NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 601 of 2771

BACK DOOR LOCK

BL-167

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

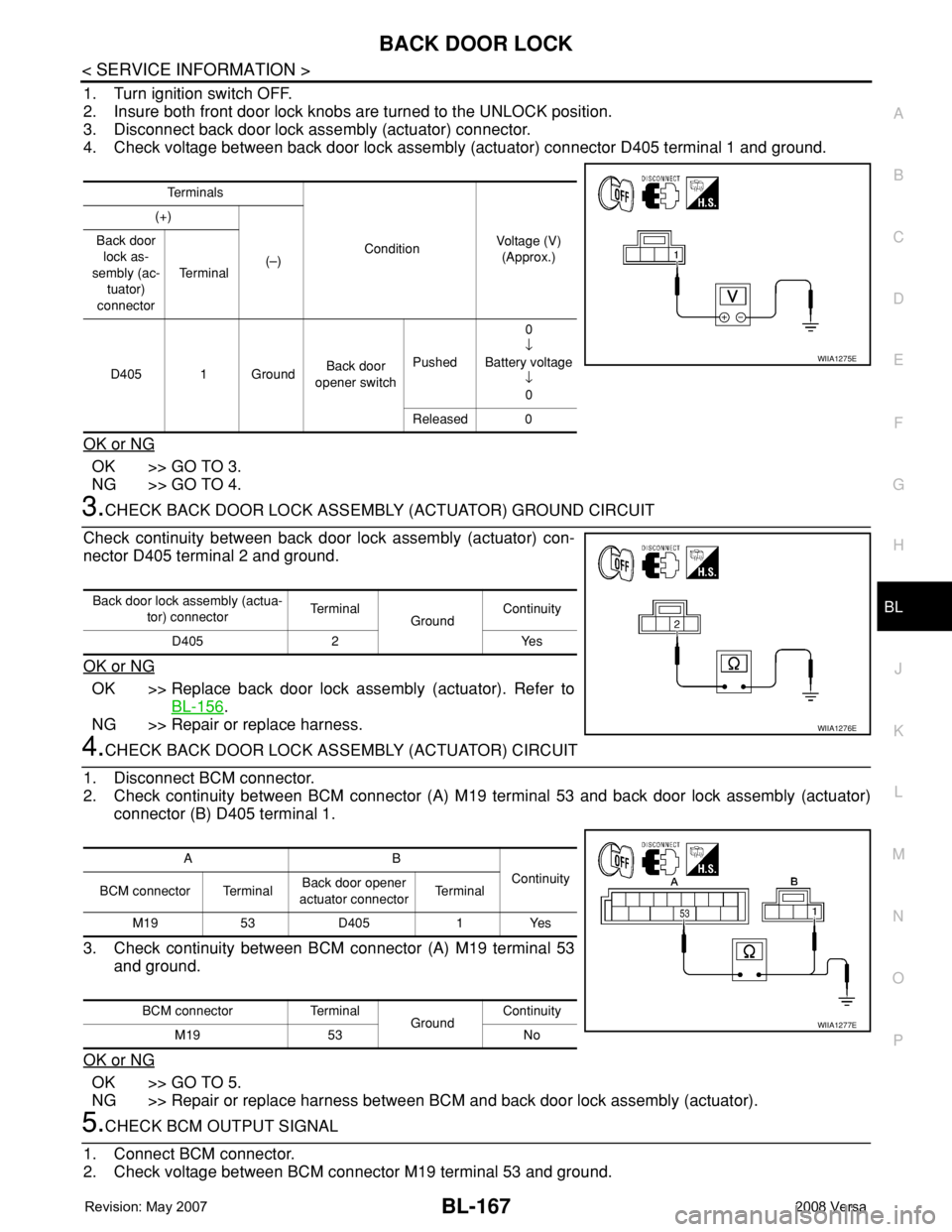

1. Turn ignition switch OFF.

2. Insure both front door lock knobs are turned to the UNLOCK position.

3. Disconnect back door lock assembly (actuator) connector.

4. Check voltage between back door lock assembly (actuator) connector D405 terminal 1 and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

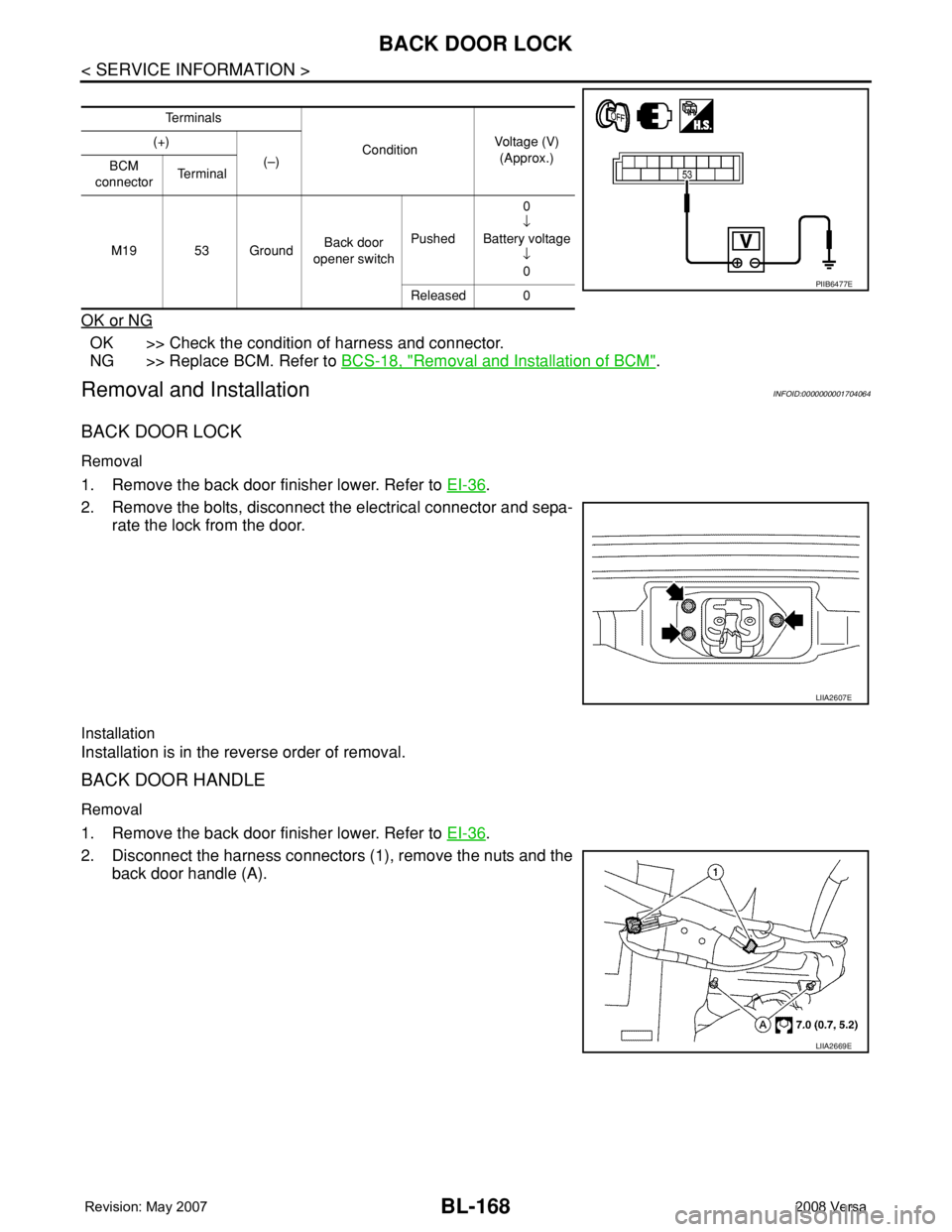

3.CHECK BACK DOOR LOCK ASSEMBLY (ACTUATOR) GROUND CIRCUIT

Check continuity between back door lock assembly (actuator) con-

nector D405 terminal 2 and ground.

OK or NG

OK >> Replace back door lock assembly (actuator). Refer to

BL-156

.

NG >> Repair or replace harness.

4.CHECK BACK DOOR LOCK ASSEMBLY (ACTUATOR) CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM connector (A) M19 terminal 53 and back door lock assembly (actuator)

connector (B) D405 terminal 1.

3. Check continuity between BCM connector (A) M19 terminal 53

and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness between BCM and back door lock assembly (actuator).

5.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM connector M19 terminal 53 and ground.

Te r m i n a l s

ConditionVoltage (V)

(Approx.) (+)

(–) Back door

lock as-

sembly (ac-

tuator)

connectorTe r m i n a l

D405 1 GroundBack door

opener switchPushed0

↓

Battery voltage

↓

0

Released 0

WIIA1275E

Back door lock assembly (actua-

tor) connectorTe r m i n a l

GroundContinuity

D405 2 Yes

WIIA1276E

AB

Continuity

BCM connector TerminalBack door opener

actuator connectorTe r m i n a l

M19 53 D405 1 Yes

BCM connector Terminal

GroundContinuity

M19 53 No

WIIA1277E

Page 602 of 2771

BL-168

< SERVICE INFORMATION >

BACK DOOR LOCK

OK or NG

OK >> Check the condition of harness and connector.

NG >> Replace BCM. Refer to BCS-18, "

Removal and Installation of BCM".

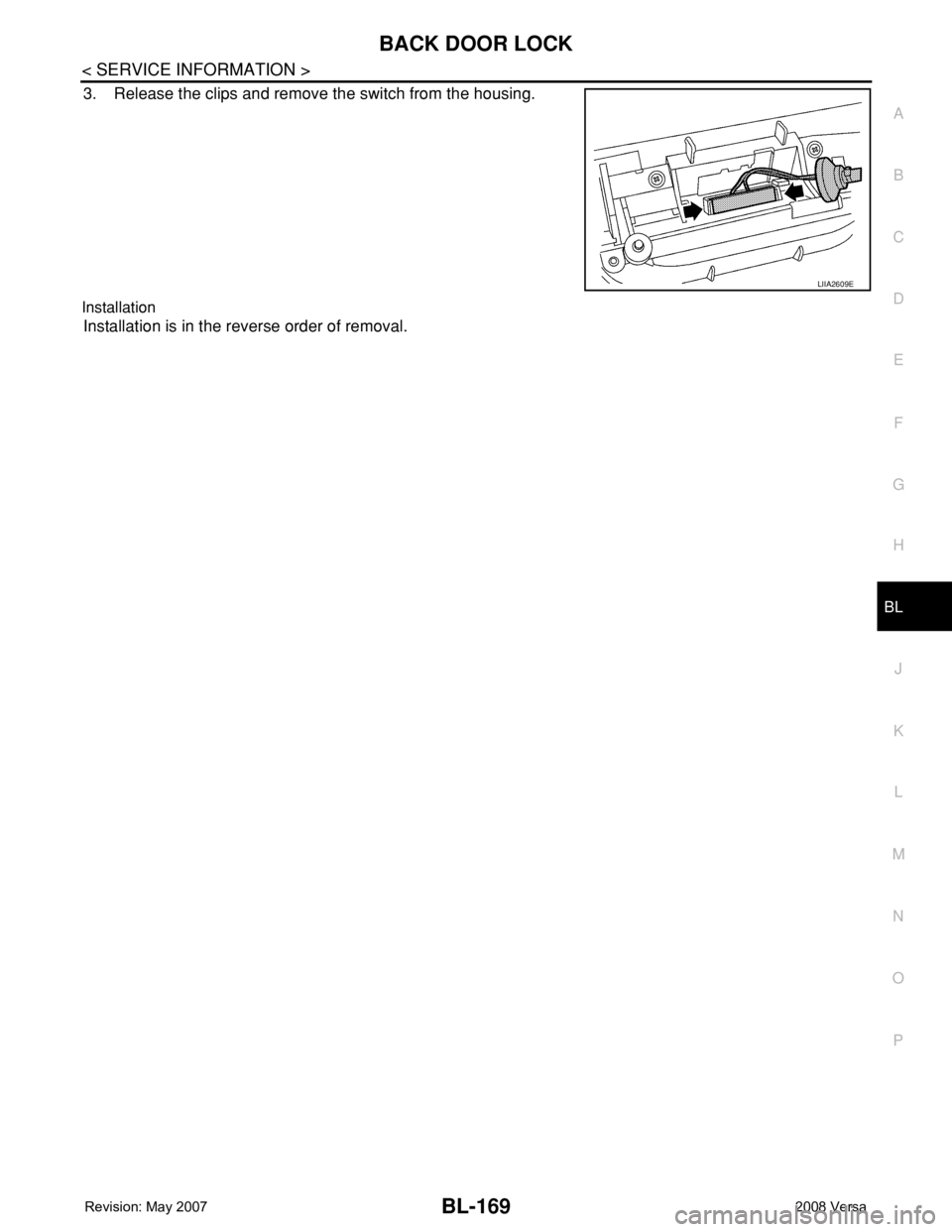

Removal and InstallationINFOID:0000000001704064

BACK DOOR LOCK

Removal

1. Remove the back door finisher lower. Refer to EI-36.

2. Remove the bolts, disconnect the electrical connector and sepa-

rate the lock from the door.

Installation

Installation is in the reverse order of removal.

BACK DOOR HANDLE

Removal

1. Remove the back door finisher lower. Refer to EI-36.

2. Disconnect the harness connectors (1), remove the nuts and the

back door handle (A).

Te r m i n a l s

ConditionVoltage (V)

(Approx.) (+)

(–)

BCM

connectorTe r m i n a l

M19 53 GroundBack door

opener switchPushed0

↓

Battery voltage

↓

0

Released 0

PIIB6477E

LIIA2607E

LIIA2669E

Page 603 of 2771

BACK DOOR LOCK

BL-169

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

3. Release the clips and remove the switch from the housing.

Installation

Installation is in the reverse order of removal.

LIIA2609E

Page 604 of 2771

BL-170

< SERVICE INFORMATION >

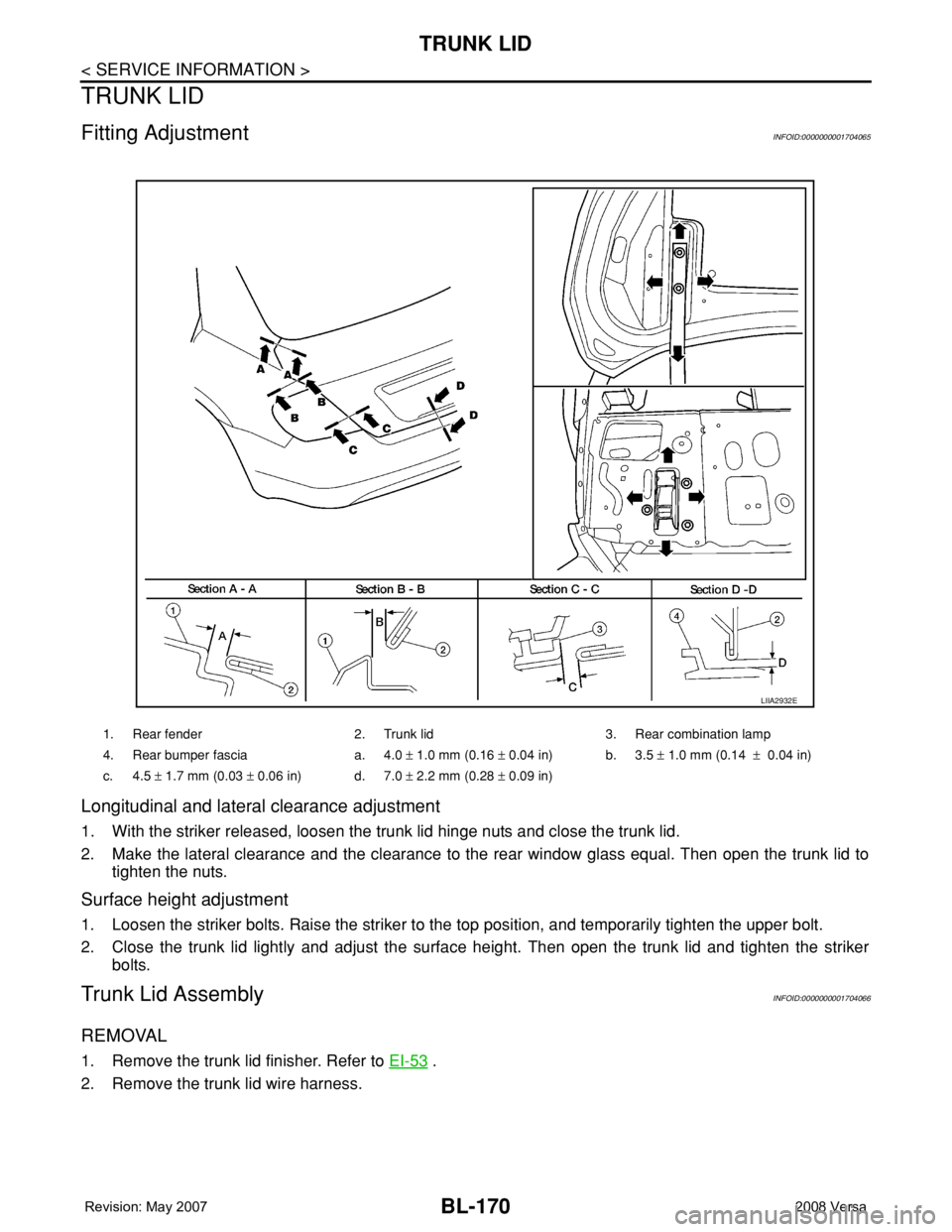

TRUNK LID

TRUNK LID

Fitting AdjustmentINFOID:0000000001704065

Longitudinal and lateral clearance adjustment

1. With the striker released, loosen the trunk lid hinge nuts and close the trunk lid.

2. Make the lateral clearance and the clearance to the rear window glass equal. Then open the trunk lid to

tighten the nuts.

Surface height adjustment

1. Loosen the striker bolts. Raise the striker to the top position, and temporarily tighten the upper bolt.

2. Close the trunk lid lightly and adjust the surface height. Then open the trunk lid and tighten the striker

bolts.

Trunk Lid AssemblyINFOID:0000000001704066

REMOVAL

1. Remove the trunk lid finisher. Refer to EI-53 .

2. Remove the trunk lid wire harness.

1. Rear fender 2. Trunk lid 3. Rear combination lamp

4. Rear bumper fascia a. 4.0 ± 1.0 mm (0.16 ± 0.04 in) b. 3.5 ± 1.0 mm (0.14 ± 0.04 in)

c. 4.5 ± 1.7 mm (0.03 ± 0.06 in) d. 7.0 ± 2.2 mm (0.28 ± 0.09 in)

LIIA2932E

Page 605 of 2771

TRUNK LID

BL-171

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

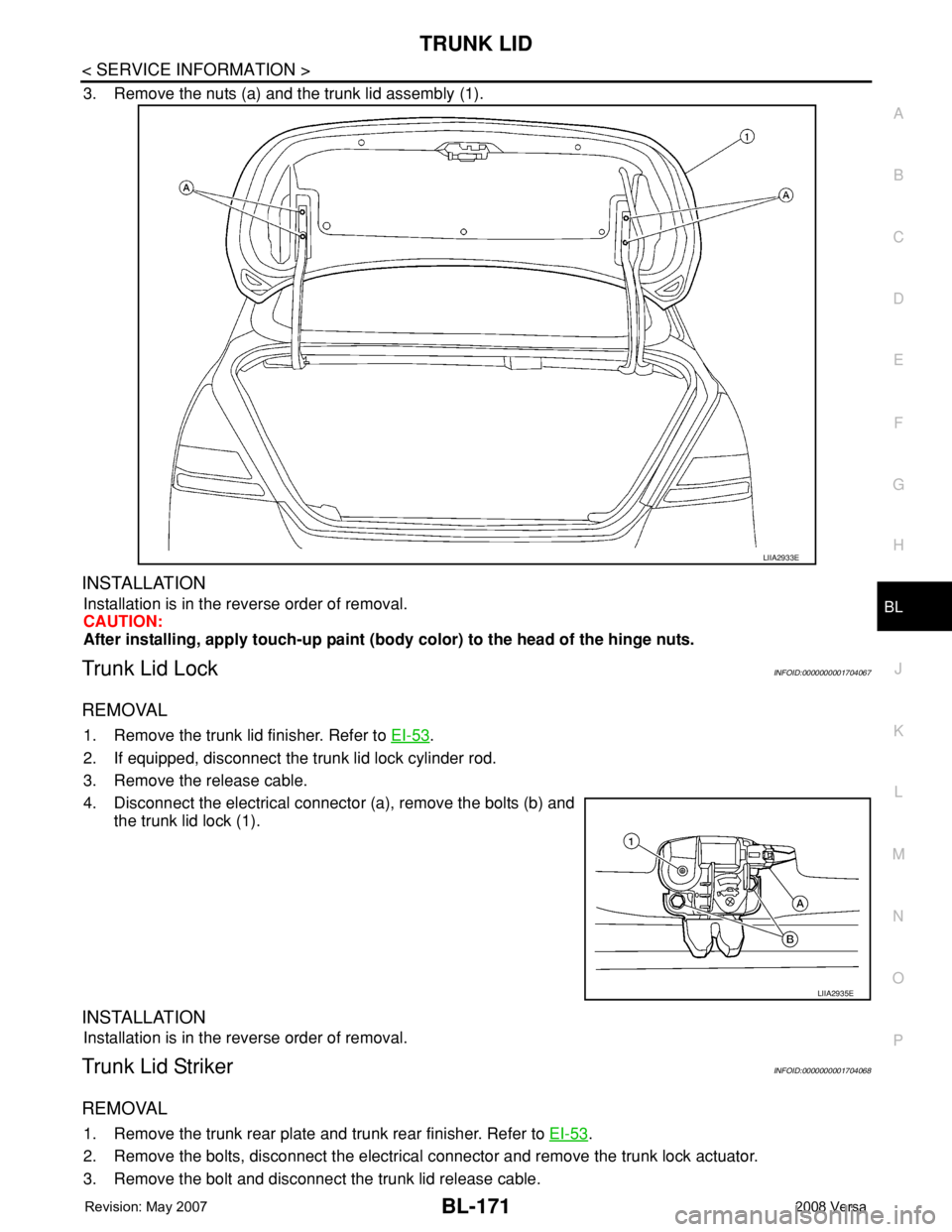

3. Remove the nuts (a) and the trunk lid assembly (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installing, apply touch-up paint (body color) to the head of the hinge nuts.

Trunk Lid LockINFOID:0000000001704067

REMOVAL

1. Remove the trunk lid finisher. Refer to EI-53.

2. If equipped, disconnect the trunk lid lock cylinder rod.

3. Remove the release cable.

4. Disconnect the electrical connector (a), remove the bolts (b) and

the trunk lid lock (1).

INSTALLATION

Installation is in the reverse order of removal.

Trunk Lid StrikerINFOID:0000000001704068

REMOVAL

1. Remove the trunk rear plate and trunk rear finisher. Refer to EI-53.

2. Remove the bolts, disconnect the electrical connector and remove the trunk lock actuator.

3. Remove the bolt and disconnect the trunk lid release cable.

LIIA2933E

LIIA2935E

Page 606 of 2771

BL-172

< SERVICE INFORMATION >

TRUNK LID

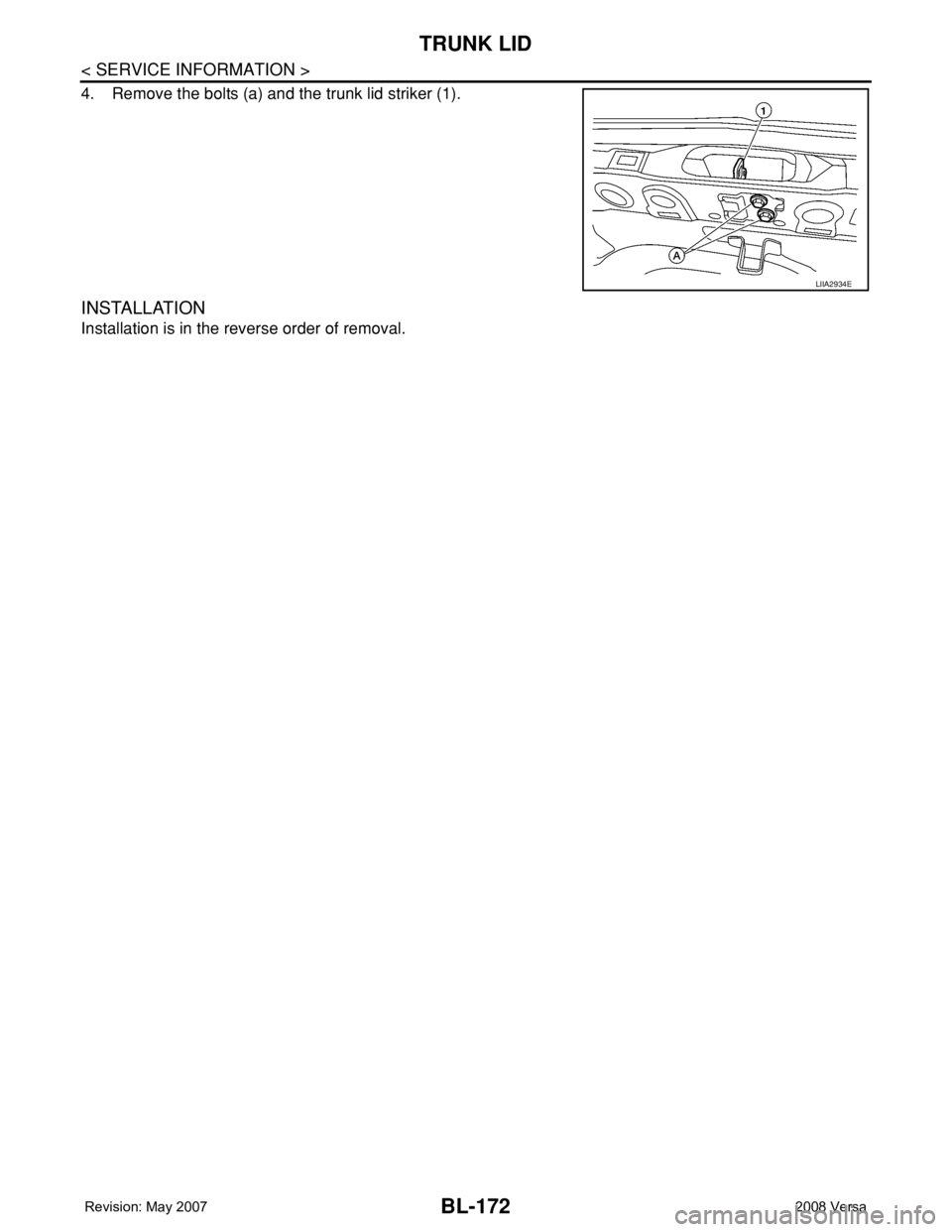

4. Remove the bolts (a) and the trunk lid striker (1).

INSTALLATION

Installation is in the reverse order of removal.

LIIA2934E

Page 607 of 2771

TRUNK LID OPENER

BL-173

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

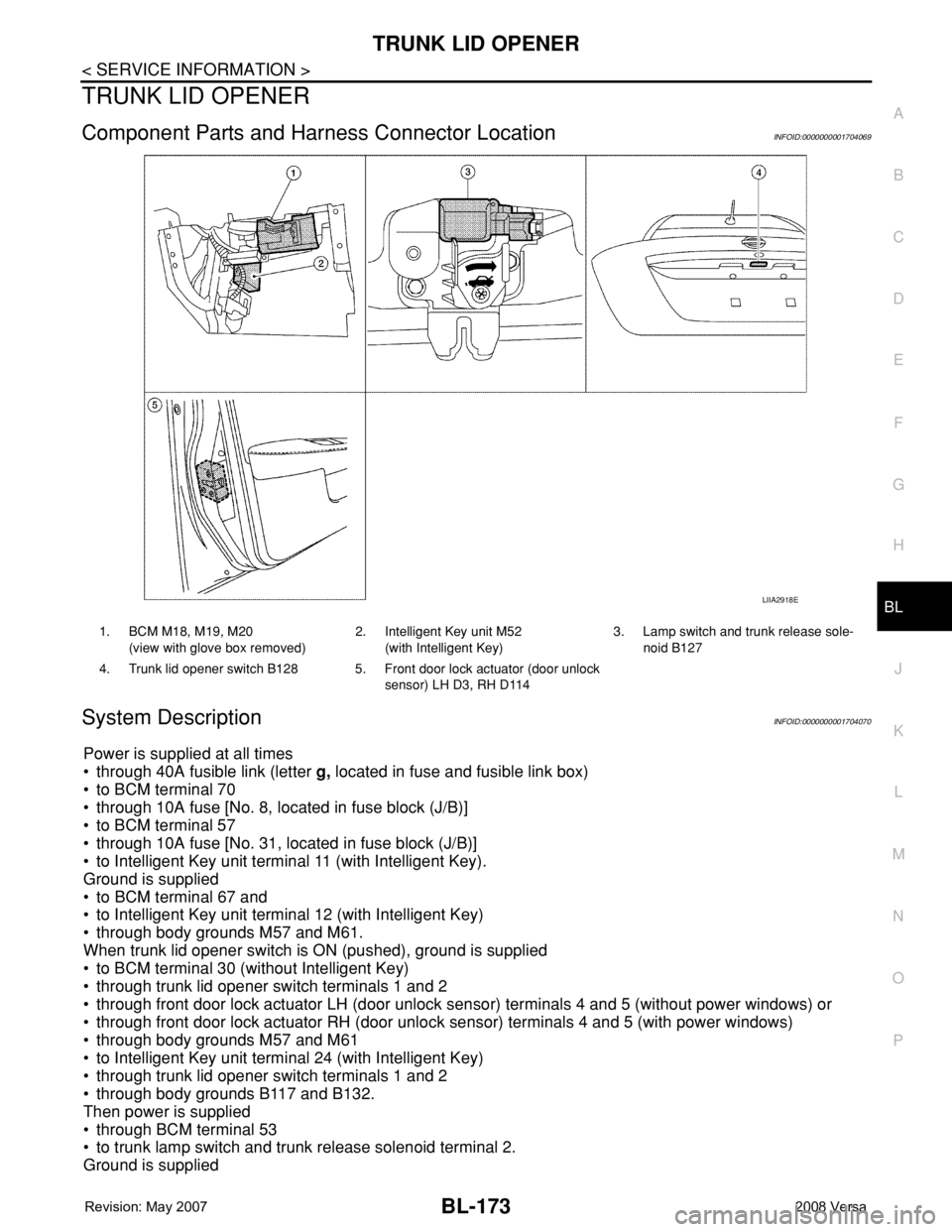

TRUNK LID OPENER

Component Parts and Harness Connector LocationINFOID:0000000001704069

System DescriptionINFOID:0000000001704070

Power is supplied at all times

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 31, located in fuse block (J/B)]

• to Intelligent Key unit terminal 11 (with Intelligent Key).

Ground is supplied

• to BCM terminal 67 and

• to Intelligent Key unit terminal 12 (with Intelligent Key)

• through body grounds M57 and M61.

When trunk lid opener switch is ON (pushed), ground is supplied

• to BCM terminal 30 (without Intelligent Key)

• through trunk lid opener switch terminals 1 and 2

• through front door lock actuator LH (door unlock sensor) terminals 4 and 5 (without power windows) or

• through front door lock actuator RH (door unlock sensor) terminals 4 and 5 (with power windows)

• through body grounds M57 and M61

• to Intelligent Key unit terminal 24 (with Intelligent Key)

• through trunk lid opener switch terminals 1 and 2

• through body grounds B117 and B132.

Then power is supplied

• through BCM terminal 53

• to trunk lamp switch and trunk release solenoid terminal 2.

Ground is supplied

LIIA2918E

1. BCM M18, M19, M20

(view with glove box removed)2. Intelligent Key unit M52

(with Intelligent Key)3. Lamp switch and trunk release sole-

noid B127

4. Trunk lid opener switch B128 5. Front door lock actuator (door unlock

sensor) LH D3, RH D114

Page 608 of 2771

BL-174

< SERVICE INFORMATION >

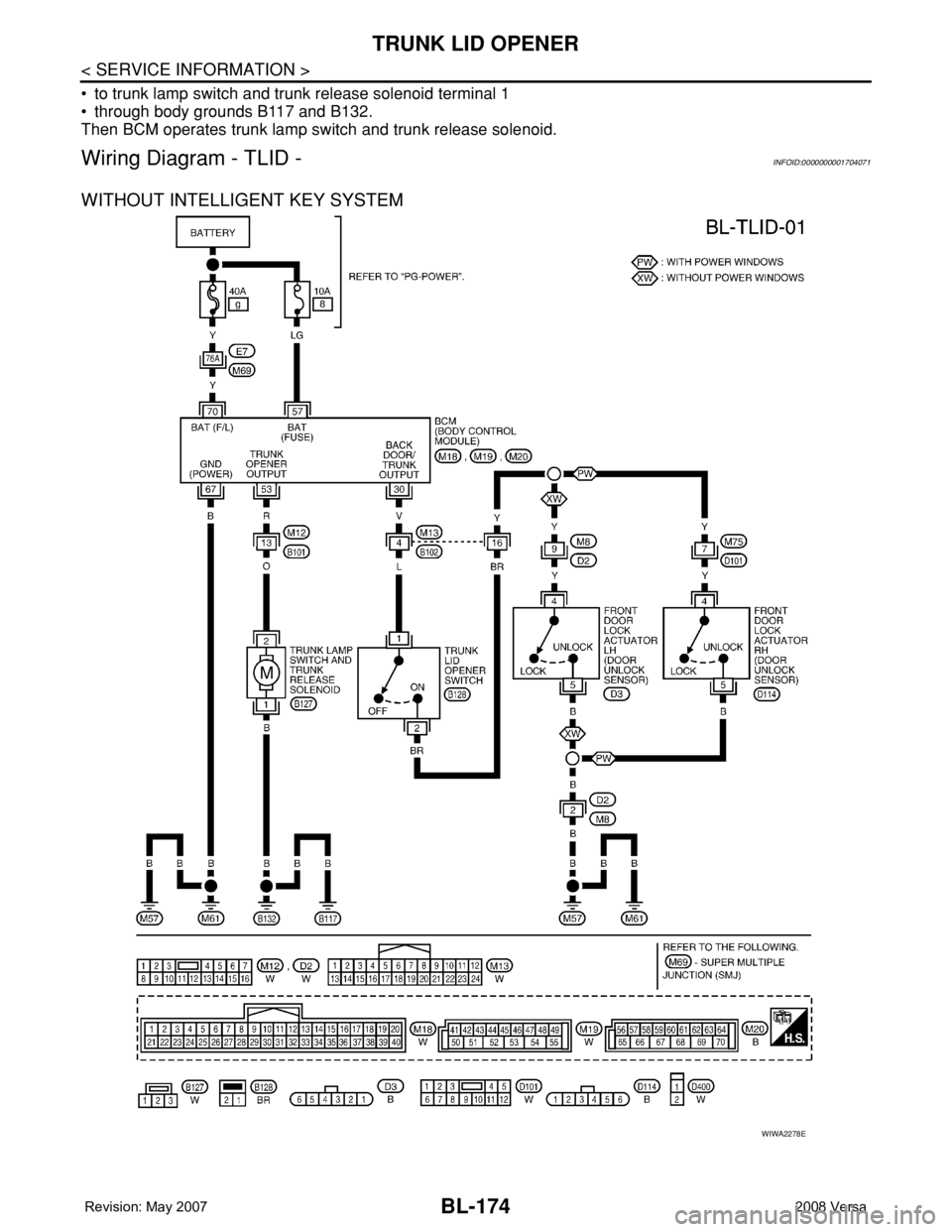

TRUNK LID OPENER

• to trunk lamp switch and trunk release solenoid terminal 1

• through body grounds B117 and B132.

Then BCM operates trunk lamp switch and trunk release solenoid.

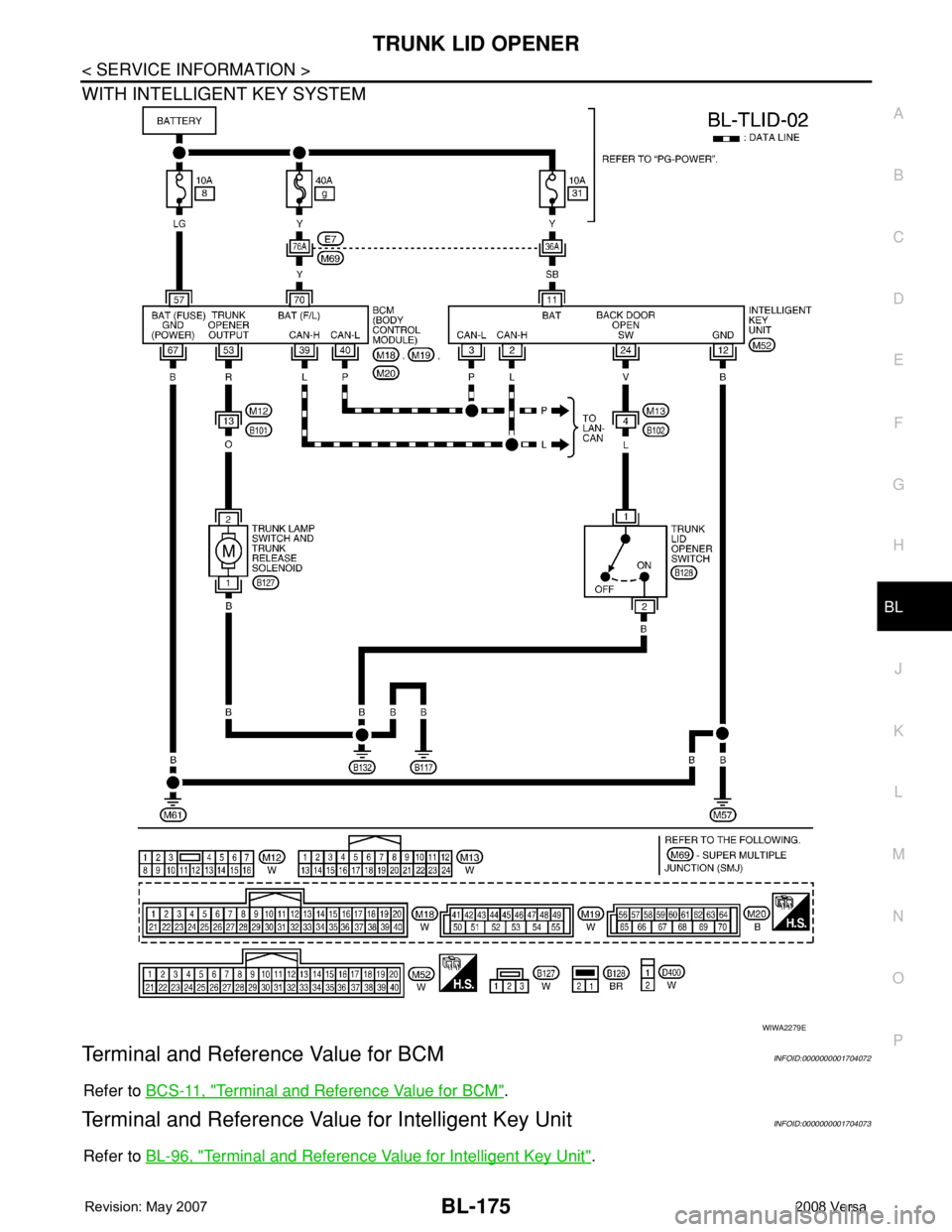

Wiring Diagram - TLID -INFOID:0000000001704071

WITHOUT INTELLIGENT KEY SYSTEM

WIWA2278E

Page 609 of 2771

TRUNK LID OPENER

BL-175

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

WITH INTELLIGENT KEY SYSTEM

Terminal and Reference Value for BCMINFOID:0000000001704072

Refer to BCS-11, "Terminal and Reference Value for BCM".

Terminal and Reference Value for Intelligent Key UnitINFOID:0000000001704073

Refer to BL-96, "Terminal and Reference Value for Intelligent Key Unit".

WIWA2279E

Page 610 of 2771

BL-176

< SERVICE INFORMATION >

TRUNK LID OPENER

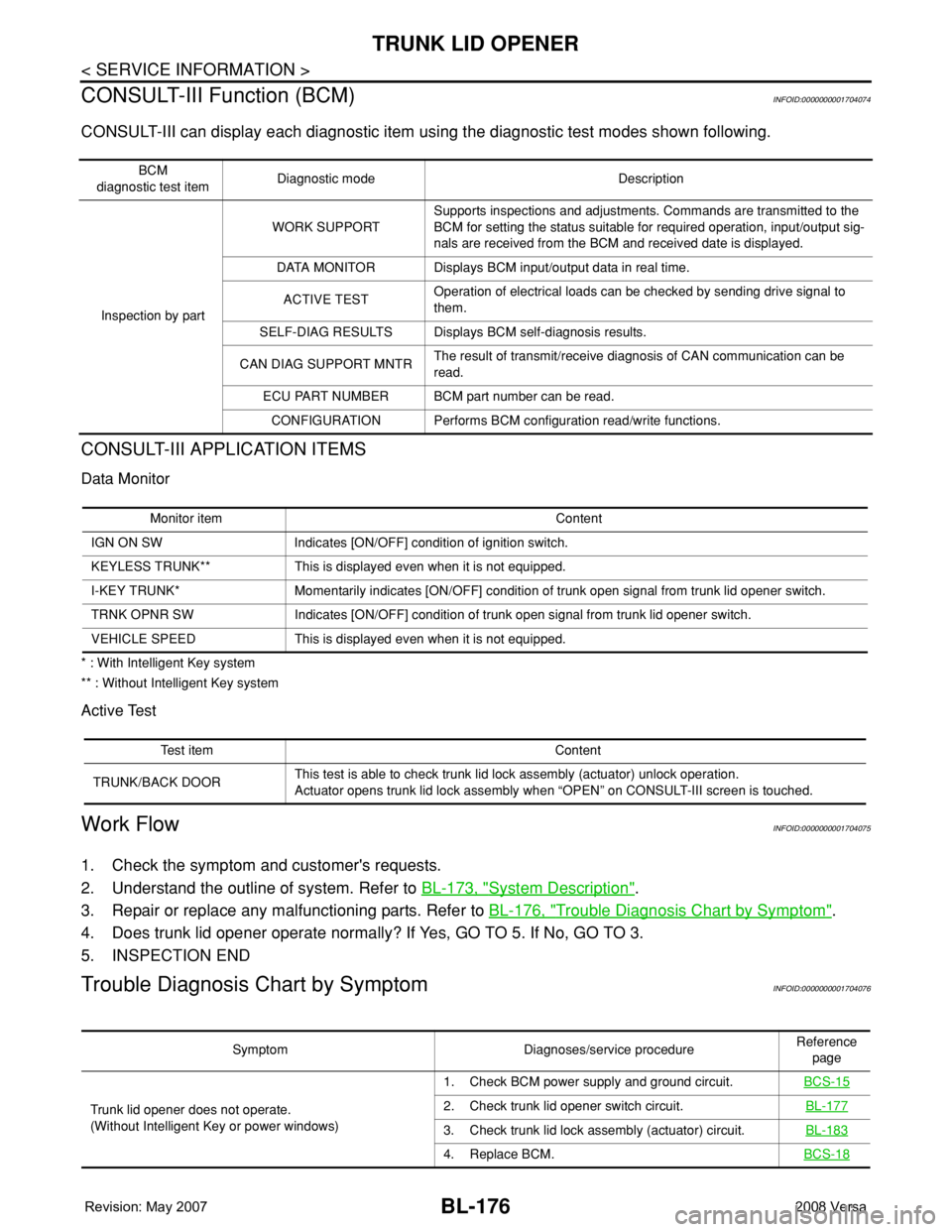

CONSULT-III Function (BCM)

INFOID:0000000001704074

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-III APPLICATION ITEMS

Data Monitor

* : With Intelligent Key system

** : Without Intelligent Key system

Active Test

Work FlowINFOID:0000000001704075

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-173, "

System Description".

3. Repair or replace any malfunctioning parts. Refer to BL-176, "

Trouble Diagnosis Chart by Symptom".

4. Does trunk lid opener operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. INSPECTION END

Trouble Diagnosis Chart by SymptomINFOID:0000000001704076

BCM

diagnostic test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the

BCM for setting the status suitable for required operation, input/output sig-

nals are received from the BCM and received date is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TESTOperation of electrical loads can be checked by sending drive signal to

them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTRThe result of transmit/receive diagnosis of CAN communication can be

read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Monitor item Content

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

KEYLESS TRUNK** This is displayed even when it is not equipped.

I-KEY TRUNK* Momentarily indicates [ON/OFF] condition of trunk open signal from trunk lid opener switch.

TRNK OPNR SW Indicates [ON/OFF] condition of trunk open signal from trunk lid opener switch.

VEHICLE SPEED This is displayed even when it is not equipped.

Test item Content

TRUNK/BACK DOORThis test is able to check trunk lid lock assembly (actuator) unlock operation.

Actuator opens trunk lid lock assembly when “OPEN” on CONSULT-III screen is touched.

Symptom Diagnoses/service procedureReference

page

Trunk lid opener does not operate.

(Without Intelligent Key or power windows)1. Check BCM power supply and ground circuit.BCS-15

2. Check trunk lid opener switch circuit.BL-177

3. Check trunk lid lock assembly (actuator) circuit.BL-183

4. Replace BCM.BCS-18