run flat NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 123 of 5883

![NISSAN TIIDA 2007 Service Repair Manual AV-118

< SYMPTOM DIAGNOSIS >[AUDIO WITH NAVIGATION]

NORMAL OPERATING CONDITION

THE CURRENT POSITION MARK JUMPS.

In the following cases, the current location mark may appear to jump as a result of auto NISSAN TIIDA 2007 Service Repair Manual AV-118

< SYMPTOM DIAGNOSIS >[AUDIO WITH NAVIGATION]

NORMAL OPERATING CONDITION

THE CURRENT POSITION MARK JUMPS.

In the following cases, the current location mark may appear to jump as a result of auto](/img/5/57395/w960_57395-122.png)

AV-118

< SYMPTOM DIAGNOSIS >[AUDIO WITH NAVIGATION]

NORMAL OPERATING CONDITION

THE CURRENT POSITION MARK JUMPS.

In the following cases, the current location mark may appear to jump as a result of automatic correction of the

current location.

When map matching has been done

- The current location mark may seem to jump if current location and the current location mark are different

when map matching is done. At this time, the location may be “corrected” to the incorrect road or to a loca-

tion which is not on a road.

When GPS location correction has been done

- The current location mark may seem to jump if current location and the current location mark are different

when location is corrected using GPS measurements. At this time, the location may be “corrected” to a loca-

tion which is not on a road.

THE CURRENT LOCATION MARK IS IN A RIVER OR THE SEA.

The navigation system moves the current location mark with no distinction between land and rivers or sea. It

may appear that the vehicle is driving in a river or the sea if the location mark is somehow out of place.

CURRENT LOCATION MARK ROTATES WITHOUT OPERATION

The rotating condition is recorded as the stop condition if the ignition switch is turned ON with the turntable

rotating. Therefore, the current location mark might rotate when actually stopping.

WHEN DRIVING ON THE SAME ROAD, SOMETIMES THE CURRENT LOCATION MARK IS IN THE

CORRECT PLACE AND SOMETIMES IT IS IN THE INCORRECT PLACE.

The conditions of the GPS antenna (GPS data) and gyroscope (angular speed sensor) change gradually.

Depending on the road traveled and operation of the steering wheel, the location detection results will be dif-

ferent. Therefore, even on a road on which the location has never been incorrect, conditions may cause the

vehicle mark to deviate.

LOCATION CORRECTION BY MAP MATCHING IS SLOW.

The map matching function needs to refer to the data of the surrounding area. It is necessary to drive some

distance for the function to work.

Because of the way map matching operates, when there are many roads running in similar directions in the

surrounding area a matching determination may be impossible. The location will remain uncorrected until

some special feature is found.

ALTHOUGH THE GPS RECEIVING DISPLAY IS GREEN, THE VEHICLE MARK DOES NOT RE-

TURN TO THE CORRECT LOCATION.

GPS accuracy has a malfunction range of about 10 m (30 ft). In some cases the current location mark may

not be on the correct street, even when GPS location correction is done.

The navigation system compares the results of GPS location detection with the results from map-matching

location detection. The one that is determined to have higher accuracy is used.

Position correction by GPS is not available while the vehicle is stopped.

THE NAME OF THE CURRENT PLACE IS NOT DISPLAYED.

The current place name might not be displayed when there is no name of place information in the map screen.

THE DISPLAY IS DIFFERENT BETWEEN BIRDVIEW® AND (FLAT) MAP DISPLAY.

The following is different at Birdview®.

The current place name displays names that are primarily in the direction of vehicle travel.

The amount of time before the vehicle travel or turn angle is updated on the screen is longer than for the

(flat) map display.

The conditions for display of place names, roads, and other data are different for nearby areas and for more

distant areas.

Some trimming of the character data is done to prevent the display from becoming too complex. In some

cases and in some locations, the display contents may differ.

The same place name, street name, etc. may be displayed multiple times.

Page 2719 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-72

< ON-VEHICLE REPAIR >[HR16DE]

CAMSHAFT

Make sure that there is no foreign material on the oil filter (1) and

check it for clogging.

Check the oil filter for damage.

If there is some damage NISSAN TIIDA 2007 Service Repair Manual EM-72

< ON-VEHICLE REPAIR >[HR16DE]

CAMSHAFT

Make sure that there is no foreign material on the oil filter (1) and

check it for clogging.

Check the oil filter for damage.

If there is some damage](/img/5/57395/w960_57395-2718.png)

EM-72

< ON-VEHICLE REPAIR >[HR16DE]

CAMSHAFT

Make sure that there is no foreign material on the oil filter (1) and

check it for clogging.

Check the oil filter for damage.

If there is some damage, replace the oil filter, the plug, and the

washer as a set.

Camshaft Runout

1. Put V-block on a precise flat table, and support No. 2 and 5 jour-

nals of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft

sprocket) because it has a different diameter from the other

four locations.

2. Set a dial indicator vertically to No. 3 journal.

3. Turn camshaft to one direction with hands, and measure the

camshaft runout on the dial indicator. (Total indicator reading)

4. If it exceeds the limit, replace camshaft.

Camshaft Cam Height

1. Measure the camshaft cam height with a micrometer (A).

2. If wear exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance

CAMSHAFT JOURNAL DIAMETER

Measure the outer diameter of camshaft journal with a micrometer

(A).

CAMSHAFT BRACKET INNER DIAMETER

Tighten camshaft bracket bolts with the specified torque. Refer to EM-59, "

Removal and Installation".

PBIC3693E

Standard and Limit:

Refer to EM-123, "

Camshaft".

PBIC2499E

Standard and Cam wear Limit:

Refer to EM-123, "

Camshaft".

PBIC3178J

Standard: Refer to EM-123, "Camshaft".

PBIC3179J

Page 2720 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-73

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure inner diameter (B) of camshaft bracket with a bore gauge

(A).

CAMSHAFT JOURNAL OIL CLEARANCE

(Oil clearance) = NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-73

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure inner diameter (B) of camshaft bracket with a bore gauge

(A).

CAMSHAFT JOURNAL OIL CLEARANCE

(Oil clearance) =](/img/5/57395/w960_57395-2719.png)

CAMSHAFT

EM-73

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure inner diameter (B) of camshaft bracket with a bore gauge

(A).

CAMSHAFT JOURNAL OIL CLEARANCE

(Oil clearance) = (Camshaft bracket inner diameter) – (Camshaft journal diameter)

If it exceeds the limit, replace either or both camshaft and cylinder head.

NOTE:

Camshaft brackets cannot be replaced as single parts, because they are machined together with cylinder

head. Replace whole cylinder head assembly.

Camshaft End Play

1. Install camshaft in cylinder head. Refer to EM-59, "Removal and Installation".

2. Install a dial indicator (A) in thrust direction on front end of cam-

shaft. Measure the camshaft end play on the dial indicator when

camshaft is moved forward/backward (in direction to axis).

Measure the following parts if out of the standard.

- Dimension “A” for cylinder head No. 1 journal bearing

- Dimension “B” for camshaft thrust

Follow the standards above, and then replace camshaft and/or

cylinder head.

Camshaft Sprocket Runout

1. Put V-block on precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter

from the other four locations.Standard: Refer to EM-123, "

Camshaft".

PBIC3180J

Standard and Limit: Refer to EM-123, "Camshaft".

Standard and Limit: Refer to EM-123, "

Camshaft".

PBIC3694E

Standard : 4.000 - 4.030 mm (0.1575 - 0.1587 in)

Standard : 3.877 - 3.925 mm (0.1526 - 0.1545 in)

KBIA3345J

Page 2760 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CYLINDER BLOCK

EM-113

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

CRANKSHAFT PIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft pin journal with a micrometer.

NISSAN TIIDA 2007 Service Repair Manual CYLINDER BLOCK

EM-113

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

CRANKSHAFT PIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft pin journal with a micrometer.

](/img/5/57395/w960_57395-2759.png)

CYLINDER BLOCK

EM-113

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

CRANKSHAFT PIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft pin journal with a micrometer.

If out of the standard, measure the connecting rod bearing oil clearance. Then use undersize bearing.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

Measure the dimensions at four different points as shown in the

figure on each main journal and pin journal with a micrometer.

Out-of-round is indicated by the difference in dimensions between

“X” and “Y” at “A” and “B”.

Taper is indicated by the difference in dimension between “A” and

“B” at “X” and “Y”.

If the measured value exceeds the limit, correct or replace crankshaft.

If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then select

main bearing and/or connecting rod bearing.

CRANKSHAFT RUNOUT

Place a V-block on a precise flat table to support the journals on

the both end of crankshaft.

Place a dial indicator (A) straight up on the No. 3 journal.

While rotating crankshaft, read the movement of the pointer on the

dial indicator. (Total indicator reading)

If it exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Install connecting rod bearings to connecting rod and cap, and tighten connecting rod bolts to the specified

torque. Refer to EM-101, "

Disassembly and Assembly".

Measure the inner diameter of connecting rod bearing with an

inside micrometer.

(Bearing oil clearance) = (Connecting rod bearing inner diameter)

– (Crankshaft pin journal diameter)

If the clearance exceeds the limit, select proper connecting rod

bearing according to connecting rod big end diameter and crank-

shaft pin journal diameter to obtain the specified bearing oil clear-

ance. Refer to EM-117, "

Connecting Rod Bearing".

Method of Using Plastigage

Remove engine oil and dust on crankshaft pin and the surfaces of each bearing completely.

Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

Install connecting rod bearings to connecting rod and cap, and tighten connecting rod bolts to the specified

torque. Refer to EM-101, "

Disassembly and Assembly".

CAUTION:Standard : Refer to EM-127, "

Cylinder Block".

Limit:

Out-of-round (Difference between“X”and“Y”)

Taper (Difference between“A”and“B”)

: Refer to EM-127, "

Cylinder Block".PBIC3459J

Limit : Refer to EM-127, "Cylinder Block".

PBIC3458J

Standard and Limit

: Refer to EM-130, "

Connecting Rod Bearing".

PBIC1642E

Page 2835 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-188

< ON-VEHICLE REPAIR >[MR18DE]

CAMSHAFT

13. Remove valve lifters.

NOTE:

Identify installed positions, and store them without mixing them up.

INSPECTION AFTER REMOVAL

Camshaft Runout

1. Put V-bl NISSAN TIIDA 2007 Service Repair Manual EM-188

< ON-VEHICLE REPAIR >[MR18DE]

CAMSHAFT

13. Remove valve lifters.

NOTE:

Identify installed positions, and store them without mixing them up.

INSPECTION AFTER REMOVAL

Camshaft Runout

1. Put V-bl](/img/5/57395/w960_57395-2834.png)

EM-188

< ON-VEHICLE REPAIR >[MR18DE]

CAMSHAFT

13. Remove valve lifters.

NOTE:

Identify installed positions, and store them without mixing them up.

INSPECTION AFTER REMOVAL

Camshaft Runout

1. Put V-block on a precise flat table, and support No. 2 and 5 jour-

nal of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft

sprocket) because it has a different diameter from the other

four locations.

2. Set dial indicator (A) vertically to No. 3 journal.

3. Turn camshaft to one direction with hands, and measure the

camshaft runout on dial indicator. (Total indicator reading)

4. If it exceeds the limit, replace camshaft.

Camshaft Cam Height

1. Measure the camshaft cam height with a micrometer (A).

2. If it exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance

CAMSHAFT JOURNAL OUTER DIAMETER

Measure the outer diameter of camshaft journal with a micrometer

(A).

CAMSHAFT BRACKET INNER DIAMETER

Tighten camshaft bracket bolts with specified torque. Use the "INSTALLATION" procedure. Standard : Less than 0.02 mm (0.0008 in).

Limit : 0.05 mm (0.0020 in)

PBIC3177J

Standard:

Intake : 44.605 - 44.795 mm (1.7560 - 1.7635 in)

Exhaust : 43.175 - 43.365 mm (1.6997 - 1.7072 in)

Limit:

Intake : 44.405 mm (1.7482 in)

Exhaust : 42.975 mm (1.6919 in)

PBIC3178J

Standard:

No. 1 : 27.935 - 27.955 mm (1.0998 - 1.1006 in)

No. 2, 3, 4, 5 : 24.950 - 24.970 mm (0.9823 - 0.9831 in)

PBIC3179J

Page 2836 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-189

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure the inner diameter of camshaft bracket with a bore gauge

(A).

CAMSHAFT JOURNAL OIL CLEARANCE

(Oil clearance) = NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-189

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure the inner diameter of camshaft bracket with a bore gauge

(A).

CAMSHAFT JOURNAL OIL CLEARANCE

(Oil clearance) =](/img/5/57395/w960_57395-2835.png)

CAMSHAFT

EM-189

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure the inner diameter of camshaft bracket with a bore gauge

(A).

CAMSHAFT JOURNAL OIL CLEARANCE

(Oil clearance) = (Camshaft bracket inner diameter) – (Camshaft journal diameter)

If it exceeds the limit, replace camshaft or cylinder head, or both.

NOTE:

Camshaft bracket cannot be replaced as a single part, because it is machined together with cylinder head.

Replace whole cylinder head assembly.

Camshaft End Play

1. Install camshaft in cylinder head.

2. Install dial indicator in thrust direction on front end of camshaft.

Read the end play of dial indicator (A) when camshaft is moved

forward/backward (in direction to axis).

Measure the following parts if out of the standard.

- Dimension “A” for groove of cylinder head No. 1 journal

- Dimension “B” for camshaft flange

Refer to the standards above, and then replace camshaft and/

or cylinder head.

Camshaft Sprocket Runout

1. Put V-block on precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter

from the other four locations.

B : Measuring direction of inner diameter

Standard:

No. 1 : 28.000 - 28.021 mm (1.1024 - 1.1032 in)

No. 2, 3, 4, 5 : 25.000 - 25.021 mm (0.9843 - 0.9851 in)

PBIC3180J

Standard:

No. 1 : 0.045 - 0.086 mm (0.0018 - 0.0034 in)

No. 2, 3, 4, 5 : 0.030 - 0.071 mm (0.0012 - 0.0028 in)

Limit:

: 0.15 mm (0.0059 in)

Standard : 0.075 - 0.153 mm (0.0030 - 0.0060 in)

Limit : 0.24 mm (0.0094 in)

PBIC3181J

Standard : 4.000 - 4.030 mm (0.1575 - 0.1587 in)

Standard : 3.877 - 3.925 mm (0.1526 - 0.1545 in)

PBIC3183J

Page 2872 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE UNIT

EM-225

< DISASSEMBLY AND ASSEMBLY >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure the outer diameter of crankshaft main journals with a

micrometer (A).

If out of the standard, measur NISSAN TIIDA 2007 Service Repair Manual ENGINE UNIT

EM-225

< DISASSEMBLY AND ASSEMBLY >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure the outer diameter of crankshaft main journals with a

micrometer (A).

If out of the standard, measur](/img/5/57395/w960_57395-2871.png)

ENGINE UNIT

EM-225

< DISASSEMBLY AND ASSEMBLY >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Measure the outer diameter of crankshaft main journals with a

micrometer (A).

If out of the standard, measure the main bearing oil clearance.

Then use undersize bearing. Refer to "MAIN BEARING OIL

CLEARANCE".

CRANKSHAFT PIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft pin journal with a micrometer.

If out of the standard, measure the connecting rod bearing oil clearance. Then use undersize bearing. Refer

to "CONNECTING ROD BEARING OIL CLEARANCE".

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

Measure the dimensions at four different points as shown on each

main journal and pin journal with a micrometer.

Out-of-round is indicated by the difference in dimensions between

“X” and “Y” at “A” and “B”.

Taper is indicated by the difference in dimension between “A” and

“B” at “X” and “Y”.

If the measured value exceeds the limit, correct or replace crankshaft.

If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then select

main bearing and/or connecting rod bearing. Refer to "MAIN BEARING OIL CLEARANCE" and/or "CON-

NECTING ROD BEARING OIL CLEARANCE".

CRANKSHAFT RUNOUT

Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

Place a dial indicator (A) straight up on the No. 3 journal.

While rotating crankshaft, read the movement of the pointer on the

dial indicator. (Total indicator reading)

If it exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Standard: 51.959 - 51.979 mm (2.0456 - 2.0464 in) dia.

PBIC3457J

Standard: 43.953 - 43.971 mm (1.7304-1.7311 in) dia.

Limit:

Out-of-round (Difference between “X” and “Y”)

: 0.0035 mm (0.0001 in)

Taper (Difference between “A” and “B”)

: 0.0035 mm (0.0001 in)

PBIC3459J

Standard : 0.05 mm (0.0020 in)

Limit : 0.10 mm (0.0040 in)

PBIC3458J

Page 2947 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-300

< ON-VEHICLE REPAIR >[K9K]

CAMSHAFT

7. Screw the collar nut until the cover touches the cylinder head.

8. Install camshaft sprocket and sprocket holder [SST: — (Mot.

1606-A)] (A).

9. Install NISSAN TIIDA 2007 Service Repair Manual EM-300

< ON-VEHICLE REPAIR >[K9K]

CAMSHAFT

7. Screw the collar nut until the cover touches the cylinder head.

8. Install camshaft sprocket and sprocket holder [SST: — (Mot.

1606-A)] (A).

9. Install](/img/5/57395/w960_57395-2946.png)

EM-300

< ON-VEHICLE REPAIR >[K9K]

CAMSHAFT

7. Screw the collar nut until the cover touches the cylinder head.

8. Install camshaft sprocket and sprocket holder [SST: — (Mot.

1606-A)] (A).

9. Install timing belt. Refer to EM-291, "

Removal and Installation".

10. Installation is in the reverse order of removal.

InspectionINFOID:0000000001381503

INSPECTION AFTER REMOVAL

Camshaft Runout

1. Put V-block on a precise flat table, and support No. 2 and 4 journal of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft

sprocket) because it has a different diameter from the other

four locations.

2. Set dial indicator (A) vertically to No. 3 journal.

3. Turn camshaft in one direction and measure the camshaft

runout on dial indicator. (Total indicator reading)

4. If it exceeds the limit, replace camshaft.

Camshaft Cam Height

1. Measure the camshaft cam height with a suitable tool (A).

2. If it exceeds the limit, replace camshaft.

Camshaft End Play

MBIB0433E

E1BIA0054ZZ

Standard : Refer to EM-333, "Camshaft".

PBIC3177J

Standard : Refer to EM-333, "Camshaft".

PBIC3178J

Page 3182 of 5883

FSU-6

< ON-VEHICLE MAINTENANCE >

FRONT SUSPENSION ASSEMBLY

ON-VEHICLE MAINTENANCE

FRONT SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001716890

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

STRUT INSPECTION

Check for oil leakage, damage and replace as necessary.

Wheel Alignment InspectionINFOID:0000000001716891

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-5, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FA X - 5 , "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-18, "

Wheelarch Height (Unladen*)" .

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

This type of alignment is recommended for any NISSAN vehicle.

The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

The alignment machine itself should be capable of accepting any NISSAN vehicle.

The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

Your alignment machine should be regularly calibrated in order to give correct information.

Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-17, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators. Axial end play : 0 mm (0 in)

Page 3278 of 5883

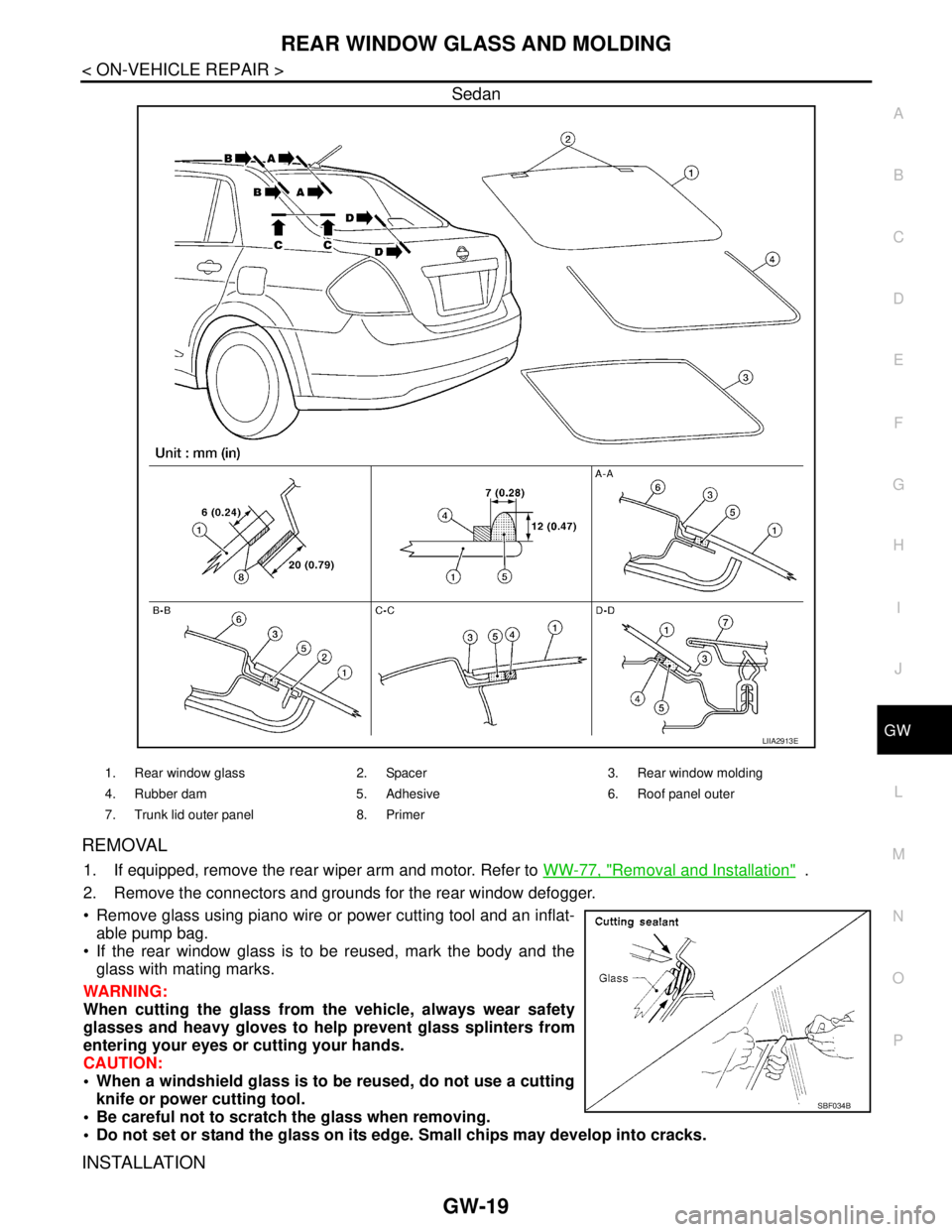

REAR WINDOW GLASS AND MOLDING

GW-19

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

GW

N

O

P

Sedan

REMOVAL

1. If equipped, remove the rear wiper arm and motor. Refer to WW-77, "Removal and Installation" .

2. Remove the connectors and grounds for the rear window defogger.

Remove glass using piano wire or power cutting tool and an inflat-

able pump bag.

If the rear window glass is to be reused, mark the body and the

glass with mating marks.

WARNING:

When cutting the glass from the vehicle, always wear safety

glasses and heavy gloves to help prevent glass splinters from

entering your eyes or cutting your hands.

CAUTION:

When a windshield glass is to be reused, do not use a cutting

knife or power cutting tool.

Be careful not to scratch the glass when removing.

Do not set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

LIIA2913E

1. Rear window glass 2. Spacer 3. Rear window molding

4. Rubber dam 5. Adhesive 6. Roof panel outer

7. Trunk lid outer panel 8. Primer

SBF034B