NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 571 of 2771

INTELLIGENT KEY SYSTEM

BL-137

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

OK or NG

OK >> Replace Intelligent Key unit. Refer to BL-142, "Removal

and Installation of Intelligent Key Unit".

NG >> GO TO 2.

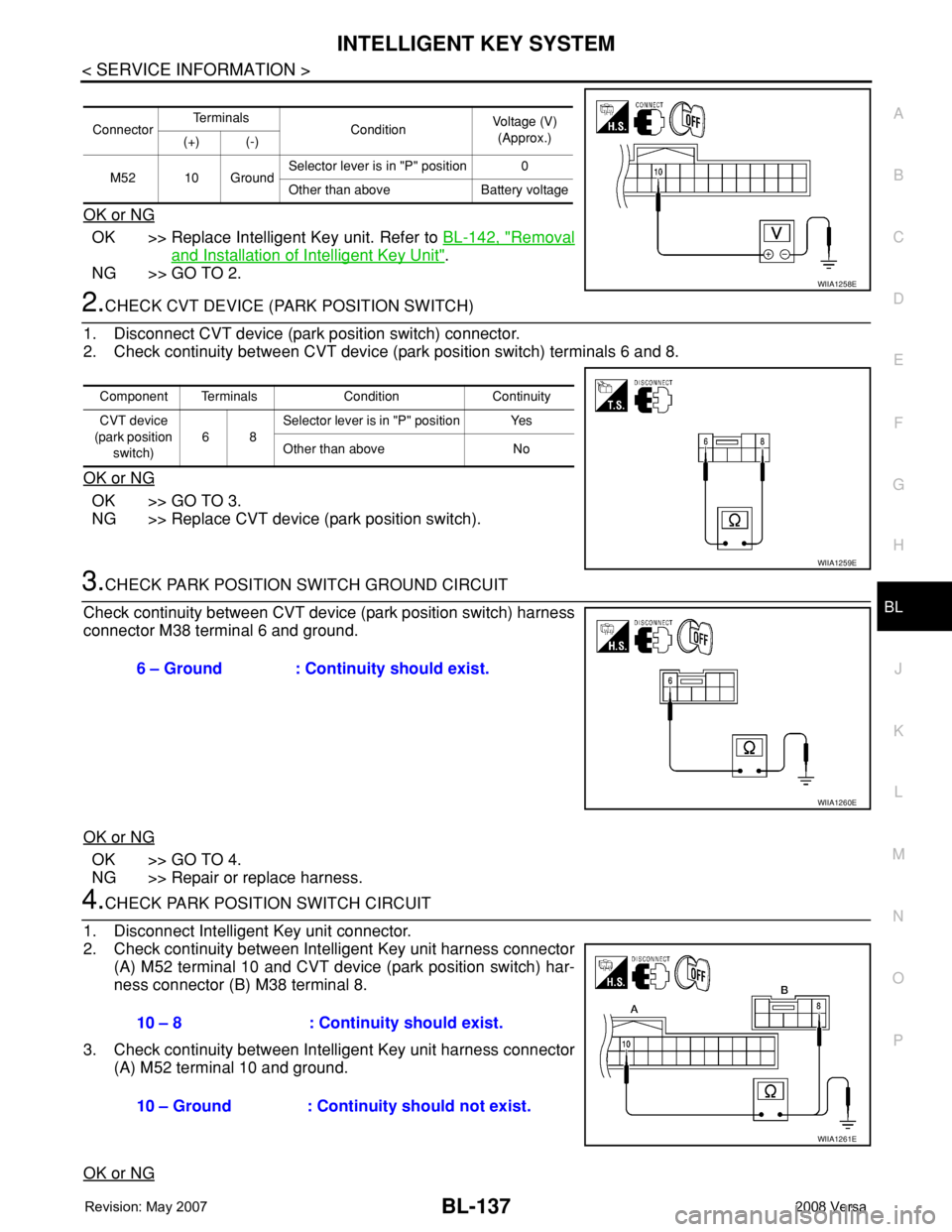

2.CHECK CVT DEVICE (PARK POSITION SWITCH)

1. Disconnect CVT device (park position switch) connector.

2. Check continuity between CVT device (park position switch) terminals 6 and 8.

OK or NG

OK >> GO TO 3.

NG >> Replace CVT device (park position switch).

3.CHECK PARK POSITION SWITCH GROUND CIRCUIT

Check continuity between CVT device (park position switch) harness

connector M38 terminal 6 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK PARK POSITION SWITCH CIRCUIT

1. Disconnect Intelligent Key unit connector.

2. Check continuity between Intelligent Key unit harness connector

(A) M52 terminal 10 and CVT device (park position switch) har-

ness connector (B) M38 terminal 8.

3. Check continuity between Intelligent Key unit harness connector

(A) M52 terminal 10 and ground.

OK or NG

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M52 10 GroundSelector lever is in "P" position 0

Other than above Battery voltage

WIIA1258E

Component Terminals Condition Continuity

CVT device

(park position

switch)68Selector lever is in "P" position Yes

Other than above No

WIIA1259E

6 – Ground : Continuity should exist.

WIIA1260E

10 – 8 : Continuity should exist.

10 – Ground : Continuity should not exist.

WIIA1261E

Page 572 of 2771

BL-138

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

OK >> GO TO 5.

NG >> Repair or replace harness.

5.CHECK INTELLIGENT KEY OUTPUT SIGNAL

1. Connect Intelligent Key unit connector and CVT device (park position switch) connector.

2. Check voltage between Intelligent Key unit connector M52 terminal 10 and ground.

OK or NG

OK >> CVT device (park position switch) circuit is OK.

NG >> Replace Intelligent Key unit. Refer to BL-142, "

Removal

and Installation of Intelligent Key Unit".

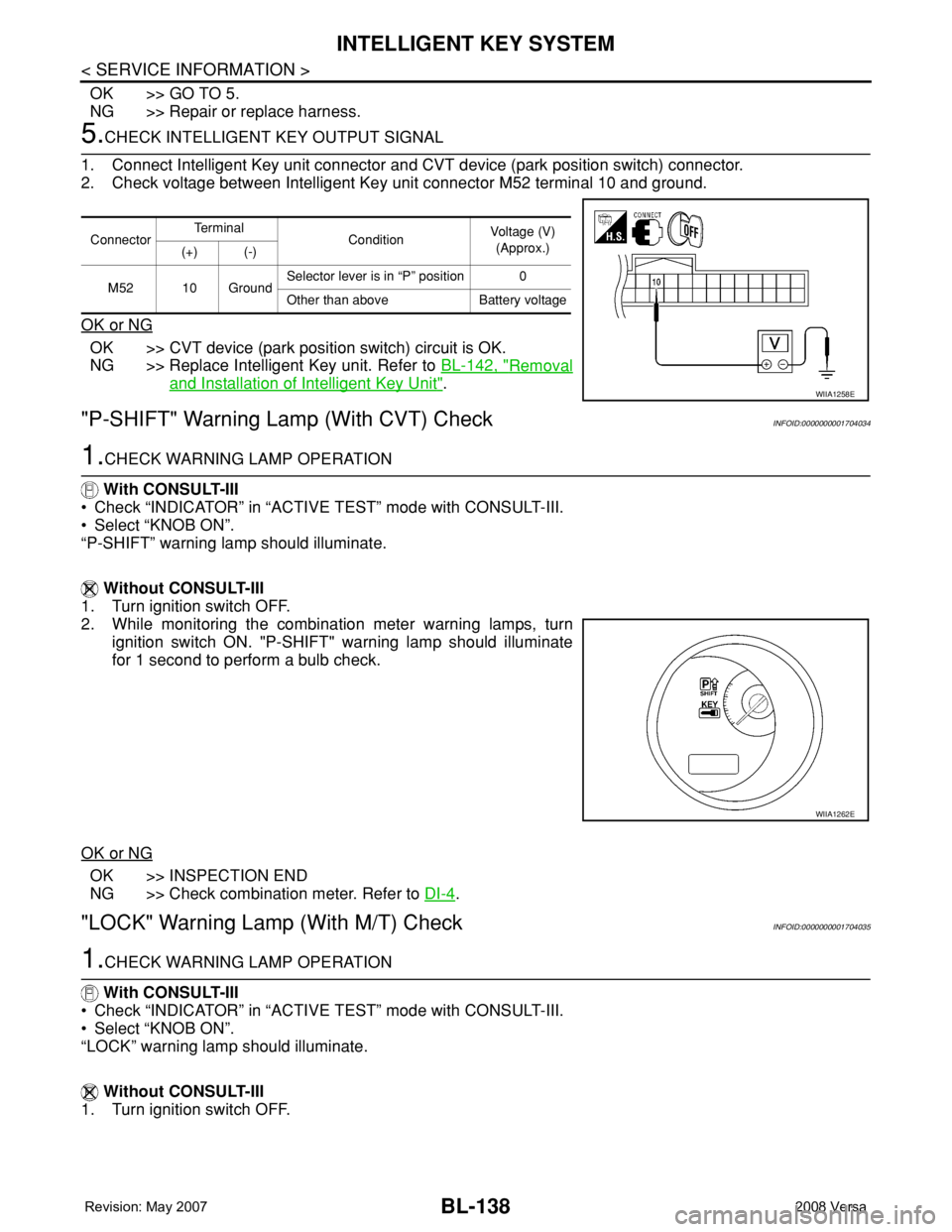

"P-SHIFT" Warning Lamp (With CVT) CheckINFOID:0000000001704034

1.CHECK WARNING LAMP OPERATION

With CONSULT-III

• Check “INDICATOR” in “ACTIVE TEST” mode with CONSULT-III.

• Select “KNOB ON”.

“P-SHIFT” warning lamp should illuminate.

Without CONSULT-III

1. Turn ignition switch OFF.

2. While monitoring the combination meter warning lamps, turn

ignition switch ON. "P-SHIFT" warning lamp should illuminate

for 1 second to perform a bulb check.

OK or NG

OK >> INSPECTION END

NG >> Check combination meter. Refer to DI-4

.

"LOCK" Warning Lamp (With M/T) CheckINFOID:0000000001704035

1.CHECK WARNING LAMP OPERATION

With CONSULT-III

• Check “INDICATOR” in “ACTIVE TEST” mode with CONSULT-III.

• Select “KNOB ON”.

“LOCK” warning lamp should illuminate.

Without CONSULT-III

1. Turn ignition switch OFF.

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

M52 10 GroundSelector lever is in “P” position 0

Other than above Battery voltage

WIIA1258E

WIIA1262E

Page 573 of 2771

INTELLIGENT KEY SYSTEM

BL-139

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

2. While monitoring the combination meter warning lamps, turn

ignition switch ON. "LOCK" warning lamp should illuminate for 1

second to perform a bulb check.

OK or NG

OK >> INSPECTION END

NG >> Check combination meter. Refer to DI-4

.

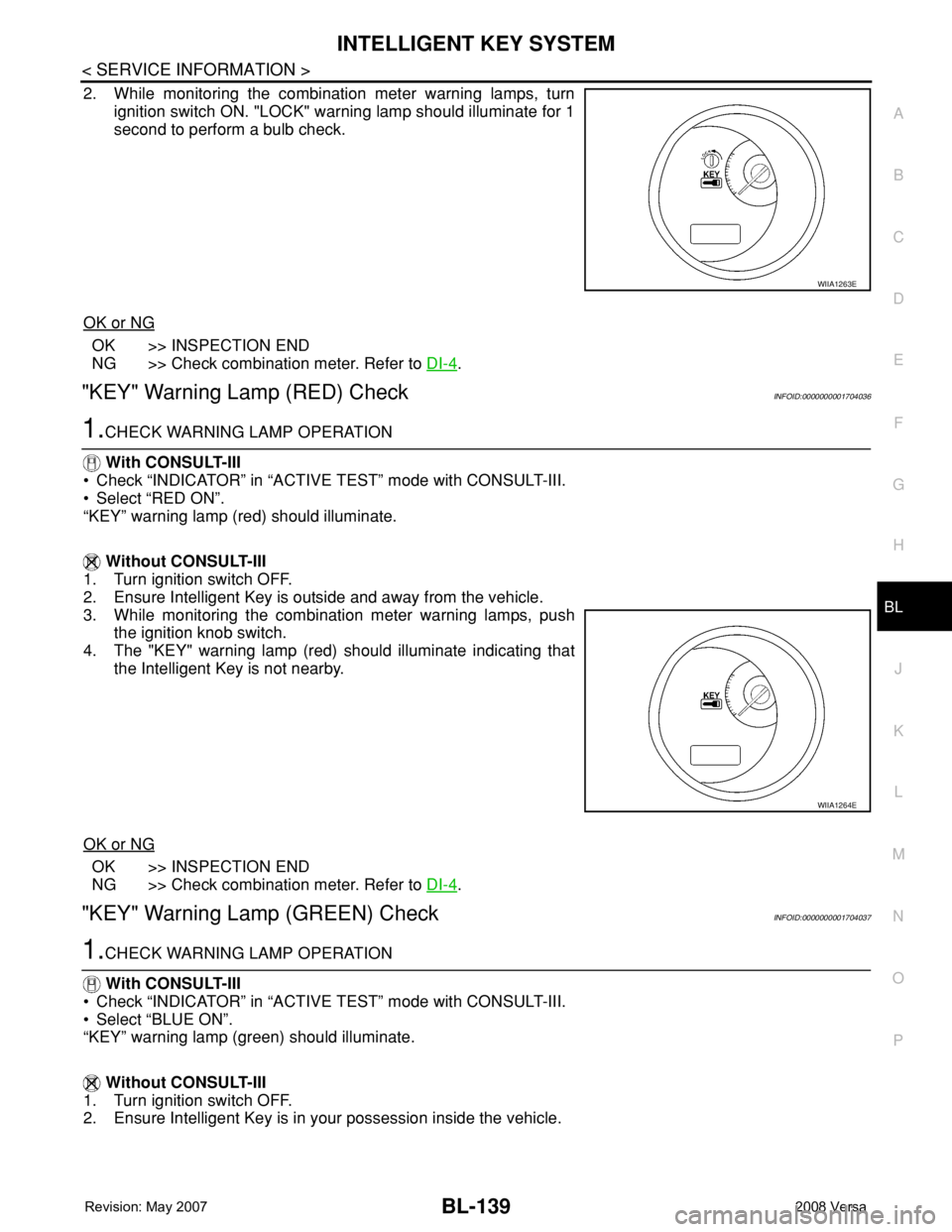

"KEY" Warning Lamp (RED) CheckINFOID:0000000001704036

1.CHECK WARNING LAMP OPERATION

With CONSULT-III

• Check “INDICATOR” in “ACTIVE TEST” mode with CONSULT-III.

• Select “RED ON”.

“KEY” warning lamp (red) should illuminate.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Ensure Intelligent Key is outside and away from the vehicle.

3. While monitoring the combination meter warning lamps, push

the ignition knob switch.

4. The "KEY" warning lamp (red) should illuminate indicating that

the Intelligent Key is not nearby.

OK or NG

OK >> INSPECTION END

NG >> Check combination meter. Refer to DI-4

.

"KEY" Warning Lamp (GREEN) CheckINFOID:0000000001704037

1.CHECK WARNING LAMP OPERATION

With CONSULT-III

• Check “INDICATOR” in “ACTIVE TEST” mode with CONSULT-III.

• Select “BLUE ON”.

“KEY” warning lamp (green) should illuminate.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Ensure Intelligent Key is in your possession inside the vehicle.

WIIA1263E

WIIA1264E

Page 574 of 2771

BL-140

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

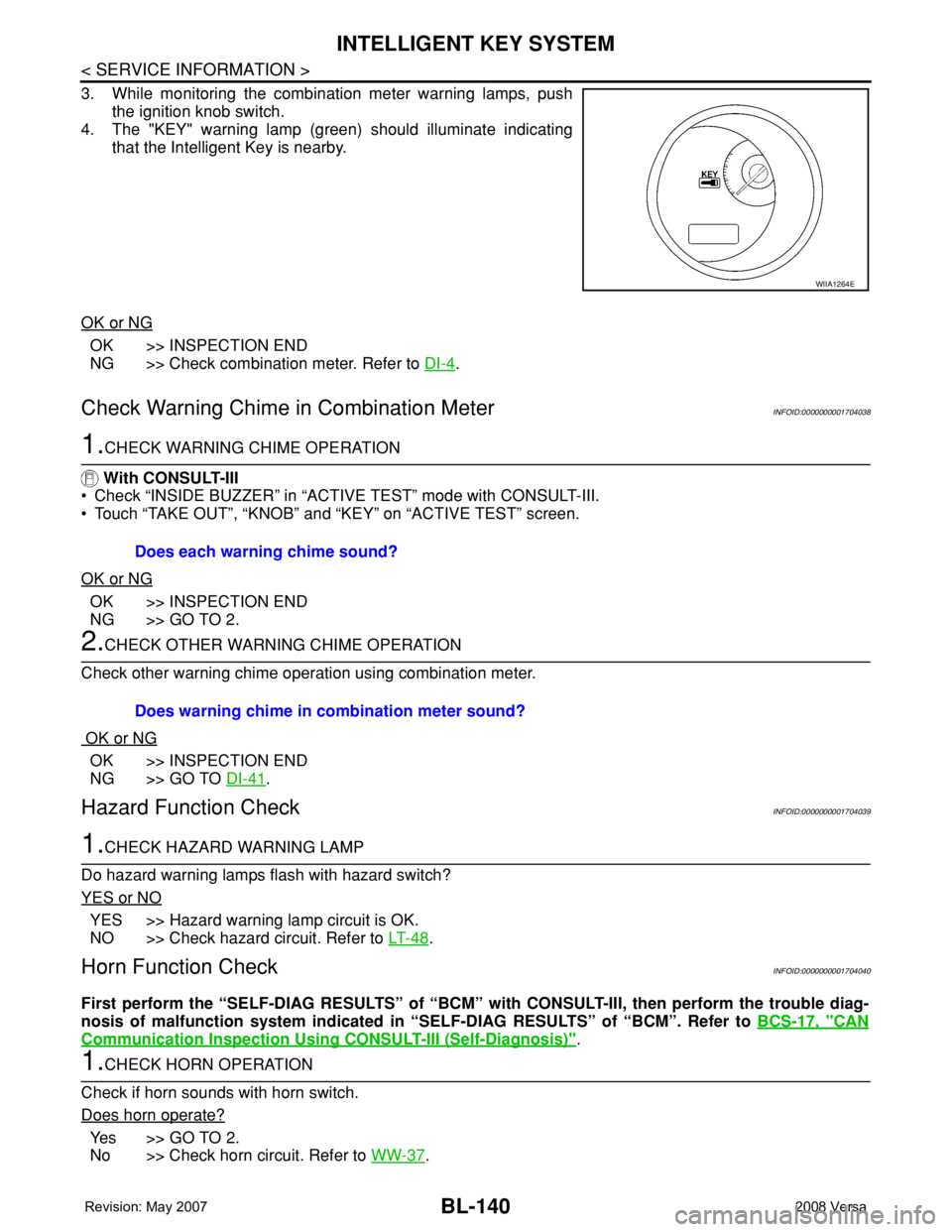

3. While monitoring the combination meter warning lamps, push

the ignition knob switch.

4. The "KEY" warning lamp (green) should illuminate indicating

that the Intelligent Key is nearby.

OK or NG

OK >> INSPECTION END

NG >> Check combination meter. Refer to DI-4

.

Check Warning Chime in Combination MeterINFOID:0000000001704038

1.CHECK WARNING CHIME OPERATION

With CONSULT-III

• Check “INSIDE BUZZER” in “ACTIVE TEST” mode with CONSULT-III.

• Touch “TAKE OUT”, “KNOB” and “KEY” on “ACTIVE TEST” screen.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK OTHER WARNING CHIME OPERATION

Check other warning chime operation using combination meter.

OK or NG

OK >> INSPECTION END

NG >> GO TO DI-41

.

Hazard Function CheckINFOID:0000000001704039

1.CHECK HAZARD WARNING LAMP

Do hazard warning lamps flash with hazard switch?

YES or NO

YES >> Hazard warning lamp circuit is OK.

NO >> Check hazard circuit. Refer to LT- 4 8

.

Horn Function CheckINFOID:0000000001704040

First perform the “SELF-DIAG RESULTS” of “BCM” with CONSULT-III, then perform the trouble diag-

nosis of malfunction system indicated in “SELF-DIAG RESULTS” of “BCM”. Refer to BCS-17, "

CAN

Communication Inspection Using CONSULT-III (Self-Diagnosis)".

1.CHECK HORN OPERATION

Check if horn sounds with horn switch.

Does horn operate?

Ye s > > G O T O 2 .

No >> Check horn circuit. Refer to WW-37

.

WIIA1264E

Does each warning chime sound?

Does warning chime in combination meter sound?

Page 575 of 2771

INTELLIGENT KEY SYSTEM

BL-141

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

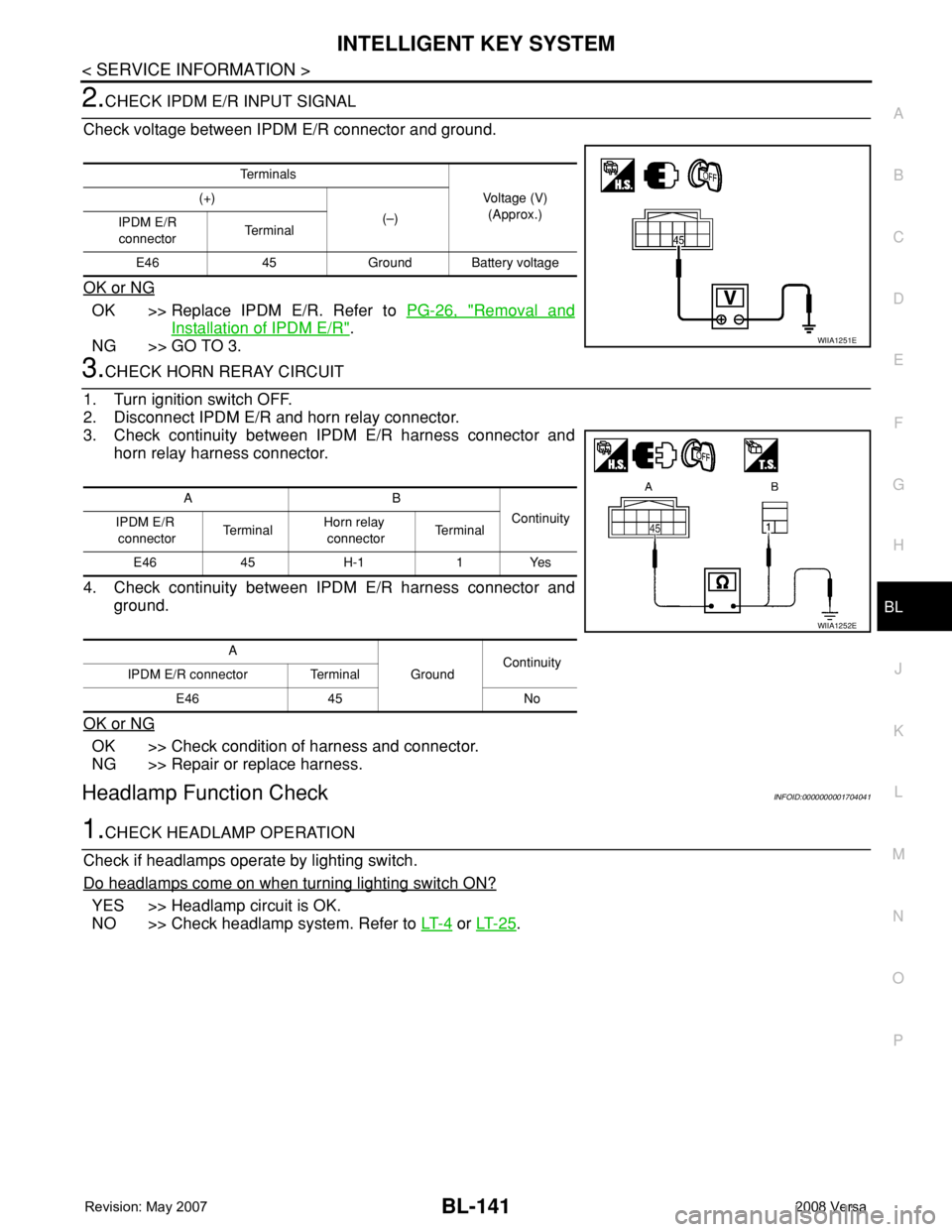

2.CHECK IPDM E/R INPUT SIGNAL

Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and

Installation of IPDM E/R".

NG >> GO TO 3.

3.CHECK HORN RERAY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R and horn relay connector.

3. Check continuity between IPDM E/R harness connector and

horn relay harness connector.

4. Check continuity between IPDM E/R harness connector and

ground.

OK or NG

OK >> Check condition of harness and connector.

NG >> Repair or replace harness.

Headlamp Function CheckINFOID:0000000001704041

1.CHECK HEADLAMP OPERATION

Check if headlamps operate by lighting switch.

Do headlamps come on when turning lighting switch ON?

YES >> Headlamp circuit is OK.

NO >> Check headlamp system. Refer to LT- 4

or LT- 2 5.

Te r m i n a l s

Voltage (V)

(Approx.) (+)

(–)

IPDM E/R

connectorTe r m i n a l

E46 45 Ground Battery voltage

WIIA1251E

AB

Continuity

IPDM E/R

connectorTe r m i n a lHorn relay

connectorTe r m i n a l

E46 45 H-1 1 Yes

A

GroundContinuity

IPDM E/R connector Terminal

E46 45 No

WIIA1252E

Page 576 of 2771

BL-142

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

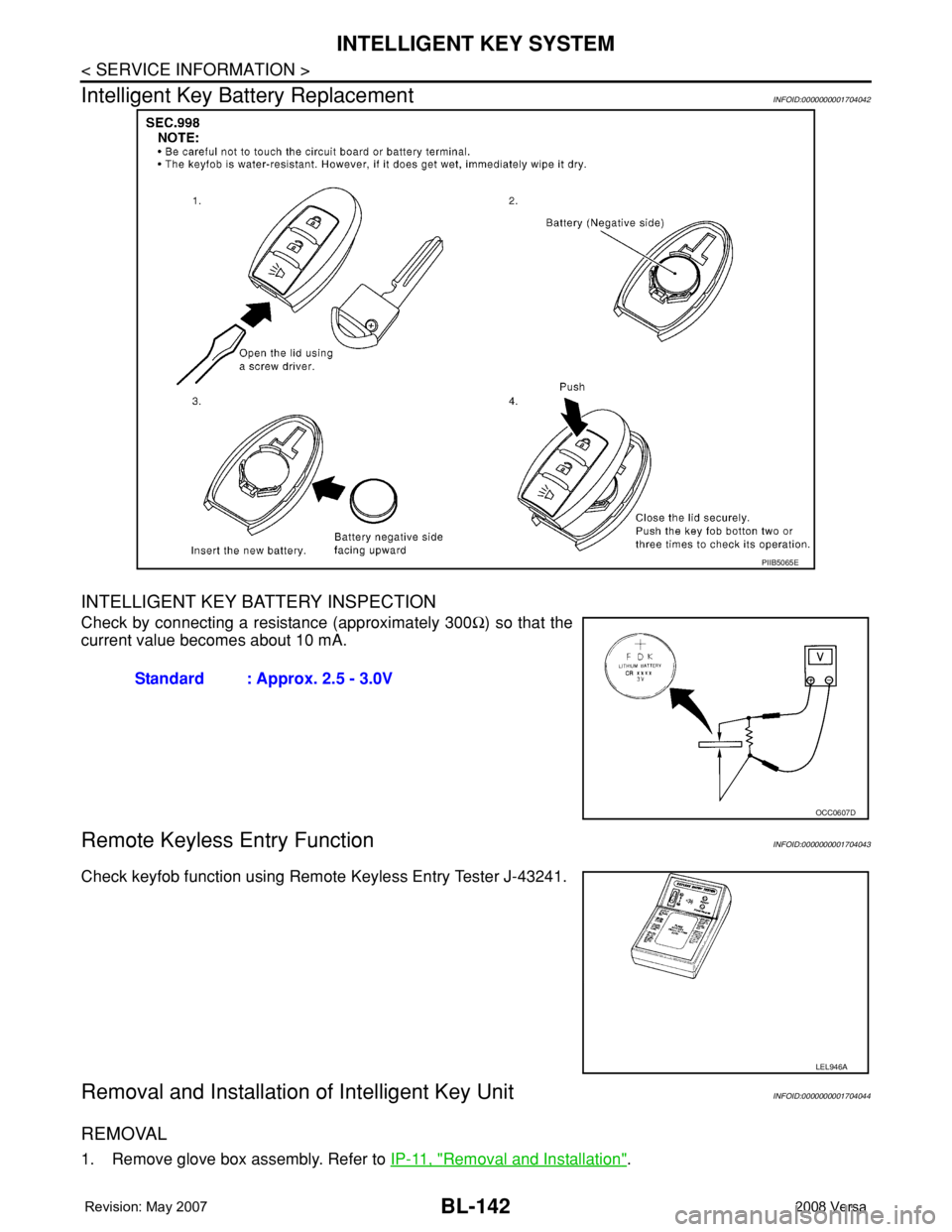

Intelligent Key Battery Replacement

INFOID:0000000001704042

INTELLIGENT KEY BATTERY INSPECTION

Check by connecting a resistance (approximately 300Ω) so that the

current value becomes about 10 mA.

Remote Keyless Entry FunctionINFOID:0000000001704043

Check keyfob function using Remote Keyless Entry Tester J-43241.

Removal and Installation of Intelligent Key UnitINFOID:0000000001704044

REMOVAL

1. Remove glove box assembly. Refer to IP-11, "Removal and Installation".

PIIB5065E

Standard : Approx. 2.5 - 3.0V

OCC0607D

LEL946A

Page 577 of 2771

INTELLIGENT KEY SYSTEM

BL-143

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

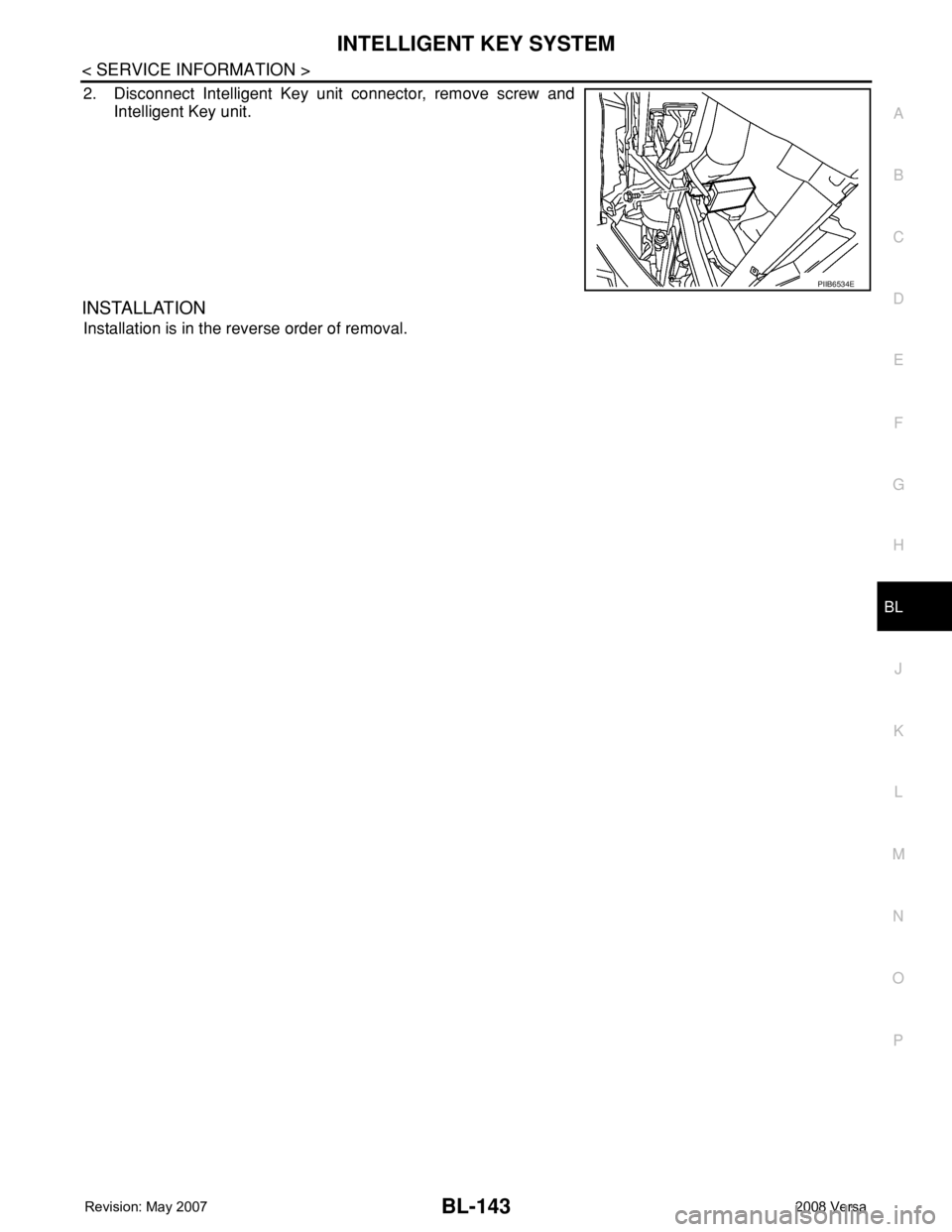

2. Disconnect Intelligent Key unit connector, remove screw and

Intelligent Key unit.

INSTALLATION

Installation is in the reverse order of removal.

PIIB6534E

Page 578 of 2771

BL-144

< SERVICE INFORMATION >

DOOR

DOOR

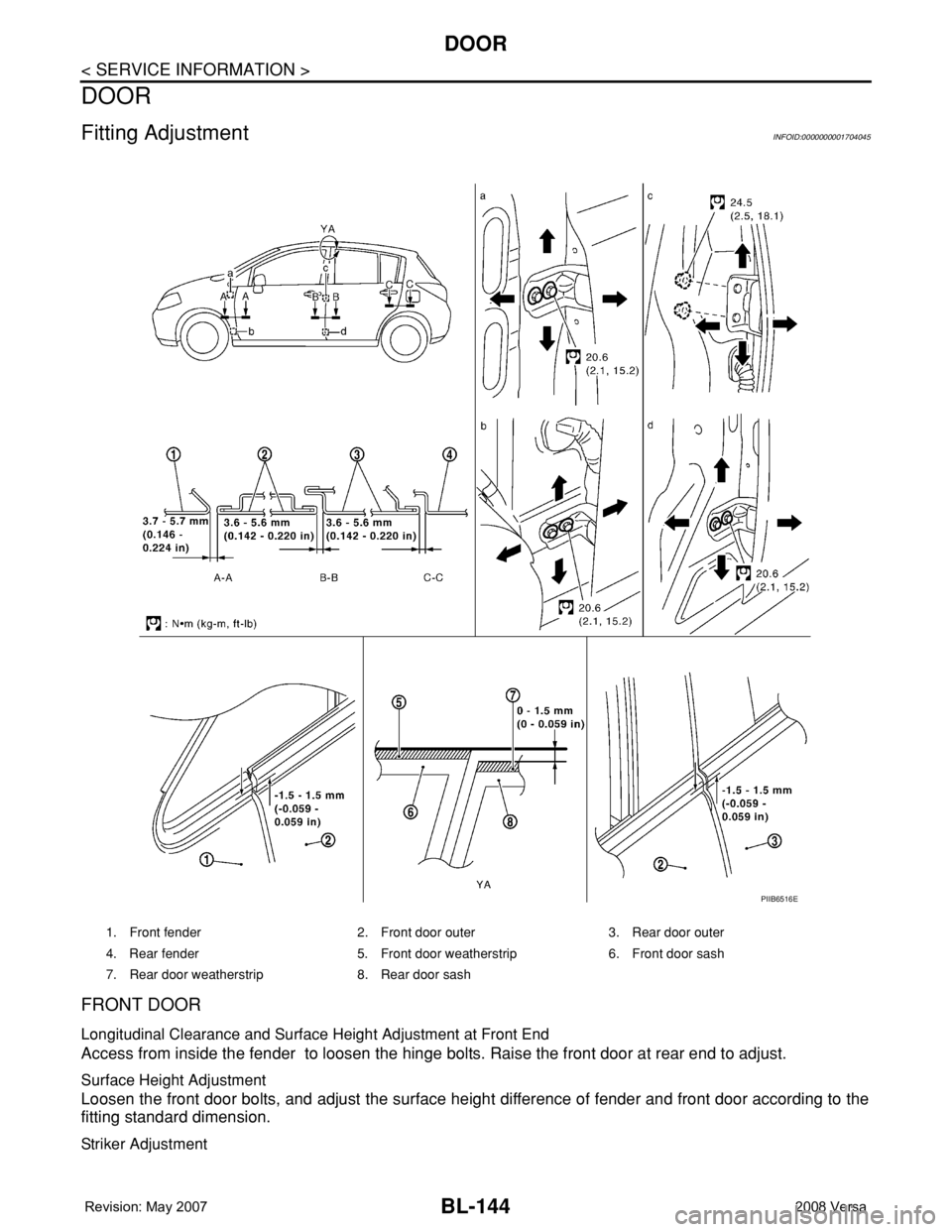

Fitting AdjustmentINFOID:0000000001704045

FRONT DOOR

Longitudinal Clearance and Surface Height Adjustment at Front End

Access from inside the fender to loosen the hinge bolts. Raise the front door at rear end to adjust.

Surface Height Adjustment

Loosen the front door bolts, and adjust the surface height difference of fender and front door according to the

fitting standard dimension.

Striker Adjustment

1. Front fender 2. Front door outer 3. Rear door outer

4. Rear fender 5. Front door weatherstrip 6. Front door sash

7. Rear door weatherstrip 8. Rear door sash

PIIB6516E

Page 579 of 2771

DOOR

BL-145

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

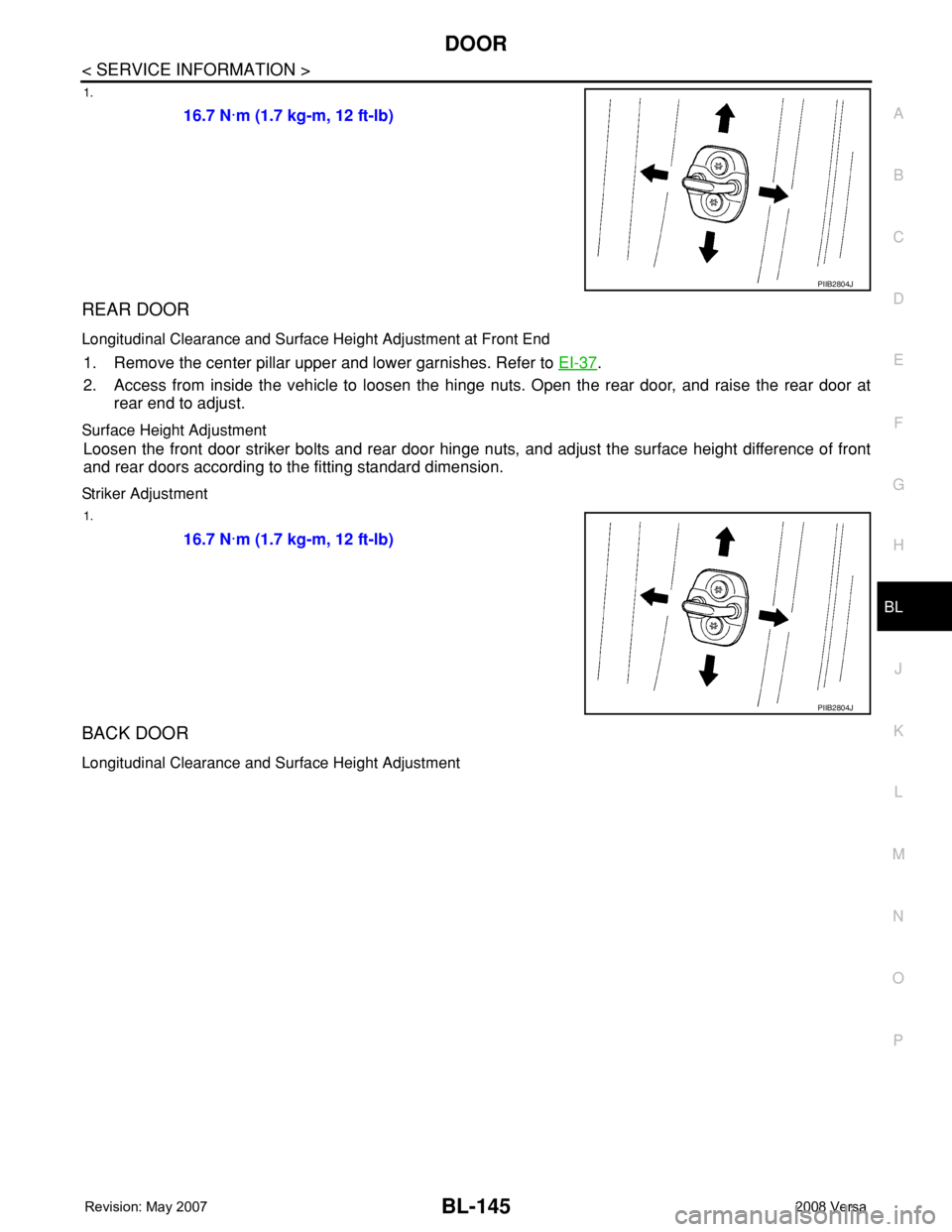

1.

REAR DOOR

Longitudinal Clearance and Surface Height Adjustment at Front End

1. Remove the center pillar upper and lower garnishes. Refer to EI-37.

2. Access from inside the vehicle to loosen the hinge nuts. Open the rear door, and raise the rear door at

rear end to adjust.

Surface Height Adjustment

Loosen the front door striker bolts and rear door hinge nuts, and adjust the surface height difference of front

and rear doors according to the fitting standard dimension.

Striker Adjustment

1.

BACK DOOR

Longitudinal Clearance and Surface Height Adjustment

16.7 N·m (1.7 kg-m, 12 ft-lb)

PIIB2804J

16.7 N·m (1.7 kg-m, 12 ft-lb)

PIIB2804J

Page 580 of 2771

BL-146

< SERVICE INFORMATION >

DOOR

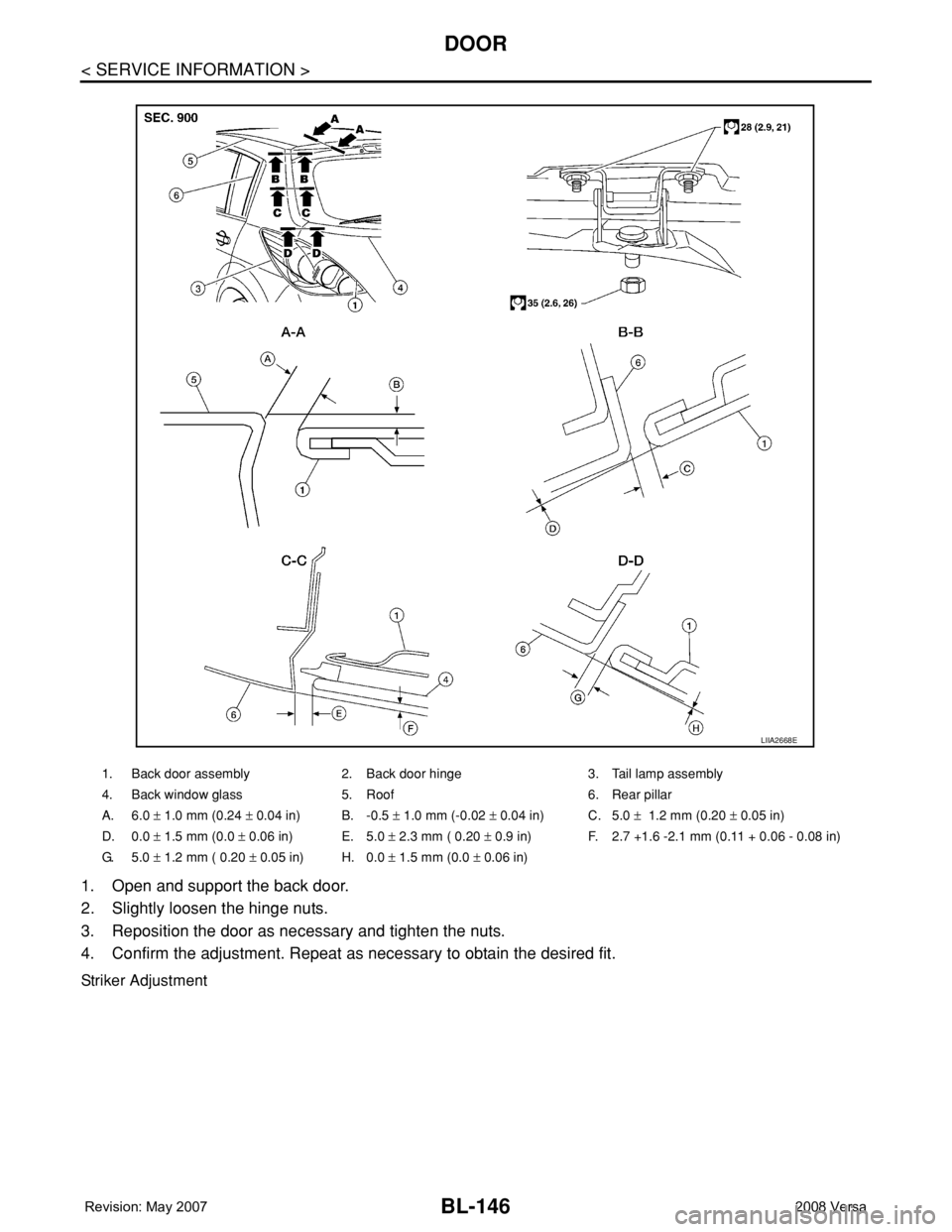

1. Open and support the back door.

2. Slightly loosen the hinge nuts.

3. Reposition the door as necessary and tighten the nuts.

4. Confirm the adjustment. Repeat as necessary to obtain the desired fit.

Striker Adjustment

1. Back door assembly 2. Back door hinge 3. Tail lamp assembly

4. Back window glass 5. Roof 6. Rear pillar

A. 6.0 ± 1.0 mm (0.24 ± 0.04 in) B. -0.5 ± 1.0 mm (-0.02 ± 0.04 in) C. 5.0 ± 1.2 mm (0.20 ± 0.05 in)

D. 0.0 ± 1.5 mm (0.0 ± 0.06 in) E. 5.0 ± 2.3 mm ( 0.20 ± 0.9 in) F. 2.7 +1.6 -2.1 mm (0.11 + 0.06 - 0.08 in)

G. 5.0 ± 1.2 mm ( 0.20 ± 0.05 in) H. 0.0 ± 1.5 mm (0.0 ± 0.06 in)

LIIA2668E