engines NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 1678 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ECM

EC-329

< ECU DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

NISSAN TIIDA 2007 Service Repair Manual ECM

EC-329

< ECU DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON](/img/5/57395/w960_57395-1677.png)

ECM

EC-329

< ECU DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N POSI SW Ignition switch: ONShift lever: P or N (A/T), Neutral (M/T) ON

Shift lever: Except above OFF

PW/ST SIGNAL Engine: After warming up, idle the

engineSteering wheel: Not being turned OFF

Steering wheel: Being turned ON

LOAD SIGNAL Ignition switch: ONRear window defogger switch: ON

and/or Lighting switch: 2nd positionON

Rear window defogger switch and lighting

switch: OFFOFF

IGNITION SW Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW Engine: After warming up, idle the

engineHeater fan switch: ON ON

Heater fan switch: OFF OFF

BRAKE SW Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1 Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 10° - 20° BTDC

2,000 rpm 25° - 45° BTDC

CAL/ALD VALUE Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 10% - 35%

2,500 rpm 10% - 35%

MASS AIRFLOW Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 1.0 - 4.0 g·m/s

2,500 rpm 2.0 - 10.0 g·m/s

PURG VOL C/V Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 0%

2,000 rpm 0% - 50%

INT/V TIM (B1) Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 40

°CA

INT/V SOL (B1) Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 0% - 2%

2,000 rpm Approx. 0% - 90%

AIR COND RLY Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)ON Monitor Item Condition Values/Status

Page 1985 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-636

< ECU DIAGNOSIS >[HR16DE (WITHOUT EURO-OBD)]

ECM

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N NISSAN TIIDA 2007 Service Repair Manual EC-636

< ECU DIAGNOSIS >[HR16DE (WITHOUT EURO-OBD)]

ECM

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N](/img/5/57395/w960_57395-1984.png)

EC-636

< ECU DIAGNOSIS >[HR16DE (WITHOUT EURO-OBD)]

ECM

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N POSI SW Ignition switch: ONShift lever: P or N (A/T), Neutral (M/T) ON

Shift lever: Except above OFF

PW/ST SIGNAL Engine: After warming up, idle the

engineSteering wheel: Not being turned OFF

Steering wheel: Being turned ON

LOAD SIGNAL Ignition switch: ONRear window defogger switch: ON

and/or Lighting switch: 2nd positionON

Rear window defogger switch and lighting

switch: OFFOFF

IGNITION SW Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW Engine: After warming up, idle the

engineHeater fan switch: ON ON

Heater fan switch: OFF OFF

BRAKE SW Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1 Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 10° - 20° BTDC

2,000 rpm 25° - 45° BTDC

PURG VOL C/V Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 0%

2,000 rpm 0% - 50%

INT/V TIM (B1) Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 40°CA

INT/V SOL (B1) Engine: After warming up

Shift lever: P or N (A/T), Neutral

(M/T)

Air conditioner switch: OFF

No loadIdle 0% - 2%

2,000 rpm Approx. 0% - 90%

AIR COND RLY Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)

ON

FUEL PUMP RLY For 1 seconds after turning ignition switch: ON

Engine running or crankingON

Except above OFF

THRTL RELAY Ignition switch: ON ONMonitor Item Condition Values/Status

Page 2340 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ECM

EC-991

< ECU DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor oper NISSAN TIIDA 2007 Service Repair Manual ECM

EC-991

< ECU DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor oper](/img/5/57395/w960_57395-2339.png)

ECM

EC-991

< ECU DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N POSI SW Ignition switch: ONShift lever: Neutral ON

Selector lever: Except above OFF

PW/ST SIGNAL Engine: After warming up, idle the

engineSteering wheel: Not being turned OFF

Steering wheel: Being turned ON

LOAD SIGNAL Ignition switch: ONRear window defogger switch: ON

and/or Lighting switch: 2nd positionON

Rear window defogger switch and lighting

switch: OFFOFF

IGNITION SW Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW Engine: After warming up, idle the

engineHeater fan switch: ON ON

Heater fan switch: OFF OFF

BRAKE SW Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1 Engine: After warming up

Shift lever:Neutral

Air conditioner switch: OFF

No loadIdle 2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING Engine: After warming up

Shift lever:Neutral

Air conditioner switch: OFF

No loadIdle 10° - 20° BTDC

2,000 rpm 25° - 45° BTDC

PURG VOL C/V Engine: After warming up

Shift lever:Neutral

Air conditioner switch: OFF

No loadIdle 0%

2,000 rpm 20% - 90%

INT/V TIM (B1) Engine: After warming up

Shift lever:Neutral

Air conditioner switch: OFF

No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 20°CA

INT/V SOL (B1) Engine: After warming up

Shift lever:Neutral

Air conditioner switch: OFF

No loadIdle 0%

2,000 rpm Approx. 0% - 60%

AIR COND RLY Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)ON

FUEL PUMP RLY For 1 seconds after turning ignition switch: ON

Engine running or crankingON

Except above OFF

THRTL RELAY Ignition switch: ON ON

COOLING FAN Engine: After warming up, idle the

engine

Air conditioner switch: OFFEngine coolant temperature is 97 °C

(207°F) or less.OFF

Engine coolant temperature is between

98°C (208°F) and 99°C (210°F)LOW

Engine coolant temperature is 100°C

(212°F) or moreHIGH

HO2S1 HTR (B1) Engine: After warming up

Engine speed: Above 3,600 rpmON

Engine speed: Above 3,600 rpm OFF Monitor Item Condition Values/Status

Page 2653 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-6

< SYMPTOM DIAGNOSIS >[HR16DE]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381372

1. Locate the area where n NISSAN TIIDA 2007 Service Repair Manual EM-6

< SYMPTOM DIAGNOSIS >[HR16DE]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381372

1. Locate the area where n](/img/5/57395/w960_57395-2652.png)

EM-6

< SYMPTOM DIAGNOSIS >[HR16DE]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381372

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noiseTyp e of

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

Top of en-

gine

Rocker

cover

Cylinder

headTicking or

clickingCA—AB—Tappet

noiseValve clearanceEM-21

Rattle C A — A B CCamshaft

bearing

noiseCamshaft journal oil

clearance

Camshaft runoutEM-123EM-123

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock—A—BB—Piston pin

noisePiston to piston pin oil

clearance

Connecting rod small

end clearanceEM-127

EM-130

Slap or

rapA——BBAPiston

slap noisePiston to cylinder bore

clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-127EM-127

EM-127

EM-130

Knock A B C B B BConnect-

ing rod

bearing

noiseConnecting rod small

end clearance

Connecting rod bearing

oil clearanceEM-127EM-130

Knock A B — A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-131EM-127

Front of

engine

Front cov-

erTapping or

tickingAA—BBBTiming

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operationEM-57

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belt

(Sticking

or slip-

ping)Drive belt deflection

EM-122

Creaking A B A B A BDrive belt

(Slipping)Idler pulley bearing op-

eration

Squall

CreakAB—BABWater

pump

noiseWater pump operationCO-21

Page 2780 of 5883

![NISSAN TIIDA 2007 Service Repair Manual NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-133

< SYMPTOM DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Use the Chart Below to Help You Find the Cause of the SymptomINFOID:0000000001 NISSAN TIIDA 2007 Service Repair Manual NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-133

< SYMPTOM DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Use the Chart Below to Help You Find the Cause of the SymptomINFOID:0000000001](/img/5/57395/w960_57395-2779.png)

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-133

< SYMPTOM DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Use the Chart Below to Help You Find the Cause of the SymptomINFOID:0000000001337775

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedA. Rotational mechanism B. Water pump C. Timing chain

D. Drive belt E. Crankshaft pulley F. A/C compressor

G. Water pump H. Generator I. Tension pulley

J. Valve mechanism K. Valves

Location

of noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

Top of en-

gine

Rocker

cover

Cylinder

headTicking or

clickingCA—AB—Tappet

noiseValve clearanceEM-238

Rattle C A — A B CCamshaft

bearing

noiseCamshaft journal oil

clearance

Camshaft runoutEM-186EM-186

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock—A—BB—Piston pin

noisePiston to piston pin oil

clearance

Connecting rod bushing

oil clearanceEM-219

EM-219

Slap or

rapA——BBAPiston

slap noisePiston to cylinder bore

clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-219EM-219

EM-219

EM-219

Knock A B C B B BConnect-

ing rod

bearing

noiseConnecting rod bushing

oil clearance

Connecting rod bearing

oil clearanceEM-219EM-219

Knock A B — A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-219EM-219

Front of

engine

Front cov-

erTapping or

tickingAA—BBBTiming

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operationEM-177

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belt

(Sticking

or slip-

ping)Drive belt deflection

EM-142

CreakingA B ABABDrive belt

(Slipping)Idler pulley bearing op-

eration

Squall

CreakAB—BABWater

pump

noiseWater pump operationCO-44

Page 2897 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-250

< SYMPTOM DIAGNOSIS >[K9K]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381449

1. Locate the area where no NISSAN TIIDA 2007 Service Repair Manual EM-250

< SYMPTOM DIAGNOSIS >[K9K]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381449

1. Locate the area where no](/img/5/57395/w960_57395-2896.png)

EM-250

< SYMPTOM DIAGNOSIS >[K9K]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381449

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

Top of en-

gine

Rocker

cover

Cylinder

headTicking or

clickingCA—AB—Tappet

noiseValve clearanceEM-266

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

rapA——B B APiston

slap noisePiston ring end gapEM-330

Front of

engine

Timing

belt coverTapping or

tickingAA—BBBTiming

belt ten-

sioner

noiseTiming belt tensioner

operationEM-291

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belts

(Sticking

or slip-

ping)Drive belts deflectionEM-263

Squall

CreakAB—BABWater

pump

noiseWater pump operationCO-66

Page 2949 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-302

< REMOVAL AND INSTALLATION >[K9K]

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Exploded ViewINFOID:0000000001381504

Removal and InstallationINFOID:0000000001381505

WARNING:

Situat NISSAN TIIDA 2007 Service Repair Manual EM-302

< REMOVAL AND INSTALLATION >[K9K]

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Exploded ViewINFOID:0000000001381504

Removal and InstallationINFOID:0000000001381505

WARNING:

Situat](/img/5/57395/w960_57395-2948.png)

EM-302

< REMOVAL AND INSTALLATION >[K9K]

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Exploded ViewINFOID:0000000001381504

Removal and InstallationINFOID:0000000001381505

WARNING:

Situate vehicle on a flat and solid surface.

Place chocks at front and back of rear wheels.

For engines not equipped with engine slingers, attach proper slingers and bolts described in PARTS

CATALOG.

CAUTION:

Always be careful to work safely, avoid forceful or uninstructed operations.

Do not start working until exhaust system and coolant are cool enough.

If items or work required are not covered by the main engine section, follow the procedures in the

applicable sections.

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for unavoid-

able reasons, support at the rear axle jacking point with transmission jack or similar tool before

starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking rear axle, refer to GI-48, "

Garage Jack and Safety Stand

and 2-Pole Lift" or GI-49, "Board-On Lift".

REMOVAL

Description of Work

1. Engine mounting insulator LH 2. Engine mounting frame support LH 3. Engine mounting bracket LH

4. Upper torque rod 5. Engine mounting insulator RH 6. Engine mounting bracket RH (upper)

7. Engine mounting bracket RH (lower) 8. Lower torque rod bracket 9. Lower torque rod

: Vehicle front

AWBIA0162GB

Page 3257 of 5883

CONSULT-III CHECKING SYSTEM

GI-63

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

PCONSULT-III CHECKING SYSTEM

DescriptionINFOID:0000000001691472

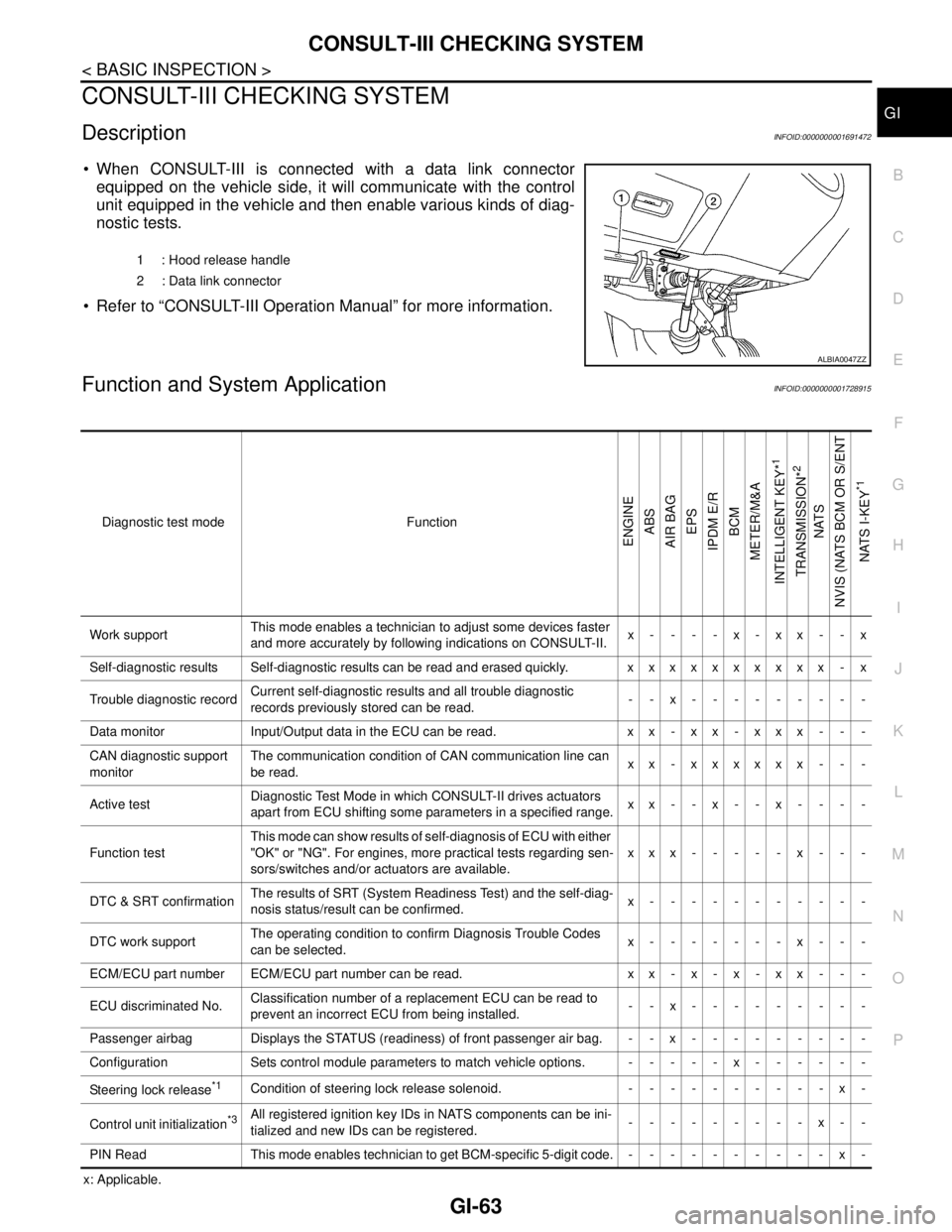

When CONSULT-III is connected with a data link connector

equipped on the vehicle side, it will communicate with the control

unit equipped in the vehicle and then enable various kinds of diag-

nostic tests.

Refer to “CONSULT-III Operation Manual” for more information.

Function and System ApplicationINFOID:0000000001728915

x: Applicable.1 : Hood release handle

2 : Data link connector

ALBIA0047ZZ

Diagnostic test mode Function

ENGINE

ABS

AIR BAG

EPS

IPDM E/R

BCM

METER/M&A

INTELLIGENT KEY*

1

TRANSMISSION*

2

NATS

NVIS (NATS BCM OR S/ENT

NATS I-KEY

*1

Work supportThis mode enables a technician to adjust some devices faster

and more accurately by following indications on CONSULT-II.x----x-xx--x

Self-diagnostic results Self-diagnostic results can be read and erased quickly. xxxxxxxxxx - x

Trouble diagnostic recordCurrent self-diagnostic results and all trouble diagnostic

records previously stored can be read.--x---------

Data monitor Input/Output data in the ECU can be read. x x - x x - x x x - - -

CAN diagnostic support

monitorThe communication condition of CAN communication line can

be read.xx - xxxxxx - - -

Active testDiagnostic Test Mode in which CONSULT-II drives actuators

apart from ECU shifting some parameters in a specified range.xx--x--x----

Function testThis mode can show results of self-diagnosis of ECU with either

"OK" or "NG". For engines, more practical tests regarding sen-

sors/switches and/or actuators are available.xxx-----x---

DTC & SRT confirmationThe results of SRT (System Readiness Test) and the self-diag-

nosis status/result can be confirmed.x-----------

DTC work supportThe operating condition to confirm Diagnosis Trouble Codes

can be selected.x-------x---

ECM/ECU part number ECM/ECU part number can be read. x x - x - x - x x - - -

ECU discriminated No.Classification number of a replacement ECU can be read to

prevent an incorrect ECU from being installed.--x---------

Passenger airbag Displays the STATUS (readiness) of front passenger air bag. --x---------

Configuration Sets control module parameters to match vehicle options. -----x------

Steering lock release

*1Condition of steering lock release solenoid. ----------x-

Control unit initialization

*3All registered ignition key IDs in NATS components can be ini-

tialized and new IDs can be registered.---------x--

PIN Read This mode enables technician to get BCM-specific 5-digit code.----------x-

Page 4259 of 5883

RECOMMENDED FLUIDS AND LUBRICANTS

MA-19

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

RECOMMENDED FLUIDS AND LUBRICANTS

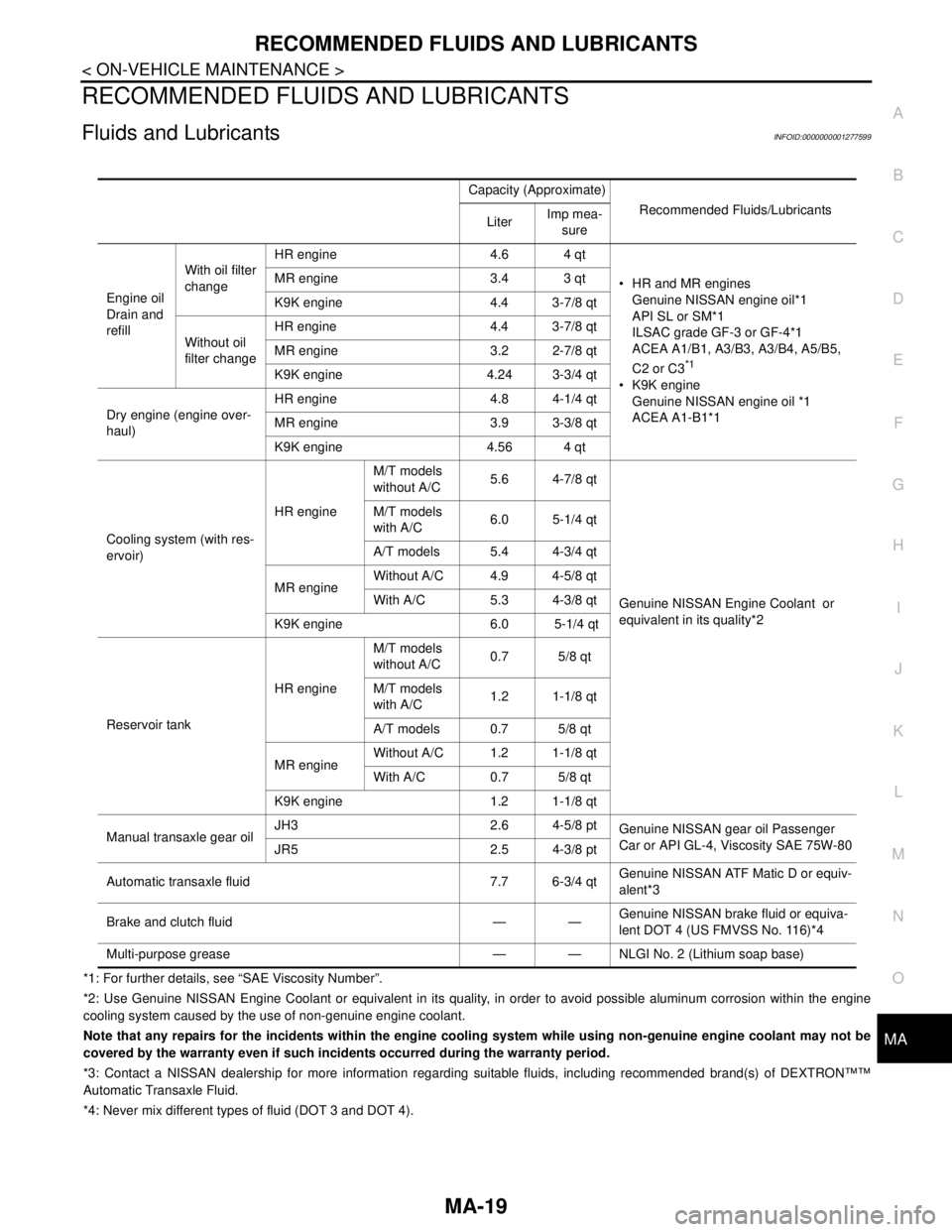

Fluids and LubricantsINFOID:0000000001277599

*1: For further details, see “SAE Viscosity Number”.

*2: Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine

cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*3: Contact a NISSAN dealership for more information regarding suitable fluids, including recommended brand(s) of DEXTRON™™

Automatic Transaxle Fluid.

*4: Never mix different types of fluid (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

LiterImp mea-

sure

Engine oil

Drain and

refillWith oil filter

changeHR engine 4.6 4 qt

HR and MR engines

Genuine NISSAN engine oil*1

API SL or SM*1

ILSAC grade GF-3 or GF-4*1

ACEA A1/B1, A3/B3, A3/B4, A5/B5,

C2 or C3

*1

K9K engine

Genuine NISSAN engine oil *1

ACEA A1-B1*1 MR engine 3.4 3 qt

K9K engine 4.4 3-7/8 qt

Without oil

filter changeHR engine 4.4 3-7/8 qt

MR engine 3.2 2-7/8 qt

K9K engine 4.24 3-3/4 qt

Dry engine (engine over-

haul)HR engine 4.8 4-1/4 qt

MR engine 3.9 3-3/8 qt

K9K engine 4.56 4 qt

Cooling system (with res-

ervoir)HR engineM/T models

without A/C5.6 4-7/8 qt

Genuine NISSAN Engine Coolant or

equivalent in its quality*2 M/T models

with A/C6.0 5-1/4 qt

A/T models 5.4 4-3/4 qt

MR engineWithout A/C 4.9 4-5/8 qt

With A/C 5.3 4-3/8 qt

K9K engine 6.0 5-1/4 qt

Reservoir tankHR engineM/T models

without A/C0.7 5/8 qt

M/T models

with A/C1.2 1-1/8 qt

A/T models 0.7 5/8 qt

MR engineWithout A/C 1.2 1-1/8 qt

With A/C 0.7 5/8 qt

K9K engine 1.2 1-1/8 qt

Manual transaxle gear oilJH3 2.6 4-5/8 pt

Genuine NISSAN gear oil Passenger

Car or API GL-4, Viscosity SAE 75W-80

JR5 2.5 4-3/8 pt

Automatic transaxle fluid 7.7 6-3/4 qtGenuine NISSAN ATF Matic D or equiv-

alent*3

Brake and clutch fluid — —Genuine NISSAN brake fluid or equiva-

lent DOT 4 (US FMVSS No. 116)*4

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)