to be

engaged.

The refrigerant pressure sensor

should not be suspected. Satis-

factory engine operating condi-

tions (engine coolant

temperature, engine load etc.).

INACTIVE: One of the above

conditions has not been met.NONE

3Fast idle speed re-

questACCEL IDL RQ INACTIVE NONE

4 Refrigerant pressureRFRGERNT PRSSIndicates the value in Bar for the

refrigerant fluid in the system.

Default value: 0 Bar.In the event of a malfunction, per-

form the trouble diagnosis for DTC

P0530 REFRUGERANT PRES-

SURE SENSOR.

RFRGERNT FLUID V 0.1V < RFRGERNT FLUID V <

4.8V

5Engine coolant tem-

peratureWATER TEMPClose to ambient temperature

(cold engine).

Indicates the engine coolant tem-

perature in °C.In the event of a malfunction, per-

form the trouble diagnosis for DTC

P0115 ECT SENSOR.

6 Vehicle speed VEHICLE SPEED0 km/h (mph)

Indicates the vehicle speed in km/h

(mph). This parameter is transmit-

ted by the “ABS actuator and elec-

tric unit (control unit)” or

combination meter via CAN com-

munication line.Perform the trouble diagnosis for

CAN communication line. Perform

the trouble diagnosis for “ABS ac-

tuator and electric unit (control

unit)” or combination meter.

Order Function Parameter Display and notes Trouble diagnosis

1 Fan speed request*FAN ASSEMBLY INACTIVE

NONE. FAN UNIT LOW -

FAN UNIT HIGH -

Page 2583 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-1234

< ECU DIAGNOSIS >[K9K]

ECM

CRUISE CONTROL/SPEED LIMITER SUB FUNCTION

Test Condition: Engine Stopped and Ignition Switch ON

Test Condition: Engine at Idle

PROTECTION SUBFUNCTION

Test Condition: NISSAN TIIDA 2007 Service Repair Manual EC-1234

< ECU DIAGNOSIS >[K9K]

ECM

CRUISE CONTROL/SPEED LIMITER SUB FUNCTION

Test Condition: Engine Stopped and Ignition Switch ON

Test Condition: Engine at Idle

PROTECTION SUBFUNCTION

Test Condition:](/img/5/57395/w960_57395-2582.png)

EC-1234

< ECU DIAGNOSIS >[K9K]

ECM

CRUISE CONTROL/SPEED LIMITER SUB FUNCTION

Test Condition: Engine Stopped and Ignition Switch ON

Test Condition: Engine at Idle

PROTECTION SUBFUNCTION

Test Condition: Engine Stopped and Ignition Switch ON

2Compressor

engagement re-

questDMND LNK COMPThe ECM requests the IPDM E/R

(via CAN communication line) to

start the compressor

ACTIVE: The CAN communica-

tion should not be suspected on

the Automatic Transmission,

IPDM E/R or Intelligent Key unit

or BCM system.

The Intelligent Key unit or BCM

should request the ECM to be en-

gaged.

The refrigerant pressure sensor

should not be suspected. Satis-

factory engine operating condi-

tions (engine coolant

temperature, engine load etc.).

INACTIVE: One of the above

conditions has not been met.NONE

3Fast idle speed re-

questACCEL IDL RQINACTIVE

or

ACTIVE

(Air conditioning is operate)NONE

4Refrigerant pres-

sureRFRGERNT PRSSIndicates the value in Bar for the re-

frigerant fluid in the system.

Default value: 0 Bar.In the event of a malfunction, per-

form the trouble diagnosis for DTC

P0530 REFRUGERANT PRES-

SURE SENSOR.

RFRGERNT FLUID V 0.1V < RFRGERNT FLUID V< 4.8V

5Engine coolant

temperatureWATER TEMPIndicates the engine coolant tem-

perature in °C.In the event of a malfunction, per-

form the trouble diagnosis for DTC

P0115 ECT SENSOR.

6 Vehicle speed VEHICLE SPEED0 km/h (mph)

Indicates the vehicle speed in km/h

(mph). This parameter is transmit-

ted by the “ABS actuator and elec-

tric unit (control unit)” or

combination meter via CAN com-

munication line.Perform the trouble diagnosis for

CAN communication line. Perform

the trouble diagnosis for “ABS actu-

ator and electric unit (control unit)”

or combination meter. Order Function Parameter Display and notes Trouble diagnosis

Order Function Parameter Display and notes Trouble diagnosis

1Cruise control/speed

limiterCRS CN/S LMTR INACTIVEIn the event of a malfunction, per-

form the trouble diagnosis for DTC

P0575 ASCD STEERING SWITCH.

Order Function Parameter Display and notes Trouble diagnosis

1Cruise control/speed

limiterCRS CN/S LMTR INACTIVEIn the event of a malfunction, perform

the trouble diagnosis for DTC P0575

ASCD STEERING SWITCH.

Page 3210 of 5883

GI-16

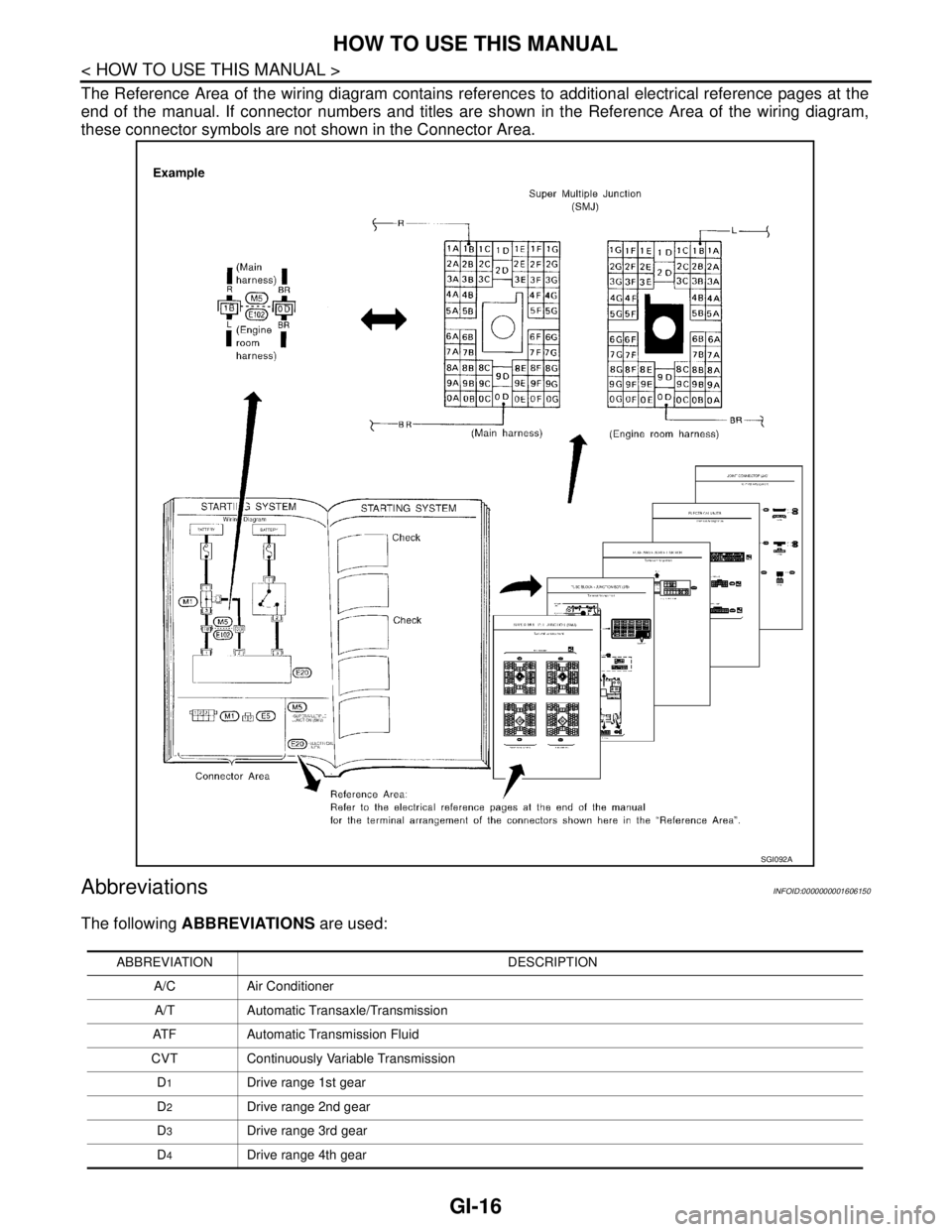

< HOW TO USE THIS MANUAL >

HOW TO USE THIS MANUAL

The Reference Area of the wiring diagram contains references to additional electrical reference pages at the

end of the manual. If connector numbers and titles are shown in the Reference Area of the wiring diagram,

these connector symbols are not shown in the Connector Area.

AbbreviationsINFOID:0000000001606150

The following ABBREVIATIONS are used:

SGI092A

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

CVT Continuously Variable Transmission

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

Page 3219 of 5883

ABBREVIATIONS

GI-25

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

PABBREVIATIONS

Abbreviation ListINFOID:0000000001691463

The following ABBREVIATIONS are used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

AWD All wheel drive

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

FR, RR Front, Rear

LH, RH Left-Hand, Right-Hand

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range 2nd gear

2

12nd range 1st gear

1

21st range 2nd gear

1

11st range 1st gear

Page 3238 of 5883

GI-44

< PRECAUTION >

PRECAUTIONS

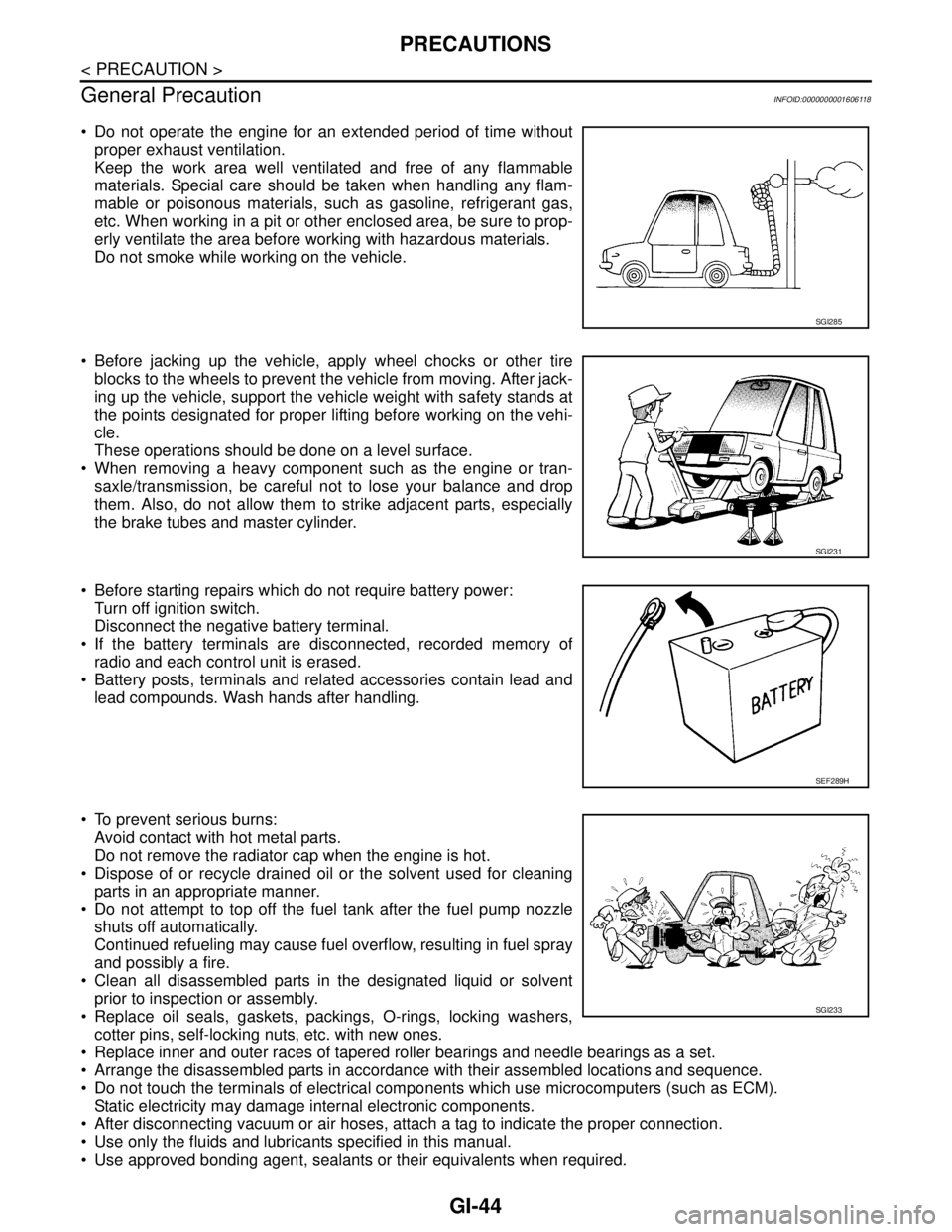

General Precaution

INFOID:0000000001606118

Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any flammable

materials. Special care should be taken when handling any flam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or other enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

Battery posts, terminals and related accessories contain lead and

lead compounds. Wash hands after handling.

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of or recycle drained oil or the solvent used for cleaning

parts in an appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

SGI285

SGI231

SEF289H

SGI233