power steering fluid NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 218 of 5883

BR-26

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

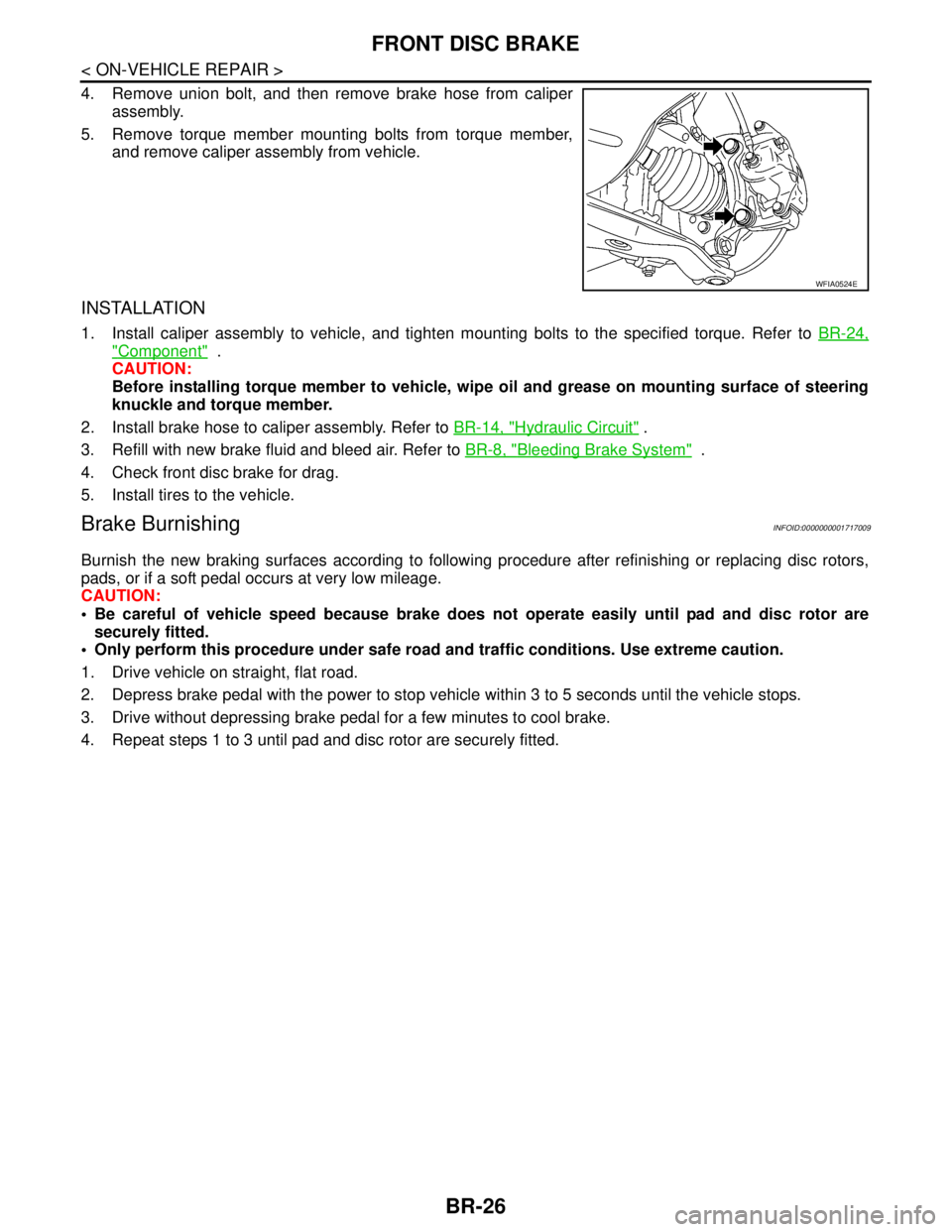

4. Remove union bolt, and then remove brake hose from caliper

assembly.

5. Remove torque member mounting bolts from torque member,

and remove caliper assembly from vehicle.

INSTALLATION

1. Install caliper assembly to vehicle, and tighten mounting bolts to the specified torque. Refer to BR-24,

"Component" .

CAUTION:

Before installing torque member to vehicle, wipe oil and grease on mounting surface of steering

knuckle and torque member.

2. Install brake hose to caliper assembly. Refer to BR-14, "

Hydraulic Circuit" .

3. Refill with new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System" .

4. Check front disc brake for drag.

5. Install tires to the vehicle.

Brake BurnishingINFOID:0000000001717009

Burnish the new braking surfaces according to following procedure after refinishing or replacing disc rotors,

pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Be careful of vehicle speed because brake does not operate easily until pad and disc rotor are

securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake pedal for a few minutes to cool brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

WFIA0524E

Page 2705 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM -58

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

Check for cracks and any excessive wear at link plates and roller

links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLAT NISSAN TIIDA 2007 Service Repair Manual EM -58

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

Check for cracks and any excessive wear at link plates and roller

links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLAT](/img/5/57395/w960_57395-2704.png)

EM -58

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

Check for cracks and any excessive wear at link plates and roller

links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-19, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise

will stop after hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.A: Crack

B: Wear

JPBIA0091ZZ

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Page 2722 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, chec NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, chec](/img/5/57395/w960_57395-2721.png)

CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-19, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspection procedure of EC section. Refer to EC-131, "

Diagnosis Pro-

cedure" (EURO-OBD), EC-484, "Diagnosis Procedure" (WITHOUT EURO-OBD).

Check when engine is cold so as to prevent burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-6, "

Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release the fuel pressure. Refer to EC-377, "

Inspection" (EURO-OBD), EC-681, "Inspection" (WITHOUT

EURO-OBD).

b. Remove intake manifold. Refer to EM-29, "

Exploded View".

c. Disconnect ignition coil and injector harness connectors. Refer to EM-47, "

Exploded View".

3. Remove intake valve timing control solenoid valve. Refer to EM-50, "

Exploded View".

4. Crank engine, and then make sure that engine oil comes out

from intake valve timing control solenoid valve hole (A). End

crank after checking.

WARNING:

Be careful not to touch rotating parts (drive belts, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil and so as to prevent engine oil contamination.

Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belts,

engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

1: Plug

:Engine front

PBIC3706E

Page 2729 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-82

< ON-VEHICLE REPAIR >[HR16DE]

CYLINDER HEAD

In this step, loosen bolts in reverse order of that indicated.

d. Tighten all bolts.

e. Turn all bolts 75 degrees clockwise (angle tightening).

CAUTIO NISSAN TIIDA 2007 Service Repair Manual EM-82

< ON-VEHICLE REPAIR >[HR16DE]

CYLINDER HEAD

In this step, loosen bolts in reverse order of that indicated.

d. Tighten all bolts.

e. Turn all bolts 75 degrees clockwise (angle tightening).

CAUTIO](/img/5/57395/w960_57395-2728.png)

EM-82

< ON-VEHICLE REPAIR >[HR16DE]

CYLINDER HEAD

In this step, loosen bolts in reverse order of that indicated.

d. Tighten all bolts.

e. Turn all bolts 75 degrees clockwise (angle tightening).

CAUTION:

Check and confirm the tightening angle by using the angle

wrench [SST: KV10112100] (A) or protractor. Avoid judg-

ment by visual inspection without the tool.

f. Turn all bolts 75 degrees clockwise again (angle tightening).

3. Installation is in the reverse order of removal, for the remaining parts.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-19, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Disassembly and AssemblyINFOID:0000000001381422

: 40.0 N·m (4.1 kg-m, 30 ft-lb)

PBIC3733E

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2740 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-93

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc. NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-93

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.](/img/5/57395/w960_57395-2739.png)

ENGINE ASSEMBLY

EM-93

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2840 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-193

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bol NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-193

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bol](/img/5/57395/w960_57395-2839.png)

CAMSHAFT

EM-193

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bolt.

11. Install timing chain and related parts. Refer to EM-176

.

12. Inspect and adjust valve clearance. Refer to EM-148, "

Valve Clearance".

13. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to GI-27, "

Recommended Chemical Products and Sealants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspection procedure of EC section. Refer to EC-796, "

Diagnosis Pro-

cedure".

Check when engine is cold so as to prevent burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-15, "

Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Remove intake manifold. Refer to EM-156, "

Component".

b. Disconnect ignition coil and injector harness connectors.

3. Remove intake valve timing control solenoid valve. Refer to EM-176, "

Component".

1 : Camshaft sprocket (INT)

Camshaft sprocket

bolt (EXH): 88.2 N·m (9.0 kg-m, 65 ft-lb)

PBIC3454J

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2857 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installi NISSAN TIIDA 2007 Service Repair Manual EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installi](/img/5/57395/w960_57395-2856.png)

EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installing the upper torque rod, apply a light coat of silicone

lubricant (A) to the washer facing side of the bushing inner tube as

shown.

NOTE:

Apply silicone lubricant (A) by dabbing the outward facing tube

surface with a sponge or suitable tool.

Do not apply excess lubricant.

Make sure that each mounting insulator is seated properly, and tighten nuts and bolts.

Tighten engine mounting insulator (RH) bolts in the numerical

order shown.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to LU-15, "

Inspection", CO-35, "Inspection".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle fluid, power steering fluid, brake fluid, etc.: Vehicle front

LBIA0470E

: Vehicle front

WBIA0785E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 3219 of 5883

ABBREVIATIONS

GI-25

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

PABBREVIATIONS

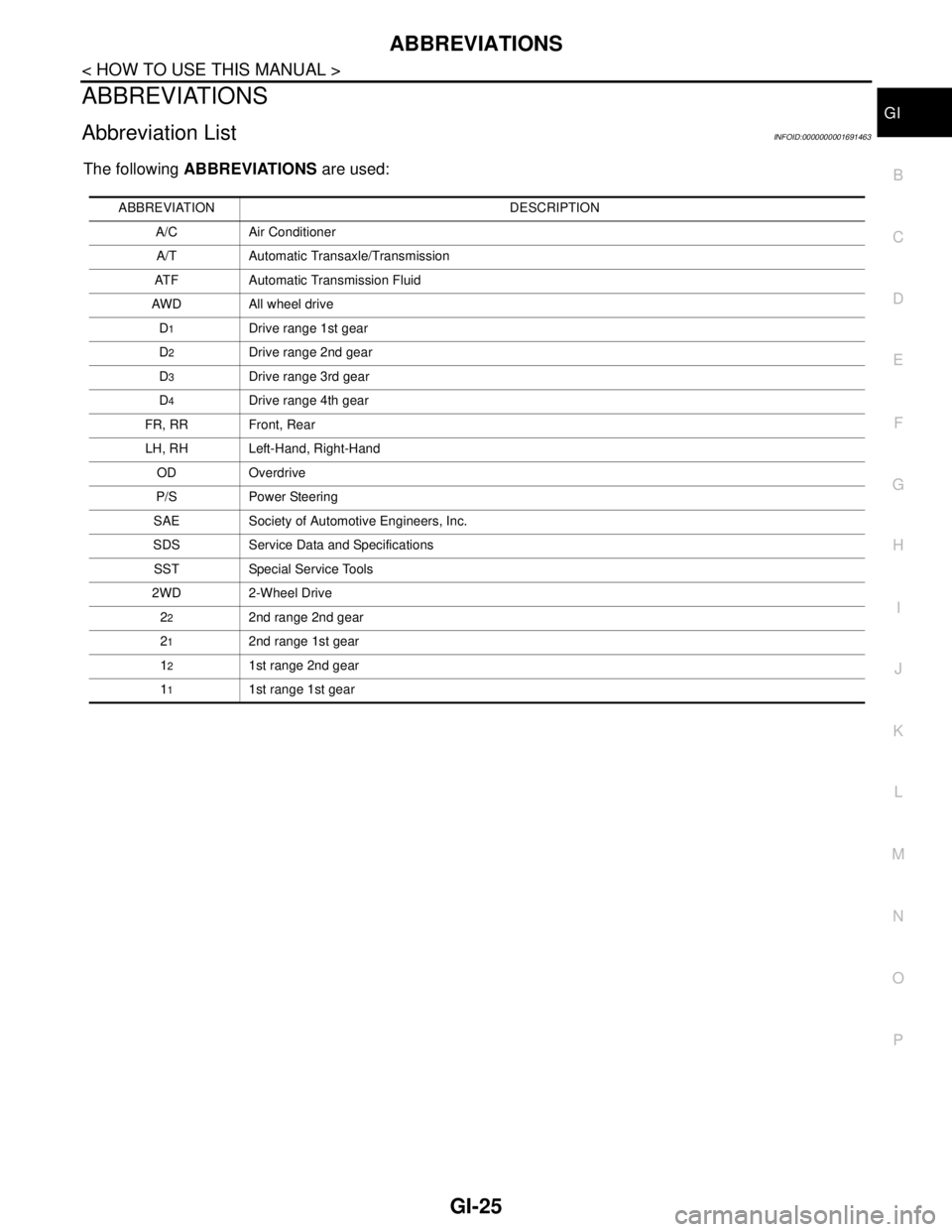

Abbreviation ListINFOID:0000000001691463

The following ABBREVIATIONS are used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

AWD All wheel drive

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

FR, RR Front, Rear

LH, RH Left-Hand, Right-Hand

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range 2nd gear

2

12nd range 1st gear

1

21st range 2nd gear

1

11st range 1st gear

Page 4344 of 5883

MWI

COMBINATION METER

MWI-37

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

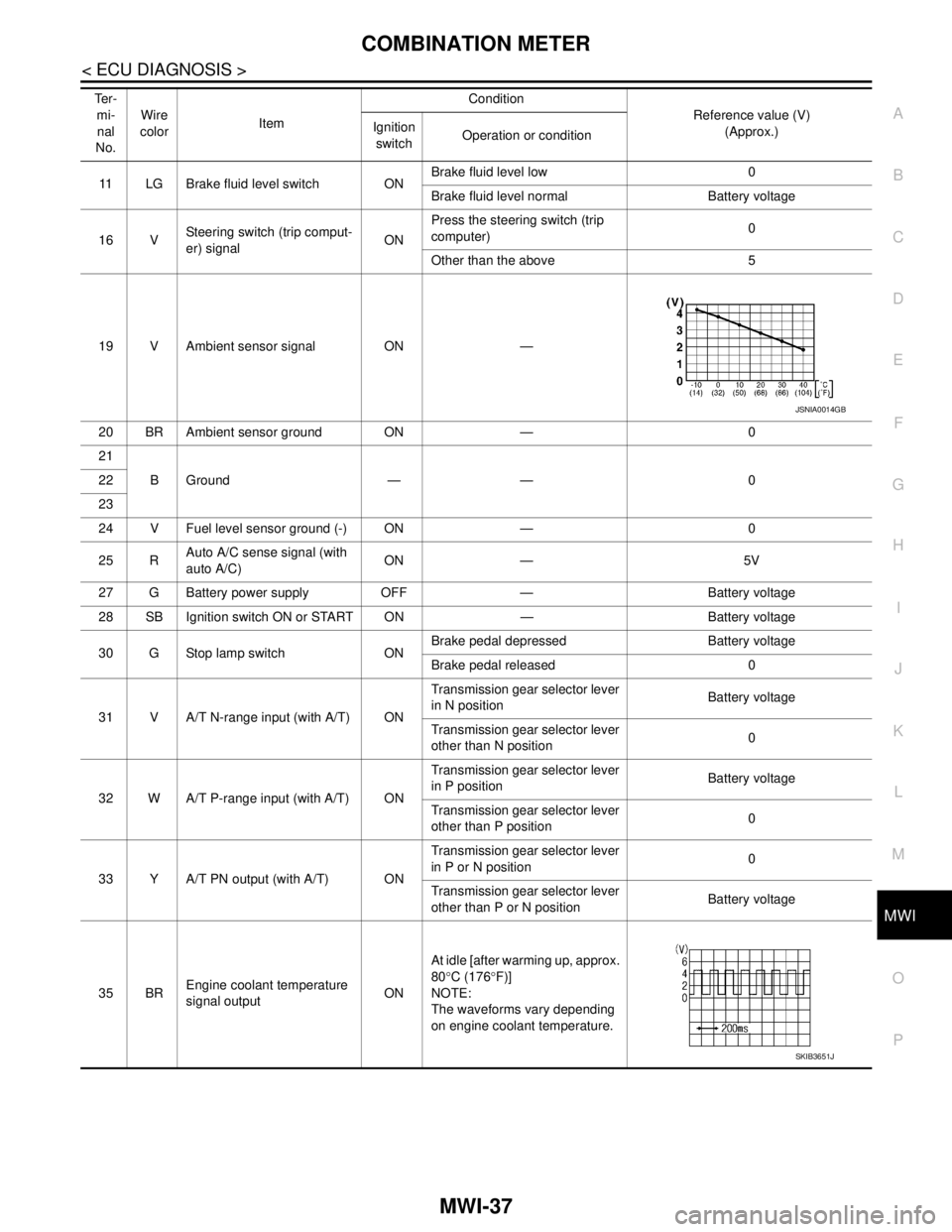

11 LG Brake fluid level switch ONBrake fluid level low 0

Brake fluid level normal Battery voltage

16 VSteering switch (trip comput-

er) signalONPress the steering switch (trip

computer)0

Other than the above 5

19 V Ambient sensor signal ON —

20 BR Ambient sensor ground ON — 0

21

BGround — — 0 22

23

24 V Fuel level sensor ground (-) ON — 0

25 RAuto A/C sense signal (with

auto A/C)ON — 5V

27 G Battery power supply OFF — Battery voltage

28 SB Ignition switch ON or START ON — Battery voltage

30 G Stop lamp switch ONBrake pedal depressed Battery voltage

Brake pedal released 0

31 V A/T N-range input (with A/T) ONTransmission gear selector lever

in N positionBattery voltage

Transmission gear selector lever

other than N position0

32 W A/T P-range input (with A/T) ONTransmission gear selector lever

in P positionBattery voltage

Transmission gear selector lever

other than P position0

33 Y A/T PN output (with A/T) ONTransmission gear selector lever

in P or N position0

Transmission gear selector lever

other than P or N positionBattery voltage

35 BREngine coolant temperature

signal outputONAt idle [after warming up, approx.

80°C (176°F)]

NOTE:

The waveforms vary depending

on engine coolant temperature. Te r -

mi-

nal

No.Wire

colorItemCondition

Reference value (V)

(Approx.) Ignition

switchOperation or condition

JSNIA0014GB

SKIB3651J

Page 4949 of 5883

TM-3

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

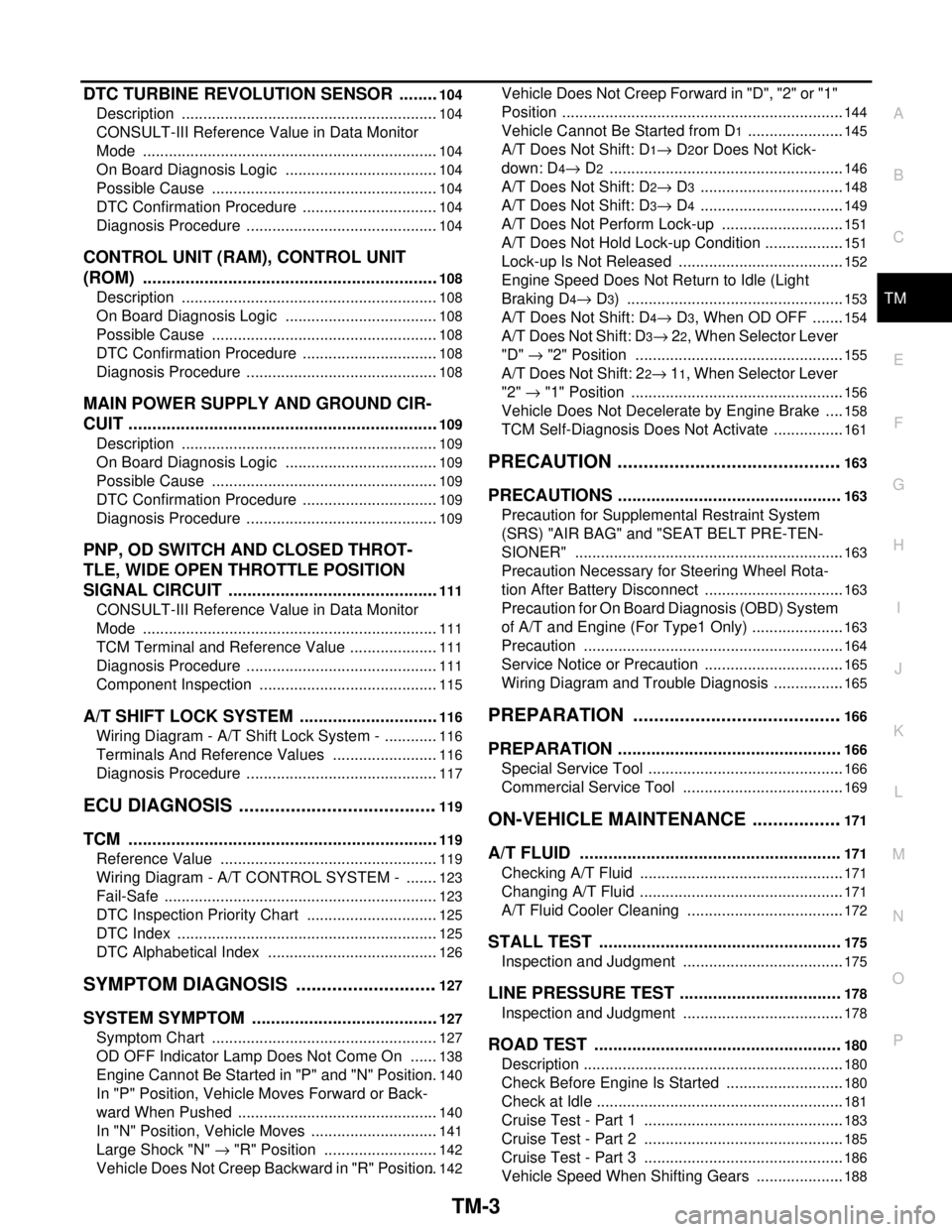

DTC TURBINE REVOLUTION SENSOR .........104

Description ............................................................104

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

104

On Board Diagnosis Logic ....................................104

Possible Cause .....................................................104

DTC Confirmation Procedure ................................104

Diagnosis Procedure .............................................104

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

108

Description ............................................................108

On Board Diagnosis Logic ....................................108

Possible Cause .....................................................108

DTC Confirmation Procedure ................................108

Diagnosis Procedure .............................................108

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

109

Description ............................................................109

On Board Diagnosis Logic ....................................109

Possible Cause .....................................................109

DTC Confirmation Procedure ................................109

Diagnosis Procedure .............................................109

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT .............................................

111

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

111

TCM Terminal and Reference Value .....................111

Diagnosis Procedure .............................................111

Component Inspection ..........................................115

A/T SHIFT LOCK SYSTEM ..............................116

Wiring Diagram - A/T Shift Lock System - .............116

Terminals And Reference Values .........................116

Diagnosis Procedure .............................................117

ECU DIAGNOSIS .......................................119

TCM ..................................................................119

Reference Value ...................................................119

Wiring Diagram - A/T CONTROL SYSTEM - ........123

Fail-Safe ................................................................123

DTC Inspection Priority Chart ...............................125

DTC Index .............................................................125

DTC Alphabetical Index ........................................126

SYMPTOM DIAGNOSIS ............................127

SYSTEM SYMPTOM ........................................127

Symptom Chart .....................................................127

OD OFF Indicator Lamp Does Not Come On .......138

Engine Cannot Be Started in "P" and "N" Position ..140

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

140

In "N" Position, Vehicle Moves ..............................141

Large Shock "N" → "R" Position ...........................142

Vehicle Does Not Creep Backward in "R" Position ..142

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ..................................................................

144

Vehicle Cannot Be Started from D1 .......................145

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 .......................................................146

A/T Does Not Shift: D2→ D3 ..................................148

A/T Does Not Shift: D3→ D4 ..................................149

A/T Does Not Perform Lock-up .............................151

A/T Does Not Hold Lock-up Condition ...................151

Lock-up Is Not Released .......................................152

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................153

A/T Does Not Shift: D4→ D3, When OD OFF ........154

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

155

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

156

Vehicle Does Not Decelerate by Engine Brake .....158

TCM Self-Diagnosis Does Not Activate .................161

PRECAUTION ............................................163

PRECAUTIONS ...............................................163

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

163

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

163

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine (For Type1 Only) ......................

163

Precaution .............................................................164

Service Notice or Precaution .................................165

Wiring Diagram and Trouble Diagnosis .................165

PREPARATION .........................................166

PREPARATION ...............................................166

Special Service Tool ..............................................166

Commercial Service Tool ......................................169

ON-VEHICLE MAINTENANCE ..................171

A/T FLUID .......................................................171

Checking A/T Fluid ................................................171

Changing A/T Fluid ................................................171

A/T Fluid Cooler Cleaning .....................................172

STALL TEST ...................................................175

Inspection and Judgment ......................................175

LINE PRESSURE TEST ..................................178

Inspection and Judgment ......................................178

ROAD TEST ....................................................180

Description .............................................................180

Check Before Engine Is Started ............................180

Check at Idle ..........................................................181

Cruise Test - Part 1 ...............................................183

Cruise Test - Part 2 ...............................................185

Cruise Test - Part 3 ...............................................186

Vehicle Speed When Shifting Gears .....................188