engine control system NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 710 of 4331

BL

N

O P

- BCM

- Mechanical key

• NATS trouble diagnoses, system initialization and additional registration of other NATS mechanical key IDs

must be carried out using CONSULT-III hardware and CO NSULT-III NATS software. When NATS initializa-

tion has been completed, the ID of the inserted mechanical key can be displayed.

Regarding the procedures of NATS initialization and mec hanical key ID registration, refer to CONSULT-III

operation manual NATS.

SECURITY INDICATOR • Forewarns that the vehicle is equipped with NATS.

• Security indicator will not blink while the ignition knob is in ON or START state. NOTE:

Because security indicator is highly efficient, the battery is barely affected.

Condition of Secu rity Indicator

• When operating the ignition switch with Intelligent Key, se curity indicator lamp will turn off at once if ignition

switch is pressed and blinks when ignition switch is released.

• When operating the ignition switch with mechanical key security indicator will turn off at once if mechanical key is inserted into key cylinder and blinks when mechanical key is removed.

(Once the mechanical key is inserted into key cylinder, BCM will only perform the key ID verification with

mechanical key)

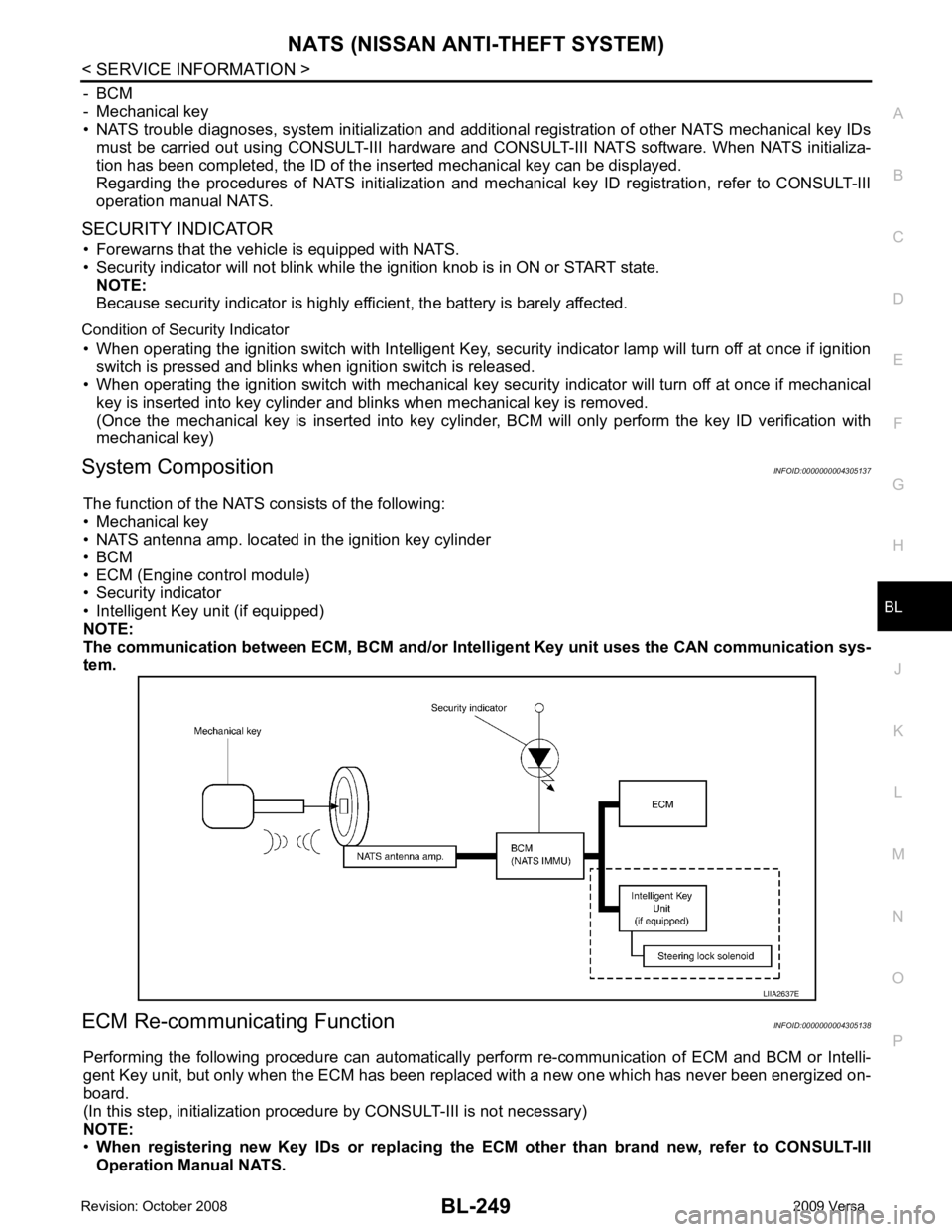

System Composition INFOID:0000000004305137

The function of the NATS consists of the following:

• Mechanical key

• NATS antenna amp. located in the ignition key cylinder

• BCM

• ECM (Engine control module)

• Security indicator

• Intelligent Key unit (if equipped)

NOTE:

The communication between ECM, BCM and/or Intelligent K ey unit uses the CAN communication sys-

tem.

ECM Re-communicating Function INFOID:0000000004305138

Performing the following procedure can automatically perform re-communication of ECM and BCM or Intelli-

gent Key unit, but only when the ECM has been replaced with a new one which has never been energized on-

board.

(In this step, initialization procedur e by CONSULT-III is not necessary)

NOTE:

• When registering new Key IDs or replacing the ECM other than brand new, refer to CONSULT-III

Operation Manual NATS.

Page 720 of 4331

BL

N

O P

This indication means that malfunction have been

detected in NATS and engine control system.

>> GO TO 8 U1000-U1010 " (MR type 1) or

EC-1015, " U0101-

U1001 " (MR type 2).

Without engine diagnostic codes present, refer to EC-577, " Trouble Diagnosis Introduction " (MR type 1) or

EC-1089, " Trouble Diagnosis Introduction " (MR type 2).

NOTE:

If only “NATS MALFUNCTION” is display ed, erase the self-diagnosis results.

>> GO TO 11

Page 843 of 4331

BRC

N

O P

Precaution for Brake Control

INFOID:0000000004307252

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check brake booster operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near t he control module, ABS function may have a malfunction

or error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits or improper wiring.

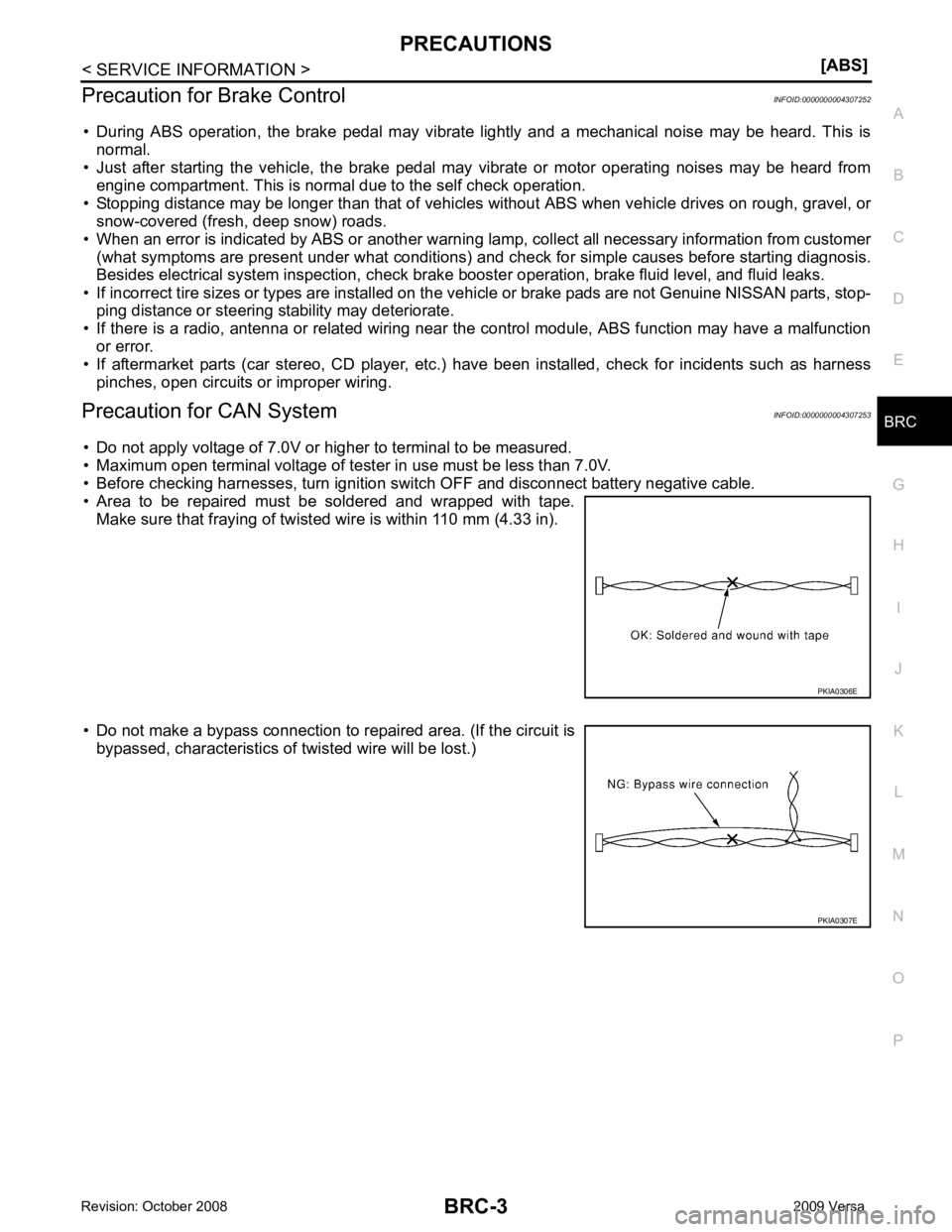

Precaution for CAN System INFOID:0000000004307253

• Do not apply voltage of 7.0V or higher to terminal to be measured.

• Maximum open terminal voltage of tester in use must be less than 7.0V.

• Before checking harnesses, turn ignition switch OFF and disconnect battery negative cable.

• Area to be repaired must be soldered and wrapped with tape. Make sure that fraying of twisted wire is within 110 mm (4.33 in).

• Do not make a bypass connection to repaired area. (If the circuit is bypassed, characteristics of twisted wire will be lost.)

Page 845 of 4331

BRC

N

O P

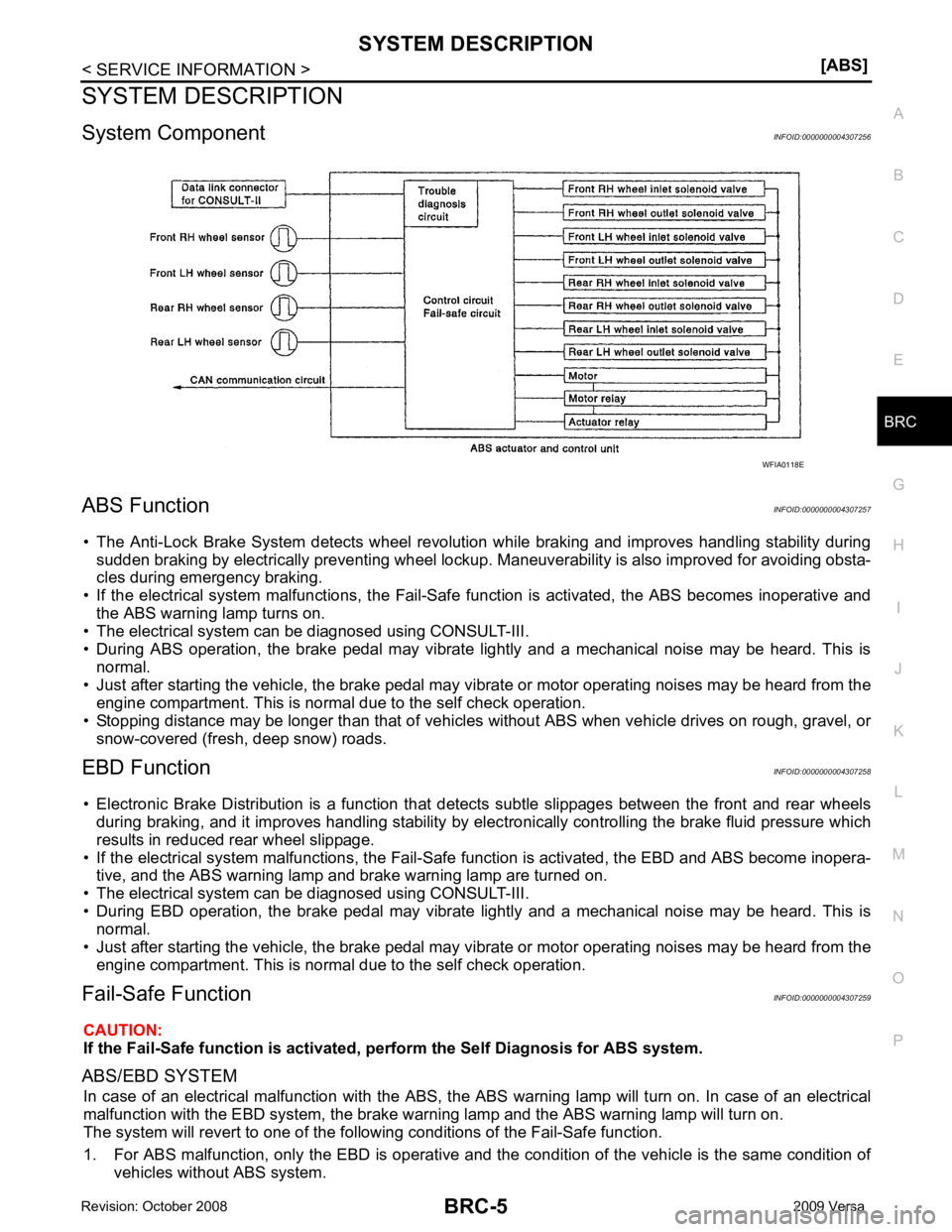

SYSTEM DESCRIPTION

System Component INFOID:0000000004307256

ABS Function INFOID:0000000004307257

• The Anti-Lock Brake System detects wheel revolution while braking and improves handling stability during sudden braking by electrically preventing wheel lockup. Maneuverability is also improved for avoiding obsta-

cles during emergency braking.

• If the electrical system malfunctions, the Fail-Safe function is activated, the ABS becomes inoperative and

the ABS warning lamp turns on.

• The electrical system can be diagnosed using CONSULT-III.

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD Function INFOID:0000000004307258

• Electronic Brake Distribution is a function that detec ts subtle slippages between the front and rear wheels

during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

• If the electrical system malfunctions, the Fail-Safe function is activated, the EBD and ABS become inopera-

tive, and the ABS warning lamp and brake warning lamp are turned on.

• The electrical system can be diagnosed using CONSULT-III.

• During EBD operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

Fail-Safe Function INFOID:0000000004307259

CAUTION:

If the Fail-Safe function is activated, perform the Self Diagnosis for ABS system.

ABS/EBD SYSTEM In case of an electrical malfunction with the ABS, the ABS warning lamp wi ll turn on. In case of an electrical

malfunction with the EBD system, the brake warni ng lamp and the ABS warning lamp will turn on.

The system will revert to one of the follo wing conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and t he condition of the vehicle is the same condition of

vehicles without ABS system.

Page 857 of 4331

BRC

N

O P

• If ABS actuator and electric unit (control unit) connec

tion is loose, tighten the piping to the specified

torque and recheck for leaks.

• If there is damage to the connection flare nut or A BS actuator and electric unit (control unit) threads,

replace the damaged part and recheck for leaks.

• When there is fluid leaking or seeping from a fluid connection, use a clean cloth to wipe off the fluid and recheck for leaks. If fluid is still seeping out, repl ace the damaged part. If the fluid is leaking at the ABS

actuator and electric unit (control unit), replace the ABS actuator and electric unit (control unit) assem-

bly.

CAUTION:

The ABS actuator and electric unit (control un it) cannot be disassembled and must be replaced

as an assembly.

3. Check the brake pads for excessive wear.

POWER SYSTEM TERMINAL LOOSENESS AND BATTERY INSPECTION Make sure the battery positive cable, negative cabl e and ground connection are not loose. In addition, make

sure the battery is sufficiently charged.

ABS WARNING LAMP INSPECTION 1. Make sure ABS warning lamp turns on for approximately 2 seconds when the ignition switch is turned ON. If it does not, check CAN communications. If ther e are no errors with the CAN communication system,

replace the combination meter. Refer to IP-12, " Removal and Installation " .

2. Make sure the lamp turns off approximately 2 seconds after the ignition switch is turned ON. If the lamp does not turn off, conduct self-diagnosis of ABS act uator and electric unit (control unit). If no malfunctions

are detected in self-diagnosis, replace combination meter. Refer to IP-12, " Removal and Installation " .

3. After conducting the self-diagnosis, be sure to erase the error memory. Refer to BRC-18, " CONSULT-III

Function (ABS) " .

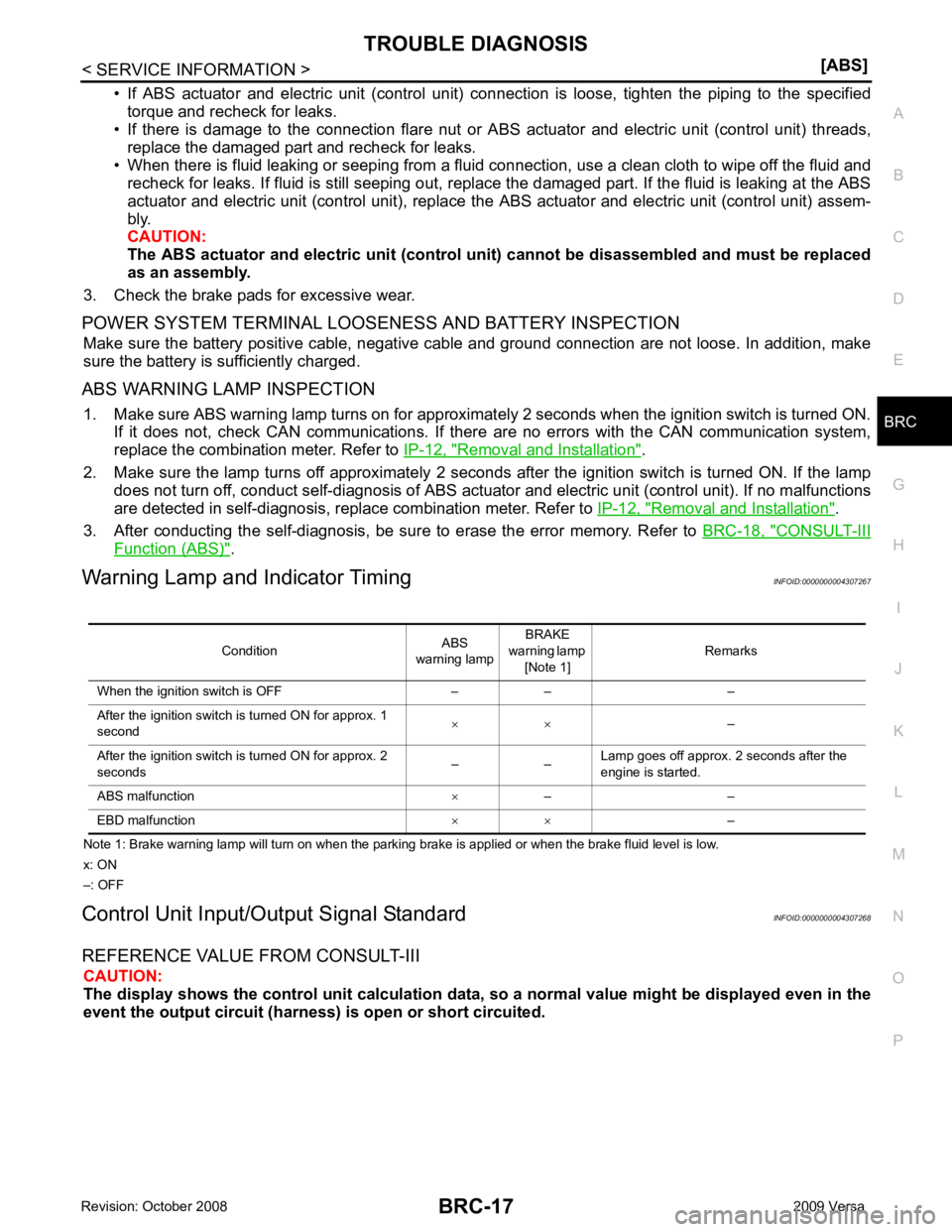

Warning Lamp and Indicator Timing INFOID:0000000004307267

Note 1: Brake warning lamp will turn on when the parking brake is applied or when the brake fluid level is low.

x: ON

–: OFF

Control Unit Input/Out put Signal Standard INFOID:0000000004307268

REFERENCE VALUE FROM CONSULT-III CAUTION:

The display shows the control unit calculation data, so a normal value might be displayed even in the

event the output circuit (harness) is open or short circuited.

Condition

ABS

warning lamp BRAKE

warning lamp [Note 1] Remarks

When the ignition switch is OFF – – –

After the ignition switch is turned ON for approx. 1

second × ×

–

After the ignition switch is turned ON for approx. 2

seconds – –Lamp goes off approx. 2 seconds after the

engine is started.

ABS malfunction ×– –

EBD malfunction × ×–

Page 858 of 4331

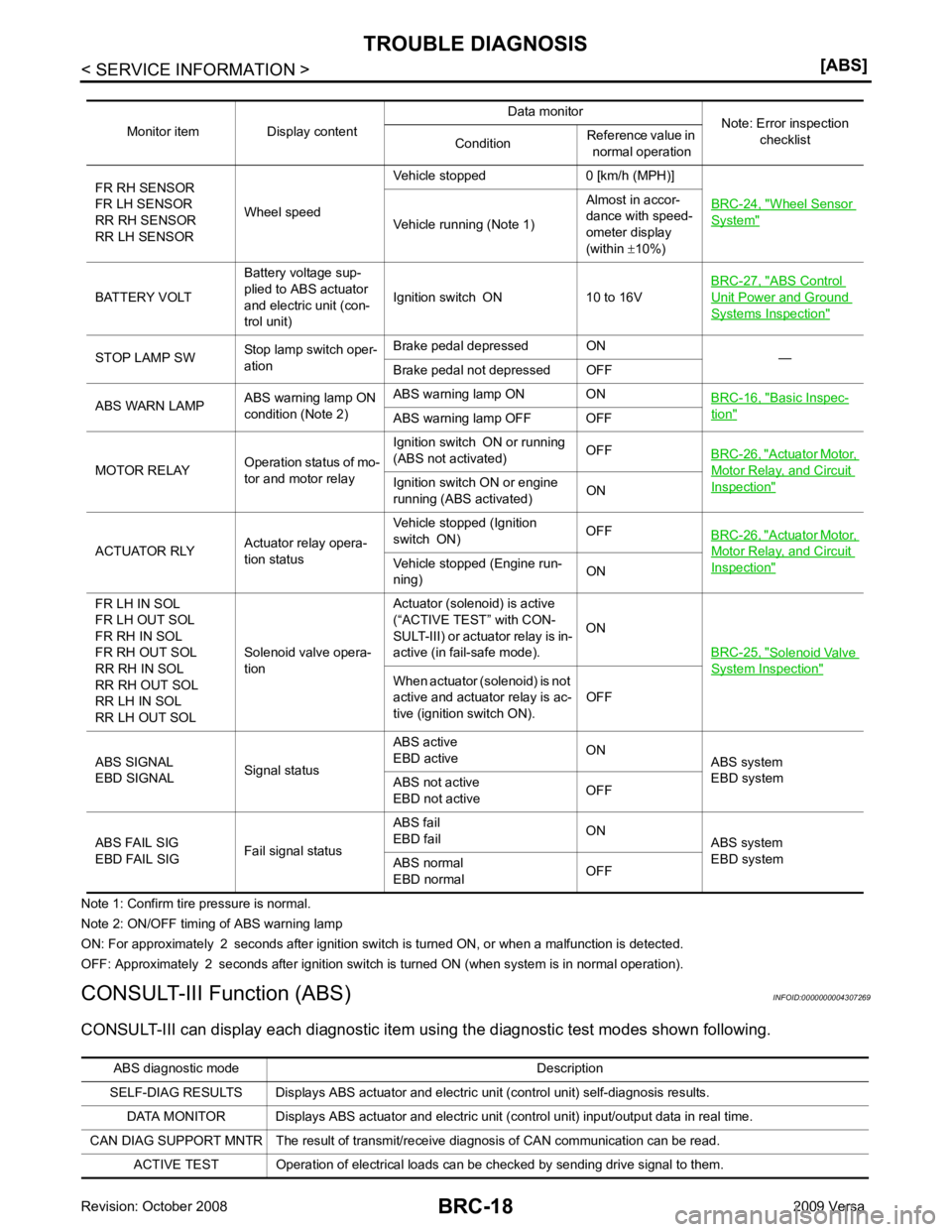

Wheel Sensor

System "

Vehicle running (Note 1)

Almost in accor-

dance with speed-

ometer display

(within ±10%)

BATTERY VOLT Battery voltage sup-

plied to ABS actuator

and electric unit (con-

trol unit) Ignition switch ON 10 to 16V

BRC-27, " ABS Control

Unit Power and Ground

Systems Inspection "

STOP LAMP SW

Stop lamp switch oper-

ation Brake pedal depressed ON

—

Brake pedal not depressed OFF

ABS WARN LAMP ABS warning lamp ON

condition (Note 2) ABS warning lamp ON ON

BRC-16, " Basic Inspec-

tion "

ABS warning lamp OFF OFF

MOTOR RELAY Operation status of mo-

tor and motor relay Ignition switch ON or running

(ABS not activated) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Ignition switch ON or engine

running (ABS activated) ON

ACTUATOR RLY Actuator relay opera-

tion status Vehicle stopped (Ignition

switch ON) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Vehicle stopped (Engine run-

ning) ON

FR LH IN SOL

FR LH OUT SOL

FR RH IN SOL

FR RH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL Solenoid valve opera-

tion Actuator (solenoid) is active

(“ACTIVE TEST” with CON-

SULT-III) or actuator relay is in-

active (in fail-safe mode). ON

BRC-25, " Solenoid Valve

System Inspection "

When actuator (solenoid) is not

active and actuator relay is ac-

tive (ignition switch ON). OFF

ABS SIGNAL

EBD SIGNAL Signal statusABS active

EBD active ON

ABS system

EBD system

ABS not active

EBD not active OFF

ABS FAIL SIG

EBD FAIL SIG Fail signal statusABS fail

EBD fail ON

ABS system

EBD system

ABS normal

EBD normal OFFABS diagnostic mo

de Description

SELF-DIAG RESULTS Displays ABS actuator and electric unit (control unit) self-diagnosis results.

DATA MONITOR Displays ABS actuator and electric unit (control unit) input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Page 859 of 4331

BRC

N

O P

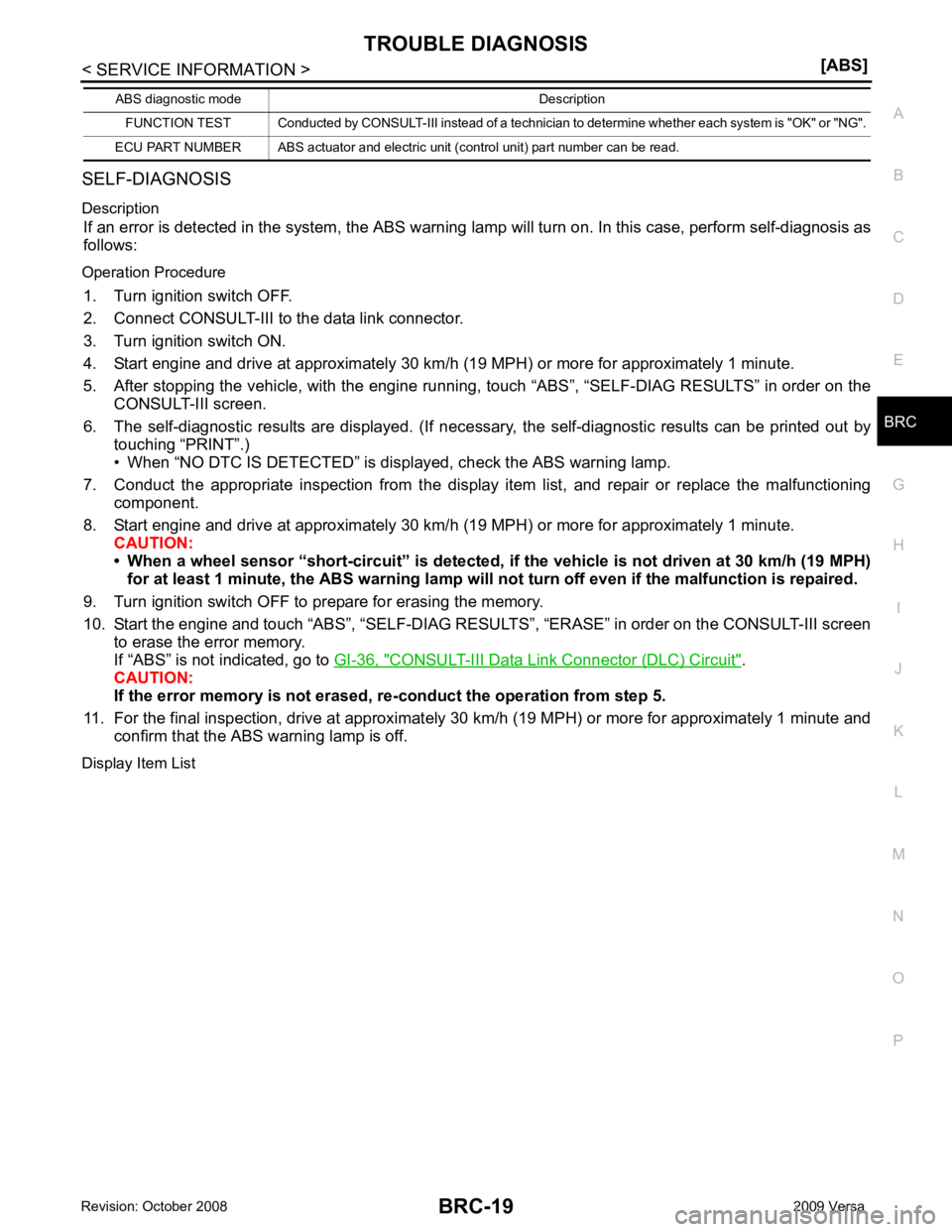

SELF-DIAGNOSIS

Description If an error is detected in the system, the ABS warning lamp will turn on. In this case, perform self-diagnosis as

follows:

Operation Procedure 1. Turn ignition switch OFF.

2. Connect CONSULT-III to the data link connector.

3. Turn ignition switch ON.

4. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

5. After stopping the vehicle, with the engine running, t ouch “ABS”, “SELF-DIAG RESULTS” in order on the

CONSULT-III screen.

6. The self-diagnostic results are displayed. (If nece ssary, the self-diagnostic results can be printed out by

touching “PRINT”.)

• When “NO DTC IS DETECTED” is displayed, check the ABS warning lamp.

7. Conduct the appropriate inspection from the display item list, and repair or replace the malfunctioning

component.

8. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

• When a wheel sensor “short-circuit” is detected, if the vehicle is not driven at 30 km/h (19 MPH)

for at least 1 minute, the ABS warn ing lamp will not turn off even if the malfunction is repaired.

9. Turn ignition switch OFF to prepare for erasing the memory.

10. Start the engine and touch “ABS”, “SELF-DIAG RESU LTS”, “ERASE” in order on the CONSULT-III screen

to erase the error memory.

If “ABS” is not indicated, go to GI-36, " CONSULT-III Data Link Connector (DLC) Circuit " .

CAUTION:

If the error memory is not erased, re -conduct the operation from step 5.

11. For the final inspection, drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute and

confirm that the ABS warning lamp is off.

Display Item List FUNCTION TEST Conducted by CONSULT-III in

stead of a technician to determine whether each sy stem is "OK" or "NG".

ECU PART NUMBER ABS actuator and electric unit (control unit) part number can be read.

ABS diagnostic mode Description

Page 875 of 4331

BRC

N

O P

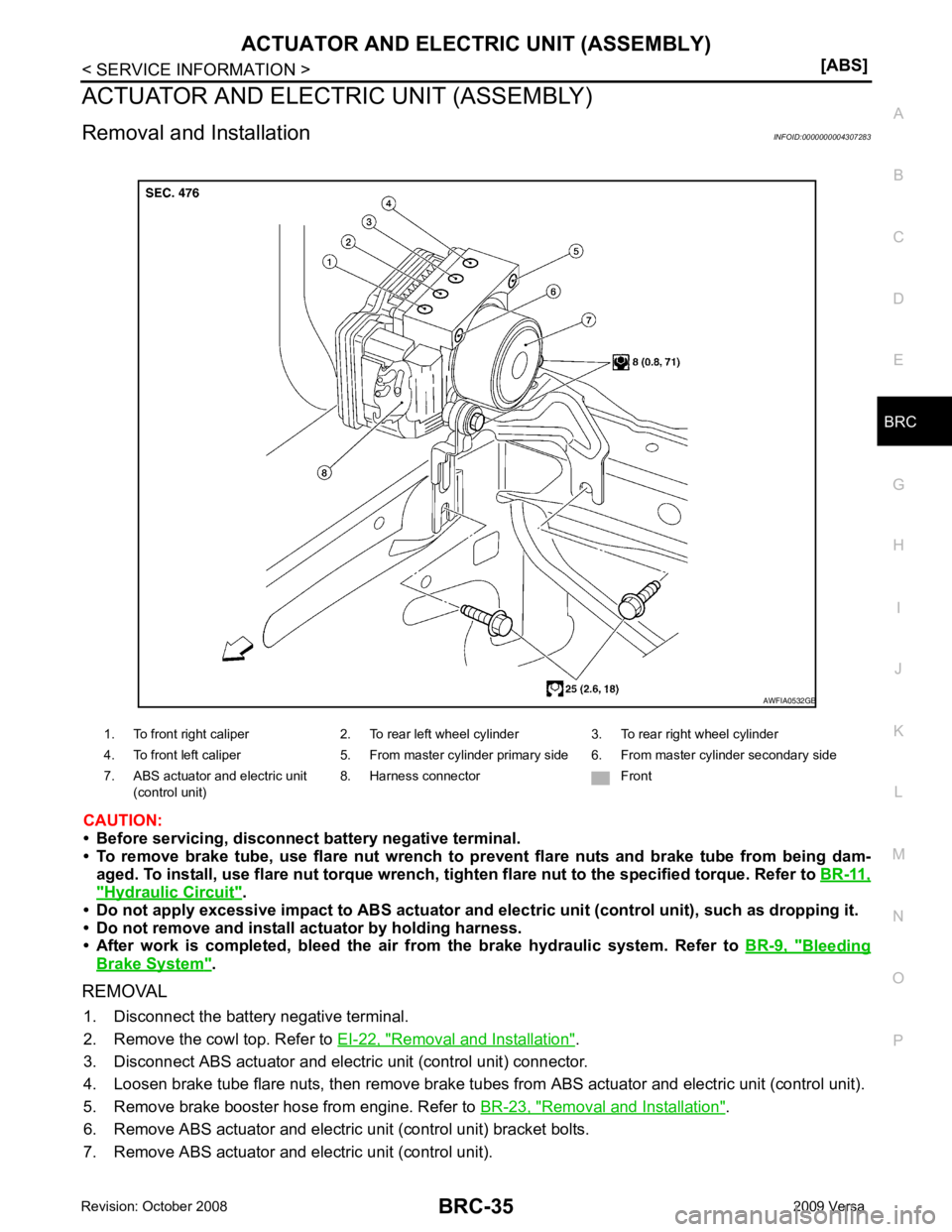

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and Installation INFOID:0000000004307283

CAUTION:

• Before servicing, disconnect battery negative terminal.

• To remove brake tube, use flare nut wrench to pr event flare nuts and brake tube from being dam-

aged. To install, use flare nut torque wrench, ti ghten flare nut to the specified torque. Refer to BR-11," Hydraulic Circuit " .

• Do not apply excessive impact to ABS actuator and elect ric unit (control unit), such as dropping it.

• Do not remove and install actuator by holding harness.

• After work is completed, bleed the air from the brake hydraulic system. Refer to BR-9, " Bleeding

Brake System " .

REMOVAL 1. Disconnect the battery negative terminal.

2. Remove the cowl top. Refer to EI-22, " Removal and Installation " .

3. Disconnect ABS actuator and electric unit (control unit) connector.

4. Loosen brake tube flare nuts, then remove brake tubes from ABS actuator and electric unit (control unit).

5. Remove brake booster hose from engine. Refer to BR-23, " Removal and Installation " .

6. Remove ABS actuator and electric unit (control unit) bracket bolts.

7. Remove ABS actuator and electric unit (control unit). 1. To front right caliper 2. To rear left wheel cylinder 3. To rear right wheel cylinder

4. To front left caliper 5. From master cylinder primary side 6. From master cylinder secondary side

7. ABS actuator and electric unit (control unit) 8. Harness connector Front

Page 897 of 4331

CO

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784387

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004784348

NOTE:

• This Procedure is applied only to models with Inte lligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 906 of 4331

Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

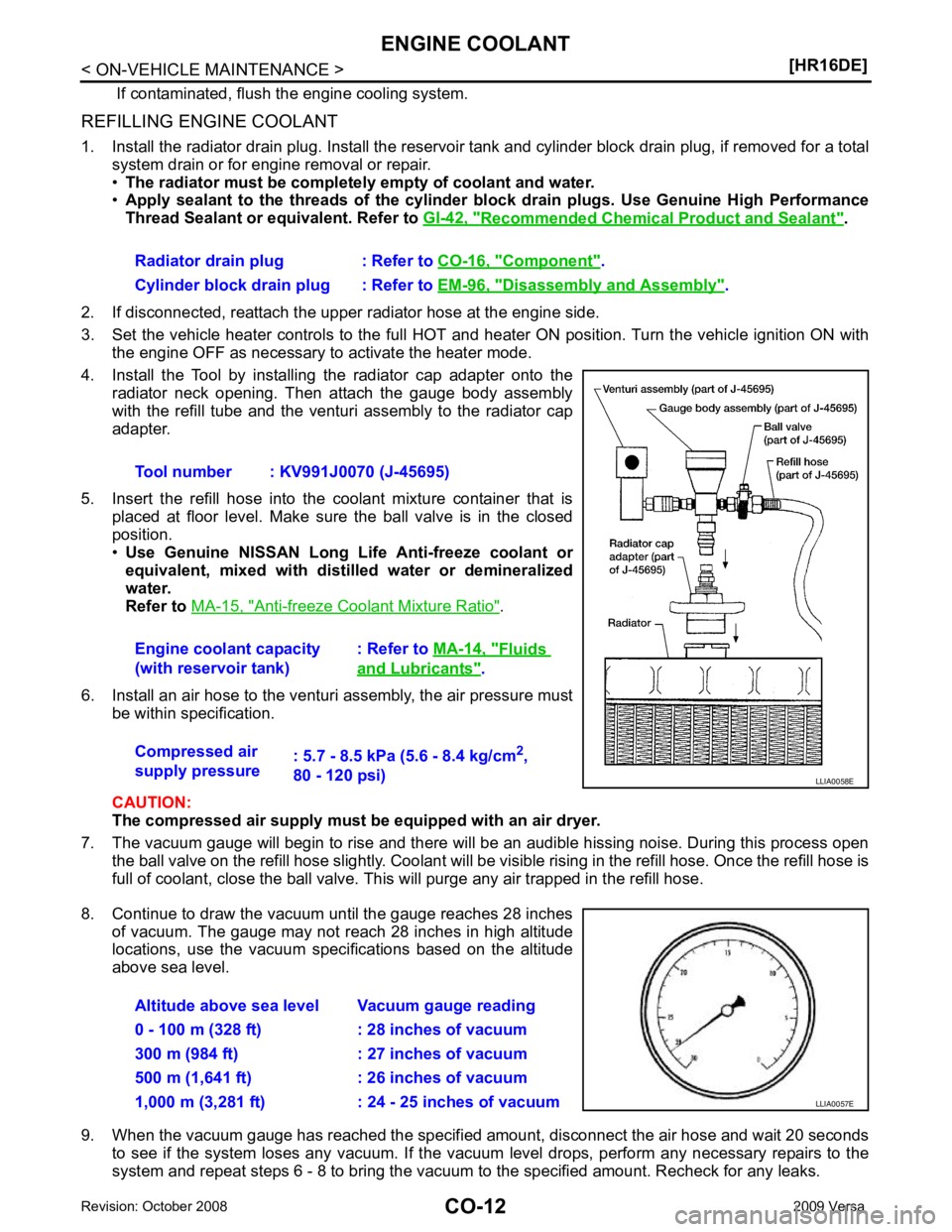

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

Radiator drain plug : Refer to

CO-16, " Component " .

Cylinder block drain plug : Refer to EM-96, " Disassembly and Assembly " .

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, " Fluids

and Lubricants " .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

,

80 - 120 psi)