NISSAN TIIDA 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1891 of 4331

![NISSAN TIIDA 2009 Service Repair Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-535

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

>> GO TO 4. 4.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister NISSAN TIIDA 2009 Service Repair Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-535

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

>> GO TO 4. 4.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister](/img/5/57398/w960_57398-1890.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-535

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

>> GO TO 4. 4.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose. 5.

CHECK VENT HOSES AND VENT TUBES

Check hoses and tubes between EVAP canister and refue ling EVAP vapor cut valve for clogging, kink, loose-

ness and improper connection.

OK or NG OK >> GO TO 6.

NG >> Repair or replace hoses and tubes. 6.

CHECK FILLER NECK TUBE

Check recirculation line for clogging, dents and cracks.

OK or NG OK >> GO TO 7.

NG >> Replace filler neck tube. 7.

CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-535, " Component Inspection " .

OK or NG OK >> GO TO 8.

NG >> Replace refueling EVAP vapor cut valve with fuel tank. 8.

CHECK FUEL FILLER TUBE

Check filler neck tube and hose connected to the fuel tank for clogging, dents and cracks.

OK or NG OK >> GO TO 9.

NG >> Replace fuel filler tube. 9.

CHECK ONE-WAY FUEL VALVE-I

Check one-way valve for clogging.

OK or NG OK >> GO TO 10.

NG >> Repair or replace one-way fuel valve with fuel tank. 10.

CHECK ONE-WAY FUEL VALVE-II

1. Make sure that fuel is drained from the tank.

2. Remove fuel filler tube and hose.

3. Check one-way fuel valve for operation as follows.

When a stick is inserted, the valve should open, when removing

stick it should close.

Do not drop any material into the tank.

OK or NG OK >>

INSPECTION END

NG >> Replace fuel filler tube or replace one-way fuel valve with fuel tank.

Component Inspection INFOID:0000000004537034

REFUELING EVAP VAPOR CUT VALVE With CONSULT-III SEF665U

Page 1892 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-536< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel feed hose located on the NISSAN TIIDA 2009 Service Repair Manual EC-536< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel feed hose located on the](/img/5/57398/w960_57398-1891.png)

EC-536< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel feed hose located on the fuel gauge retainer.

b. Connect a spare fuel hose, one side to fuel gauge retainer where the hose was removed and the other

side to a fuel container.

c. Drain fuel using “FUEL PUMP RELAY” in “ACTIVE TEST” mode with CONSULT-III.

3. Check refueling EVAP vapor cut valve for being stuck to close as follows. Blow air into the refueling EVAP vapor cut valv e (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

4. Check refueling EVAP vapor cut valve for being stuck to open as follows.

a. Connect vacuum pump to hose end.

b. Remove fuel gauge retainer with fuel gauge unit. Always replace O-ring with new one.

c. Put fuel tank upside down.

d. Apply vacuum pressure to hose end [ −13.3 kPa ( −100 mmHg, −3.94 inHg)] with fuel gauge retainer

remaining open and check that the pressure is applicable.

Without CONSULT-III

1. Remove fuel tank. Refer to FL-9 .

2. Drain fuel from the tank as follows:

a. Remove fuel gauge retainer.

b. Drain fuel from the tank using a handy pump into a fuel container.

3. Check refueling EVAP vapor cut valve for being stuck to close as follows. Blow air into the refueling EVAP vapor cut valv e (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

4. Check refueling EVAP vapor cut valve for being stuck to open as follows.

a. Connect vacuum pump to hose end. 1. Filler tube 2. Recirculation line 3. EVAP/ORVR line

4. Vacuum/pressure handy pump 5. Fuel tank BBIA0694E

Page 1893 of 4331

![NISSAN TIIDA 2009 Service Repair Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-537

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new on NISSAN TIIDA 2009 Service Repair Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-537

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new on](/img/5/57398/w960_57398-1892.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-537

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new one.

c. Put fuel tank upside down.

d. Apply vacuum pressure to hose end [ −13.3 kPa ( −100 mmHg, −3.94 inHg)] with fuel gauge retainer

remaining open and check that the pressure is applicable.

1. Filler tube 2. Recirculation line 3. EVAP/ORVR line

4. Vacuum/pressure handy pump 5. Fuel tank BBIA0694E

Page 1894 of 4331

PBIB1589E

Page 1895 of 4331

EC

NP

O

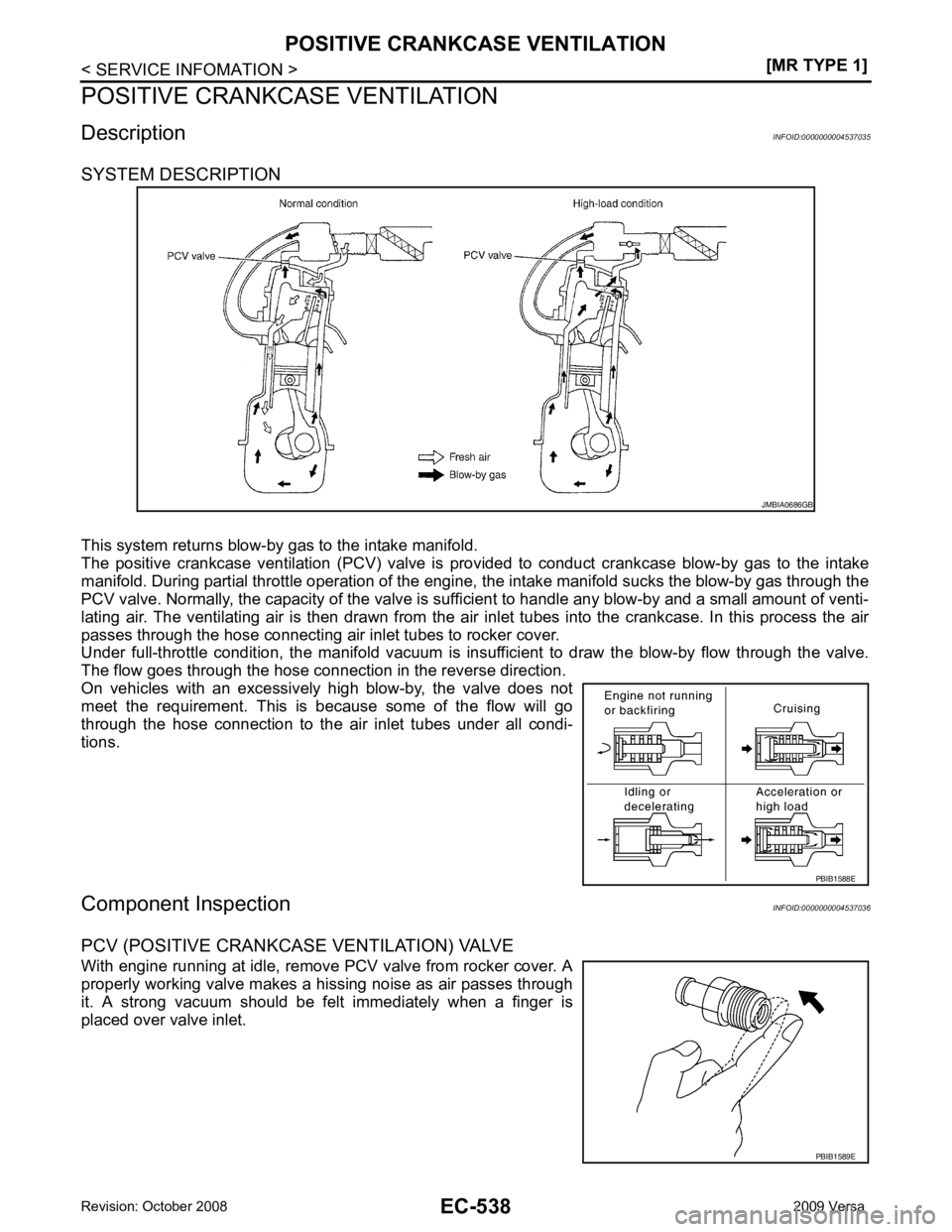

PCV VALVE VENTILATION HOSE

1. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If any hose cannot be freed of obstructions, replace.

Page 1896 of 4331

U1000-U1010 " .

• Check that no DTC is displayed in “SELF DIAGNOSIS RESULT” mode of “BCM” before erasing the

detected DTC in “ENGINE” mode with CONSULT-III.

• When replacing ECM, refer to EC-571, " Procedure After Replacing ECM " .

Page 1897 of 4331

EC

NP

O

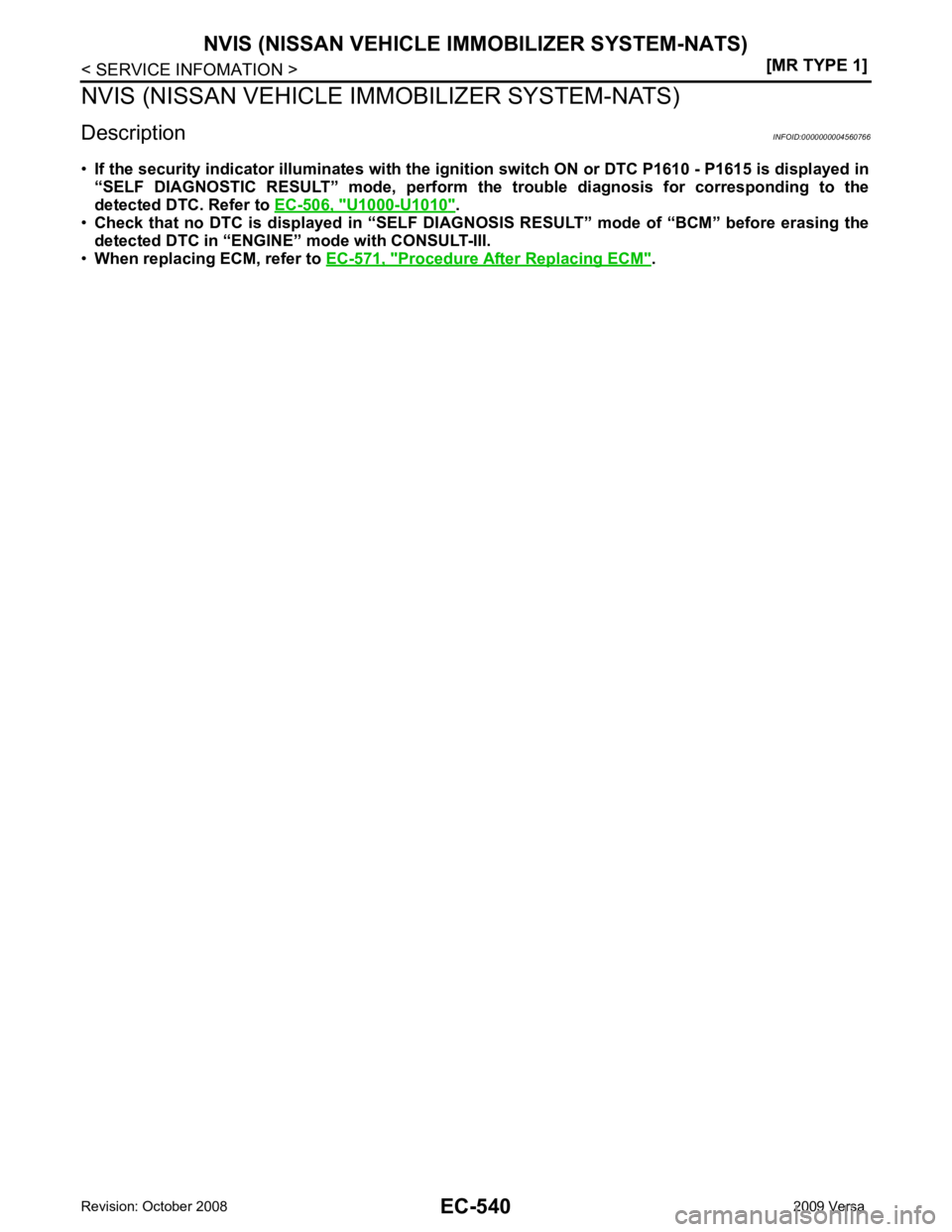

ON BOARD DIAGNOSTIC (OBD) SYSTEM

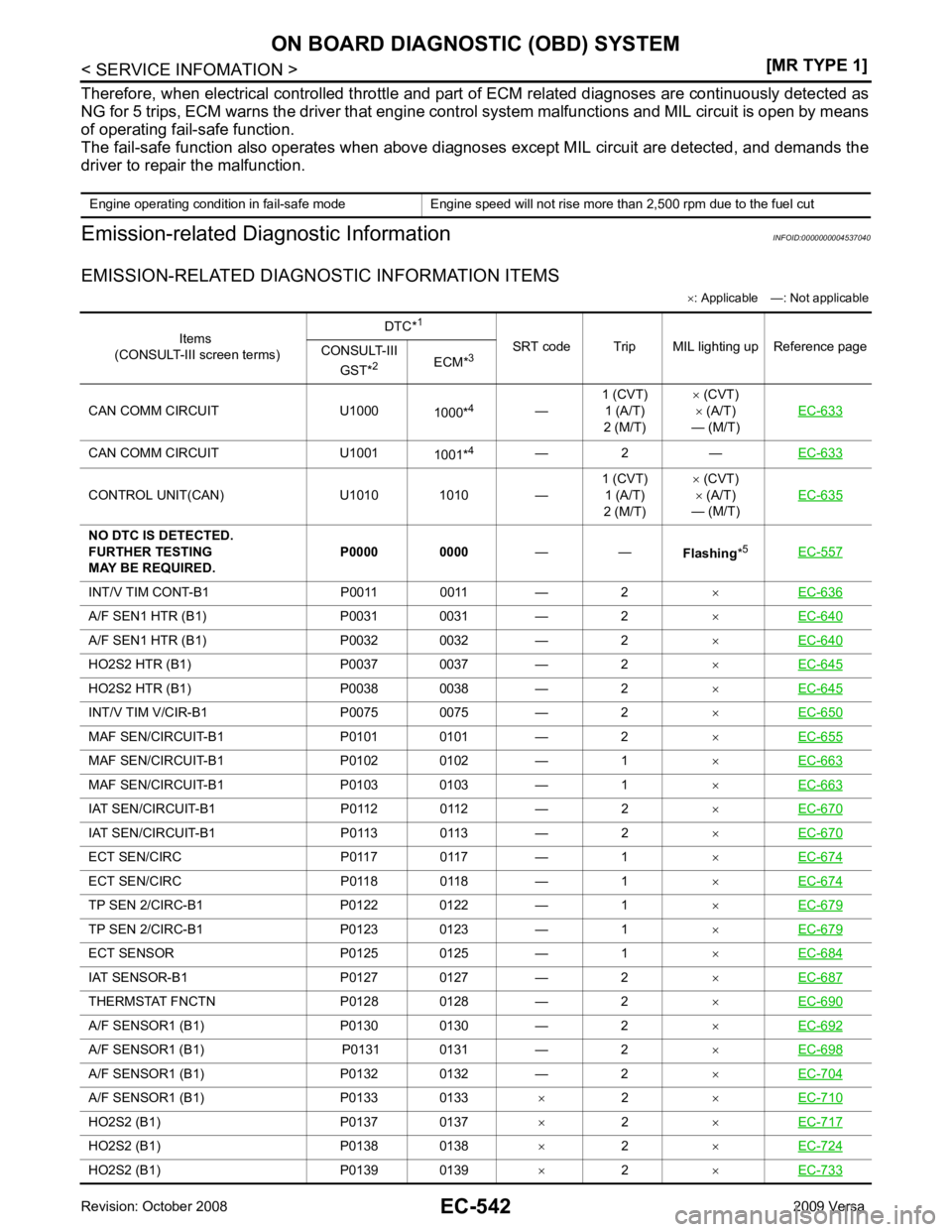

Introduction INFOID:0000000004537038

The ECM has an on board diagnostic system, which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emis sion-related diagnostic information including:

The above information can be checked using procedures listed in the table below. ×: Applicable —: Not applicable

*: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

The malfunction indicator lamp (MIL) on the instrument panel lights up when the same malfunction is detected

in two consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode.

(Refer to EC-582, " Fail-Safe Chart " .)

Two Trip Detection Logic INFOID:0000000004537039

When a malfunction is detected for the first time, 1st tr ip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MIL will not light up at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MIL lights up. The MIL lights up at the same time when the DTC is stored. <2nd

trip> The “trip” in the “Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic item s will cause the ECM to light up or blink the MIL,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

×: Applicable —: Not applicable

When there is an open circuit on MIL circuit, the ECM c annot warn the driver by MIL lighting up when there is

malfunction on engine control system. Emission-related diagnostic information Diagnostic service

Diagnostic Tr ouble Code (DTC) Service $03 of SAE J1979

Freeze Frame data Service $02 of SAE J1979

System Readiness Test (SRT) code Service $01 of SAE J1979

1st Trip Diagnostic Trou ble Code (1st Trip DTC) Service $07 of SAE J1979

1st Trip Freeze Frame data

Test values and Test limi ts Service $06 of SAE J1979

Calibration ID Servic e $09 of SAE J1979

DTC 1st trip DTC Freeze Frame

data 1st trip Freeze

Frame data SRT code SRT status Test value

CONSULT-III × × × × × × —

GST × × × —× × ×

ECM × ×* — — — ×— Items

MIL DTC 1st trip DTC

1st trip 2nd trip 1st trip

displaying 2nd trip

displaying 1st trip

displaying 2nd trip

display-

ing

Blinking Lighting

up Blinking

Lighting

up

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected ×

— — — — — ×—

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected — —

×— — ×— —

One trip detection diagnoses

(Refer to EC-542, " Emission-relat-

ed Diagnostic Information " .)

—

×— — ×— — —

Except above — — — ×— × × —

Page 1898 of 4331

Items

(CONSULT-III screen terms) DTC*

1

SRT code Trip MIL lighting up Reference page

CONSULT-III

GST* 2

ECM*3

CAN COMM CIRCUIT U1000 1000*4

—1 (CVT)

1 (A/T)

2 (M/T) ×

(CVT)

× (A/T)

— (M/T) EC-633CAN COMM CIRCUIT U1001

1001*4

— 2 — EC-633CONTROL UNIT(CAN) U1010 1010 —

1 (CVT)

1 (A/T)

2 (M/T) ×

(CVT)

× (A/T)

— (M/T) EC-635INT/V TIM CONT-B1 P0011 0011 — 2

×EC-636 A/F SEN1 HTR (B1) P0031 0031 — 2

×EC-640 A/F SEN1 HTR (B1) P0032 0032 — 2

×EC-640 HO2S2 HTR (B1) P0037 0037 — 2

×EC-645 HO2S2 HTR (B1) P0038 0038 — 2

×EC-645 INT/V TIM V/CIR-B1 P0075 0075 — 2

×EC-650 MAF SEN/CIRCUIT-B1 P0101 0101 — 2

×EC-655 MAF SEN/CIRCUIT-B1 P0102 0102 — 1

×EC-663 MAF SEN/CIRCUIT-B1 P0103 0103 — 1

×EC-663 IAT SEN/CIRCUIT-B1 P0112 0112 — 2

×EC-670 IAT SEN/CIRCUIT-B1 P0113 0113 — 2

×EC-670 ECT SEN/CIRC P0117 0117 — 1

×EC-674 ECT SEN/CIRC P0118 0118 — 1

×EC-674 TP SEN 2/CIRC-B1 P0122 0122 — 1

×EC-679 TP SEN 2/CIRC-B1 P0123 0123 — 1

×EC-679 ECT SENSOR P0125 0125 — 1

×EC-684 IAT SENSOR-B1 P0127 0127 — 2

×EC-687 THERMSTAT FNCTN P0128 0128 — 2

×EC-690 A/F SENSOR1 (B1) P0130 0130 — 2

×EC-692 A/F SENSOR1 (B1) P0131 0131 — 2

×EC-698 A/F SENSOR1 (B1) P0132 0132 — 2

×EC-704 A/F SENSOR1 (B1) P0133 0133

×2 ×EC-710 HO2S2 (B1) P0137 0137

×2 ×EC-717 HO2S2 (B1) P0138 0138

×2 ×EC-724 HO2S2 (B1) P0139 0139

×2 ×EC-733

Page 1899 of 4331

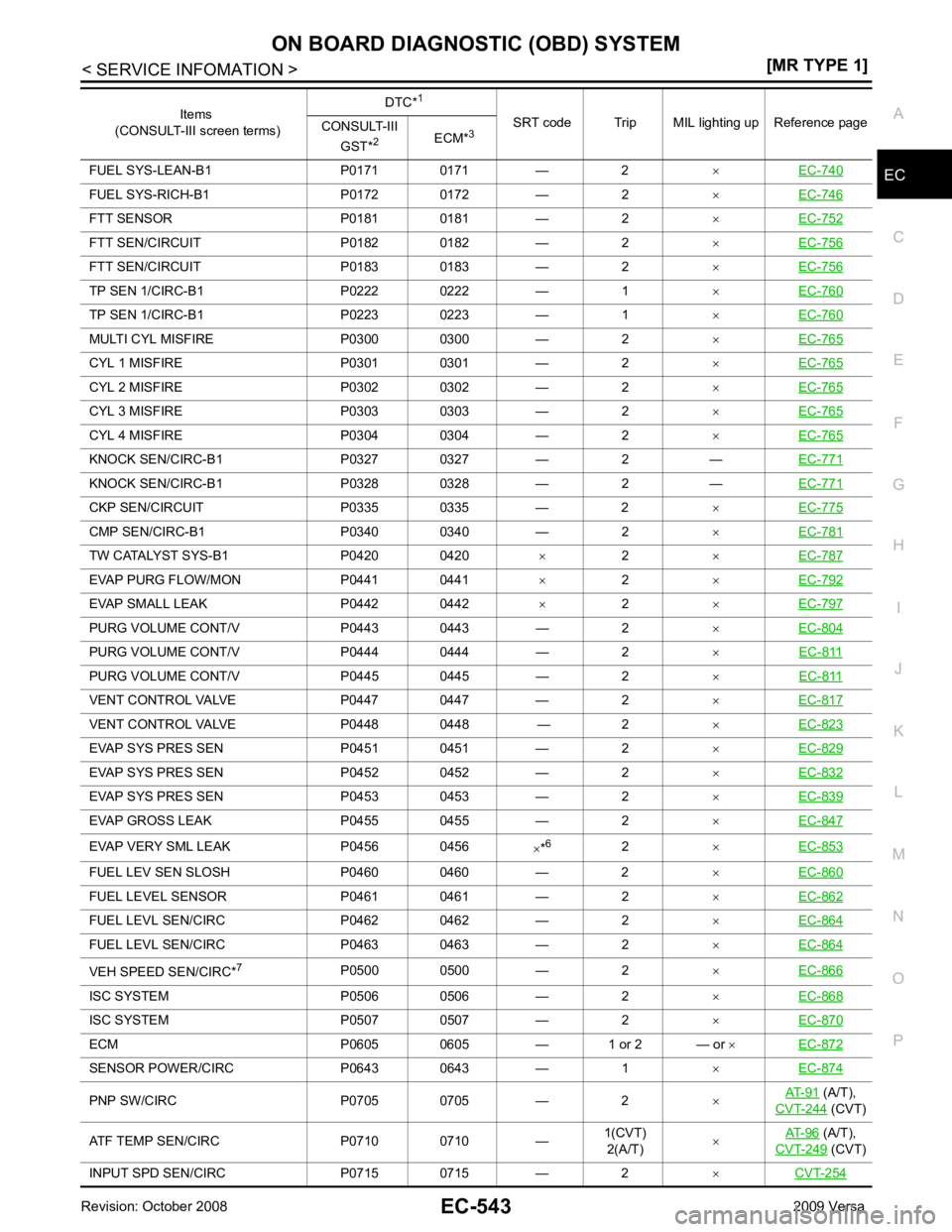

EC

NP

O

FUEL SYS-LEAN-B1 P0171 0171 — 2

×EC-740 FUEL SYS-RICH-B1 P0172 0172 — 2

×EC-746 FTT SENSOR P0181 0181 — 2

×EC-752 FTT SEN/CIRCUIT P0182 0182 — 2

×EC-756 FTT SEN/CIRCUIT P0183 0183 — 2

×EC-756 TP SEN 1/CIRC-B1 P0222 0222 — 1

×EC-760 TP SEN 1/CIRC-B1 P0223 0223 — 1

×EC-760 MULTI CYL MISFIRE P0300 0300 — 2

×EC-765 CYL 1 MISFIRE P0301 0301 — 2

×EC-765 CYL 2 MISFIRE P0302 0302 — 2

×EC-765 CYL 3 MISFIRE P0303 0303 — 2

×EC-765 CYL 4 MISFIRE P0304 0304 — 2

×EC-765 KNOCK SEN/CIRC-B1 P0327 0327 — 2 —

EC-771KNOCK SEN/CIRC-B1 P0328 0328 — 2 —

EC-771CKP SEN/CIRCUIT P0335 0335 — 2

×EC-775 CMP SEN/CIRC-B1 P0340 0340 — 2

×EC-781 TW CATALYST SYS-B1 P0420 0420

× 2 ×EC-787 EVAP PURG FLOW/MON P0441 0441

×2 ×EC-792 EVAP SMALL LEAK P0442 0442

×2 ×EC-797 PURG VOLUME CONT/V P0443 0443 — 2

×EC-804 PURG VOLUME CONT/V P0444 0444 — 2

×EC-811 PURG VOLUME CONT/V P0445 0445 — 2

×EC-811 VENT CONTROL VALVE P0447 0447 — 2

×EC-817 VENT CONTROL VALVE P0448 0448 — 2

×EC-823 EVAP SYS PRES SEN P0451 0451 — 2

×EC-829 EVAP SYS PRES SEN P0452 0452 — 2

×EC-832 EVAP SYS PRES SEN P0453 0453 — 2

×EC-839 EVAP GROSS LEAK P0455 0455 — 2

×EC-847 EVAP VERY SML LEAK P0456 0456

×*6

2 ×EC-853 FUEL LEV SEN SLOSH P0460 0460 — 2

×EC-860 FUEL LEVEL SEN

SOR P0461 0461 — 2 ×EC-862 FUEL LEVL SEN/C

IRC P0462 0462 — 2 ×EC-864 FUEL LEVL SEN/C

IRC P0463 0463 — 2 ×EC-864 VEH SPEED SEN/CIRC*

7

P0500 0500 — 2 ×EC-866 ISC SYSTEM P0506 0506 — 2

×EC-868 ISC SYSTEM P0507 0507 — 2

×EC-870 ECM P0605 0605 — 1 or 2 — or

×EC-872 SENSOR POWER/CIRC P0643 0643 — 1

×EC-874 PNP SW/CIRC P0705 0705 — 2

×AT-91 (A/T),

CVT-244 (CVT)

ATF TEMP SEN/CIRC P0710 0710 — 1(CVT)

2(A/T) ×

AT-96 (A/T),

CVT-249 (CVT)

INPUT SPD SEN/CIRC P0715 0715 — 2 ×CVT-254 Items

(CONSULT-III screen terms) DTC*

1

SRT code Trip MIL lighting up Reference page

CONSULT-III

GST* 2

ECM*3

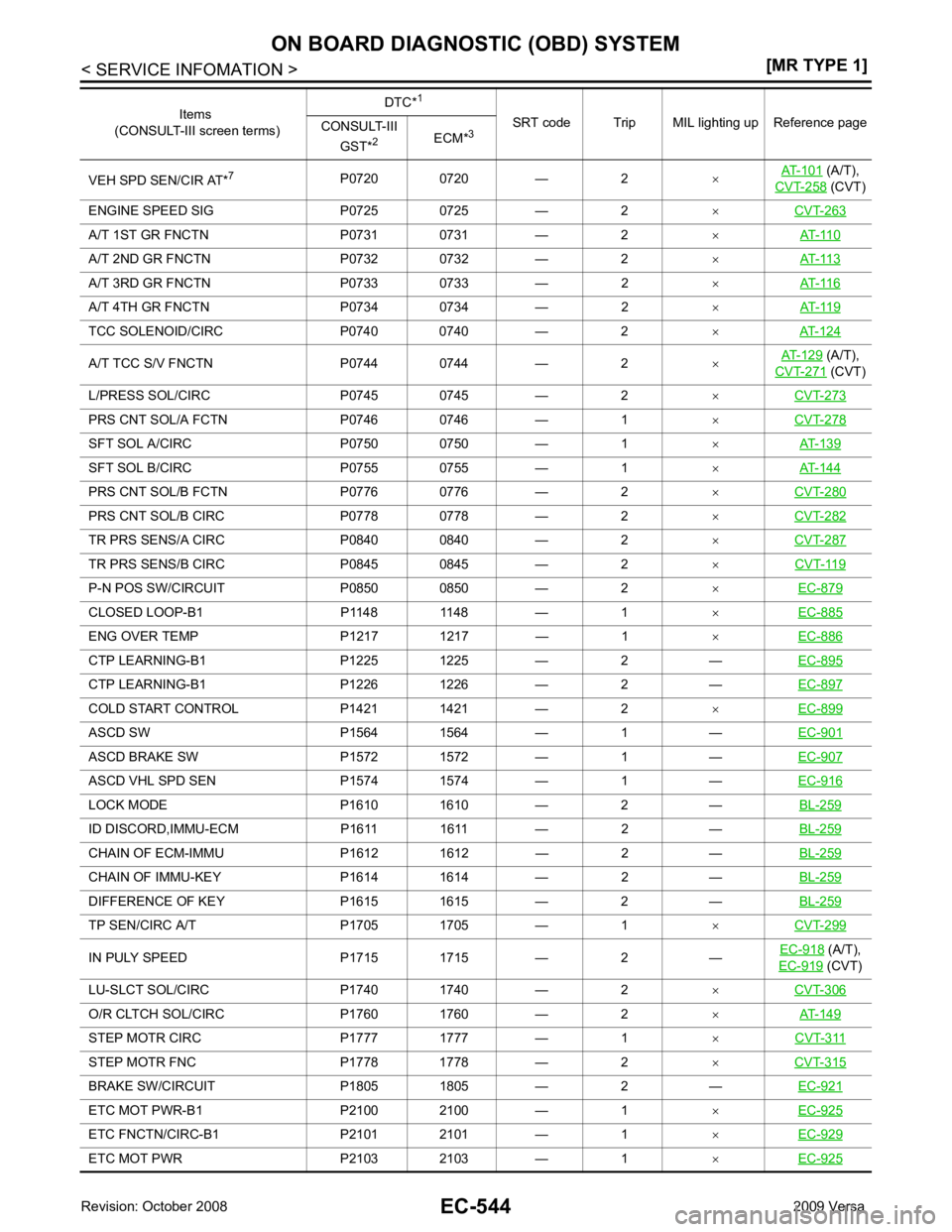

Page 1900 of 4331

(A/T),

CVT-258 (CVT)

ENGINE SPEED SIG P0725 0725 — 2 ×CVT-263 A/T 1ST GR FNCTN P0731 0731 — 2

×AT-110 A/T 2ND GR FNCTN P0732 0732 — 2

×AT-113 A/T 3RD GR FNCTN P0733 0733 — 2

×AT-116 A/T 4TH GR FNCTN P0734 0734 — 2

×AT-119 TCC SOLENOID/CIRC P0740 0740 — 2

×AT-124 A/T TCC S/V FNCTN P0744 0744 — 2

×AT-129 (A/T),

CVT-271 (CVT)

L/PRESS SOL/CIRC P0745 0745 — 2 ×CVT-273 PRS CNT SOL/A FCTN P0746 0746 — 1

×CVT-278 SFT SOL A/CIRC P0750 0750 — 1

×AT-139 SFT SOL B/CIRC P0755 0755 — 1

×AT-144 PRS CNT SOL/B FCTN P0776 0776 — 2

×CVT-280 PRS CNT SOL/B CIRC P0778 0778 — 2

×CVT-282 TR PRS SENS/A CIRC P0840 0840 — 2

×CVT-287 TR PRS SENS/B CIRC P0845 0845 — 2

×CVT-119 P-N POS SW/CIRCUIT P0850 0850 — 2

×EC-879 CLOSED LOOP-B1 P1148 1148 — 1

×EC-885 ENG OVER TEMP P1217 1217 — 1

×EC-886 CTP LEARNING-B1 P1225 1225 — 2 —

EC-895CTP LEARNING-B1 P1226 1226 — 2 —

EC-897COLD START CONTROL P1421 1421 — 2

×EC-899 ASCD SW P1564 1564 — 1 —

EC-901ASCD BRAKE SW P1572 1572 — 1 —

EC-907ASCD VHL SPD SEN P1574 1574 — 1 —

EC-916LOCK MODE P1610 1610 — 2 —

BL-259ID DISCORD,IMMU-ECM P1611 1611 — 2 —

BL-259CHAIN OF ECM-IMMU P1612 1612 — 2 —

BL-259CHAIN OF IMMU-KEY P1614 1614 — 2 —

BL-259DIFFERENCE OF KEY P1615 1615 — 2 —

BL-259TP SEN/CIRC A/T P1705 1705 — 1

×CVT-299 IN PULY SPEED P1715 1715 — 2 —

EC-918 (A/T),

EC-919 (CVT)

LU-SLCT SOL/CIRC P1740 1740 — 2 ×CVT-306 O/R CLTCH SOL/CIRC P1760 1760 — 2

×AT-149 STEP MOTR CIRC P1777 1777 — 1

×CVT-311 STEP MOTR FNC P1778 1778 — 2

×CVT-315 BRAKE SW/CIRCUIT P1805 1805 — 2 —

EC-921ETC MOT PWR-B1 P2100 2100 — 1

×EC-925 ETC FNCTN/CIRC-B1 P2101 2101 — 1

×EC-929 ETC MOT PWR P2103 2103 — 1

×EC-925 Items

(CONSULT-III screen terms) DTC*

1

SRT code Trip MIL lighting up Reference page

CONSULT-III

GST* 2

ECM*3