engine control system NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2191 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0452 EVAP CONTROL

SYSTEM PRESSURE SENSOR

EC-835

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045373331.

CHECK GROUND CONNECTIONS

1. Turn NISSAN TIIDA 2009 Service Repair Manual DTC P0452 EVAP CONTROL

SYSTEM PRESSURE SENSOR

EC-835

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045373331.

CHECK GROUND CONNECTIONS

1. Turn](/img/5/57398/w960_57398-2190.png)

DTC P0452 EVAP CONTROL

SYSTEM PRESSURE SENSOR

EC-835

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045373331.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-632, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK CONNECTOR

TER-

MI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

42 V EVAP control system pres-

sure sensor [Ignition switch: ON]

Approximately 1.8 - 4.8V

51 O Sensor ground

(EVAP control system pres-

sure sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

74 W Sensor power supply

(Refrigerant pressure

sensor) [Ignition switch: ON]

Approximately 5V

75 BR Sensor power supply

[Crankshaft position sensor

(POS)] [Ignition switch: ON]

Approximately 5V

76 W EVAP control system pres-

sure sensor power supply [Ignition switch: ON]

Approximately 5V

102 SB Sensor power supply

(Accelerator pedal position

sensor 2) [Ignition switch: ON]

Approximately 5V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2196 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-840< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0453 EVAP CONTROL

SYSTEM PRESSURE SENSOR

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and NISSAN TIIDA 2009 Service Repair Manual EC-840< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0453 EVAP CONTROL

SYSTEM PRESSURE SENSOR

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and](/img/5/57398/w960_57398-2195.png)

EC-840< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0453 EVAP CONTROL

SYSTEM PRESSURE SENSOR

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Always perform test at a temperature of 5 °C (41 °F) or more.

WITH CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Select “DATA MONITOR” mode with CONSULT-III.

5. Make sure that “FUEL T/TMP SE” is more than 0 °C (32 °F).

6. Wait at least 10 seconds.

7. Check 1st trip DTC.

8. If 1st trip DTC is detected, go to EC-842, " Diagnosis Procedure " .

WITH GST

1. Start engine and warm it up to normal operating temperature.

2. Check that voltage between ECM terminal 43 (Fuel tank temper-

ature sensor signal) and ground is less than 4.2V.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Wait at least 10 seconds.

5. Select Service $07 with GST. If 1st trip DTC is detected, go to EC-842, " Diagnosis Procedure " .

SEF113U

Page 2198 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-842< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0453 EVAP CONTROL

SYSTEM PRESSURE SENSOR

Diagnosis Procedure INFOID:00000000045373401.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen an NISSAN TIIDA 2009 Service Repair Manual EC-842< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0453 EVAP CONTROL

SYSTEM PRESSURE SENSOR

Diagnosis Procedure INFOID:00000000045373401.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen an](/img/5/57398/w960_57398-2197.png)

EC-842< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0453 EVAP CONTROL

SYSTEM PRESSURE SENSOR

Diagnosis Procedure INFOID:00000000045373401.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-632, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK CONNECTOR

TER-

MI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

42 V EVAP control system pres-

sure sensor [Ignition switch: ON]

Approximately 1.8 - 4.8V

51 O Sensor ground

(EVAP control system pres-

sure sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

74 W Sensor power supply

(Refrigerant pressure

sensor) [Ignition switch: ON]

Approximately 5V

75 BR Sensor power supply

[Crankshaft position sensor

(POS)] [Ignition switch: ON]

Approximately 5V

76 W EVAP control system pres-

sure sensor power supply [Ignition switch: ON]

Approximately 5V

102 SB Sensor power supply

(Accelerator pedal position

sensor 2) [Ignition switch: ON]

Approximately 5V:

Vehicle front

1. Engine ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2204 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-848< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0455 EVAP CONTROL SYSTEM

• Make sure that EVAP hose are connected to EVAP canister purge volume control solenoid valve

properly.

• If DT NISSAN TIIDA 2009 Service Repair Manual EC-848< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0455 EVAP CONTROL SYSTEM

• Make sure that EVAP hose are connected to EVAP canister purge volume control solenoid valve

properly.

• If DT](/img/5/57398/w960_57398-2203.png)

EC-848< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0455 EVAP CONTROL SYSTEM

• Make sure that EVAP hose are connected to EVAP canister purge volume control solenoid valve

properly.

• If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

• Perform “DTC WORK SUPPORT” when the fuel level is between 1/4 and 3/4 full, and vehicle is placed

on flat level surface.

• Open engine hood before conducting the following procedure.

WITH CONSULT-III

1. Tighten fuel filler cap securely until reteaching sound is heard.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

5. Make sure that the following conditions are met.

COOLAN TEMP/S: 0 - 70 °C (32 - 158 °F)

INT/A TEMP SE: 0 - 60 °C (32 - 140 °F)

6. Select “EVAP SML LEAK P0442/P1442” of “EV APORATIVE SYSTEM” in “DTC WORK SUPPORT” mode

with CONSULT-III.

Follow the instruction displayed.

NOTE:

If the engine speed cannot be maintained within t he range displayed on the CONSULT-III screen, go to

EC-566, " Basic Inspection " .

7. Make sure that “OK” is displayed.

If “NG” is displayed, select “SELF-DIAG RESULT S” mode with CONSULT-III and make sure that “EVAP

GROSS LEAK [P0455]” is displayed. If it is displayed, refer to EC-848, " Diagnosis Procedure " .

If P0442 is displayed, perform Diagnostic Procedure for DTC P0442, EC-798, " Diagnosis Procedure " .

WITH GST

NOTE:

Be sure to read the explanation of Driving Pattern on EC-542, " Emission-related Diagnostic Information "

before driving vehicle.

1. Start engine.

2. Drive vehicle according to Driving Pattern, EC-542, " Emission-related Diagnostic Information " .

3. Stop vehicle.

4. Turn ignition switch OFF, wait at least 10 seconds and then turn ignition switch ON.

5. Select Service $07 with GST.

• If P0441 is displayed on the screen, go to EC-793, " Diagnosis Procedure " for DTC P0441.

• If P0442 is displayed on the screen, go to EC-798, " Diagnosis Procedure " for DTC P0442.

• If P0455 is displayed on the screen, go to EC-848, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:00000000045373441.

CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

OK or NG OK >> GO TO 2.

NG >> Replace with genuine NISSAN fuel filler cap. 2.

CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened proper ly by rotating the cap clockwise. SEF915U

Page 2207 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0455 EVAP CONTROL SYSTEM

EC-851

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

4. Using EVAP leak detector, locate the EVAP leak. For the leak

detector, refer to the NISSAN TIIDA 2009 Service Repair Manual DTC P0455 EVAP CONTROL SYSTEM

EC-851

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

4. Using EVAP leak detector, locate the EVAP leak. For the leak

detector, refer to the](/img/5/57398/w960_57398-2206.png)

DTC P0455 EVAP CONTROL SYSTEM

EC-851

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

4. Using EVAP leak detector, locate the EVAP leak. For the leak

detector, refer to the instruction manual for more details.

Refer to EC-527, " Description " .

OK or NG OK >> GO TO 12.

NG >> Repair or replace. 11.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-III

1. Disconnect vacuum hose to EVAP canister purge volu me control solenoid valve at EVAP service port.

2. Start engine.

3. Perform “PURG VOL CONT/V ” in “ACTIVE TEST” mode.

4. Touch “Qu” on CONSULT-III screen to increase “PURG VOL CONT/V” opening to 100%.

5. Check vacuum hose for vacuum.

OK or NG OK >> GO TO 14.

NG >> GO TO 13. 12.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volu me control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

OK or NG OK >> GO TO 15.

NG >> GO TO 13. 13.

CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Refer to EC-594, " Vacuum Hose Drawing " .

OK or NG OK (With CONSULT-III)>>GO TO 14.

OK (Without CONSULT-III)>>GO TO 15.

NG >> Repair or reconnect the hose. 14.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-III

1. Start engine.

2. Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT- III. Check that engine speed var-

ies according to the valve opening.

OK or NG OK >> GO TO 16.

NG >> GO TO 15. 15.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to EC-815, " Component Inspection " . SEF200U

Vacuum should exist.

Vacuum should exist.

Page 2210 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-854< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0456 EVAP CONTROL SYSTEM

DTC Confirmation Procedure INFOID:0000000004537346

NOTE:

• If DTC P0456 is displayed with P0442, firs t perform trouble diagnos NISSAN TIIDA 2009 Service Repair Manual EC-854< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0456 EVAP CONTROL SYSTEM

DTC Confirmation Procedure INFOID:0000000004537346

NOTE:

• If DTC P0456 is displayed with P0442, firs t perform trouble diagnos](/img/5/57398/w960_57398-2209.png)

EC-854< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0456 EVAP CONTROL SYSTEM

DTC Confirmation Procedure INFOID:0000000004537346

NOTE:

• If DTC P0456 is displayed with P0442, firs t perform trouble diagnosis for DTC P0456.

• After repair, make sure that the hoses and clips are installed properly.

• If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

• Open engine hood before conducting following procedure.

• If any of following conditions are met just befo re the DTC confirmation procedure, leave the vehicle

for more than 1 hour.

- Fuel filler cap is removed.

- Refilled or drained the fuel.

- EVAP component parts is/are removed.

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Make sure the following conditions are met.

FUEL LEVEL SE: 0.25 - 1.4V

COOLAN TEMP/S: 0 - 32 °C (32 - 90 °F)

FUEL T/TMP SE: 0 - 35 °C (32 - 95 °F)

INT/A TEMP SE: More than 0 °C (32 °F)

If NG, turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle) or refilling/draining

fuel until the output voltage condition of the “FUE L LEVEL SE” meets within the range above and leave

the vehicle for more than 1 hour. Then start from step 1).

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON.

5. Select “EVAP V/S LEAK P0456” of “EVAPORATI VE SYSTEM” in “DTC WORK SUPPORT” mode with

CONSULT-III.

Follow the instruction displayed.

6. Make sure that “OK” is displayed.

If “NG” is displayed, refer to EC-855, " Diagnosis Procedure " .

NOTE:

• If the engine speed cannot be maintained with in the range displayed on CONSULT-III screen, go

to EC-566, " Basic Inspection " .

• Make sure that EVAP hoses are connected to EVAP canister purge volume control solenoid

valve properly.

Overall Function Check INFOID:0000000004537347

WITH GST

Use this procedure to check the overall function of the EV AP very small leak function. During this check, a 1st

trip DTC might not be confirmed.

CAUTION:

• Never use compressed air, doing so may damage the EVAP system.

• Do not start engine.

• Do not exceeded 4.12 kPa (0.042 kg/cm 2

, 0.6 psi).

1. Attach the EVAP service port adapter securely to the EVAP ser- vice port (2).

- EVAP canister purge volume control solenoid valve (1)

- : Vehicle front BBIA0703E

Page 2211 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0456 EVAP CONTROL SYSTEM

EC-855

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Set the pressure pump and a hose.

3. Also set the pressure pump with pressure gauge t NISSAN TIIDA 2009 Service Repair Manual DTC P0456 EVAP CONTROL SYSTEM

EC-855

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Set the pressure pump and a hose.

3. Also set the pressure pump with pressure gauge t](/img/5/57398/w960_57398-2210.png)

DTC P0456 EVAP CONTROL SYSTEM

EC-855

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Set the pressure pump and a hose.

3. Also set the pressure pump with pressure gauge to the EVAP service port adapter.

4. Turn ignition switch ON.

5. Connect GST and select Service $08.

6. Using Service $08 control the EVAP canister vent control valve

(close).

7. Apply pressure and make sure the following conditions are sat- isfied.

Pressure to be applied: 2.7 kPa (20 mmHg, 0.79 inHg)

Time to be waited after the pressure drawn in to the EVAP

system and the pressure to be dropped: 60 seconds and

the pressure should not be dropped more than 0.4 kPa (3 mmHg, 0.12 inHg).

If NG, go to EC-855, " Diagnosis Procedure " .

If OK, go to next step.

8. Disconnect GST.

9. Start engine and warm it up to normal operating temperature.

10. Turn ignition switch OFF and wait at least 10 seconds.

11. Restart engine and let it idle for 90 seconds.

12. Keep engine speed at 2,000 rpm for 30 seconds.

13. Turn ignition switch OFF. NOTE:

For more information, refe r to GST Instruction Manual.

Diagnosis Procedure INFOID:00000000045373481.

CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

OK or NG OK >> GO TO 2.

NG >> Replace with genuine NISSAN fuel filler cap. 2.

CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened properly by rotating the cap clockwise.

OK or NG OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck threads using air blower. 2. Retighten until reteaching sound is heard. 3.

CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG OK >> GO TO 5.

NG >> GO TO 4. 4.

CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-529, " Component Inspection " .

OK or NG OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one. SEF462UI

SEF915U

Page 2222 of 4331

.

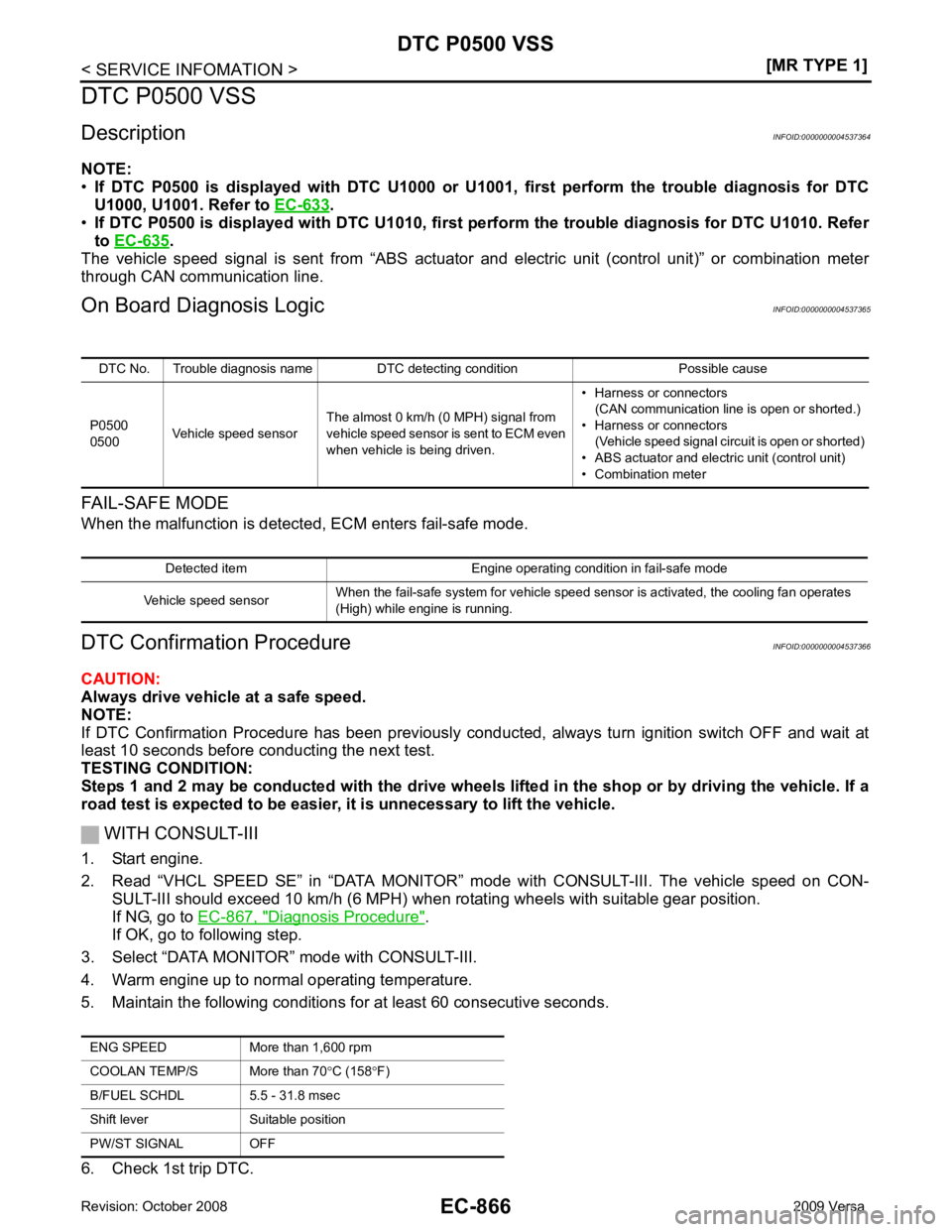

• If DTC P0500 is displayed with DTC U1010, first pe rform the trouble diagnosis for DTC U1010. Refer

to EC-635 .

The vehicle speed signal is sent from “ABS actuator and electric unit (control unit)” or combination meter

through CAN communication line.

On Board Diagn osis Logic INFOID:0000000004537365

FAIL-SAFE MODE

When the malfunction is detected, ECM enters fail-safe mode.

DTC Confirmation Procedure INFOID:0000000004537366

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels li fted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-III

1. Start engine.

2. Read “VHCL SPEED SE” in “DATA MONITOR” m ode with CONSULT-III. The vehicle speed on CON-

SULT-III should exceed 10 km/h (6 MPH) when rotating wheels with suitable gear position.

If NG, go to EC-867, " Diagnosis Procedure " .

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Warm engine up to normal operating temperature.

5. Maintain the following conditions for at least 60 consecutive seconds.

6. Check 1st trip DTC. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0500

0500 Vehicle speed sensor The almost 0 km/h (0 MPH) signal from

vehicle speed sensor is sent to ECM even

when vehicle is being driven. • Harness or connectors

(CAN communication line is open or shorted.)

• Harness or connectors (Vehicle speed signal circuit is open or shorted)

• ABS actuator and electric unit (control unit)

• Combination meter Detected item Engine operating condition in fail-safe mode

Vehicle speed sensor When the fail-safe system for vehicle speed sensor is activated, the cooling fan operates

(High) while engine is running. ENG SPEED More th

an 1,600 rpm

COOLAN TEMP/S More than 70 °C (158 °F)

B/FUEL SCHDL 5.5 - 31.8 msec

Shift lever Suitable position

PW/ST SIGNAL OFF

Page 2228 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-872< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0605 ECM

DTC P0605 ECM

Component Description INFOID:0000000004537377

The ECM consists of a microcomputer and connectors for signal

input and outp NISSAN TIIDA 2009 Service Repair Manual EC-872< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0605 ECM

DTC P0605 ECM

Component Description INFOID:0000000004537377

The ECM consists of a microcomputer and connectors for signal

input and outp](/img/5/57398/w960_57398-2227.png)

EC-872< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0605 ECM

DTC P0605 ECM

Component Description INFOID:0000000004537377

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The ECM controls the engine.

On Board Diagn osis Logic INFOID:0000000004537378

This self-diagnosis has one or two trip detection logic.

FAIL-SAFE MODE

ECM enters fail-safe mode when malfunction A is detected.

DTC Confirmation Procedure INFOID:0000000004537379

Perform PROCEDURE FOR MALFUNCTION A first. If th e 1st trip DTC cannot be confirmed, perform

PROCEDURE FOR MALFUNCTION B. If there is no malfunction on PROCEDURE FOR MALFUNCTION

B, perform PROCEDURE FOR MALFUNCTION C.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PROCEDURE FOR MALFUNCTION A

1. Turn ignition switch ON.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-873, " Diagnosis Procedure " .

PROCEDURE FOR MALFUNCTION B

1. Turn ignition switch ON and wait at least 1 second.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Check 1st trip DTC.

4. If 1st trip DTC is detected, go to EC-873, " Diagnosis Procedure " .

PROCEDURE FOR MALFUNCTION C

1. Turn ignition switch ON and wait at least 1 second.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Repeat step 3 for 32 times. PBIA9222J

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0605

0605 Engine control module A) ECM calculation function is malfunctioning.

• ECM

B) ECM EEP-ROM system is malfunctioning.

C) ECM self shut-off function is malfunctioning. Detected items Engine operation condition in fail-safe mode

Malfunction A • ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5

degrees) by the return spring.

• ECM deactivates ASCD operation.

Page 2242 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-886< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004537393

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is NISSAN TIIDA 2009 Service Repair Manual EC-886< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004537393

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is](/img/5/57398/w960_57398-2241.png)

EC-886< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004537393

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-633 .

• If DTC P1217 is displayed with DTC U1010, first pe rform the trouble diagnosis for DTC U1010. Refer

to EC-635 .

Cooling Fan Control

*1: The ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to ECM through CAN communication line.

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The contro l system has 3-step control [HIGH/LOW/OFF].

Cooling Fan Operation

Models with A/C

Models without A/C Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

1

Cooling fan

control IPDM E/R

(Cooling fan relays)

Battery

Battery voltage*1

ABS actuator and electric unit (control unit)

Vehicle speed*2

Combination meter

Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ON signal*2

Refrigerant pressure sensor Refrigerant pressure PBIB2483E

PBIB3335E