NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 2411 of 2771

DUCTS AND GRILLES

MTC-73

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

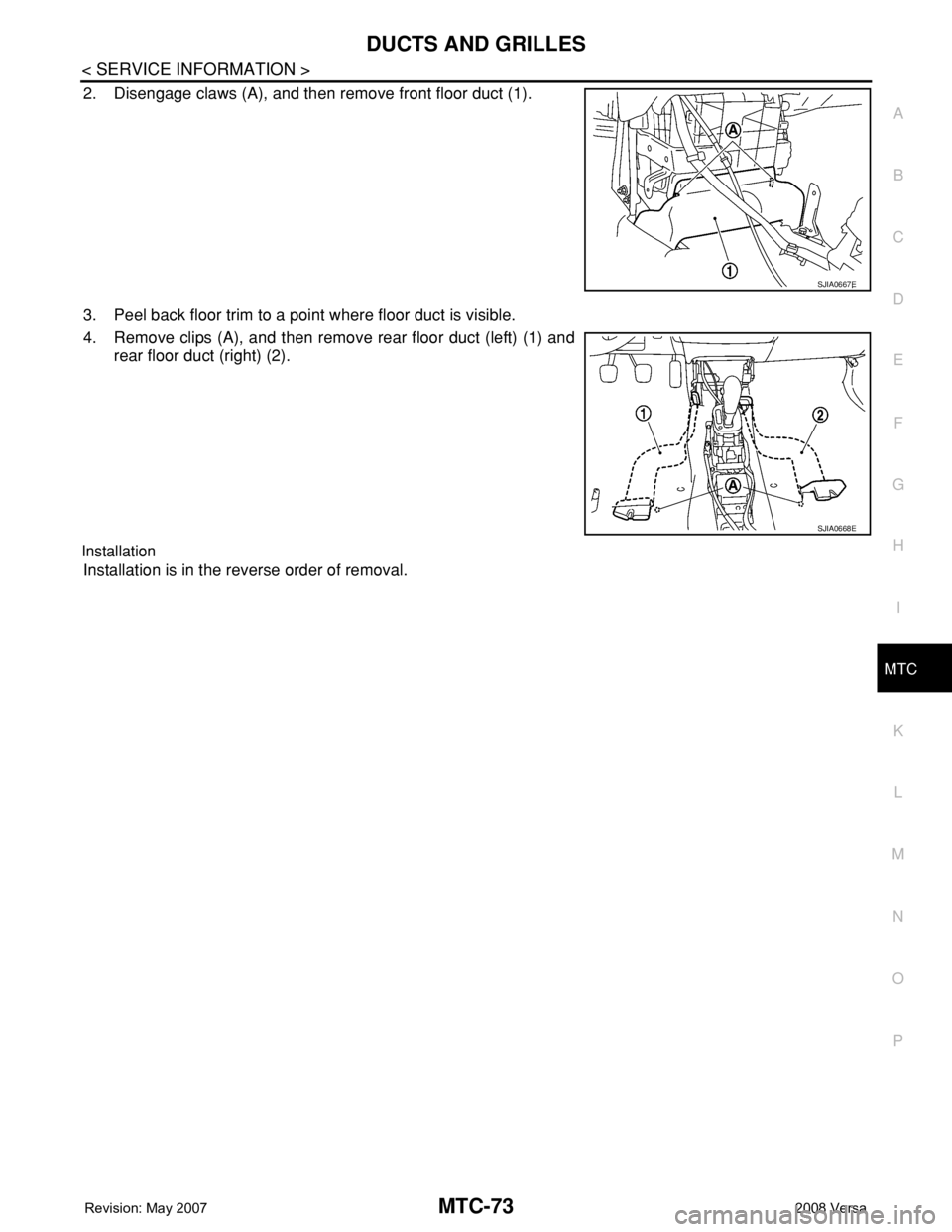

2. Disengage claws (A), and then remove front floor duct (1).

3. Peel back floor trim to a point where floor duct is visible.

4. Remove clips (A), and then remove rear floor duct (left) (1) and

rear floor duct (right) (2).

Installation

Installation is in the reverse order of removal.

SJIA0667E

SJIA0668E

Page 2412 of 2771

MTC-74

< SERVICE INFORMATION >

REFRIGERANT LINES

REFRIGERANT LINES

HFC-134a (R-134a) Service ProcedureINFOID:0000000001704322

SETTING OF SERVICE TOOLS AND EQUIPMENT

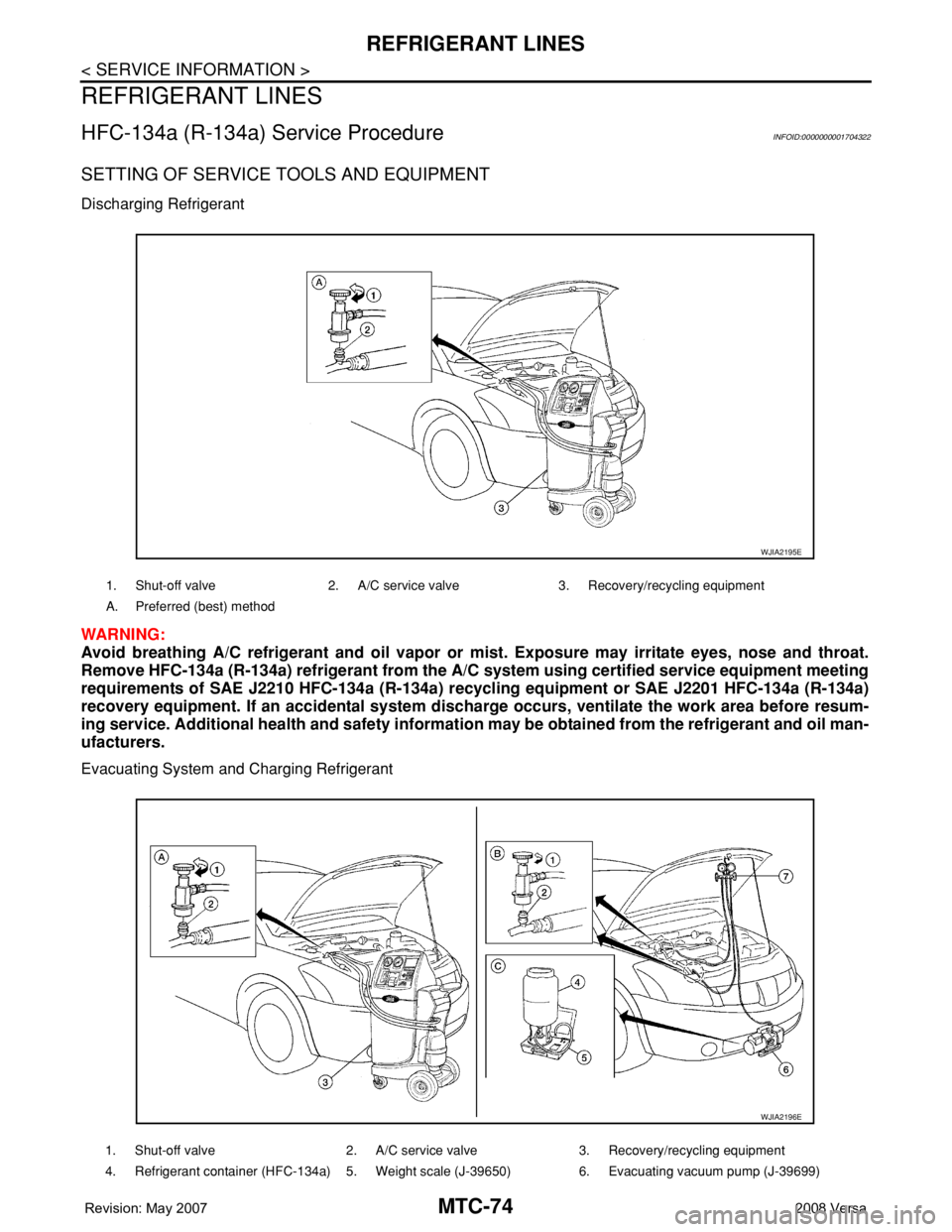

Discharging Refrigerant

WARNING:

Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) refrigerant from the A/C system using certified service equipment meeting

requirements of SAE J2210 HFC-134a (R-134a) recycling equipment or SAE J2201 HFC-134a (R-134a)

recovery equipment. If an accidental system discharge occurs, ventilate the work area before resum-

ing service. Additional health and safety information may be obtained from the refrigerant and oil man-

ufacturers.

Evacuating System and Charging Refrigerant

1. Shut-off valve 2. A/C service valve 3. Recovery/recycling equipment

A. Preferred (best) method

WJIA2195E

1. Shut-off valve 2. A/C service valve 3. Recovery/recycling equipment

4. Refrigerant container (HFC-134a) 5. Weight scale (J-39650) 6. Evacuating vacuum pump (J-39699)

WJIA2196E

Page 2413 of 2771

REFRIGERANT LINES

MTC-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

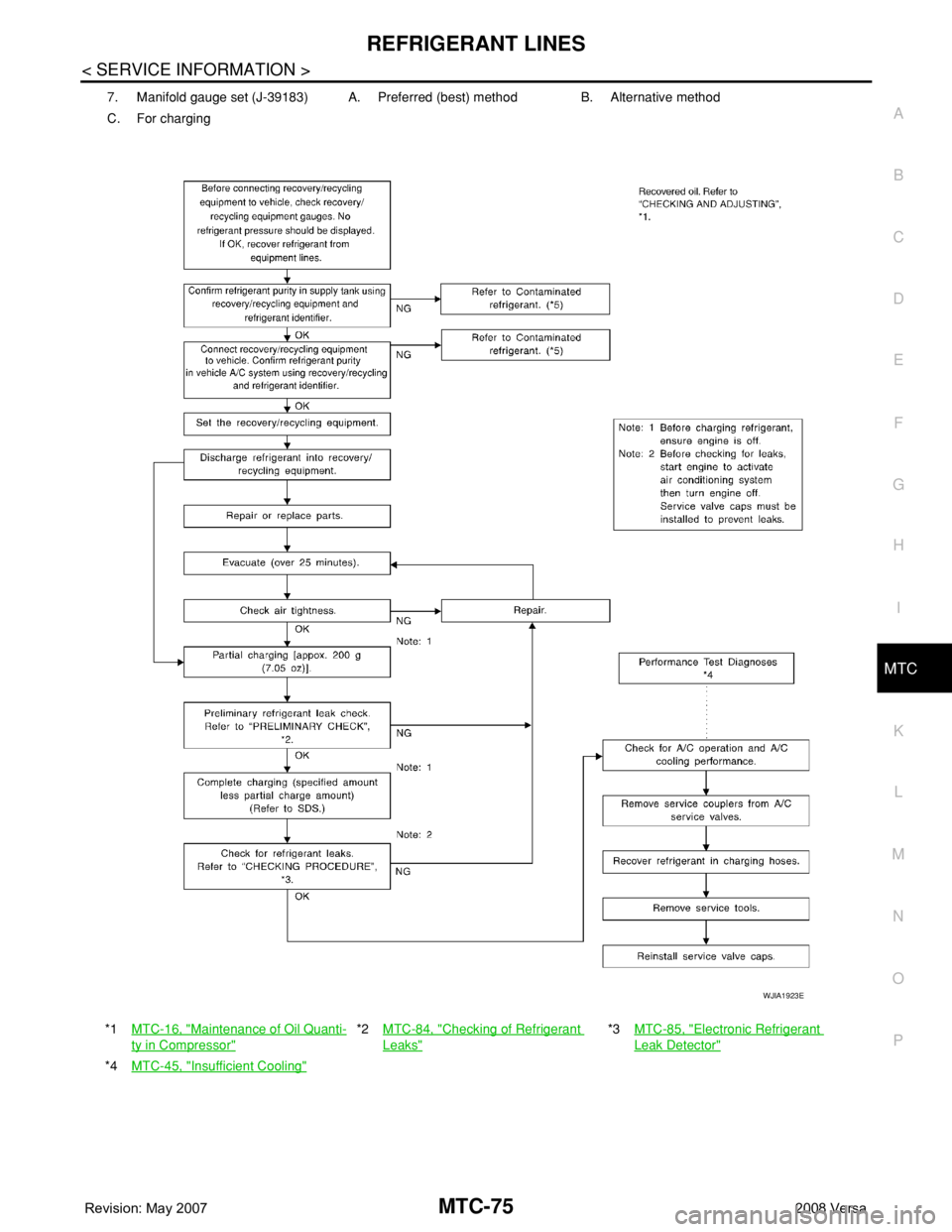

7. Manifold gauge set (J-39183) A. Preferred (best) method B. Alternative method

C. For charging

*1MTC-16, "

Maintenance of Oil Quanti-

ty in Compressor"

*2MTC-84, "Checking of Refrigerant

Leaks"

*3MTC-85, "Electronic Refrigerant

Leak Detector"

*4MTC-45, "Insufficient Cooling"

WJIA1923E

Page 2414 of 2771

MTC-76

< SERVICE INFORMATION >

REFRIGERANT LINES

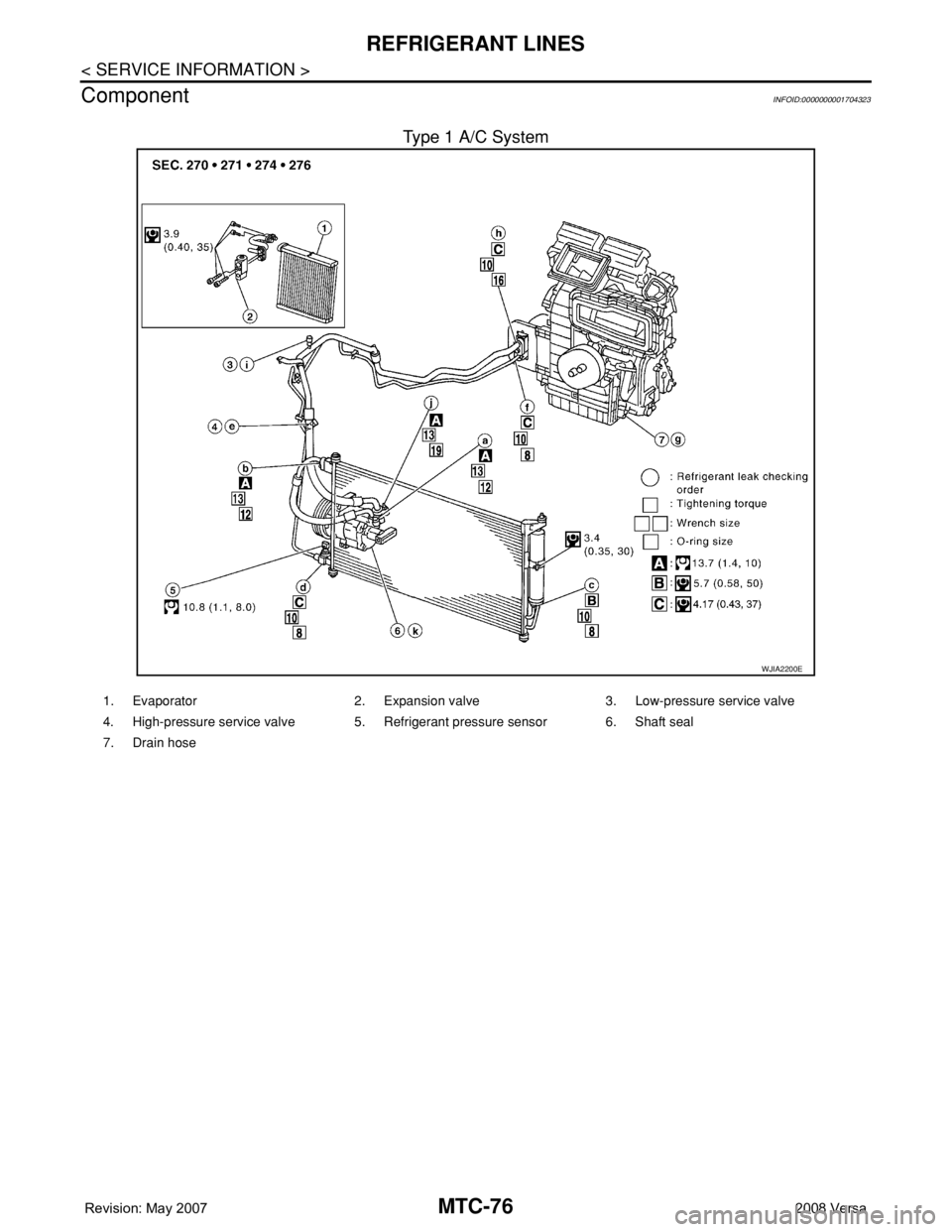

Component

INFOID:0000000001704323

Type 1 A/C System

WJIA2200E

1. Evaporator 2. Expansion valve 3. Low-pressure service valve

4. High-pressure service valve 5. Refrigerant pressure sensor 6. Shaft seal

7. Drain hose

Page 2415 of 2771

REFRIGERANT LINES

MTC-77

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

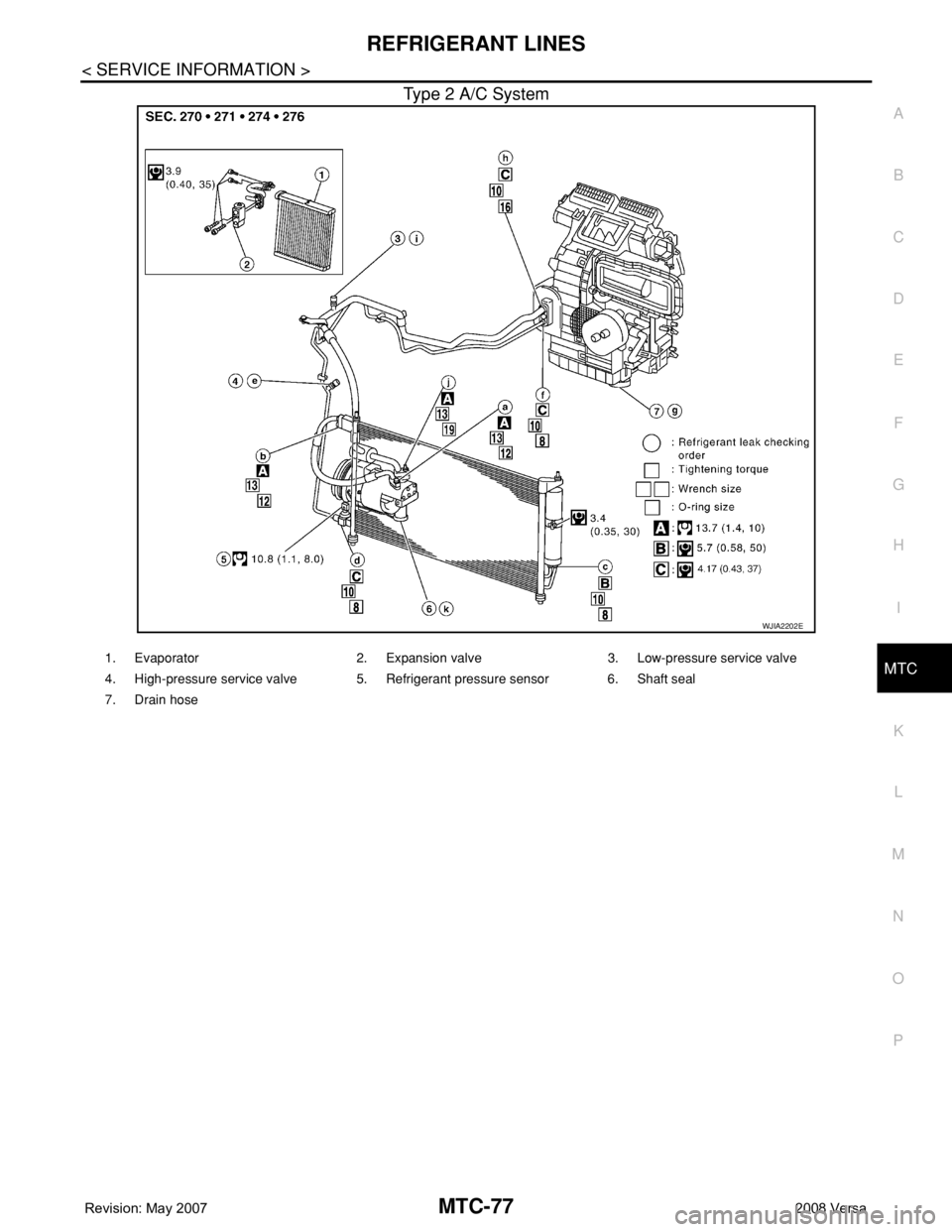

Type 2 A/C System

WJIA2202E

1. Evaporator 2. Expansion valve 3. Low-pressure service valve

4. High-pressure service valve 5. Refrigerant pressure sensor 6. Shaft seal

7. Drain hose

Page 2416 of 2771

MTC-78

< SERVICE INFORMATION >

REFRIGERANT LINES

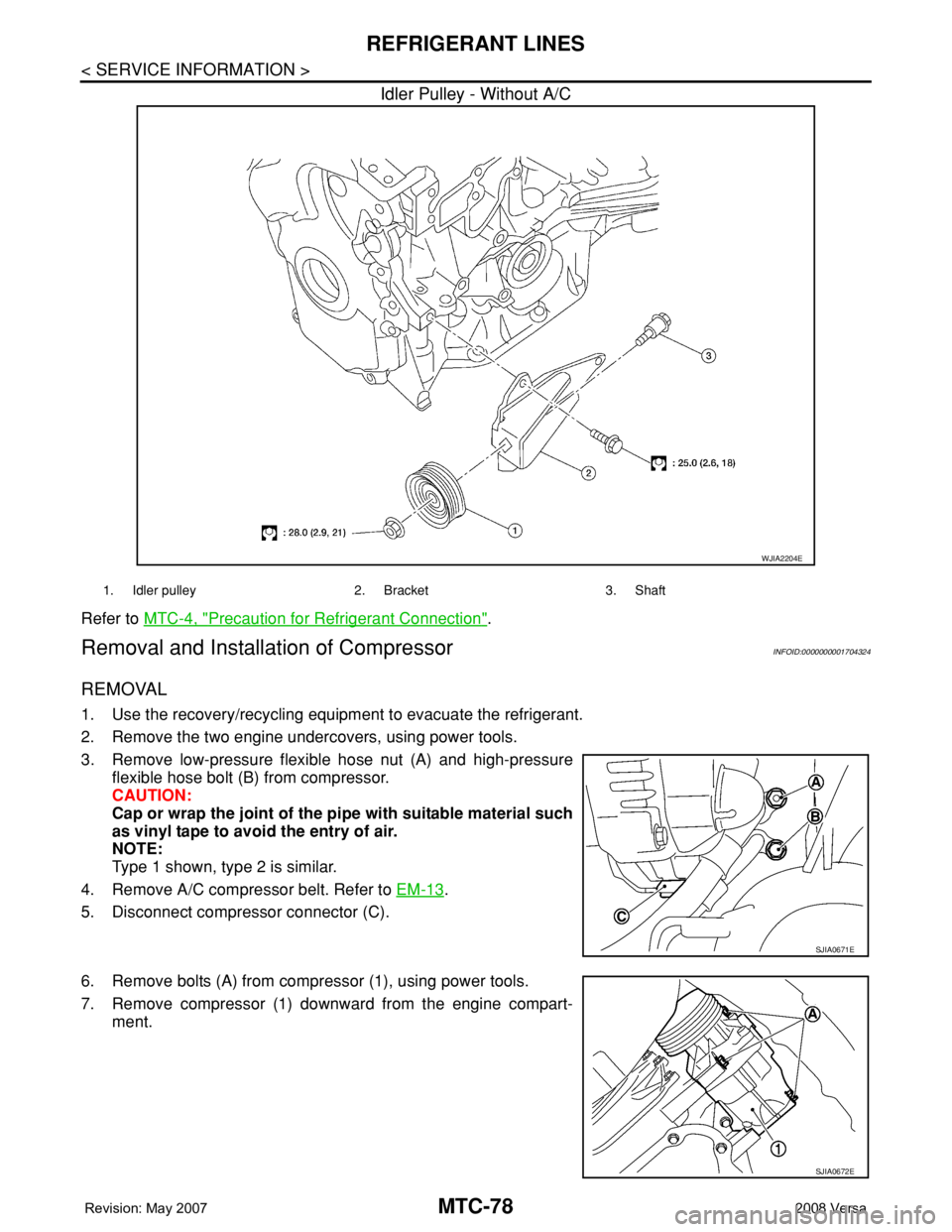

Idler Pulley - Without A/C

Refer to MTC-4, "Precaution for Refrigerant Connection".

Removal and Installation of CompressorINFOID:0000000001704324

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove the two engine undercovers, using power tools.

3. Remove low-pressure flexible hose nut (A) and high-pressure

flexible hose bolt (B) from compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

NOTE:

Type 1 shown, type 2 is similar.

4. Remove A/C compressor belt. Refer to EM-13

.

5. Disconnect compressor connector (C).

6. Remove bolts (A) from compressor (1), using power tools.

7. Remove compressor (1) downward from the engine compart-

ment.

WJIA2204E

1. Idler pulley 2. Bracket 3. Shaft

SJIA0671E

SJIA0672E

Page 2417 of 2771

REFRIGERANT LINES

MTC-79

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

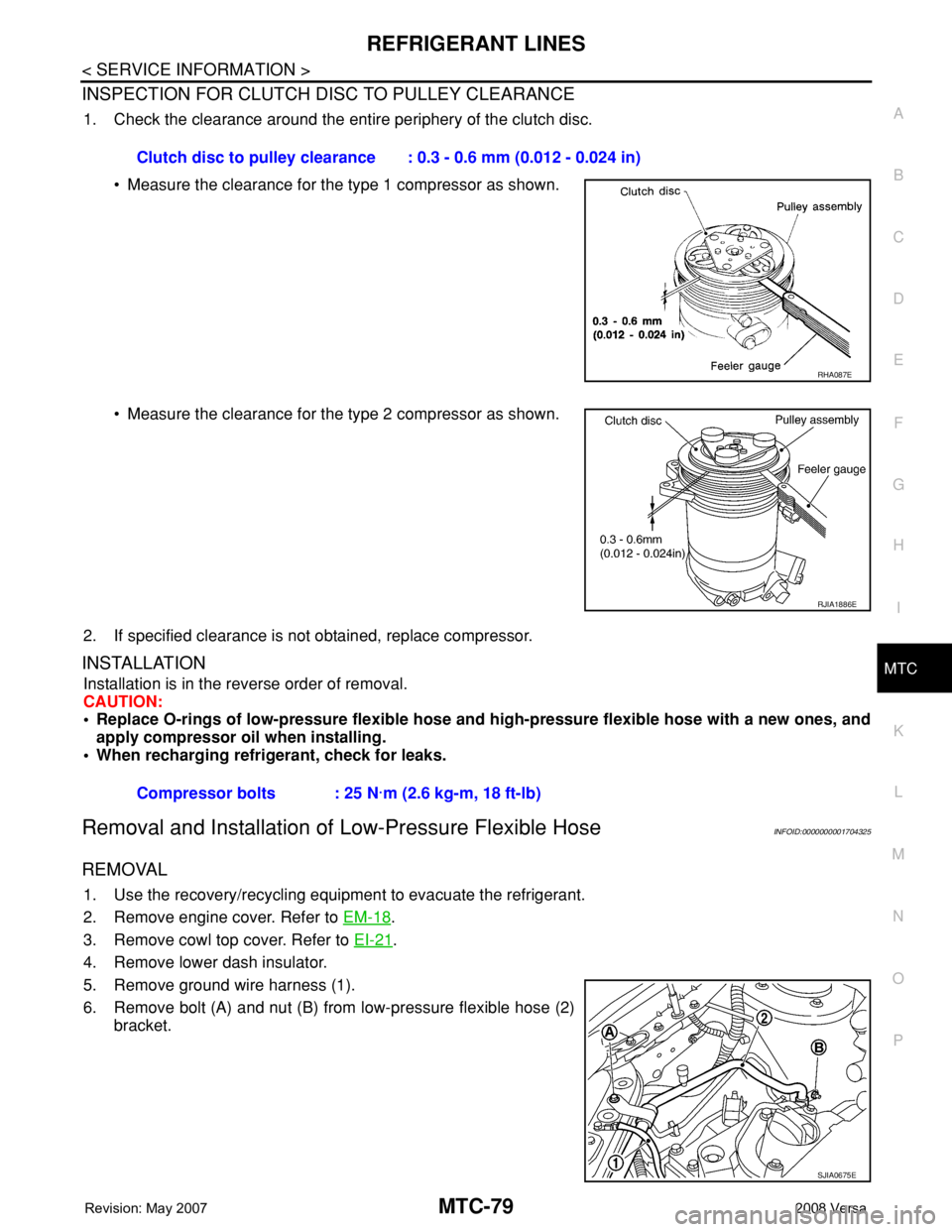

INSPECTION FOR CLUTCH DISC TO PULLEY CLEARANCE

1. Check the clearance around the entire periphery of the clutch disc.

• Measure the clearance for the type 1 compressor as shown.

• Measure the clearance for the type 2 compressor as shown.

2. If specified clearance is not obtained, replace compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of low-pressure flexible hose and high-pressure flexible hose with a new ones, and

apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

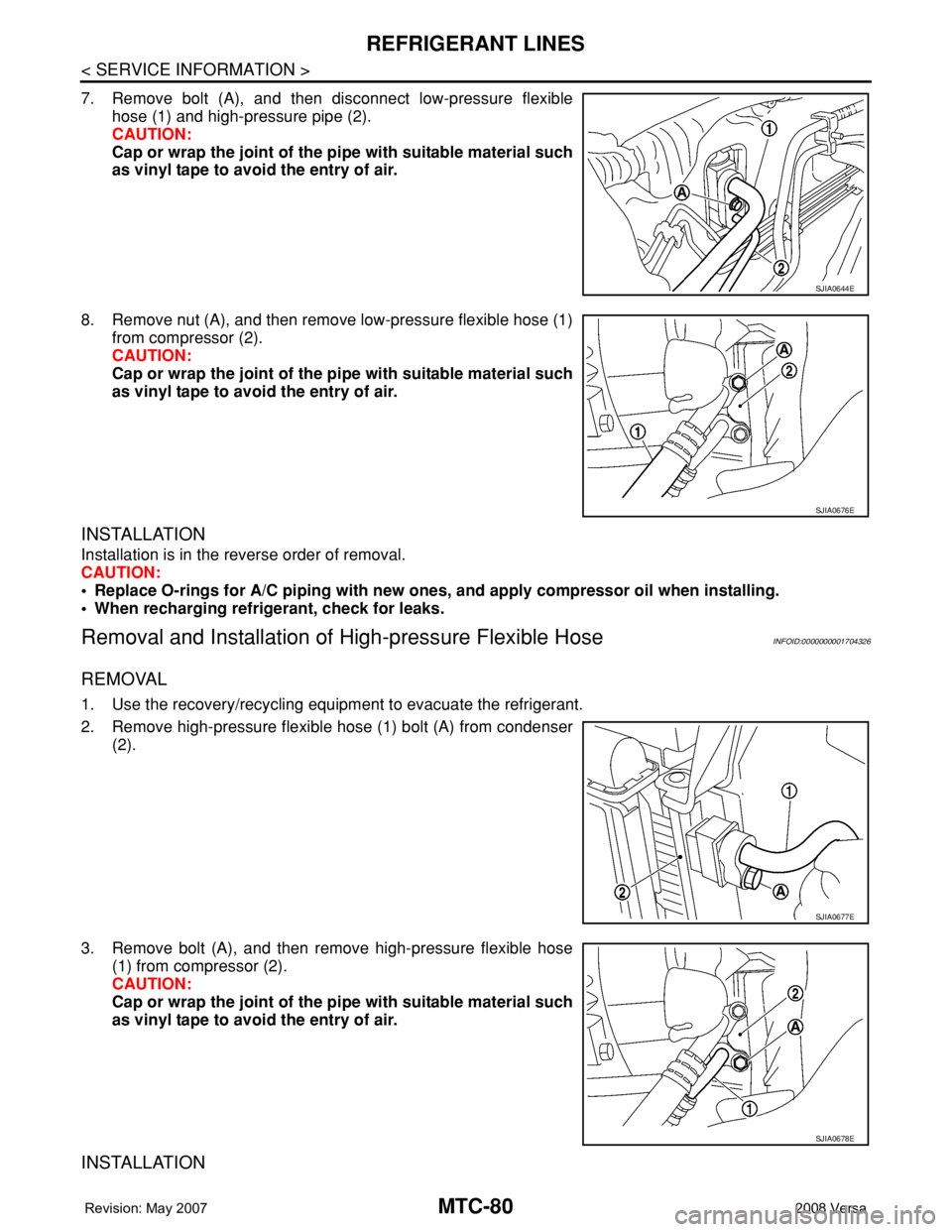

Removal and Installation of Low-Pressure Flexible HoseINFOID:0000000001704325

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove engine cover. Refer to EM-18

.

3. Remove cowl top cover. Refer to EI-21

.

4. Remove lower dash insulator.

5. Remove ground wire harness (1).

6. Remove bolt (A) and nut (B) from low-pressure flexible hose (2)

bracket.Clutch disc to pulley clearance : 0.3 - 0.6 mm (0.012 - 0.024 in)

RHA087E

RJIA1886E

Compressor bolts : 25 N·m (2.6 kg-m, 18 ft-lb)

SJIA0675E

Page 2418 of 2771

MTC-80

< SERVICE INFORMATION >

REFRIGERANT LINES

7. Remove bolt (A), and then disconnect low-pressure flexible

hose (1) and high-pressure pipe (2).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

8. Remove nut (A), and then remove low-pressure flexible hose (1)

from compressor (2).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of High-pressure Flexible HoseINFOID:0000000001704326

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove high-pressure flexible hose (1) bolt (A) from condenser

(2).

3. Remove bolt (A), and then remove high-pressure flexible hose

(1) from compressor (2).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

SJIA0644E

SJIA0676E

SJIA0677E

SJIA0678E

Page 2419 of 2771

REFRIGERANT LINES

MTC-81

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of high-pressure flexible hose with a new ones, and apply compressor oil when

installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of High-pressure PipeINFOID:0000000001704327

REMOVAL

1. Remove low-pressure flexible hose. Refer to MTC-79, "Removal and Installation of Low-Pressure Flexible

Hose".

2. Remove high-pressure pipe from the clips.

3. Remove high-pressure pipe bolt (A), and then remove high-

pressure pipe (1) from condenser (2).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of high-pressure pipe with a new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of Refrigerant Pressure SensorINFOID:0000000001704328

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Disconnect connector, and then remove refrigerant pressure

sensor (1) from condenser (2).

CAUTION:

When working, be careful not to damage the condenser

fins.

1. High-pressure pipe A. High-pressure pipe clips

SJIA0679E

SJIA0680E

SJIA0681E

Page 2420 of 2771

MTC-82

< SERVICE INFORMATION >

REFRIGERANT LINES

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of refrigerant pressure sensor with a new one, and apply compressor oil when

installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of CondenserINFOID:0000000001704329

REMOVAL

1. Remove the three upper headlamp bolts to reposition the headlamps out of the way

2. Remove the radiator core support upper. Refer to BL-19

.

3. Remove high-pressure flexible hose and high-pressure pipe from condenser. Refer to MTC-80, "

Removal

and Installation of High-pressure Flexible Hose" and MTC-81, "Removal and Installation of High-pres-

sure Pipe" .

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

4. Disconnect refrigerant pressure sensor connector.

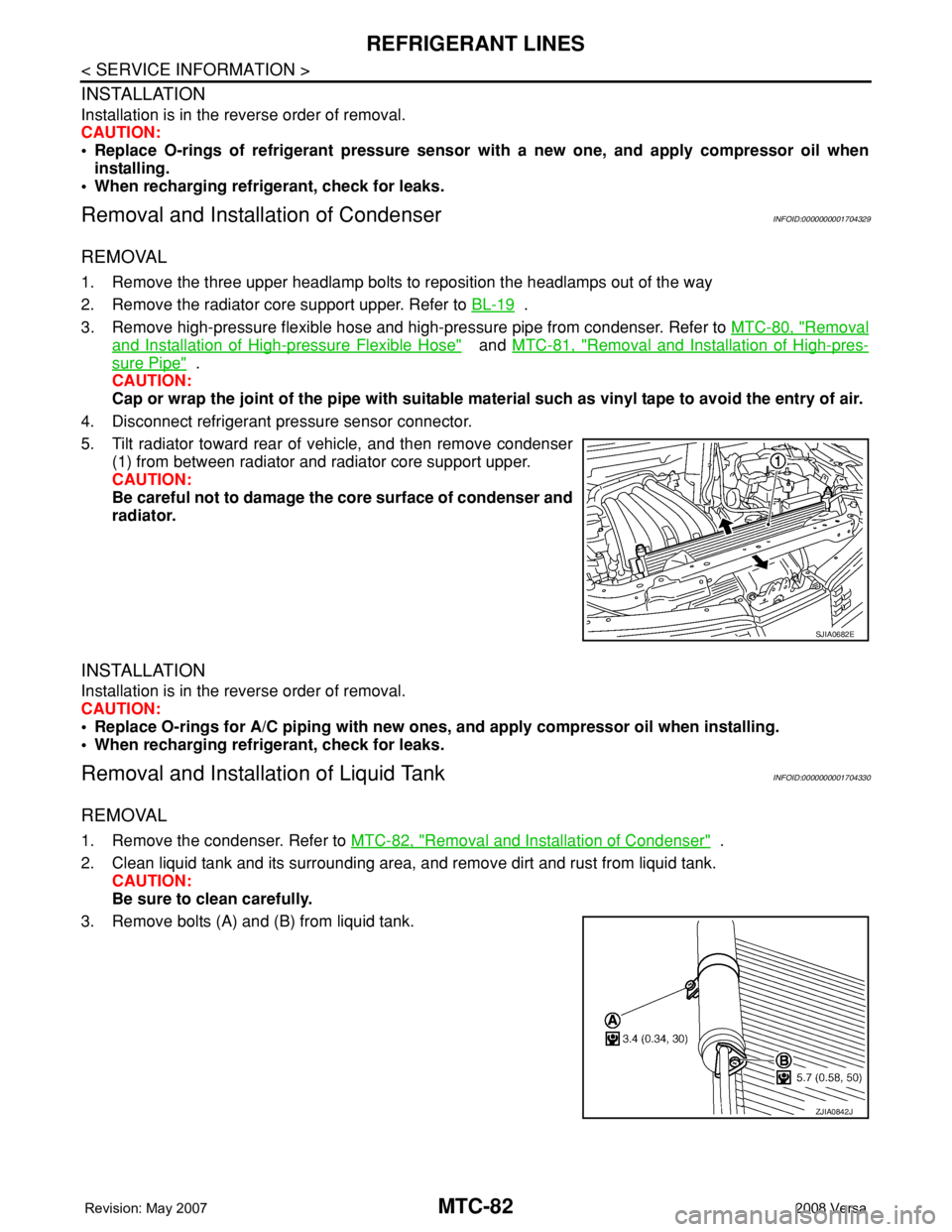

5. Tilt radiator toward rear of vehicle, and then remove condenser

(1) from between radiator and radiator core support upper.

CAUTION:

Be careful not to damage the core surface of condenser and

radiator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of Liquid TankINFOID:0000000001704330

REMOVAL

1. Remove the condenser. Refer to MTC-82, "Removal and Installation of Condenser" .

2. Clean liquid tank and its surrounding area, and remove dirt and rust from liquid tank.

CAUTION:

Be sure to clean carefully.

3. Remove bolts (A) and (B) from liquid tank.

SJIA0682E

ZJIA0842J