Power Steering NISSAN TIIDA 2008 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 2518 of 2771

PS-12

< SERVICE INFORMATION >

POWER STEERING GEAR

POWER STEERING GEAR

Removal and InstallationINFOID:0000000001703862

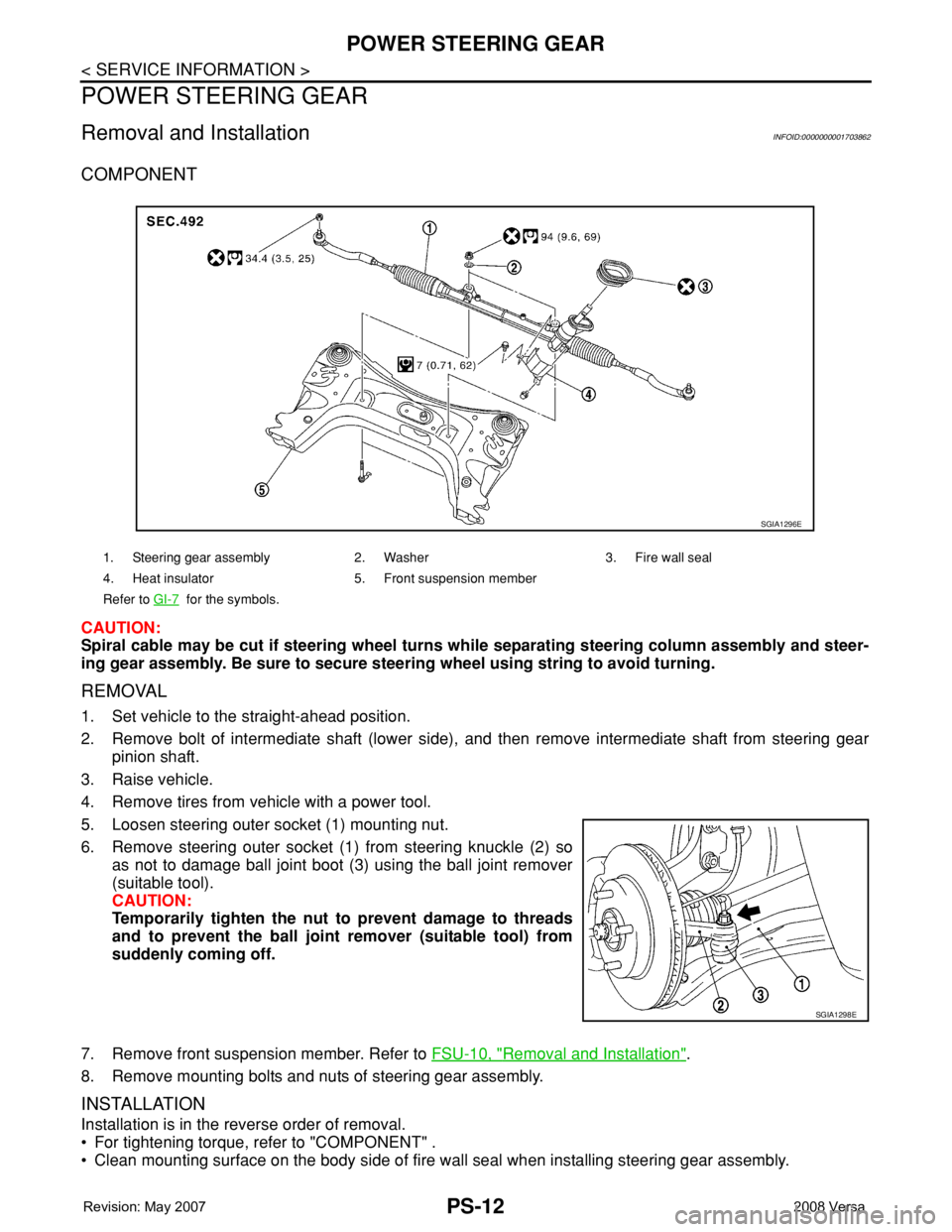

COMPONENT

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using string to avoid turning.

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove bolt of intermediate shaft (lower side), and then remove intermediate shaft from steering gear

pinion shaft.

3. Raise vehicle.

4. Remove tires from vehicle with a power tool.

5. Loosen steering outer socket (1) mounting nut.

6. Remove steering outer socket (1) from steering knuckle (2) so

as not to damage ball joint boot (3) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

7. Remove front suspension member. Refer to FSU-10, "

Removal and Installation".

8. Remove mounting bolts and nuts of steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to "COMPONENT" .

• Clean mounting surface on the body side of fire wall seal when installing steering gear assembly.

1. Steering gear assembly 2. Washer 3. Fire wall seal

4. Heat insulator 5. Front suspension member

Refer to GI-7

for the symbols.

SGIA1296E

SGIA1298E

Page 2519 of 2771

POWER STEERING GEAR

PS-13

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

• Check wheel alignment under unladen conditions with tires on level ground. Refer to FSU-6, "Wheel Align-

ment Inspection".

INSPECTION AFTER INSTALLATION

Rotate steering wheel to check for decentered condition, binding, noise or excessive steering effort.

Disassembly and AssemblyINFOID:0000000001703863

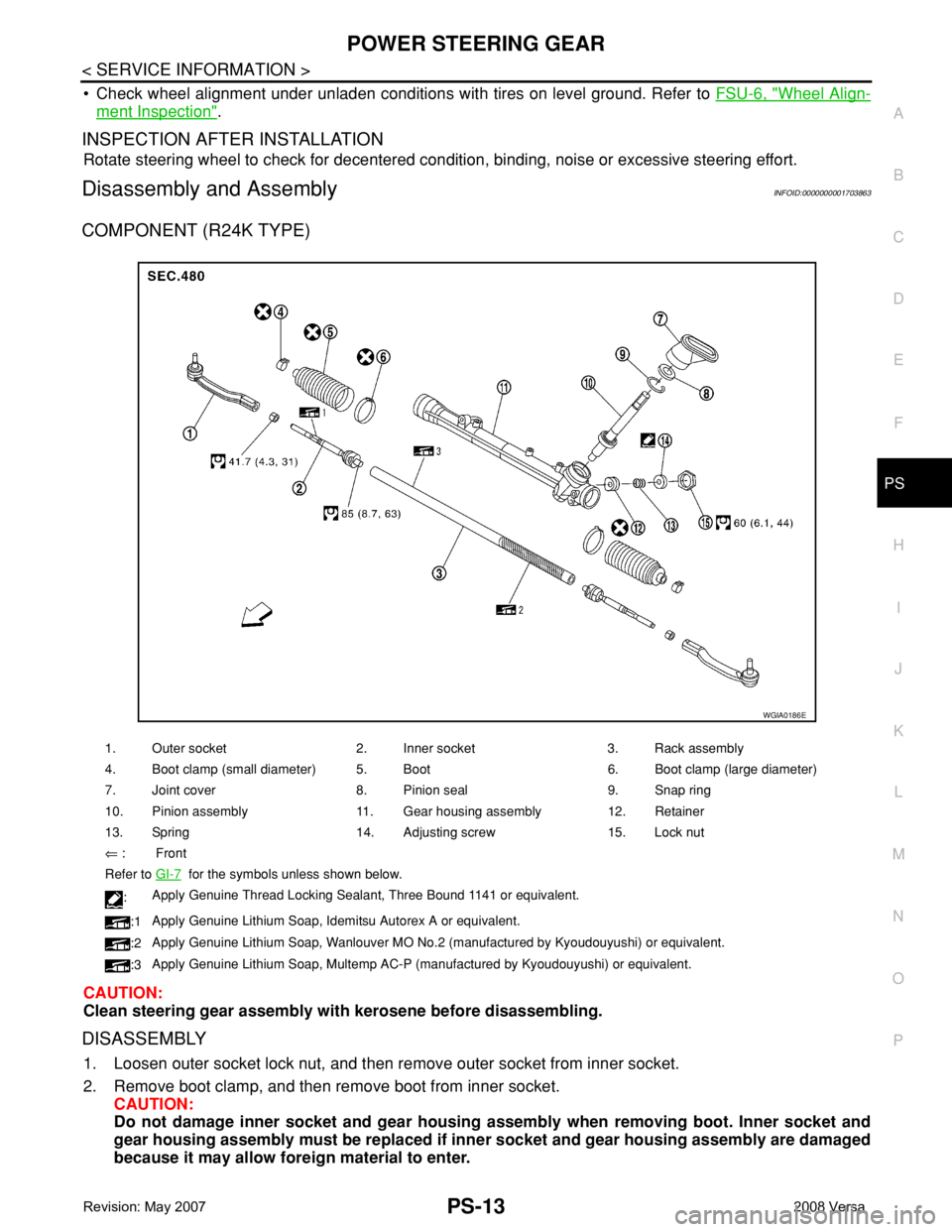

COMPONENT (R24K TYPE)

CAUTION:

Clean steering gear assembly with kerosene before disassembling.

DISASSEMBLY

1. Loosen outer socket lock nut, and then remove outer socket from inner socket.

2. Remove boot clamp, and then remove boot from inner socket.

CAUTION:

Do not damage inner socket and gear housing assembly when removing boot. Inner socket and

gear housing assembly must be replaced if inner socket and gear housing assembly are damaged

because it may allow foreign material to enter.

1. Outer socket 2. Inner socket 3. Rack assembly

4. Boot clamp (small diameter) 5. Boot 6. Boot clamp (large diameter)

7. Joint cover 8. Pinion seal 9. Snap ring

10. Pinion assembly 11. Gear housing assembly 12. Retainer

13. Spring 14. Adjusting screw 15. Lock nut

⇐ : Front

Refer to GI-7

for the symbols unless shown below.

:Apply Genuine Thread Locking Sealant, Three Bound 1141 or equivalent.

:1Apply Genuine Lithium Soap, Idemitsu Autorex A or equivalent.

:2Apply Genuine Lithium Soap, Wanlouver MO No.2 (manufactured by Kyoudouyushi) or equivalent.

:3Apply Genuine Lithium Soap, Multemp AC-P (manufactured by Kyoudouyushi) or equivalent.

WGIA0186E

Page 2520 of 2771

PS-14

< SERVICE INFORMATION >

POWER STEERING GEAR

3. Remove inner socket from rack assembly while holding the flat portion of the rack next to the inner socket

using a suitable tool.

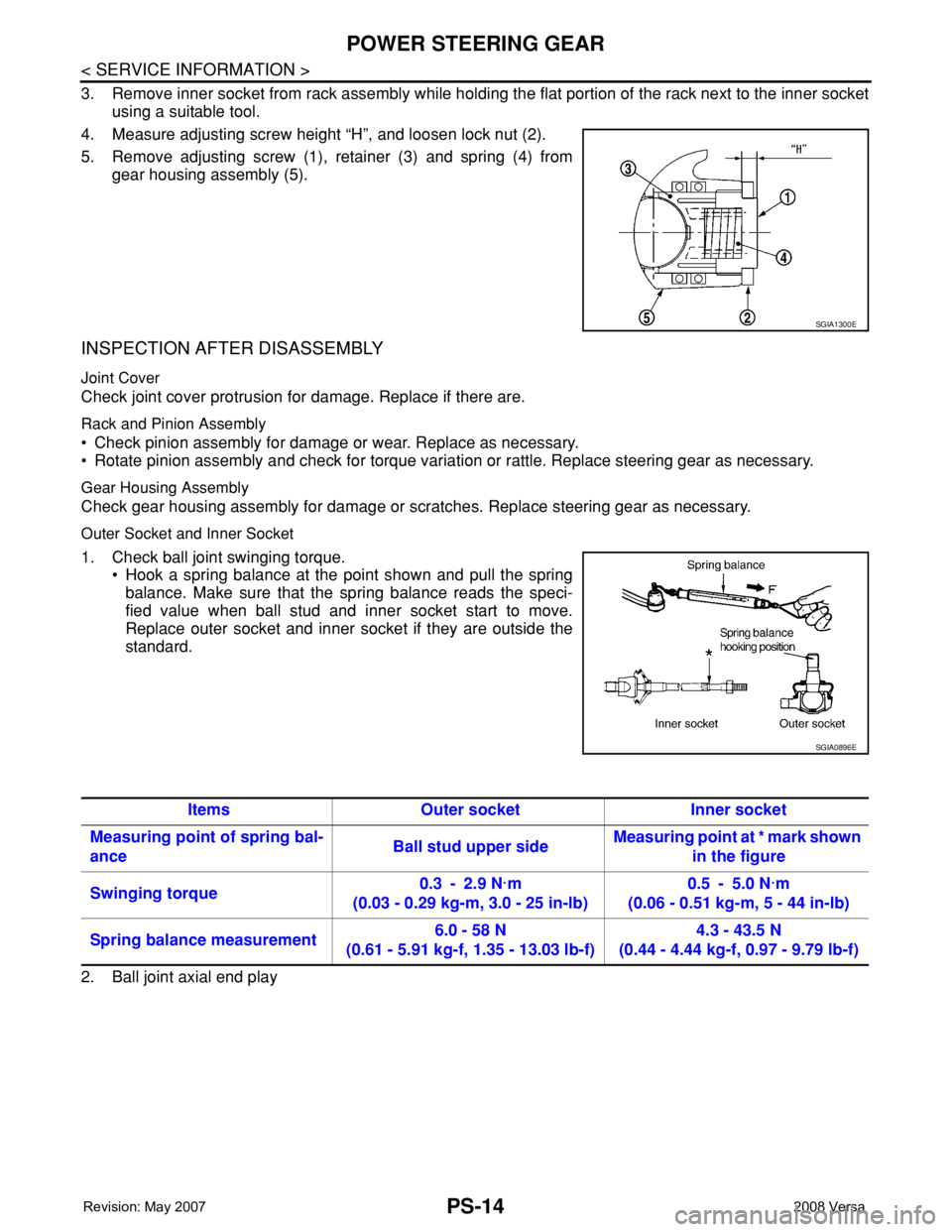

4. Measure adjusting screw height “H”, and loosen lock nut (2).

5. Remove adjusting screw (1), retainer (3) and spring (4) from

gear housing assembly (5).

INSPECTION AFTER DISASSEMBLY

Joint Cover

Check joint cover protrusion for damage. Replace if there are.

Rack and Pinion Assembly

• Check pinion assembly for damage or wear. Replace as necessary.

• Rotate pinion assembly and check for torque variation or rattle. Replace steering gear as necessary.

Gear Housing Assembly

Check gear housing assembly for damage or scratches. Replace steering gear as necessary.

Outer Socket and Inner Socket

1. Check ball joint swinging torque.

• Hook a spring balance at the point shown and pull the spring

balance. Make sure that the spring balance reads the speci-

fied value when ball stud and inner socket start to move.

Replace outer socket and inner socket if they are outside the

standard.

2. Ball joint axial end play

SGIA1300E

SGIA0896E

Items Outer socket Inner socket

Measuring point of spring bal-

anceBall stud upper sideMeasuring point at * mark shown

in the figure

Swinging torque0.3 - 2.9 N·m

(0.03 - 0.29 kg-m, 3.0 - 25 in-lb)0.5 - 5.0 N·m

(0.06 - 0.51 kg-m, 5 - 44 in-lb)

Spring balance measurement6.0 - 58 N

(0.61 - 5.91 kg-f, 1.35 - 13.03 lb-f)4.3 - 43.5 N

(0.44 - 4.44 kg-f, 0.97 - 9.79 lb-f)

Page 2521 of 2771

POWER STEERING GEAR

PS-15

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

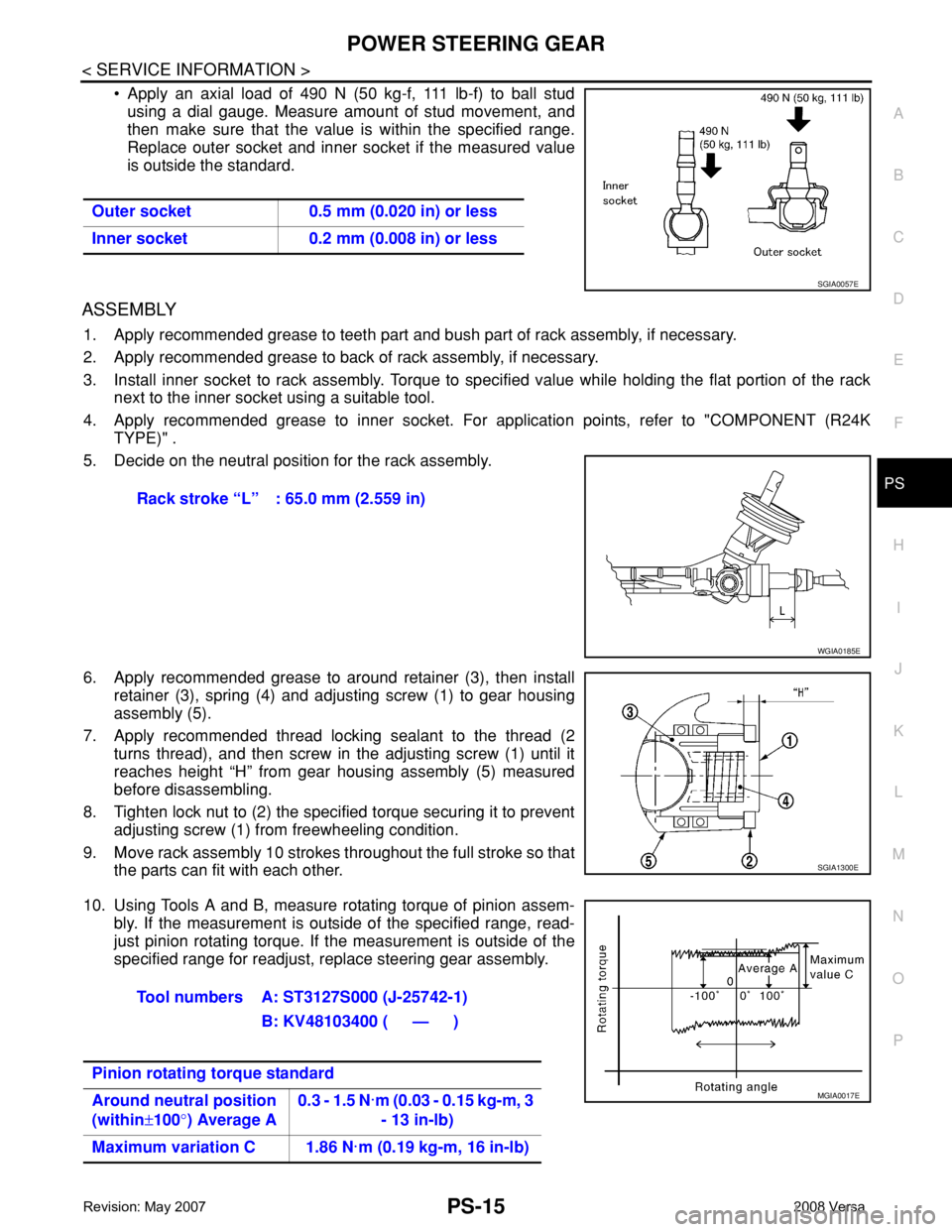

• Apply an axial load of 490 N (50 kg-f, 111 lb-f) to ball stud

using a dial gauge. Measure amount of stud movement, and

then make sure that the value is within the specified range.

Replace outer socket and inner socket if the measured value

is outside the standard.

ASSEMBLY

1. Apply recommended grease to teeth part and bush part of rack assembly, if necessary.

2. Apply recommended grease to back of rack assembly, if necessary.

3. Install inner socket to rack assembly. Torque to specified value while holding the flat portion of the rack

next to the inner socket using a suitable tool.

4. Apply recommended grease to inner socket. For application points, refer to "COMPONENT (R24K

TYPE)" .

5. Decide on the neutral position for the rack assembly.

6. Apply recommended grease to around retainer (3), then install

retainer (3), spring (4) and adjusting screw (1) to gear housing

assembly (5).

7. Apply recommended thread locking sealant to the thread (2

turns thread), and then screw in the adjusting screw (1) until it

reaches height “H” from gear housing assembly (5) measured

before disassembling.

8. Tighten lock nut to (2) the specified torque securing it to prevent

adjusting screw (1) from freewheeling condition.

9. Move rack assembly 10 strokes throughout the full stroke so that

the parts can fit with each other.

10. Using Tools A and B, measure rotating torque of pinion assem-

bly. If the measurement is outside of the specified range, read-

just pinion rotating torque. If the measurement is outside of the

specified range for readjust, replace steering gear assembly. Outer socket 0.5 mm (0.020 in) or less

Inner socket 0.2 mm (0.008 in) or less

SGIA0057E

Rack stroke “L” : 65.0 mm (2.559 in)

WGIA0185E

SGIA1300E

Tool numbers A: ST3127S000 (J-25742-1)

B: KV48103400 ( — )

Pinion rotating torque standard

Around neutral position

(within±100°) Average A0.3 - 1.5 N·m (0.03 - 0.15 kg-m, 3

- 13 in-lb)

Maximum variation C 1.86 N·m (0.19 kg-m, 16 in-lb)

MGIA0017E

Page 2522 of 2771

PS-16

< SERVICE INFORMATION >

POWER STEERING GEAR

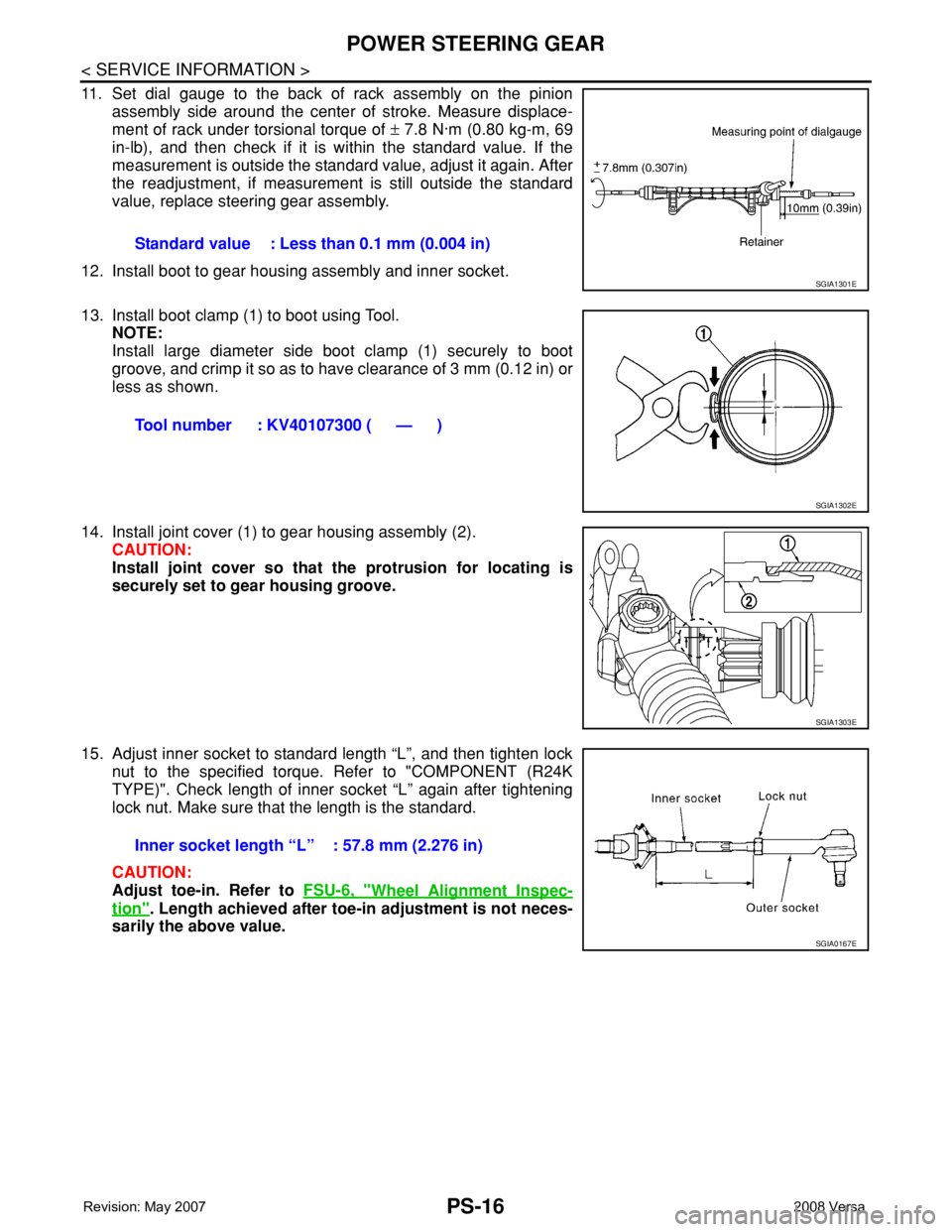

11. Set dial gauge to the back of rack assembly on the pinion

assembly side around the center of stroke. Measure displace-

ment of rack under torsional torque of ± 7.8 N·m (0.80 kg-m, 69

in-lb), and then check if it is within the standard value. If the

measurement is outside the standard value, adjust it again. After

the readjustment, if measurement is still outside the standard

value, replace steering gear assembly.

12. Install boot to gear housing assembly and inner socket.

13. Install boot clamp (1) to boot using Tool.

NOTE:

Install large diameter side boot clamp (1) securely to boot

groove, and crimp it so as to have clearance of 3 mm (0.12 in) or

less as shown.

14. Install joint cover (1) to gear housing assembly (2).

CAUTION:

Install joint cover so that the protrusion for locating is

securely set to gear housing groove.

15. Adjust inner socket to standard length “L”, and then tighten lock

nut to the specified torque. Refer to "COMPONENT (R24K

TYPE)". Check length of inner socket “L” again after tightening

lock nut. Make sure that the length is the standard.

CAUTION:

Adjust toe-in. Refer to FSU-6, "

Wheel Alignment Inspec-

tion". Length achieved after toe-in adjustment is not neces-

sarily the above value.Standard value : Less than 0.1 mm (0.004 in)

SGIA1301E

Tool number : KV40107300 ( — )

SGIA1302E

SGIA1303E

Inner socket length “L” : 57.8 mm (2.276 in)

SGIA0167E

Page 2685 of 2771

![NISSAN TIIDA 2008 Service Workshop Manual STC-2

< SERVICE INFORMATION >[EPS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000 NISSAN TIIDA 2008 Service Workshop Manual STC-2

< SERVICE INFORMATION >[EPS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000](/img/5/57399/w960_57399-2684.png)

STC-2

< SERVICE INFORMATION >[EPS]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703869

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001703870

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precaution for EPS SystemINFOID:0000000001703871

CAUTION:

Check or confirm the following item when performing the trouble diagnosis.

Page 2687 of 2771

![NISSAN TIIDA 2008 Service Workshop Manual STC-4

< SERVICE INFORMATION >[EPS]

EPS SYSTEM

EPS SYSTEM

System DescriptionINFOID:0000000001703872

EPS CONTROL UNIT

• EPS control unit performs an arithmetical operation on data, such

as steering wh NISSAN TIIDA 2008 Service Workshop Manual STC-4

< SERVICE INFORMATION >[EPS]

EPS SYSTEM

EPS SYSTEM

System DescriptionINFOID:0000000001703872

EPS CONTROL UNIT

• EPS control unit performs an arithmetical operation on data, such

as steering wh](/img/5/57399/w960_57399-2686.png)

STC-4

< SERVICE INFORMATION >[EPS]

EPS SYSTEM

EPS SYSTEM

System DescriptionINFOID:0000000001703872

EPS CONTROL UNIT

• EPS control unit performs an arithmetical operation on data, such

as steering wheel turning force (sensor signal) from the torque

sensor, vehicle speed signal, etc. Then it generates an optimum

assist torque to the EPS motor according to the driving condition.

• EPS control unit decreases the output to EPS motor while

extremely using the power steering function (e.g., full steering) for

protecting EPS motor and EPS control unit (Protect overload sta-

tus). While activating protect overload status, the assist torque

gradually decreases, and the steering wheel turning force

becomes heavy. The normal assist torque reactivates by not steer-

ing.

• In case of an error in the electrical system, the fail-safe function

stops output signals to the EPS motor. Then the previous state is changed to the manual steering state.

• Self-diagnosis can be done with CONSULT-III.

EPS MOTOR

EPS motor provides the assist torque by control signal from EPS control unit.

TORQUE SENSOR

Torque sensor detects the steering torque, and transmit the signal to

EPS control unit.

REDUCTION GEAR

Reduction gear increases the assist torque provided from EPS motor with worm gears, and outputs to the col-

umn shaft.

EPS WARNING LAMP

Turns ON when there is a malfunction in EPS system. It indicates that fail-safe mode is engaged and enters a

manual steering state (Control turning force steering wheel becomes heavy).

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF after the engine starts

if system is normal.

EPS Warning Lamp Indication

SGIA1647E

SGIA1648E

Condition EPS warning lamp

Lamp checkTurns ON when ignition switch is turned ON.

Turns OFF after engine start.

EPS system malfunctionON

Other than above (system normal) OFF

Page 2688 of 2771

![NISSAN TIIDA 2008 Service Workshop Manual EPS SYSTEM

STC-5

< SERVICE INFORMATION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

SchematicINFOID:0000000001703873

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationINFOID:0000000001703874

SYSTEM DESCRIPT NISSAN TIIDA 2008 Service Workshop Manual EPS SYSTEM

STC-5

< SERVICE INFORMATION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

SchematicINFOID:0000000001703873

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationINFOID:0000000001703874

SYSTEM DESCRIPT](/img/5/57399/w960_57399-2687.png)

EPS SYSTEM

STC-5

< SERVICE INFORMATION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

SchematicINFOID:0000000001703873

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationINFOID:0000000001703874

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer to LAN-23, "

CAN System Specification Chart".

WGIA0187E

Component parts Function

EPS control unit

(Electric power steering control unit)• Outputs optimum assist torque signal to EPS motor.

• Reduces output signals to EPS motor and protects EPS motor and EPS control unit when us-

ing power steering continuously and excessively.

• As a fail-safe function, turned off output signal to EPS motor and then enters a manual steer-

ing state, if malfunction is detected in EPS system.

EPS motor Products assist torque by control signal from EPS control unit.

Torque sensor Detects steering wheel turning force and outputs sensor signal to EPS control unit.

Reduction gear Increases motor-produced assist torque by worm gear and transmits it to column shaft.

EPS warning lamp Illuminates if malfunction is detected in electrical system of EPS system.

ECMTransmits the following signals via CAN communication to EPS control unit.

• Engine status signal

ABS actuator and electric unit (con-

trol unit) (With ABS)Transmits the following signals via CAN communication to EPS control unit.

• Vehicle speed signal

Combination meterTransmits the following signals via CAN communication to EPS control unit.

• Vehicle speed signal

TCM (Without ABS)Transmits the following signals via CAN communication to EPS control unit.

• Vehicle speed signal

Page 2693 of 2771

![NISSAN TIIDA 2008 Service Workshop Manual STC-10

< SERVICE INFORMATION >[EPS]

TROUBLE DIAGNOSIS

*1 : In the front of the value, “L” is displayed at steering left and “R” is displayed at steering right.

*2 : Almost in accordance with t NISSAN TIIDA 2008 Service Workshop Manual STC-10

< SERVICE INFORMATION >[EPS]

TROUBLE DIAGNOSIS

*1 : In the front of the value, “L” is displayed at steering left and “R” is displayed at steering right.

*2 : Almost in accordance with t](/img/5/57399/w960_57399-2692.png)

STC-10

< SERVICE INFORMATION >[EPS]

TROUBLE DIAGNOSIS

*1 : In the front of the value, “L” is displayed at steering left and “R” is displayed at steering right.

*2 : Almost in accordance with the value of “MOTOR SIG”. It is not a malfunction though these values are not accorded when steering

quickly.

*3 : It is not a malfunction, though it might not be corresponding just after ignition switch is turned ON.

*4 : It turns to OFF after waiting for a short period of time.

EPS Terminal and Reference ValueINFOID:0000000001703880

EPS HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR EPS CONTROL UNIT

Monitor item (Unit) Content Condition Display value

MOTOR VOL (V)Power supply voltage for

EPS control unitIgnition switch: ON Battery voltage

TORQUE SENSOR (Nm)Steering wheel turning

forceEngine runningSteering wheel: Not

steering (There is no

steering force) 0.00 Nm

Steering wheel: Steer-

ing0 – 8.19 Nm

*1 (The value

is changed according to

steering left or right)

MOTOR SIG (A)Command current to EPS

motorEngine runningSteering wheel: Not

steering (There is no

steering force)0.00 A

Steering wheel: Steer-

ing0 – 65.00 A (The value is

changed according to

steering left or right)

MOTOR CURRENT (A)Consumption current of

EPS motorEngine runningSteering wheel: Not

steering (There is no

steering force)0.00 A

Steering wheel: Steer-

ing0 – 65.00 A

*2 (The value

is changed according to

steering left or right)

VEHICLE SPEED (km/h) or (mph) Vehicle speedVehicle stopped 0 km/h (0 mph)

While drivingApproximately equal to

the indication on speed-

ometer (Inside of ±10%)

*3

WARNING LAMP (ON/OFF)EPS warning lamp condi-

tionEPS warning lamp: ON ON

EPS warning lamp: OFF OFF

DERATING STAT (ON/OFF) Protect overload status Engine runningSteering wheel: Nor-

mal steeringOFF

Steering wheel: Steer-

ing over the stopON

*4

ENGINE STATUS (RUN/STOP) Engine statusEngine stopped

(Engine speed: Less than 400 rpm)STOP

Engine running

(Engine speed: 400 rpm or more)RUN

SGIA1624E

Page 2694 of 2771

![NISSAN TIIDA 2008 Service Workshop Manual TROUBLE DIAGNOSIS

STC-11

< SERVICE INFORMATION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

Data are reference values and are measured between each terminal and ground.

CAUTION:

When using a circuit tester NISSAN TIIDA 2008 Service Workshop Manual TROUBLE DIAGNOSIS

STC-11

< SERVICE INFORMATION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

Data are reference values and are measured between each terminal and ground.

CAUTION:

When using a circuit tester](/img/5/57399/w960_57399-2693.png)

TROUBLE DIAGNOSIS

STC-11

< SERVICE INFORMATION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

Data are reference values and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

CONSULT-III Function (EPS)INFOID:0000000001703881

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAG RESULTS MODE

Display Item List

Te r m i n a lWire

colorItem Condition Data (Approx.)

4 V Torque sensor sub Engine runningSteering wheel: Not steering

(There in no steering force)2.5 V

Steering wheel: Steering1.7 V – 3.3 V

(The value is changed accord-

ing to steering left or right)

5 BR Torque sensor power supplyIgnition switch: ON 8 V

Ignition switch: OFF 0 V

6 G Torque sensor main Engine runningSteering wheel: Not steering

(There is no steering force)2.5 V

Steering wheel: Steering1.7 V – 3.3 V

(The value is changed accord-

ing to steering left or right)

7 R Torque sensor ground Always 0 V

9 L CAN-H — —

10 O Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF 0 V

16 P CAN-L — —

17 R Power supply (Memory back-up)Ignition switch: ON Battery voltage

Ignition switch: OFF Battery voltage

18 B Ground Always 0 V

19 — Motor (+) — —

20 — Motor (–) — —

Diagnostic test mode Function Reference page

Self-diagnostic results • Self-diagnostic results can be read and erased quickly."SELF-DIAG

RESULTS

MODE"

Data monitor • Input/Output data in the EPS control unit can be read."DATA MONI-

TOR"

CAN diagnostic support monitor • The results of transmit/receive diagnosis of CAN communication can be read.LAN-6

ECU part number • EPS control unit part number can be read."EPS CON-

TROL UNIT

PART NUM-

BER"