engine control NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1568 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-212< COMPONENT DIAGNOSIS >

[HR16DE]

P0138 HO2S2

P0138 HO2S2

Description INFOID:0000000004780125

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level i NISSAN TIIDA 2009 Service Repair Manual EC-212< COMPONENT DIAGNOSIS >

[HR16DE]

P0138 HO2S2

P0138 HO2S2

Description INFOID:0000000004780125

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level i](/img/5/57398/w960_57398-1567.png)

EC-212< COMPONENT DIAGNOSIS >

[HR16DE]

P0138 HO2S2

P0138 HO2S2

Description INFOID:0000000004780125

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is cont rolled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1 V in richer conditions to 0 V in leaner con-

ditions.

Under normal conditions the heated ox ygen sensor 2 is not used for

engine control operation.

DTC Logic INFOID:0000000004780126

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capa city of the three way catalyst (manifold) causes the longer switching

time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the voltage is unusually high during the various driving con-

dition such as fuel-cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the minimum voltage of sensor is sufficiently low during the

various driving condition such as fuel-cut. SEF327R

PBIB1848E

PBIB2376E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0138 Heated oxygen sensor 2

circuit high voltage A)

An excessively high voltage from the

sensor is sent to ECM. • Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

B) The minimum voltage from the sensor is

not reached to the specified voltage. • Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

Page 1577 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P0139 HO2S2

EC-221

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0139 HO2S2

Description INFOID:0000000004780130

The heated oxygen sensor 2, after three way catalyst (manif NISSAN TIIDA 2009 Service Repair Manual P0139 HO2S2

EC-221

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0139 HO2S2

Description INFOID:0000000004780130

The heated oxygen sensor 2, after three way catalyst (manif](/img/5/57398/w960_57398-1576.png)

P0139 HO2S2

EC-221

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0139 HO2S2

Description INFOID:0000000004780130

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1 V in richer conditions to 0 V in leaner con-

ditions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

DTC Logic INFOID:0000000004780131

DTC DETECTION LOGIC The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel-cut.

DTC CONFIRMATION PROCEDURE 1.

INSPECTION START

Do you have CONSULT-III?

Do you have CONSULT-III? YES >> GO TO 2.

NO >> GO TO 5. 2.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 3. 3.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Start engine and warm it up to normal operating temperature. SEF327R

SEF302U

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0139 Heated oxygen sensor 2

circuit slow response It takes more time for the sensor to respond

between rich and lean than the specified

time. • Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

• Intake air leaks

Page 1585 of 4331

EC

NP

O

P0171 FUEL INJECTION SYSTEM FUNCTION

DTC Logic INFOID:0000000004780135

DTC DETECTION LOGIC With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio f eedback signal from the A/F sensors 1. The ECM calcu-

lates the necessary compensation to correct the of fset between the actual and the theoretical ratios.

In case the amount of the compensation value is extrem ely large (The actual mixture ratio is too lean.), the

ECM judges the condition as the fuel injection system malfunction and lights up the MIL (2 trip detection logic).

DTC CONFIRMATION PROCEDURE MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement " .

2. Start engine.

Is it difficult to start engine? YES >> GO TO 3.

NO >> GO TO 4. YES >> Go to

EC-231, " Diagnosis Procedure " .

NO >> Check exhaust and intake air leak visually. YES >> Go to

EC-231, " Diagnosis Procedure " .

NO >> GO TO 5. Sensor Input signal to ECM ECM function Actuator

A/F sensor 1 Density of oxygen in exhaust gas

(Mixture ratio feedback signal) Fuel injection control Fuel injectorDTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0171 Fuel injection system too

lean • Fuel injection system does not operate properly.

• The amount of mixture ratio compensation is too large. (The mixture ratio is too lean.) • Intake air leaks

• A/F sensor 1

• Fuel injector

• Exhaust gas leaks

• Incorrect fuel pressure

• Lack of fuel

• Mass air flow sensor

• Incorrect PCV hose connection

Page 1591 of 4331

EC

NP

O

P0172 FUEL INJECTION SYSTEM FUNCTION

DTC Logic INFOID:0000000004780137

DTC DETECTION LOGIC With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio f eedback signal from the A/F sensors 1. The ECM calcu-

lates the necessary compensation to correct the of fset between the actual and the theoretical ratios.

In case the amount of the compensation value is extrem ely large (The actual mixture ratio is too rich.), the

ECM judges the condition as the fuel injection system malfunction and lights up the MIL (2 trip detection logic).

DTC CONFIRMATION PROCEDURE MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement " .

2. Start engine.

Is it difficult to start engine? YES >> GO TO 3.

NO >> GO TO 4. YES >> Go to

EC-237, " Diagnosis Procedure " .

NO >> Check exhaust and intake air leak visually. YES >> Go to

EC-237, " Diagnosis Procedure " .

NO >> GO TO 5. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0172 Fuel injection system too

rich • Fuel injection system does not operate properly.

• The amount of mixture ratio compensation is too large. (The mixture ratio is too rich.) • A/F sensor 1

• Fuel injector

• Exhaust gas leaks

• Incorrect fuel pressure

• Mass air flow sensor

Page 1605 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P0222, P0223 TP SENSOR

EC-249

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0222, P0223 TP SENSOR

Description INFOID:0000000004780147

Electric throttle control actuator consis NISSAN TIIDA 2009 Service Repair Manual P0222, P0223 TP SENSOR

EC-249

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0222, P0223 TP SENSOR

Description INFOID:0000000004780147

Electric throttle control actuator consis](/img/5/57398/w960_57398-1604.png)

P0222, P0223 TP SENSOR

EC-249

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0222, P0223 TP SENSOR

Description INFOID:0000000004780147

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometer which transform the throttle valve position into

output voltage, and emit the voltage signals to the ECM. The ECM

judges the current opening angle of the throttle valve from these sig-

nals and controls the throttle valve opening angle in response to

driving conditions via the throttle control motor.

DTC Logic INFOID:0000000004780148

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to

EC-250, " Diagnosis Procedure " .

NO >> INSPECTION END PBIB0145E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0222 Throttle position sensor

1 circuit low input An excessively low voltage from the TP sensor

1 is sent to ECM. • Harness or connectors

(TP sensor 1 circuit is open or shorted.)

• Electric throttle control actuator (TP sensor 1)

P0223 Throttle position sensor

1 circuit high input An excessively high voltage from the TP sensor

1 is sent to ECM.

Page 1637 of 4331

EC

NP

O

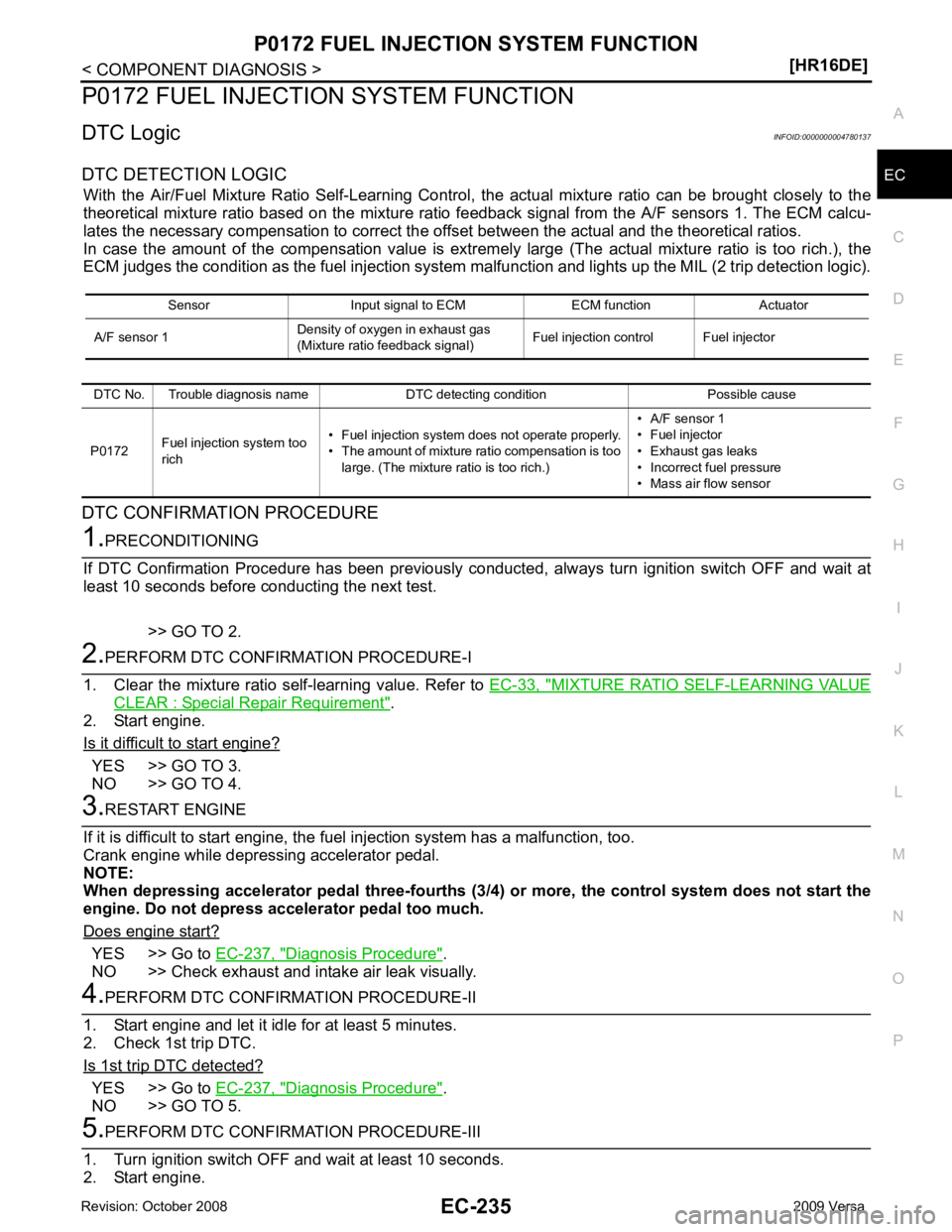

3. Disconnect vacuum hose connected to EVAP canister

purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the location of EVAP service port, refer to EC-74, " System

Description " .

4. Start engine and let it idle.

Do not depress accelerator pedal even slightly.

5. Check vacuum gauge indication before 60 seconds passed after starting engine.

6. Revving engine up to 2,000rpm after 100 seconds passed after starting engine.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 4. System Description " .

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair it. YES-1 >> With CONSULT-III: GO TO 6.

YES-2 >> Without CONSULT-III: GO TO 7.

NO >> Repair or clean hoses and/or purge port. YES >> GO TO 8.

NO >> GO TO 7. Vacuum should not exist.

Vacuum should exist. SEF368U

Page 1640 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-284< COMPONENT DIAGNOSIS >

[HR16DE]

P0442 EVAP CONTROL SYSTEM

P0442 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780172

DTC DETECTION LOGIC

NOTE:

If DTC P0442 is displayed with DTC P0456, first p NISSAN TIIDA 2009 Service Repair Manual EC-284< COMPONENT DIAGNOSIS >

[HR16DE]

P0442 EVAP CONTROL SYSTEM

P0442 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780172

DTC DETECTION LOGIC

NOTE:

If DTC P0442 is displayed with DTC P0456, first p](/img/5/57398/w960_57398-1639.png)

EC-284< COMPONENT DIAGNOSIS >

[HR16DE]

P0442 EVAP CONTROL SYSTEM

P0442 EVAP CONTROL SYSTEM

DTC Logic INFOID:0000000004780172

DTC DETECTION LOGIC

NOTE:

If DTC P0442 is displayed with DTC P0456, first pe rform the trouble diagnosis for DTC P0456. Refer to

EC-335, " DTC Logic " .

This diagnosis detects leaks in the EVAP purge line using engine intake manifold vacuum.

If pressure does not increase, the ECM will check for l eaks in the line between the fuel tank and EVAP canister

purge volume control solenoid valve, under the following “Vacuum test” conditions.

The EVAP canister vent control valve is closed to s hut the EVAP purge line off. The EVAP canister purge vol-

ume control solenoid valve will then be opened to depressurize the EVAP purge line using intake manifold

vacuum. After this occurs, the EVAP canister purge volume control solenoid valve will be closed.

CAUTION:

• Use only a genuine NISSAN fuel filler cap as a replacemen t. If an incorrect fuel filler cap is used, the

MIL may come on. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0442 EVAP control system

small leak detected

(negative pressure) EVAP control system has a leak, EVAP

control system does not operate prop-

erly. • Incorrect fuel tank vacuum relief valve

• Incorrect fuel filler cap used

• Fuel filler cap remains open or fails to close.

• Foreign matter caught in fuel filler cap.

• Leak is in line between intake manifold and EVAP

canister purge volume control solenoid valve.

• Foreign matter caught in EVAP canister vent con- trol valve.

• EVAP canister or fuel tank leaks

• EVAP purge line (pipe and rubber tube) leaks

• EVAP purge line rubber tube bent

• Loose or disconnected rubber tube

• EVAP canister vent control valve and the circuit

• EVAP canister purge volume control solenoid

valve and the circuit

• Fuel tank temperature sensor

• O-ring of EVAP canister vent control valve is

missing or damaged

• EVAP canister is saturated with water

• EVAP control system pressure sensor

• Fuel level sensor and the circuit

• Refueling EVAP vapor cut valve

• ORVR system leaks

• Drain filter PBIB1026E

Page 1651 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P0443 EVAP CANISTER PURGE VOLU

ME CONTROL SOLENOID VALVE

EC-295

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Reconnect harness connectors disconnected.

3. Start engine.

4. Perfo NISSAN TIIDA 2009 Service Repair Manual P0443 EVAP CANISTER PURGE VOLU

ME CONTROL SOLENOID VALVE

EC-295

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Reconnect harness connectors disconnected.

3. Start engine.

4. Perfo](/img/5/57398/w960_57398-1650.png)

P0443 EVAP CANISTER PURGE VOLU

ME CONTROL SOLENOID VALVE

EC-295

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Reconnect harness connectors disconnected.

3. Start engine.

4. Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT- III. Check that engine speed var-

ies according to the valve opening.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7. 7.

CHECK EVAP CANISTER PURGE VO LUME CONTROL SOLENOID VALVE

Refer to EC-296, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace EVAP canister purge volume control solenoid valve. 8.

CHECK RUBBER TUBE FOR CLOGGING

1. Disconnect rubber tube connected to EV AP canister vent control valve.

2. Check the rubber tube for clogging.

Is the inspection result normal? YES >> GO TO 9.

NO >> Clean the rubber tube using an air blower. 9.

CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-304, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 10.

NO >> Replace EVAP canister vent control valve. 10.

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?YES >> GO TO 11.

NO >> GO TO 13. 11.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EV AP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> GO TO 13.

NO >> GO TO 12. 12.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehi cle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. 13.

CHECK INTERMITTENT INCIDENT PBIB1213E

Page 1653 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P0444, P0445 EVAP CANISTER PURG

E VOLUME CONTROL SOLENOID

VALVE

EC-297

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0444, P0445 EVAP CANISTER PU

RGE VOLUME CONTROL SOLENOID

VALVE NISSAN TIIDA 2009 Service Repair Manual P0444, P0445 EVAP CANISTER PURG

E VOLUME CONTROL SOLENOID

VALVE

EC-297

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0444, P0445 EVAP CANISTER PU

RGE VOLUME CONTROL SOLENOID

VALVE](/img/5/57398/w960_57398-1652.png)

P0444, P0445 EVAP CANISTER PURG

E VOLUME CONTROL SOLENOID

VALVE

EC-297

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0444, P0445 EVAP CANISTER PU

RGE VOLUME CONTROL SOLENOID

VALVE

Description INFOID:0000000004780179

The EVAP canister purge volume control solenoid valve is used to

control the flow rate of fuel v apor from the EVAP canister. The EVAP

canister purge volume control solenoid valve is moved by ON/OFF

pulses from the ECM. The longer the ON pulse, the greater the

amount of fuel vapor that will flow through the valve.

DTC Logic INFOID:0000000004780180

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

CONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confi rm battery voltage is more than 11 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for at least 13 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-298, " Diagnosis Procedure " .

NO >> INSPECTION END JMBIA0069ZZ

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0444 EVAP canister purge volume

control solenoid valve circuit

open An excessively low voltage signal is sent

to ECM through the valve • Harness or connectors

(The solenoid valve circuit is open or

shorted.)

• EVAP canister purge volume control so- lenoid valve

P0445 EVAP canister purge volume

control solenoid valve circuit

shorted An excessively high voltage signal is sent

to ECM through the valve • Harness or connectors

(The solenoid valve circuit is shorted.)

• EVAP canister purge volume control so- lenoid valve

Page 1662 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-306< COMPONENT DIAGNOSIS >

[HR16DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

P0448 EVAP CANISTER VENT CONTROL VALVE

Description INFOID:0000000004780187

The EVAP canister vent control valve is locate NISSAN TIIDA 2009 Service Repair Manual EC-306< COMPONENT DIAGNOSIS >

[HR16DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

P0448 EVAP CANISTER VENT CONTROL VALVE

Description INFOID:0000000004780187

The EVAP canister vent control valve is locate](/img/5/57398/w960_57398-1661.png)

EC-306< COMPONENT DIAGNOSIS >

[HR16DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

P0448 EVAP CANISTER VENT CONTROL VALVE

Description INFOID:0000000004780187

The EVAP canister vent control valve is located on the EVAP canis-

ter and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal

the vent is necessary for the on board diagnosis of other evaporative

emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the evapo-

rative emission control system is depressurized and allows “EVAP

Control System” diagnosis.

DTC Logic INFOID:0000000004780188

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

4. Start engine and let it idle for at least 1 minute.

5. Repeat next procedures three times.

- Increase the engine speed up to 3,000 to 3,500 rpm and keep it for 2 minutes and 50 seconds to 3 min-

utes.

Never exceed 3 minutes.

- Fully released accelerator pedal and keep engine idle for about 5 seconds.

6. Repeat next procedure 20 times.

- Quickly increase the engine speed up to 4,000 to 4, 500 rpm or more and keep it for 25 to 30 seconds. PBIB1263E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0448 EVAP canister vent control

valve close EVAP canister vent control valve remains

closed under specified driving conditions. • EVAP canister vent control valve

• EVAP control system pressure sensor and the circuit

• Blocked rubber tube to EVAP canister

vent control valve

• EVAP canister is saturated with water