engine control NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1844 of 4331

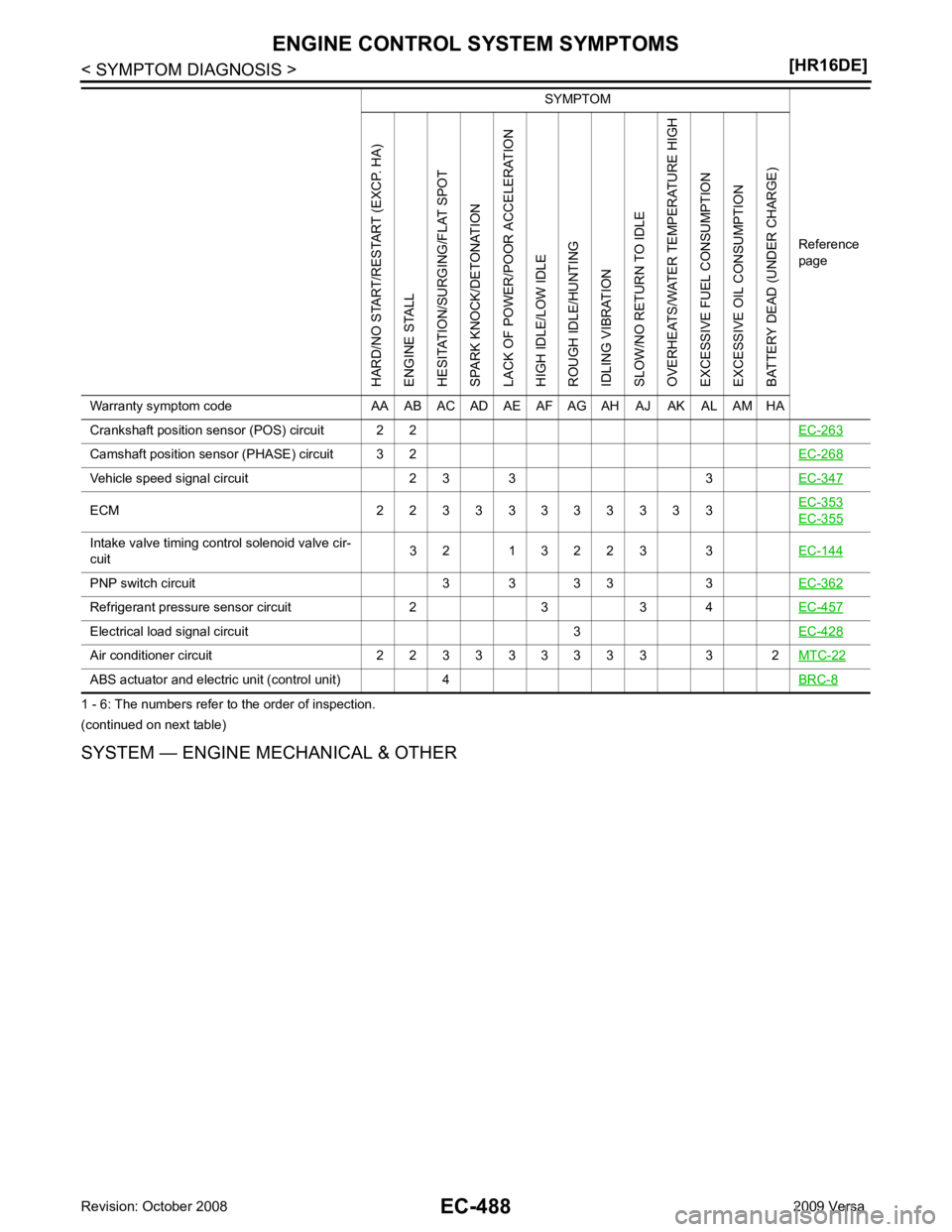

Camshaft position sensor (PHASE) circuit 3 2

EC-268Vehicle speed signal circuit 2 3 3 3

EC-347ECM 2 2 3 3 3 3 3 3 3 3 3

EC-353 EC-355

Intake valve timing control solenoid valve cir-

cuit 3 2 1 3 2 2 3 3

EC-144PNP switch circuit 3 3 3 3 3

EC-362Refrigerant pressure sensor circuit 2 3 3 4

EC-457Electrical load signal circuit 3

EC-428Air conditioner circuit 2 2 3 3 3 3 3 3 3 3 2

MTC-22ABS actuator and electric unit (control unit) 4

BRC-8SYMPTOM

Reference

pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 1845 of 4331

EC

NP

O

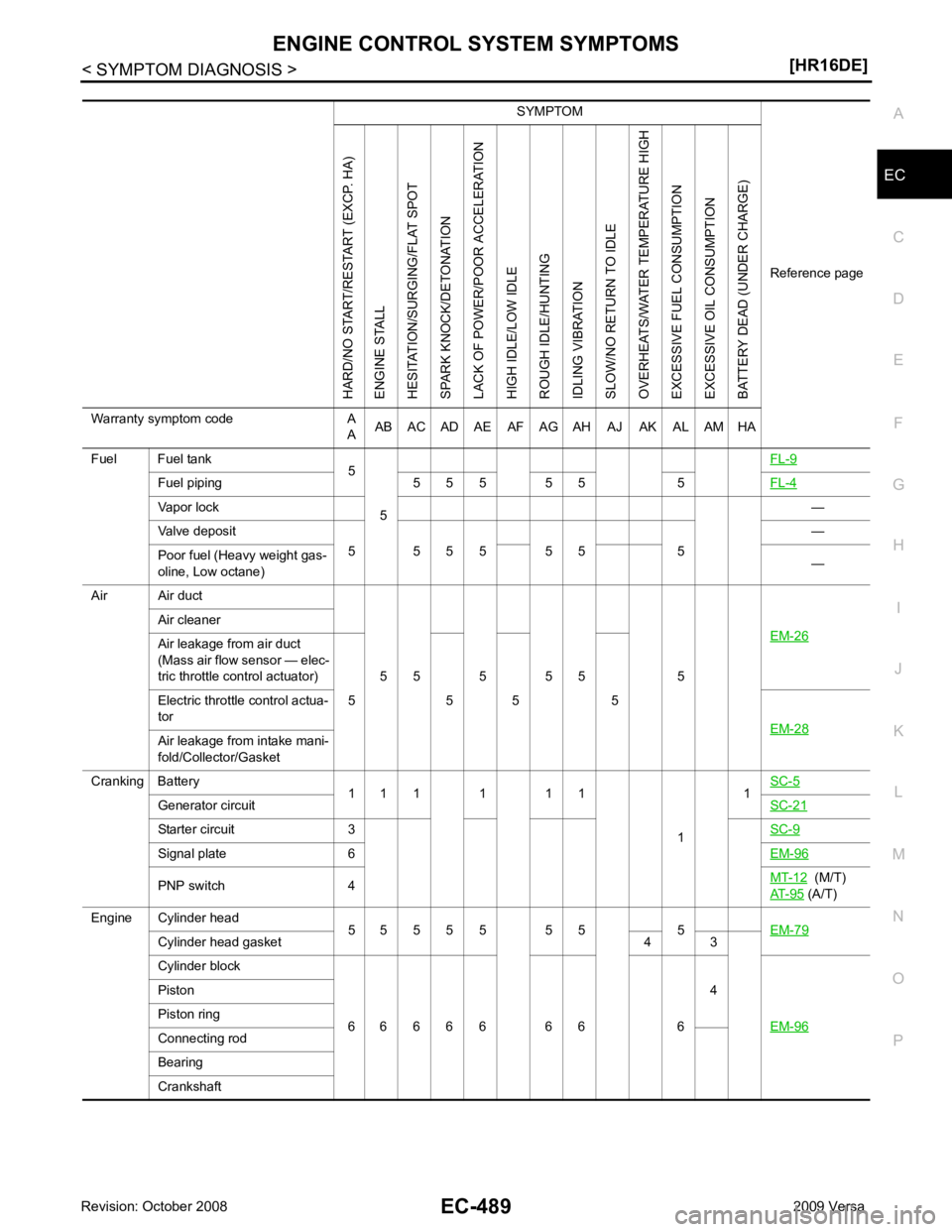

SYMPTOM

Reference pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code A AAB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-9Fuel piping 5 5 5 5 5 5

FL-4Vapor lock

—

Valve deposit 5 5 5 5 5 5 5 —

Poor fuel (Heavy weight gas-

oline, Low octane) —

Air Air duct

5 5 5 5 5 5 EM-26Air cleaner

Air leakage from air duct

(Mass air flow sensor — elec-

tric throttle control actuator)

5 5 5 5

Electric throttle control actua-

tor EM-28Air leakage from intake mani-

fold/Collector/Gasket

Cranking Battery 1 1 1 1 1 1

11

SC-5 Generator circuit

SC-21Starter circuit 3

SC-9Signal plate 6

EM-96PNP switch 4

MT-12 (M/T)

AT-95 (A/T)

Engine Cylinder head 5 5 5 5 5 5 5 5 EM-79Cylinder head gasket 4 3

Cylinder block

6 6 6 6 6 6 6 6 4

EM-96 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Page 1846 of 4331

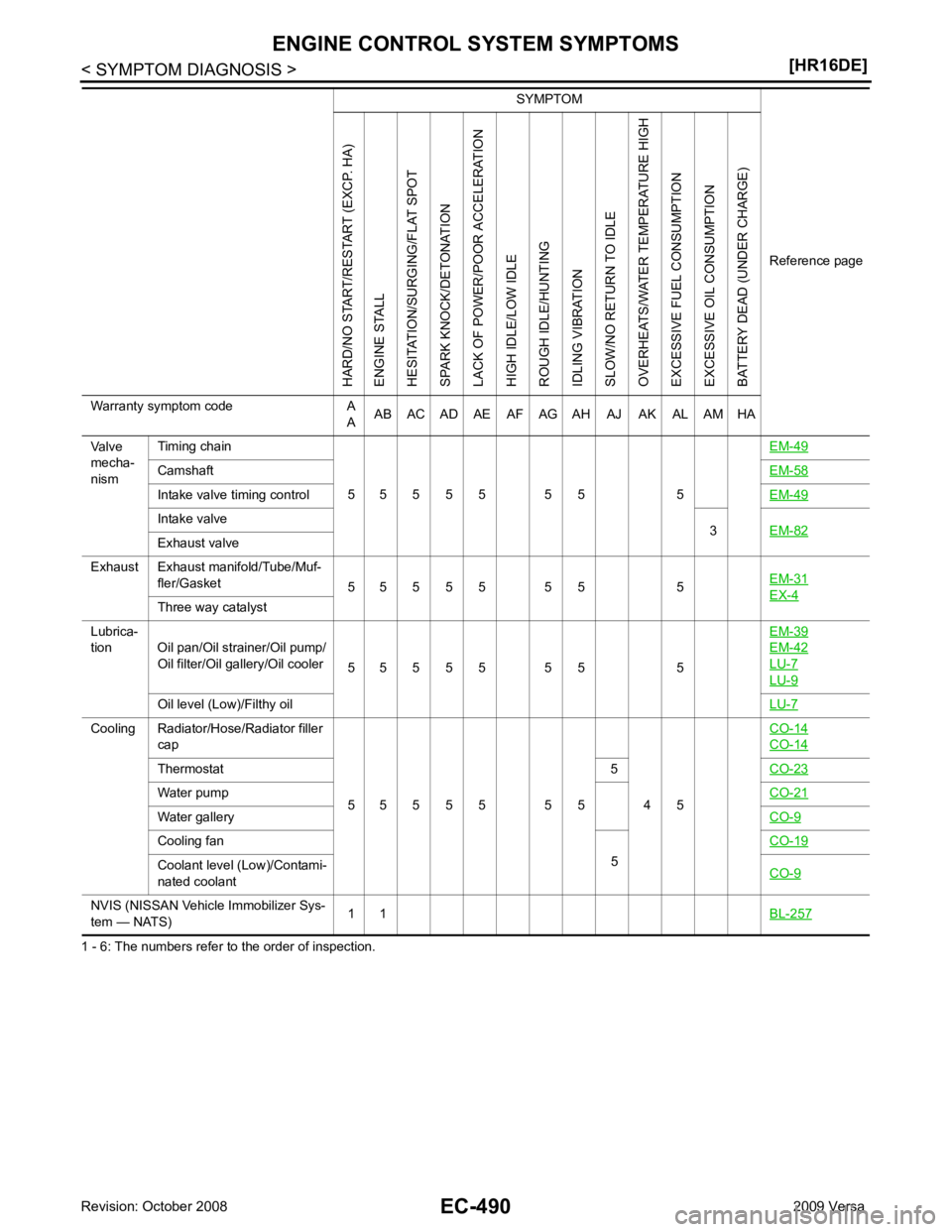

Camshaft

EM-58Intake valve timing control

EM-49Intake valve

3EM-82 Exhaust valve

Exhaust Exhaust manifold/Tube/Muf- fler/Gasket 5 5 5 5 5 5 5 5 EM-31 EX-4

Three way catalyst

Lubrica-

tion Oil pan/Oil strainer/Oil pump/ Oil filter/Oil gallery/Oil cooler 5 5 5 5 5 5 5 5 EM-39 EM-42

LU-7

LU-9

Oil level (Low)/Filthy oil

LU-7Cooling Radiator/Hose/Radiator filler

cap

5 5 5 5 5 5 5 4 5 CO-14 CO-14

Thermostat 5

CO-23Water pump

CO-21Water gallery

CO-9Cooling fan

5CO-19Coolant level (Low)/Contami-

nated coolant CO-9NVIS (NISSAN Vehicle Immobilizer Sys-

tem — NATS) 1 1

BL-257 SYMPTOM

Reference pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code A AAB AC AD AE AF AG AH AJ AK AL AM HA

Page 1847 of 4331

EC

NP

O

NORMAL OPERATING CONDITION

Description INFOID:0000000004780391

FUEL CUT CONTROL (AT NO LOAD AND HIGH ENGINE SPEED) If the engine speed is above 2,500 rpm under no load (for ex ample, the selector lever position is neutral and

engine speed is over 2,500 rpm) fuel will be cut off after some time. The exact time when the fuel is cut off var-

ies based on engine speed.

Fuel cut will be operated until the engine speed reaches 2,000 rpm, then fuel cut will be cancelled.

NOTE:

This function is different from deceleration contro l listed under Multiport Fuel Injection (MFI) System, EC-42," System Description " .

Page 1849 of 4331

![NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EC-493

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to route and secure the harnesses properly

after work. The interference of the harness with

a bracket, etc. may NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EC-493

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to route and secure the harnesses properly

after work. The interference of the harness with

a bracket, etc. may](/img/5/57398/w960_57398-1848.png)

PRECAUTIONS

EC-493

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to route and secure the harnesses properly

after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfuncti on of the EVAP system or fuel injection system,

etc.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

General Precautions INFOID:0000000004780395

• Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disc onnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect negative battery cable.

• Do not disassemble ECM.

• If a battery cable is disconnect ed, the memory will return to

the ECM value.

The ECM will now start to self-control at its initial value. Thus,

engine operation can vary slight ly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be cleared within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting ECM harness c onnector (1), fasten (B) it

securely with a lever as far as it will go as shown in the figure.

• When connecting or disconnect ing pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and cond enser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal- SEF289H

2. ECM

A. Loosen PBIA9222J

PBIB2947E

PBIB0090E

Page 1851 of 4331

EC

NP

O

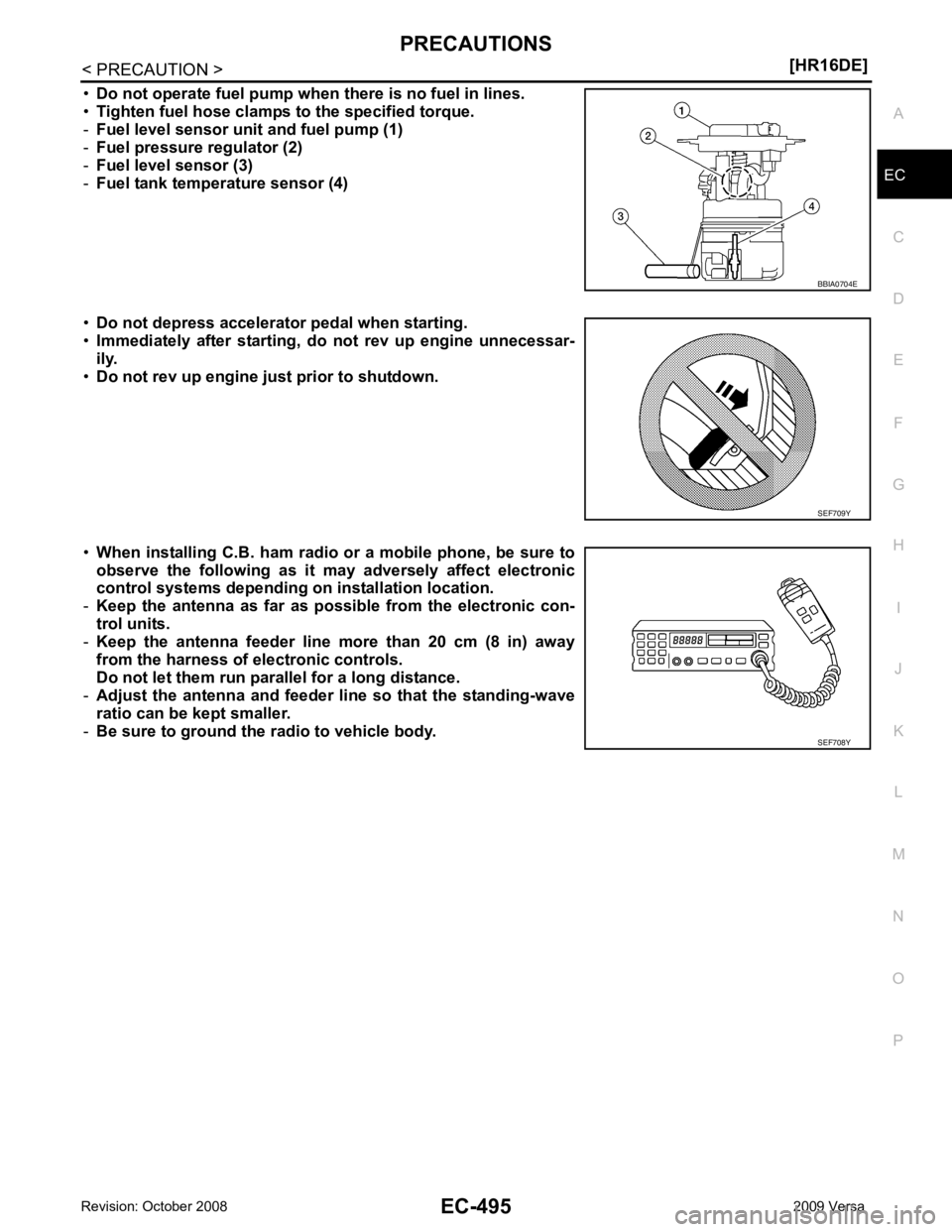

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine ju st prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run para llel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

ratio can be kept smaller.

- Be sure to ground the radio to vehicle body.

Page 1865 of 4331

EC

NP

O

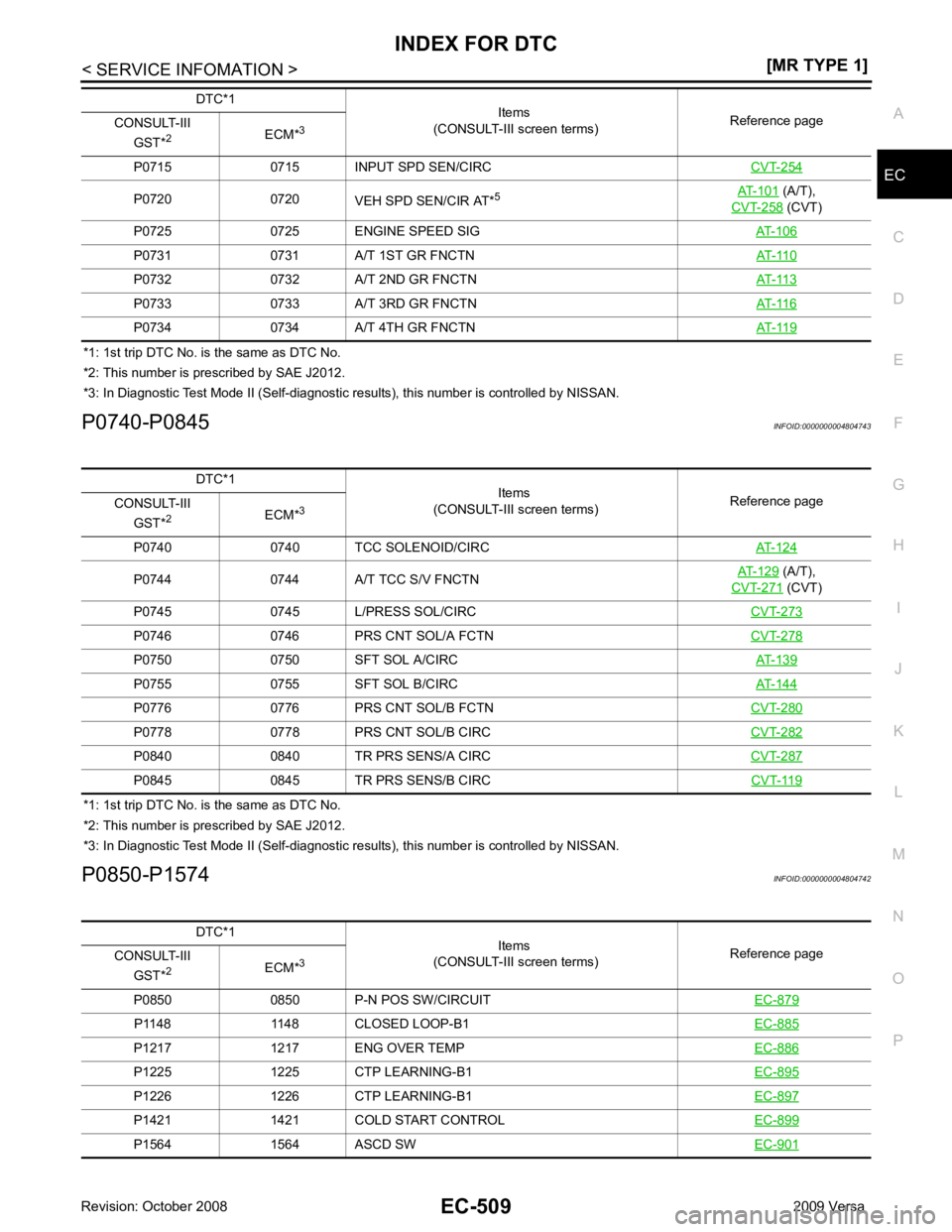

*1: 1st trip DTC No. is

the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P0740-P0845 INFOID:0000000004804743

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P0850-P1574 INFOID:0000000004804742

P0715 0715 INPUT SPD SEN/CIRC

CVT-254P0720 0720

VEH SPD SEN/CIR AT*5

AT-101 (A/T),

CVT-258 (CVT)

P0725 0725 ENGINE SPEED SIG AT-106P0731 0731 A/T 1ST GR FNCTN

AT-110P0732 0732 A/T 2ND GR FNCTN

AT-113P0733 0733 A/T 3RD GR FNCTN

AT-116P0734 0734 A/T 4TH GR FNCTN

AT-119DTC*1

Items

(CONSULT-III screen terms) Reference page

CONSULT-III

GST* 2

ECM*3 P0744 0744 A/T TCC S/V FNCTN

AT-129 (A/T),

CVT-271 (CVT)

P0745 0745 L/PRESS SOL/CIRC CVT-273P0746 0746 PRS CNT SOL/A FCTN

CVT-278P0750 0750 SFT SOL A/CIRC

AT-139P0755 0755 SFT SOL B/CIRC

AT-144P0776 0776 PRS CNT SOL/B FCTN

CVT-280P0778 0778 PRS CNT SOL/B CIRC

CVT-282P0840 0840 TR PRS SENS/A CIRC

CVT-287P0845 0845 TR PRS SENS/B CIRC

CVT-119DTC*1

Items

(CONSULT-III screen terms) Reference page

CONSULT-III

GST* 2

ECM*3

P0850 0850 P-N POS SW/CIRCUIT EC-879P1148 1148 CLOSED LOOP-B1

EC-885P1217 1217 ENG OVER TEMP

EC-886P1225 1225 CTP LEARNING-B1

EC-895P1226 1226 CTP LEARNING-B1

EC-897P1421 1421 COLD START CONTROL

EC-899P1564 1564 ASCD SW

EC-901

Page 1869 of 4331

![NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EC-513

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to connect rubber tubes properly afte

r work. A misconnected or disconnected rubber tube NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EC-513

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to connect rubber tubes properly afte

r work. A misconnected or disconnected rubber tube](/img/5/57398/w960_57398-1868.png)

PRECAUTIONS

EC-513

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

• Be sure to connect rubber tubes properly afte

r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

Precaution INFOID:0000000004537016

• Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disc onnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect negative battery cable.

• Do not disassemble ECM.

• If battery cable is disconnected, the memory will return to the

initial ECM values.

The ECM will now start to self-c ontrol at its initial values.

Engine operation can vary slight ly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting ECM harness connector, fasten (B) it

securely with a lever (1) as far as it will go as shown in the fig-

ure.

- ECM (2)

- Loosen (A)

• When connecting or disconnect ing pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and cond enser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving externa l noise, degraded operation

of ICs, etc. SEF289H

PBIA9222J

PBIB2947E

PBIB0090E

Page 1870 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-514< SERVICE INFOMATION >

[MR TYPE 1]

PRECAUTIONS

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspecti NISSAN TIIDA 2009 Service Repair Manual EC-514< SERVICE INFOMATION >

[MR TYPE 1]

PRECAUTIONS

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspecti](/img/5/57398/w960_57398-1869.png)

EC-514< SERVICE INFOMATION >

[MR TYPE 1]

PRECAUTIONS

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspection and m ake sure ECM functions prop-

erly. Refer to EC-597, " ECM Terminal and Reference Value " .

• Handle mass air flow sensor carefully to avoid damage.

• Do not disassemble m ass air flow sensor.

• Do not clean mass air flow senso r with any type of detergent.

• Do not disassemble electric throttle control actuator.

• Even a slight leak in the ai r intake system can cause serious

incidents.

• Do not shock or jar the camshaft position sensor (PHASE),

crankshaft position sensor (POS).

• After performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Overall Function Check.

The DTC should not be displ ayed in the DTC Confirmation

Procedure if the repair is co mpleted. The Overall Function

Check should be a good result if the repair is completed.

• When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

• Do not use ECM ground termina ls when measuring input/out-

put voltage. Doing so may result in damage to the ECM's tran-

sistor. Use a ground other than ECM terminals, such as the

ground. MEF040D

SEF217U

SEF348N

Page 1871 of 4331

![NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torqu NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torqu](/img/5/57398/w960_57398-1870.png)

PRECAUTIONS

EC-515

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine ju st prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possible from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run para llel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body. BBIA0704E

SEF709Y

SEF708Y