indicator NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1840 of 2771

FSU-6

< SERVICE INFORMATION >

FRONT SUSPENSION ASSEMBLY

FRONT SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001703721

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

STRUT INSPECTION

Check for oil leakage, damage and replace as necessary.

Wheel Alignment InspectionINFOID:0000000001703722

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-5, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FA X - 5 , "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-17, "

Wheelarch Height (Unladen*)" .

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

• Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-16, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.Axial end play : 0 mm (0 in)

Page 1899 of 2771

GI-48

< SERVICE INFORMATION >

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 1900 of 2771

TERMINOLOGY

GI-49

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switchPark/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TBThrottle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valveLock-up cancel solenoid

Lock-up solenoid NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2001 of 2771

![NISSAN TIIDA 2008 Service Repair Manual LAN-10

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and receptio NISSAN TIIDA 2008 Service Repair Manual LAN-10

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and receptio](/img/5/57399/w960_57399-2000.png)

LAN-10

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

• The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

CONSULT-III if the following error occurs. The error is judged by the symptom.

EPS control unit Normal operation.

Combination meter• Shift position indicator and OD OFF indicator turn OFF.

• Warning lamps turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R Normal operation.Unit name Symptom

SKIB8739E

Unit name Symptom

ECM

Normal operation. BCM

EPS control unit

Combination meter

ABS actuator and electric unit (control unit)

TCM

IPDM E/R

Error Difference of symptom

Data link connector branch line open circuit Normal operation.

CAN-H, CAN-L harness short-circuitMost of the units which are connected to the CAN communication

system enter fail-safe mode or are deactivated.

Page 2002 of 2771

![NISSAN TIIDA 2008 Service Repair Manual TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open NISSAN TIIDA 2008 Service Repair Manual TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open](/img/5/57399/w960_57399-2001.png)

TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open Circuit

Example: CAN-H, CAN-L Harness Short Circuit

SKIB8740E

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM• Reverse warning chime does not sound.

• The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter• The shift position indicator and OD OFF indicator turn OFF.

• The speedometer is inoperative.

• The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

• The headlamps (Lo) turn ON.

• The cooling fan continues to rotate.

SKIB8741E

Page 2003 of 2771

![NISSAN TIIDA 2008 Service Repair Manual LAN-12

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

CAN Diagnosis with CONSULT-III

INFOID:0000000001711207

CAN diagnosis on CONSULT-III extracts the root cause by receiving the following NISSAN TIIDA 2008 Service Repair Manual LAN-12

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

CAN Diagnosis with CONSULT-III

INFOID:0000000001711207

CAN diagnosis on CONSULT-III extracts the root cause by receiving the following](/img/5/57399/w960_57399-2002.png)

LAN-12

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

CAN Diagnosis with CONSULT-III

INFOID:0000000001711207

CAN diagnosis on CONSULT-III extracts the root cause by receiving the following information.

• Response to the system call

• Control unit diagnosis information

• Self-diagnosis

• CAN diagnostic support monitor

Self-DiagnosisINFOID:0000000001711208

CAN Diagnostic Support MonitorINFOID:0000000001711209

MONITOR ITEM (CONSULT-III)

Unit name Symptom

ECM• Engine torque limiting is affected, and shift harshness increases.

• Engine speed drops.

BCM• Reverse warning chime does not sound.

• The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

• The room lamp does not turn ON.

• The engine does not start (if an error or malfunction occurs while turning the igni-

tion switch OFF.)

• The steering lock does not release (if an error or malfunction occurs while turning

the ignition switch OFF.)

EPS control unit The steering effort increases.

Combination meter• The tachometer and the speedometer do not move.

• Warning lamps turn ON.

• Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

• The headlamps (Lo) turn ON.

• The cooling fan continues to rotate.

DTCSelf-diagnosis item

(CONSULT-III indication)DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit. When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMMWhen a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less.

U1010 CONTROL UNIT [CAN]When an error is detected during the initial diag-

nosis for CAN controller of each control unit.Replace the control unit

indicating “U1010”.

Page 2015 of 2771

![NISSAN TIIDA 2008 Service Repair Manual LAN-24

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

Engine coolant temperature signal T R

Engine speed signal T R R

Engine status signal T R

Fuel consumption monitor signal T R

Malfunction ind NISSAN TIIDA 2008 Service Repair Manual LAN-24

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

Engine coolant temperature signal T R

Engine speed signal T R R

Engine status signal T R

Fuel consumption monitor signal T R

Malfunction ind](/img/5/57399/w960_57399-2014.png)

LAN-24

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

Engine coolant temperature signal T R

Engine speed signal T R R

Engine status signal T R

Fuel consumption monitor signal T R

Malfunction indicator lamp signal T R

Wide open throttle position signal T R R

A/C switch signal R T

Blower fan motor switch signal R T

Buzzer output signalTR

TR

Day time running light request signal

*3TR R

Door lock/unlock status signal T R

Door switch signal T R R R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal T R

Low beam request signal T R

Position lights request signal T R R

Rear window defogger switch signal T R

Sleep/wake up signalRT

TRR R

Theft warning horn request signal T R

Tire pressure signal

*4TR

Trunk open/close status signal T R

Turn indicator signal T R

EPS operation signal R T

EPS warning lamp signal T R

Door lock/unlock/trunk open request signal R T

Hazard request signal R T

Ignition knob switch signal R T

KEY warning lamp signal T R

LOCK warning lamp signal T R

Panic alarm request signal R T

Fuel level sensor signal R T

Overdrive control switch signal T R R

P/N range signal T R

Stop lamp switch signal T R R

Vehicle speed signalRRR T

RRRT R

R

*5R*5T*5

ABS warning lamp signal R TSignal name/Connecting unit

ECM

BCM

EPS

I-KEY

M&A

ABS

TCM

*1

TCM

*2

IPDM-E

Page 2016 of 2771

![NISSAN TIIDA 2008 Service Repair Manual CAN COMMUNICATION SYSTEM

LAN-25

< FUNCTION DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

*1: A/T models

*2: CVT models

*3: Models for Canada

*4: Models for USA

*5: Models without ABS

NOTE:

CAN dat NISSAN TIIDA 2008 Service Repair Manual CAN COMMUNICATION SYSTEM

LAN-25

< FUNCTION DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

*1: A/T models

*2: CVT models

*3: Models for Canada

*4: Models for USA

*5: Models without ABS

NOTE:

CAN dat](/img/5/57399/w960_57399-2015.png)

CAN COMMUNICATION SYSTEM

LAN-25

< FUNCTION DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

*1: A/T models

*2: CVT models

*3: Models for Canada

*4: Models for USA

*5: Models without ABS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

Brake warning lamp signal R T

A/T check indicator signal R T

A/T self-diagnosis signal R T

OD OFF indicator signal R T

Output shaft revolution signal R T T

Shift position indicator signal R T T

Turbine revolution signal R T

CVT self-diagnosis signal R T

Input shaft revolution signal R T

OD OFF indicator signal R T

Front wiper stop position signal R T

High beam status signal RT

Low beam status signal RT

Oil pressure switch signal R T

Rear window defogger control signal RT Signal name/Connecting unit

ECM

BCM

EPS

I-KEY

M&A

ABS

TCM

*1

TCM

*2

IPDM-E

Page 2138 of 2771

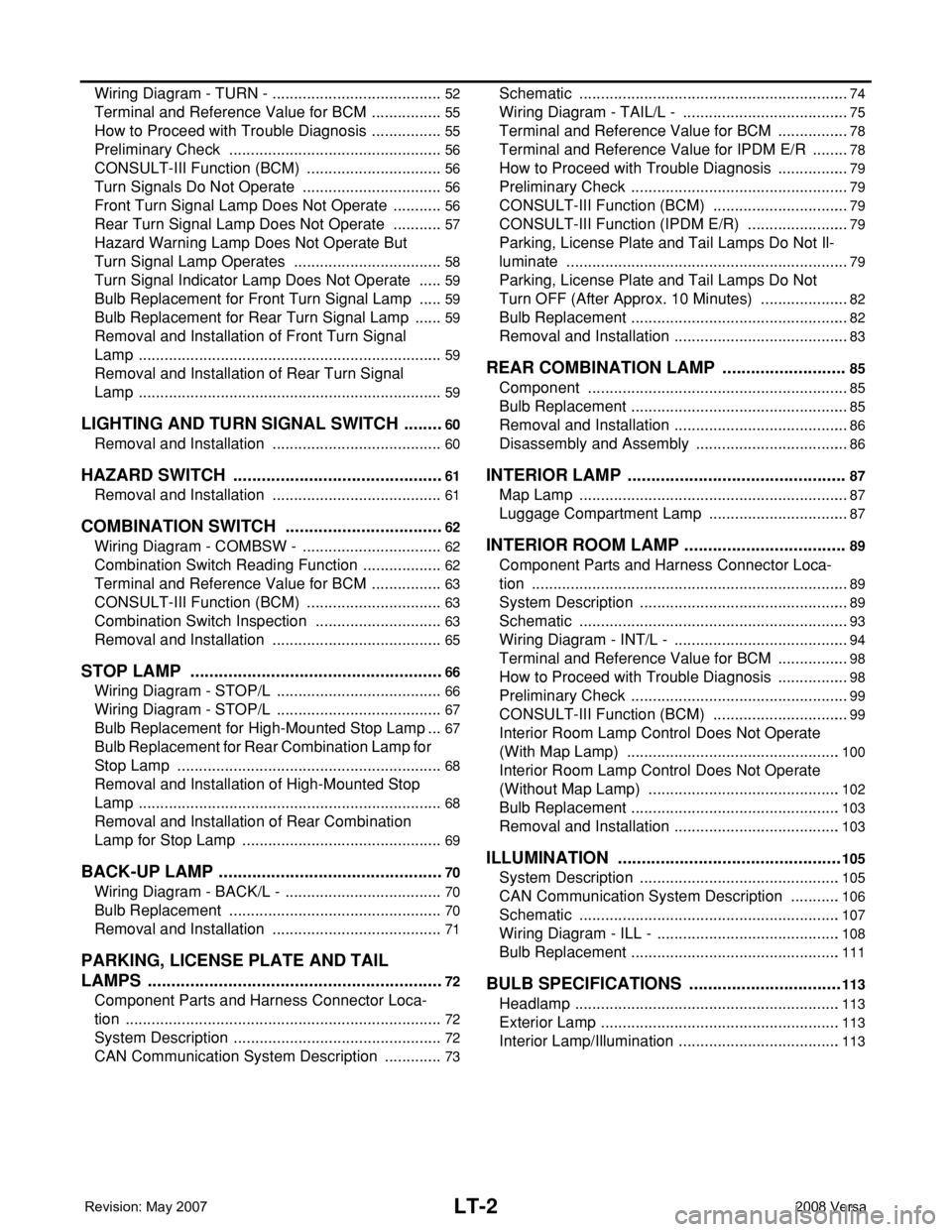

LT-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION LT

A

B

LT

N

O

P

CONTENTS

LIGHTING SYSTEM

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

HEADLAMP (FOR USA) .....................................4

Component Parts and Harness Connector Loca-

tion ............................................................................

4

System Description ...................................................4

CAN COMMUNICATION SYSTEM DESCRIP-

TION ..........................................................................

5

Schematic .................................................................6

Wiring Diagram .........................................................7

Terminal and Reference Value for BCM .................10

Terminal and Reference Value for IPDM E/R .........10

How to Perform Trouble Diagnosis .........................11

Preliminary Check ...................................................11

CONSULT-III Function (BCM) .................................11

CONSULT-III Function (IPDM E/R) .........................12

Headlamp High Beam Does Not Illuminate (Both

Sides) ......................................................................

13

Headlamp High Beam Does Not Illuminate (One

Side) ........................................................................

15

High Beam Indicator Lamp Does Not Illuminate .....16

Headlamp Low Beam Does Not Illuminate (Both

Sides) ......................................................................

16

Headlamp Low Beam Does Not Illuminate (One

Side) ........................................................................

19

Headlamps Do Not Turn OFF .................................20

Aiming Adjustment ..................................................21

Bulb Replacement ...................................................22

Removal and Installation .........................................23

Disassembly and Assembly ....................................23

HEADLAMP (FOR CANADA) - DAYTIME

LIGHT SYSTEM - ...............................................

25

Component Parts and Harness Connector Loca-

tion ..........................................................................

25

System Description .................................................25

CAN Communication System Description ...............27

Schematic ................................................................28

Wiring Diagram - DTRL - .........................................29

Terminal and Reference Value for BCM ..................32

Terminal and Reference Value for IPDM E/R ..........32

How to Perform Trouble Diagnosis ..........................33

Preliminary Check ...................................................33

CONSULT-III Function (BCM) .................................33

CONSULT-III Function (IPDM E/R) .........................33

Daytime Light Control Does Not Operate Properly

(High Beam Headlamps Operate Properly) .............

33

Aiming Adjustment ...................................................35

Bulb Replacement ...................................................36

Removal and Installation .........................................37

Disassembly and Assembly .....................................37

FRONT FOG LAMP ..........................................39

Component Parts and Harness Connector Loca-

tion ...........................................................................

39

System Description ..................................................39

CAN Communication System Description ...............40

Wiring Diagram - F/FOG - .......................................41

Terminal and Reference Value for BCM ..................42

Terminal and Reference Value for IPDM E/R ..........42

How to Proceed with Trouble Diagnosis ..................43

Preliminary Check ...................................................43

CONSULT-III Function (BCM) .................................43

CONSULT-III Function (IPDM E/R) .........................43

Front Fog lamps Do Not Illuminate (Both Sides) .....43

Front Fog Lamp Does Not Illuminate (One Side) ....45

Aiming Adjustment ...................................................46

Bulb Replacement ...................................................47

Removal and Installation .........................................47

TURN SIGNAL AND HAZARD WARNING

LAMPS ..............................................................

48

Component Parts and Harness Connector Loca-

tion ...........................................................................

48

System Description ..................................................48

CAN Communication System Description ...............50

Schematic ................................................................51

Page 2139 of 2771

LT-2

Wiring Diagram - TURN - ........................................52

Terminal and Reference Value for BCM .................55

How to Proceed with Trouble Diagnosis .................55

Preliminary Check ..................................................56

CONSULT-III Function (BCM) ................................56

Turn Signals Do Not Operate .................................56

Front Turn Signal Lamp Does Not Operate ............56

Rear Turn Signal Lamp Does Not Operate ............57

Hazard Warning Lamp Does Not Operate But

Turn Signal Lamp Operates ...................................

58

Turn Signal Indicator Lamp Does Not Operate ......59

Bulb Replacement for Front Turn Signal Lamp ......59

Bulb Replacement for Rear Turn Signal Lamp .......59

Removal and Installation of Front Turn Signal

Lamp .......................................................................

59

Removal and Installation of Rear Turn Signal

Lamp .......................................................................

59

LIGHTING AND TURN SIGNAL SWITCH .........60

Removal and Installation ........................................60

HAZARD SWITCH .............................................61

Removal and Installation ........................................61

COMBINATION SWITCH ..................................62

Wiring Diagram - COMBSW - .................................62

Combination Switch Reading Function ...................62

Terminal and Reference Value for BCM .................63

CONSULT-III Function (BCM) ................................63

Combination Switch Inspection ..............................63

Removal and Installation ........................................65

STOP LAMP ......................................................66

Wiring Diagram - STOP/L .......................................66

Wiring Diagram - STOP/L .......................................67

Bulb Replacement for High-Mounted Stop Lamp ...67

Bulb Replacement for Rear Combination Lamp for

Stop Lamp ..............................................................

68

Removal and Installation of High-Mounted Stop

Lamp .......................................................................

68

Removal and Installation of Rear Combination

Lamp for Stop Lamp ...............................................

69

BACK-UP LAMP ................................................70

Wiring Diagram - BACK/L - .....................................70

Bulb Replacement ..................................................70

Removal and Installation ........................................71

PARKING, LICENSE PLATE AND TAIL

LAMPS ...............................................................

72

Component Parts and Harness Connector Loca-

tion ..........................................................................

72

System Description .................................................72

CAN Communication System Description ..............73

Schematic ...............................................................74

Wiring Diagram - TAIL/L - .......................................75

Terminal and Reference Value for BCM .................78

Terminal and Reference Value for IPDM E/R .........78

How to Proceed with Trouble Diagnosis .................79

Preliminary Check ...................................................79

CONSULT-III Function (BCM) ................................79

CONSULT-III Function (IPDM E/R) ........................79

Parking, License Plate and Tail Lamps Do Not Il-

luminate ..................................................................

79

Parking, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) .....................

82

Bulb Replacement ...................................................82

Removal and Installation .........................................83

REAR COMBINATION LAMP ...........................85

Component .............................................................85

Bulb Replacement ...................................................85

Removal and Installation .........................................86

Disassembly and Assembly ....................................86

INTERIOR LAMP ...............................................87

Map Lamp ...............................................................87

Luggage Compartment Lamp .................................87

INTERIOR ROOM LAMP ...................................89

Component Parts and Harness Connector Loca-

tion ..........................................................................

89

System Description .................................................89

Schematic ...............................................................93

Wiring Diagram - INT/L - .........................................94

Terminal and Reference Value for BCM .................98

How to Proceed with Trouble Diagnosis .................98

Preliminary Check ...................................................99

CONSULT-III Function (BCM) ................................99

Interior Room Lamp Control Does Not Operate

(With Map Lamp) ..................................................

100

Interior Room Lamp Control Does Not Operate

(Without Map Lamp) .............................................

102

Bulb Replacement .................................................103

Removal and Installation .......................................103

ILLUMINATION ................................................105

System Description ...............................................105

CAN Communication System Description ............106

Schematic .............................................................107

Wiring Diagram - ILL - ...........................................108

Bulb Replacement .................................................111

BULB SPECIFICATIONS .................................113

Headlamp ..............................................................113

Exterior Lamp ........................................................113

Interior Lamp/Illumination ......................................113