brake fluid NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 193 of 5883

BR-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BR

A

B

BR

N

O

P

CONTENTS

BRAKE SYSTEM

PRECAUTION ...............................................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Brake System ....................................3

PREPARATION ............................................4

PREPARATION ...................................................4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ......................................5

ON-VEHICLE MAINTENANCE .....................6

BRAKE PEDAL ...................................................6

Inspection and Adjustment ........................................6

BRAKE FLUID .....................................................8

On Board Inspection .................................................8

Drain and Refill ..........................................................8

Bleeding Brake System .............................................8

FRONT DISC BRAKE ........................................10

Inspection ................................................................10

REAR DISC BRAKE ..........................................11

Inspection ................................................................11

ON-VEHICLE REPAIR .................................12

BRAKE PEDAL ..................................................12

Removal and Installation .........................................12

BRAKE TUBE AND HOSE ................................14

Hydraulic Circuit ......................................................14

Front Brake Tube and Hose ....................................14

Rear Brake Tube and Hose .....................................15

Inspection After Installation .....................................15

DUAL PROPORTIONING VALVE ....................17

Removal and Installation .........................................17

Inspection ................................................................17

BRAKE MASTER CYLINDER ..........................18

On-Board Inspection ................................................18

Removal and Installation .........................................18

BRAKE BOOSTER ...........................................19

On Board Inspection ................................................19

Removal and Installation .........................................19

VACUUM LINES ...............................................22

Component ..............................................................22

Removal and Installation .........................................22

Inspection ................................................................22

FRONT DISC BRAKE .......................................24

Component ..............................................................24

Removal and Installation of Brake Pad ...................24

Removal and Installation of Brake Caliper Assem-

bly ............................................................................

25

Brake Burnishing .....................................................26

REAR DISC BRAKE .........................................27

Component ..............................................................27

Removal and Installation of Brake Pad ...................28

Removal and Installation of Brake Caliper Assem-

bly ............................................................................

28

Brake Burnishing .....................................................29

DISASSEMBLY AND ASSEMBLY ..............30

BRAKE MASTER CYLINDER ..........................30

Disassembly and Assembly .....................................30

FRONT DISC BRAKE .......................................34

Disassembly and Assembly of Brake Caliper As-

sembly .....................................................................

34

Page 195 of 5883

PRECAUTIONS

BR-3

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001716907

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001716908

Refill using recommended brake fluid. Refer to MA-19, "Fluids and Lubricants".

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted surface of body. If brake fluid is splashed on painted surfaces

of body immediately wipe it off with cloth and then wash it away with water.

To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use a flare nut wrench when removing a brake tube and use a

flare nut torque wrench when installing a brake tube.

When installing brake tubes and hoses, be sure to check torque.

Before working, turn ignition switch OFF and disconnect connec-

tors of ABS actuator and electric unit (control unit) or the battery

cable from the negative terminal.

Burnish the new braking surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-26, "

Brake Burnishing" .

SBR686C

Page 200 of 5883

BR-8

< ON-VEHICLE MAINTENANCE >

BRAKE FLUID

BRAKE FLUID

On Board InspectionINFOID:0000000001716919

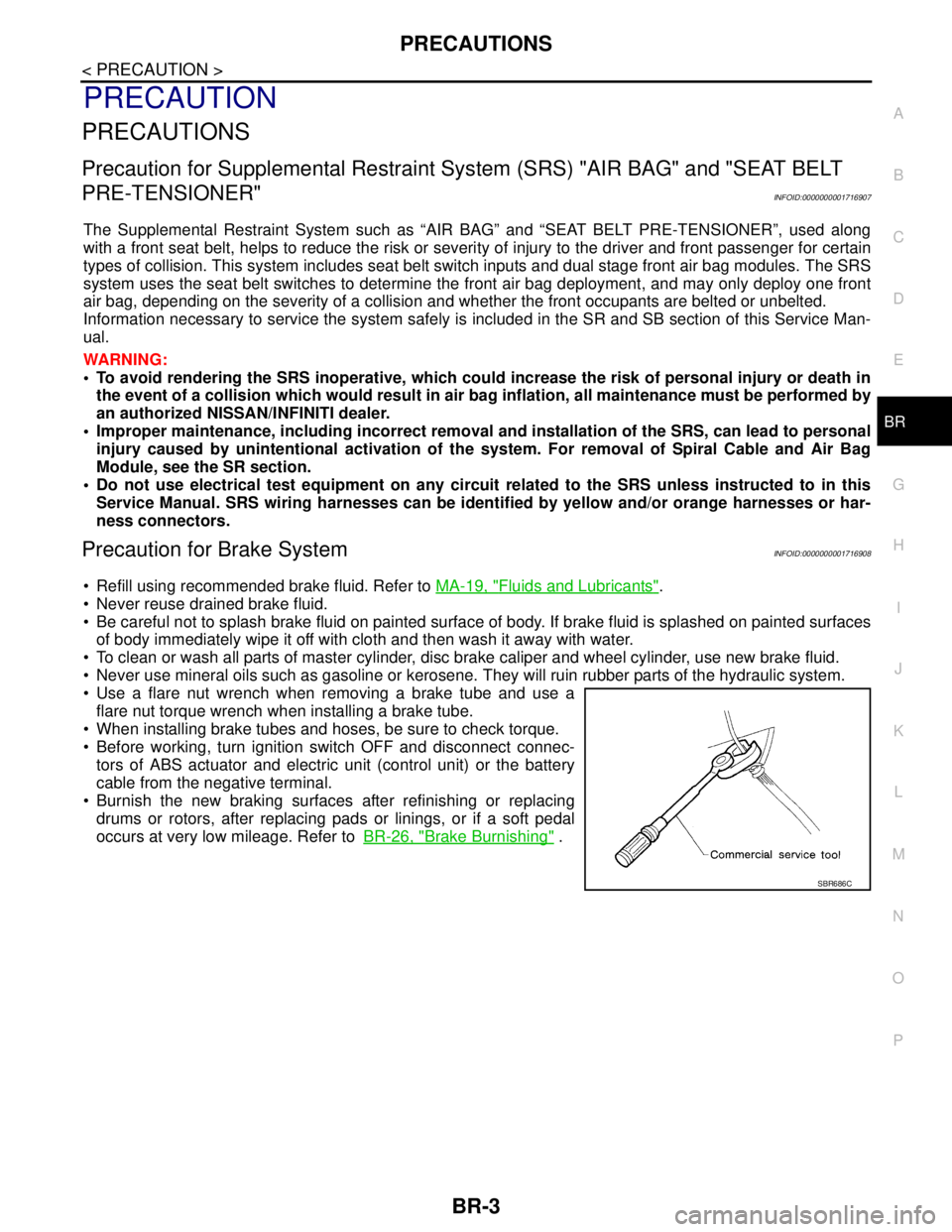

CHECKING BRAKE FLUID LEVEL

Make sure the fluid level in the reservoir tank is within the standard

(between MAX and MIN lines).

Visually check around the reservoir tank for fluid leakage.

If fluid level is excessively low, check brake system for fluid leak-

age.

Release parking brake lever and see if brake warning lamp goes

off. If not, check brake system for fluid leakage.

Drain and RefillINFOID:0000000001716920

CAUTION:

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe them with cloth and wash it away with water.

Before working, disconnect connectors of ABS actuator and electric unit (control unit) or battery

cable from the negative terminal.

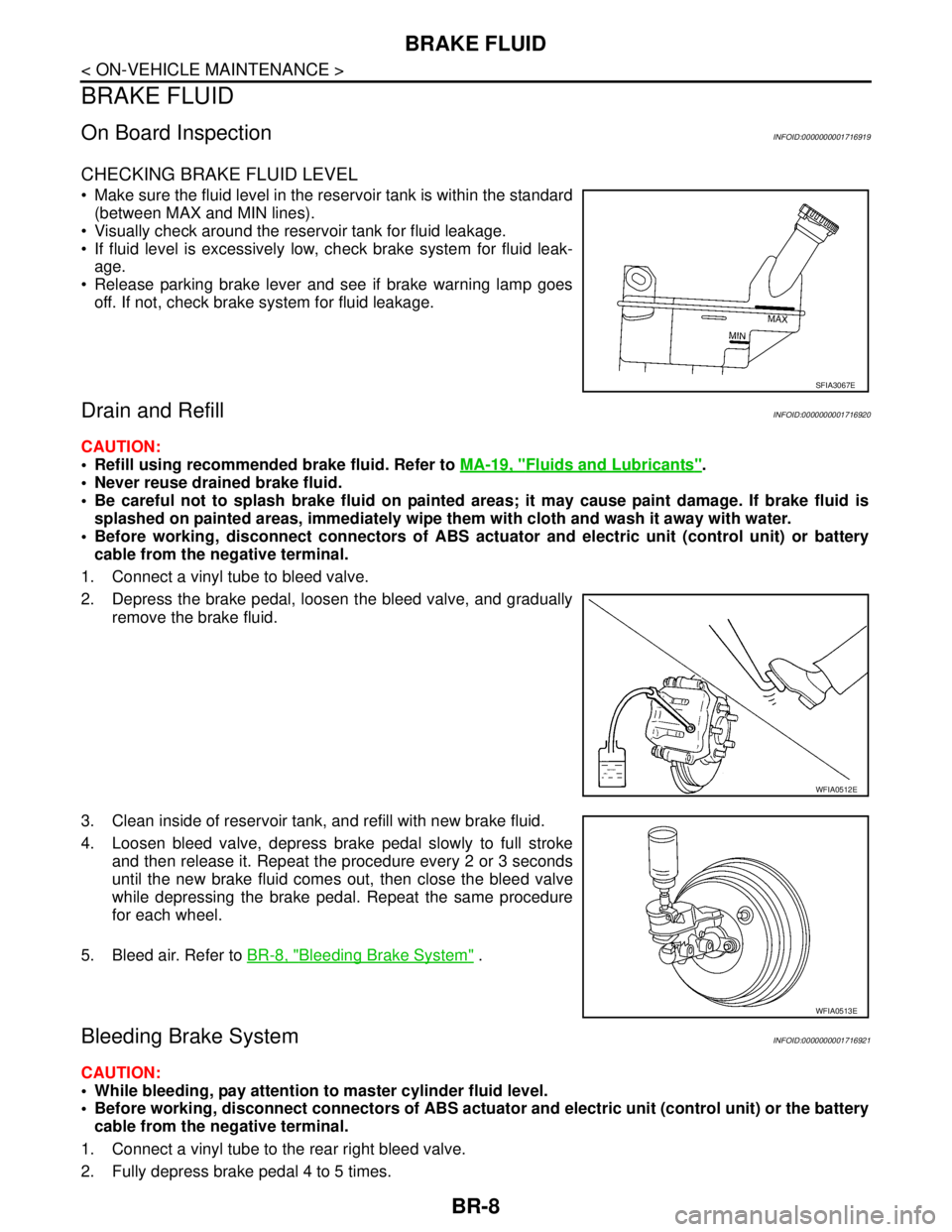

1. Connect a vinyl tube to bleed valve.

2. Depress the brake pedal, loosen the bleed valve, and gradually

remove the brake fluid.

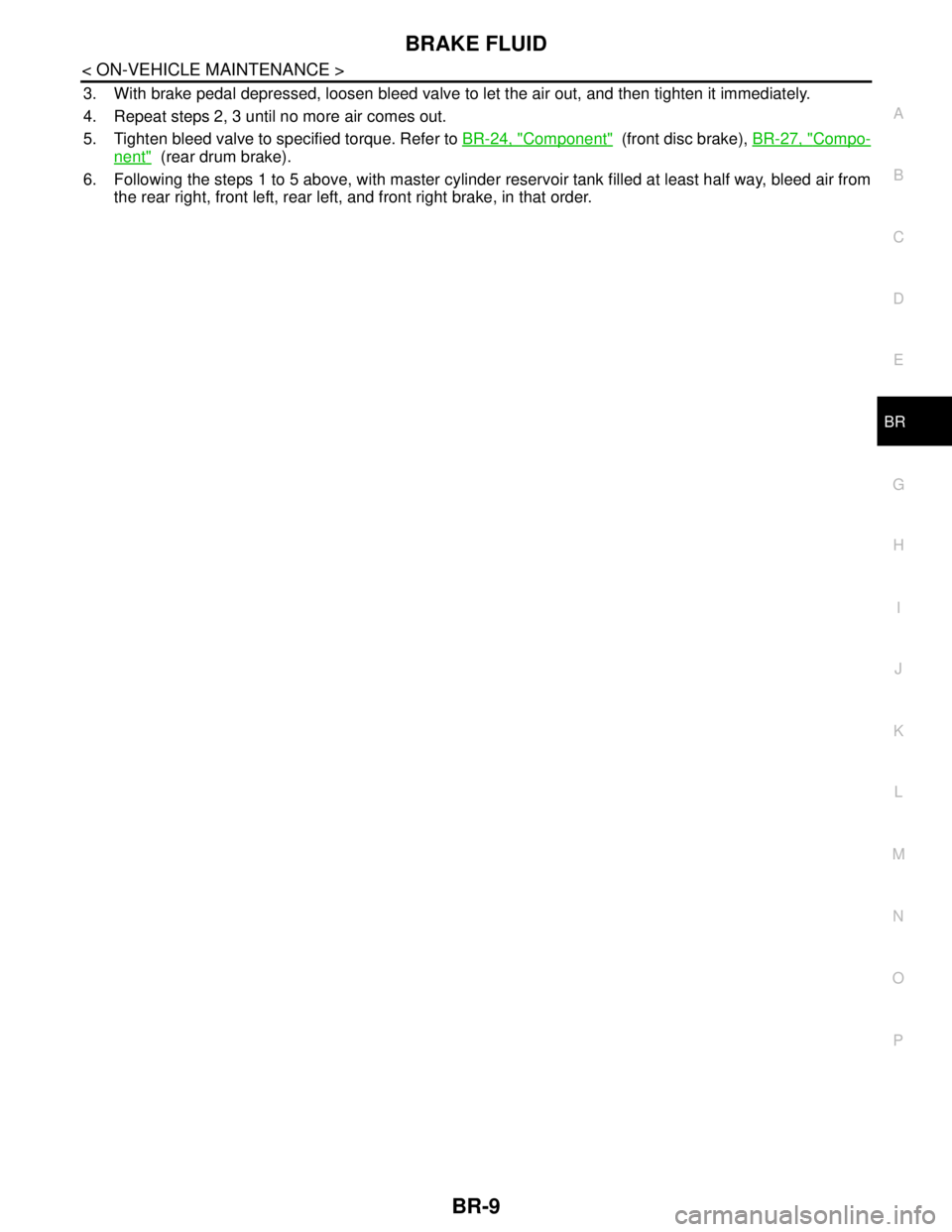

3. Clean inside of reservoir tank, and refill with new brake fluid.

4. Loosen bleed valve, depress brake pedal slowly to full stroke

and then release it. Repeat the procedure every 2 or 3 seconds

until the new brake fluid comes out, then close the bleed valve

while depressing the brake pedal. Repeat the same procedure

for each wheel.

5. Bleed air. Refer to BR-8, "

Bleeding Brake System" .

Bleeding Brake SystemINFOID:0000000001716921

CAUTION:

While bleeding, pay attention to master cylinder fluid level.

Before working, disconnect connectors of ABS actuator and electric unit (control unit) or the battery

cable from the negative terminal.

1. Connect a vinyl tube to the rear right bleed valve.

2. Fully depress brake pedal 4 to 5 times.

SFIA3067E

WFIA0512E

WFIA0513E

Page 201 of 5883

BRAKE FLUID

BR-9

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

3. With brake pedal depressed, loosen bleed valve to let the air out, and then tighten it immediately.

4. Repeat steps 2, 3 until no more air comes out.

5. Tighten bleed valve to specified torque. Refer to BR-24, "

Component" (front disc brake), BR-27, "Compo-

nent" (rear drum brake).

6. Following the steps 1 to 5 above, with master cylinder reservoir tank filled at least half way, bleed air from

the rear right, front left, rear left, and front right brake, in that order.

Page 206 of 5883

BR-14

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

BRAKE TUBE AND HOSE

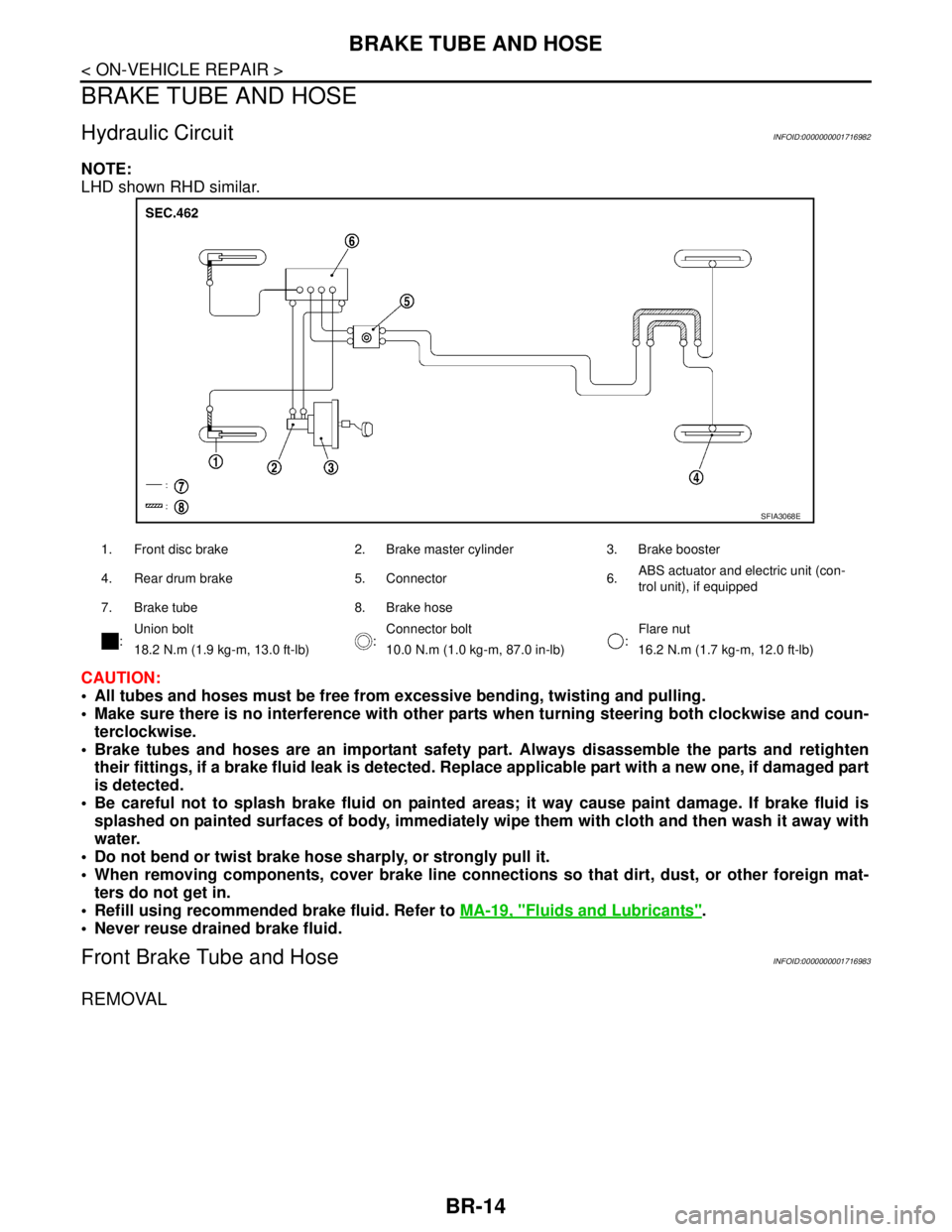

Hydraulic CircuitINFOID:0000000001716982

NOTE:

LHD shown RHD similar.

CAUTION:

All tubes and hoses must be free from excessive bending, twisting and pulling.

Make sure there is no interference with other parts when turning steering both clockwise and coun-

terclockwise.

Brake tubes and hoses are an important safety part. Always disassemble the parts and retighten

their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part

is detected.

Be careful not to splash brake fluid on painted areas; it way cause paint damage. If brake fluid is

splashed on painted surfaces of body, immediately wipe them with cloth and then wash it away with

water.

Do not bend or twist brake hose sharply, or strongly pull it.

When removing components, cover brake line connections so that dirt, dust, or other foreign mat-

ters do not get in.

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Front Brake Tube and HoseINFOID:0000000001716983

REMOVAL

1. Front disc brake 2. Brake master cylinder 3. Brake booster

4. Rear drum brake 5. Connector 6.ABS actuator and electric unit (con-

trol unit), if equipped

7. Brake tube 8. Brake hose

:Union bolt

:Connector bolt

:Flare nut

18.2 N.m (1.9 kg-m, 13.0 ft-lb) 10.0 N.m (1.0 kg-m, 87.0 in-lb) 16.2 N.m (1.7 kg-m, 12.0 ft-lb)

SFIA3068E

Page 207 of 5883

BRAKE TUBE AND HOSE

BR-15

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

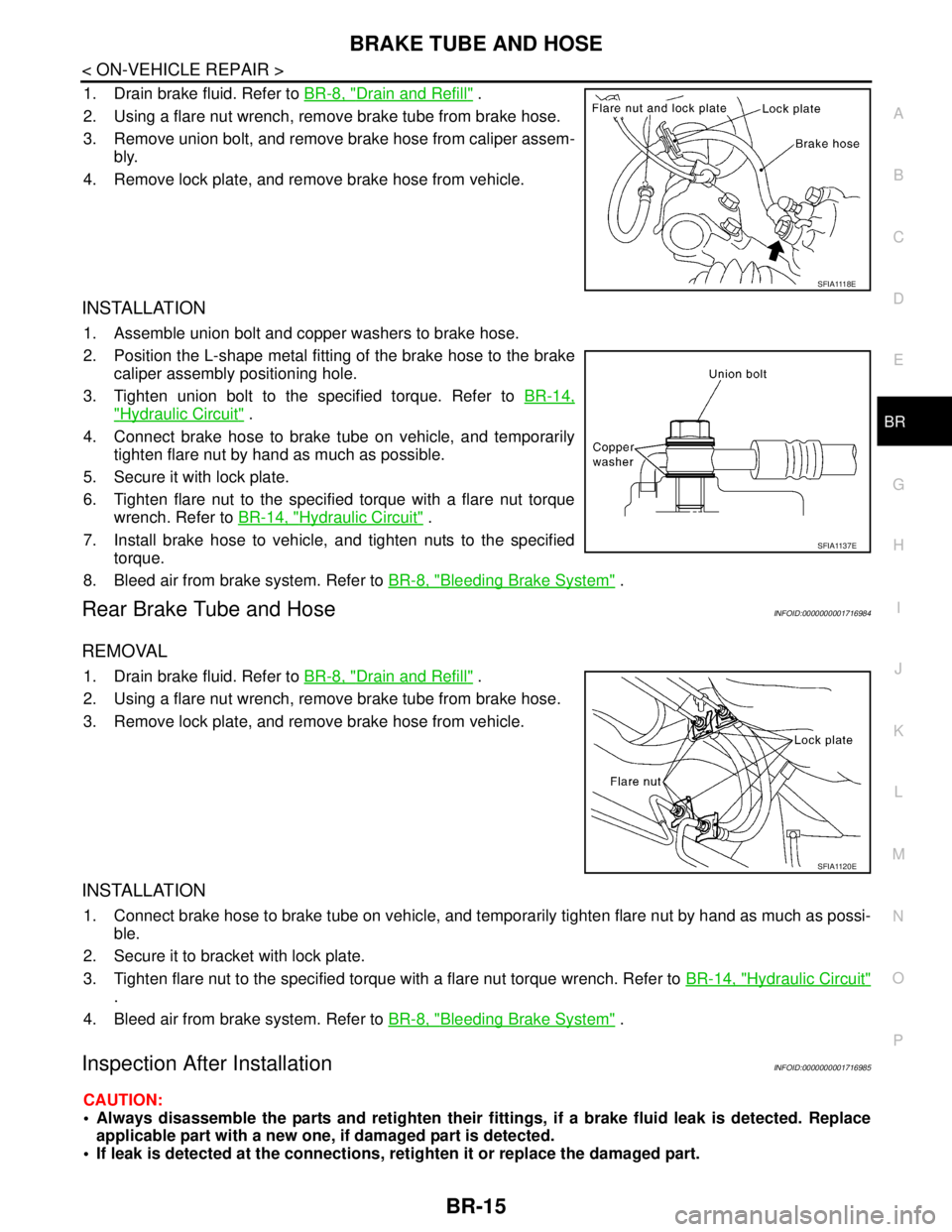

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove union bolt, and remove brake hose from caliper assem-

bly.

4. Remove lock plate, and remove brake hose from vehicle.

INSTALLATION

1. Assemble union bolt and copper washers to brake hose.

2. Position the L-shape metal fitting of the brake hose to the brake

caliper assembly positioning hole.

3. Tighten union bolt to the specified torque. Refer to BR-14,

"Hydraulic Circuit" .

4. Connect brake hose to brake tube on vehicle, and temporarily

tighten flare nut by hand as much as possible.

5. Secure it with lock plate.

6. Tighten flare nut to the specified torque with a flare nut torque

wrench. Refer to BR-14, "

Hydraulic Circuit" .

7. Install brake hose to vehicle, and tighten nuts to the specified

torque.

8. Bleed air from brake system. Refer to BR-8, "

Bleeding Brake System" .

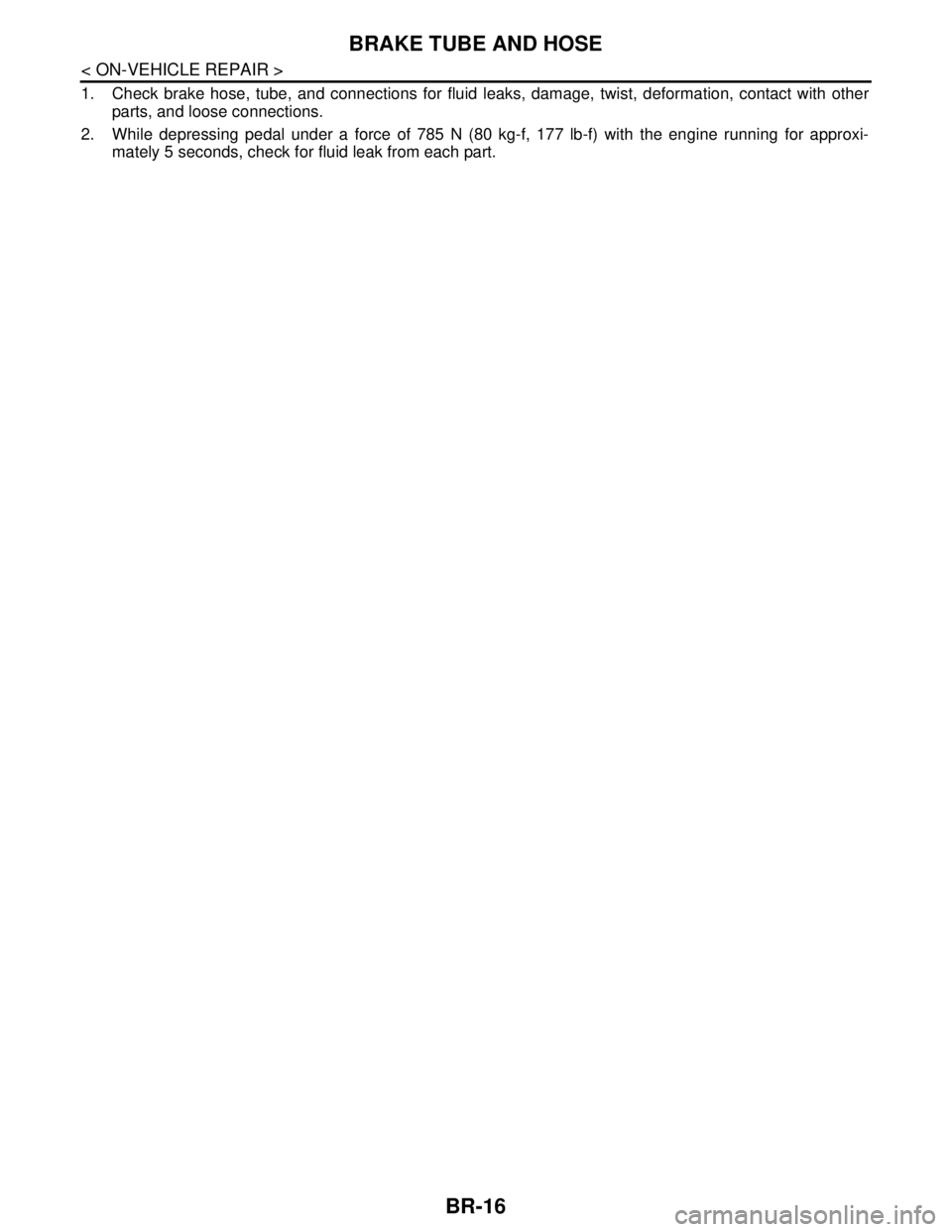

Rear Brake Tube and HoseINFOID:0000000001716984

REMOVAL

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove lock plate, and remove brake hose from vehicle.

INSTALLATION

1. Connect brake hose to brake tube on vehicle, and temporarily tighten flare nut by hand as much as possi-

ble.

2. Secure it to bracket with lock plate.

3. Tighten flare nut to the specified torque with a flare nut torque wrench. Refer to BR-14, "

Hydraulic Circuit"

.

4. Bleed air from brake system. Refer to BR-8, "

Bleeding Brake System" .

Inspection After InstallationINFOID:0000000001716985

CAUTION:

Always disassemble the parts and retighten their fittings, if a brake fluid leak is detected. Replace

applicable part with a new one, if damaged part is detected.

If leak is detected at the connections, retighten it or replace the damaged part.

S F I A 111 8 E

SFIA1137E

SFIA1120E

Page 208 of 5883

BR-16

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

1. Check brake hose, tube, and connections for fluid leaks, damage, twist, deformation, contact with other

parts, and loose connections.

2. While depressing pedal under a force of 785 N (80 kg-f, 177 lb-f) with the engine running for approxi-

mately 5 seconds, check for fluid leak from each part.

Page 209 of 5883

DUAL PROPORTIONING VALVE

BR-17

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

DUAL PROPORTIONING VALVE

Removal and InstallationINFOID:0000000001726771

Removal

1. Disconnect brake lines from dual proportioning valve.

Mark brake lines for installation.

2. Remove dual proportioning valve bolt and dual proportioning valve.

3. Remove two bolts and bracket.

Installation

Installation is in the reverse order of removal.

When installing brake lines to the dual proportioning valve, tighten to specifications. Refer to BR-14,

"Hydraulic Circuit".

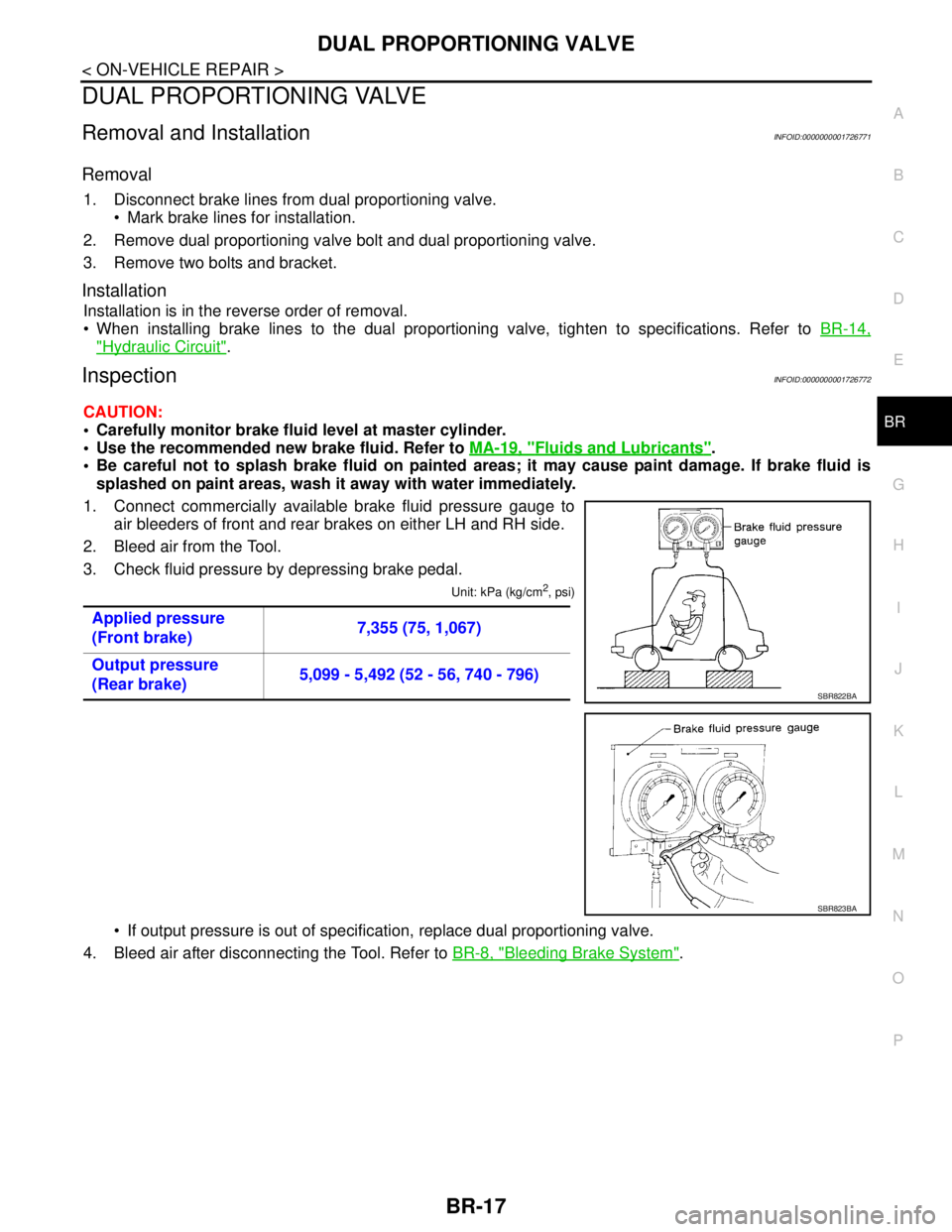

InspectionINFOID:0000000001726772

CAUTION:

Carefully monitor brake fluid level at master cylinder.

Use the recommended new brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on paint areas, wash it away with water immediately.

1. Connect commercially available brake fluid pressure gauge to

air bleeders of front and rear brakes on either LH and RH side.

2. Bleed air from the Tool.

3. Check fluid pressure by depressing brake pedal.

Unit: kPa (kg/cm2, psi)

If output pressure is out of specification, replace dual proportioning valve.

4. Bleed air after disconnecting the Tool. Refer to BR-8, "

Bleeding Brake System". Applied pressure

(Front brake)7,355 (75, 1,067)

Output pressure

(Rear brake)5,099 - 5,492 (52 - 56, 740 - 796)

SBR822BA

SBR823BA

Page 210 of 5883

BR-18

< ON-VEHICLE REPAIR >

BRAKE MASTER CYLINDER

BRAKE MASTER CYLINDER

On-Board InspectionINFOID:0000000001716996

LEAK INSPECTION

Check for leaking in a master cylinder installation surface, a reservoir tank installation surface, and brake

tube connections.

Removal and InstallationINFOID:0000000001716997

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe them with cloth and wash it away with water.

REMOVAL

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Remove battery. Refer to PG-6, "

Removal and Installation" .

3. Remove air duct and air cleaner. Refer to EM-27, "

Removal and Installation" (HR16DE), EM-154,

"Removal and Installation" (MR18DE), EM-269, "Removal and Installation" (K9K).

4. Disconnect brake fluid level switch harness connector.

5. Using a flare nut wrench, remove brake tube from master cylinder.

6. Remove master cylinder assembly nuts, and remove master cylinder assembly from vehicle..

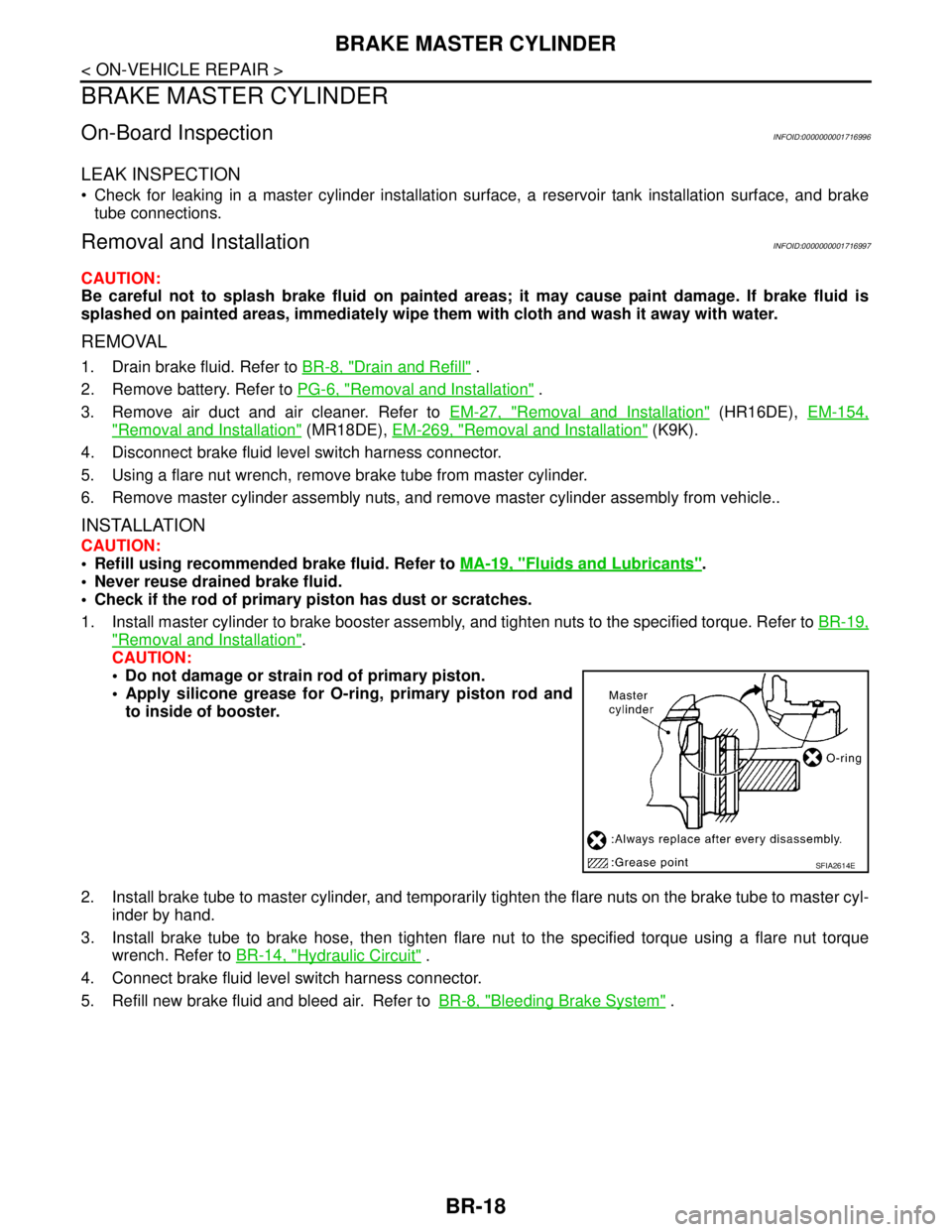

INSTALLATION

CAUTION:

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Check if the rod of primary piston has dust or scratches.

1. Install master cylinder to brake booster assembly, and tighten nuts to the specified torque. Refer to BR-19,

"Removal and Installation".

CAUTION:

Do not damage or strain rod of primary piston.

Apply silicone grease for O-ring, primary piston rod and

to inside of booster.

2. Install brake tube to master cylinder, and temporarily tighten the flare nuts on the brake tube to master cyl-

inder by hand.

3. Install brake tube to brake hose, then tighten flare nut to the specified torque using a flare nut torque

wrench. Refer to BR-14, "

Hydraulic Circuit" .

4. Connect brake fluid level switch harness connector.

5. Refill new brake fluid and bleed air. Refer toBR-8, "

Bleeding Brake System" .

SFIA2614E

Page 212 of 5883

BR-20

< ON-VEHICLE REPAIR >

BRAKE BOOSTER

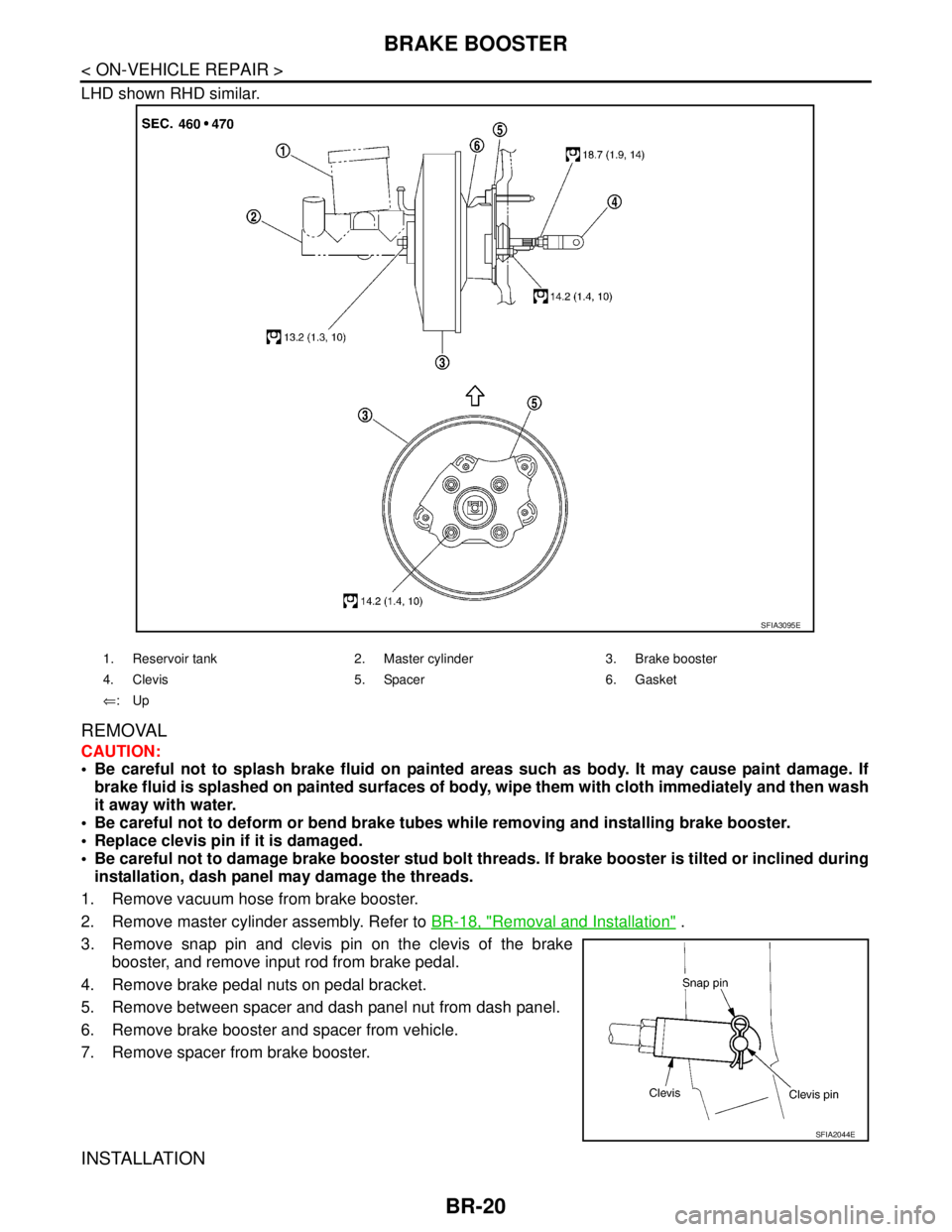

LHD shown RHD similar.

REMOVAL

CAUTION:

Be careful not to splash brake fluid on painted areas such as body. It may cause paint damage. If

brake fluid is splashed on painted surfaces of body, wipe them with cloth immediately and then wash

it away with water.

Be careful not to deform or bend brake tubes while removing and installing brake booster.

Replace clevis pin if it is damaged.

Be careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined during

installation, dash panel may damage the threads.

1. Remove vacuum hose from brake booster.

2. Remove master cylinder assembly. Refer to BR-18, "

Removal and Installation" .

3. Remove snap pin and clevis pin on the clevis of the brake

booster, and remove input rod from brake pedal.

4. Remove brake pedal nuts on pedal bracket.

5. Remove between spacer and dash panel nut from dash panel.

6. Remove brake booster and spacer from vehicle.

7. Remove spacer from brake booster.

INSTALLATION

1. Reservoir tank 2. Master cylinder 3. Brake booster

4. Clevis 5. Spacer 6. Gasket

⇐:Up

SFIA3095E

SFIA2044E