engine control system NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1361 of 4331

EC

A

N

O P

Diagnosis Procedure ...........................................

..

349

P0507 ISC SYSTEM ....................................... ..351

Description .......................................................... ..351

DTC Logic ........................................................... ..351

Diagnosis Procedure ........................................... ..351

P0603 ECM POWER SUPPLY ....................... ..353

Description .......................................................... ..353

DTC Logic ........................................................... ..353

Diagnosis Procedure ........................................... ..353

P0605 ECM ..................................................... ..355

Description .......................................................... ..355

DTC Logic ........................................................... ..355

Diagnosis Procedure ........................................... ..356

P0607 ECM ..................................................... ..357

Description .......................................................... ..357

DTC Logic ........................................................... ..357

Diagnosis Procedure ........................................... ..357

P0643 SENSOR POWER SUPPLY ............... ..358

DTC Logic ........................................................... ..358

Wiring Diagram ................................................... ..359

Diagnosis Procedure ........................................... ..359

P0850 PNP SWITCH ...................................... ..362

Description .......................................................... ..362

DTC Logic ........................................................... ..362

Component Function Check ................................ ..363

Wiring Diagram ................................................... ..364

Diagnosis Procedure ........................................... ..364

P1148 CLOSED LOOP CONTROL ................ ..367

DTC Logic ........................................................... ..367

P1217 ENGINE OVER TEMPERATURE ....... ..368

DTC Logic ........................................................... ..368

Component Function Check ................................ ..368

Diagnosis Procedure ........................................... ..369

P1225 TP SENSOR ........................................ ..372

Description .......................................................... ..372

DTC Logic ........................................................... ..372

Diagnosis Procedure ........................................... ..372

Special Repair Requirem ent .................................373

P1226 TP SENSOR ........................................ ..374

Description .......................................................... ..374

DTC Logic ........................................................... ..374

Diagnosis Procedure ........................................... ..374

Special Repair Requirem ent .................................375

P1421 COLD START CONTROL ................... ..376

Description .......................................................... ..376

DTC Logic ........................................................... ..376

Diagnosis Procedure ........................................... ..376

P1715 INPUT SPEED SENSOR (PRIMARY

SPEED SENSOR) .......................................... ..

378

Description .......................................................... ..378 DTC Logic ............................................................

..378

Diagnosis Procedure ........................................... ..378

P1805 BRAKE SWITCH ................................. 380

Description ........................................................... ..380

DTC Logic ............................................................ ..380

Wiring Diagram .................................................... ..381

Diagnosis Procedure ........................................... ..381

Component Inspection (Stop Lamp Switch) ........ ..383

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY .................................................... 384

Description ........................................................... ..384

DTC Logic ............................................................ ..384

Wiring Diagram .................................................... ..385

Diagnosis Procedure ........................................... ..385

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ....... ............................................... 388

Description ........................................................... ..388

DTC Logic ............................................................ ..388

Wiring Diagram .................................................... ..389

Diagnosis Procedure ........................................... ..389

Component Inspection ......................................... ..392

Special Repair Requiremen t ..................................392

P2118 THROTTLE CONTROL MOTOR ......... 393

Description ........................................................... ..393

DTC Logic ............................................................ ..393

Wiring Diagram .................................................... ..394

Diagnosis Procedure ........................................... ..394

Component Inspection ......................................... ..395

Special Repair Requiremen t ..................................396

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR ..................................................... 397

Description ........................................................... ..397

DTC Logic ............................................................ ..397

Diagnosis Procedure ........................................... ..397

Special Repair Requiremen t ..................................398

P2122, P2123 APP SENSOR ......................... 399

Description ........................................................... ..399

DTC Logic ............................................................ ..399

Wiring Diagram .................................................... ..400

Diagnosis Procedure ........................................... ..400

Component Inspection ......................................... ..402

Special Repair Requiremen t ..................................402

P2127, P2128 APP SENSOR ......................... 403

Description ........................................................... ..403

DTC Logic ............................................................ ..403

Wiring Diagram .................................................... ..404

Diagnosis Procedure ........................................... ..404

Component Inspection ......................................... ..406

Special Repair Requiremen t ..................................407

P2135 TP SENSOR ......................................... 408

Description ........................................................... ..408

DTC Logic ............................................................ ..408

Page 1363 of 4331

EC

A

N

O P

Inspection ............................................................

..

500

ON-VEHICLE REPAIR .... ...........................502

EVAP CANISTER ........................................... ..502

Exploded View .................................................... ..502

Removal and Installation .......................................502

Inspection ............................................................ ..503

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................504

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..504

Idle Speed ........................................................... ..504

Ignition Timing ..................................................... ..504

Calculated Load Value ........................................ ..504

Mass Air Flow Sensor ......................................... ..504

MR TYPE 1

SERVICE INFOMATION .. ..........................505

APPLICATION NOTICE ................................. ..505

How to Check Vehicle Type ................................ ..505

INDEX FOR DTC ............................................ ..506

U1000-U1010 ...................................................... ..506

P0011-P0075 ...................................................... ..506

P0101-P0128 ...................................................... ..506

P0130-P0183 ...................................................... ..507

P0222-P0420 ...................................................... ..507

P0441-P0463 ...................................................... ..508

P0500-P0643 ...................................................... ..508

P0705-P0734 ...................................................... ..508

P0740-P0845 ...................................................... ..509

P0850-P1574 ...................................................... ..509

P1610-P1615 ...................................................... ..510

P1705-P1805 ...................................................... ..510

P2100-P2A00 ...................................................... ..510

PRECAUTIONS .............................................. ..512

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

512

Precaution for Procedure without Cowl Top Cover ..512

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ............................................................. ..

512

Precaution ........................................................... ..513

PREPARATION .............................................. ..516

Special Service Tool ........................................... ..516

Commercial Service Tool .................................... ..516

ENGINE CONTROL SYSTEM ........................ ..518

Schematic ........................................................... ..518

Multiport Fuel Injection (MFI) System ................. ..518

Electronic Ignition (EI) System ............................ ..521

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

521

AIR CONDITIONING CUT CONTROL ........... ..523 Input/Output Signal Chart ....................................

..523

System Description .............................................. ..523

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................ 524

System Description .............................................. ..524

Component Description ....................................... ..525

CAN COMMUNICATION ................................. 526

System Description .............................................. ..526

EVAPORATIVE EMISSION SYSTEM ............. 527

Description ........................................................... ..527

Component Inspection ......................................... ..529

Removal and Installation ..................................... ..531

How to Detect Fuel Vapor Leakage ..................... ..531

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .................................................... 533

System Description .............................................. ..533

Diagnosis Procedure ........................................... ..533

Component Inspection ......................................... ..535

POSITIVE CRANKCASE VENTILATION ....... 538

Description ........................................................... ..538

Component Inspection ......................................... ..538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) ..................................................... 540

Description ........................................................... ..540

ON BOARD DIAGNOSTIC (OBD) SYSTEM .. 541

Introduction .......................................................... ..541

Two Trip Detection Logic ..................................... ..541

Emission-related Diagnostic Information ............. ..542

Malfunction Indicator Lamp (MIL) ..........................557

OBD System Operation Chart ............................. ..560

BASIC SERVICE PROCEDURE ..................... 566

Basic Inspection .................................................. ..566

Idle Speed and Ignition Timing Check ................. ..570

Procedure After Replacing ECM ......................... ..571

VIN Registration .................................................. ..572

Accelerator Pedal Released Position Learning ... ..572

Throttle Valve Closed Position Learning ............. ..572

Idle Air Volume Learning ..................................... ..572

Fuel Pressure Check ........................................... ..574

TROUBLE DIAGNOSIS .................................. 577

Trouble Diagnosis Introduction ............................ ..577

DTC Inspection Priority Chart .............................. ..581

Fail-Safe Chart .................................................... ..582

Symptom Matrix Chart ......................................... ..583

Engine Control Component Parts Location ......... ..588

Vacuum Hose Drawing ........................................ ..594

Circuit Diagram .................................................... ..595

ECM Harness Connector Terminal Layout .......... ..597

ECM Terminal and Reference Value ................... ..597

CONSULT-III Function (ENGINE) ....................... ..604

Generic Scan Tool (GST) Function ..................... ..612

Page 1375 of 4331

EC

A

N

O P

DTC P0850 PNP SWITCH ..............................

1401

Component Description ....................................... 1401

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1401

On Board Diagnosis Logic .................................. 1401

DTC Confirmation Procedure .............................. 1401

Overall Function Check ....................................... 1402

Wiring Diagram ................................................... 1403

Diagnosis Procedure ........................................... 1404

DTC P1148 CLOSED LOOP CONTROL ....... 1407

On Board Diagnosis Logic .................................. 1407

DTC P1217 ENGINE OVER TEMPERATURE 1408

System Description ............................................. 1408

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1409

On Board Diagnosis Logic .................................. 1409

Overall Function Check ....................................... 1409

Wiring Diagram ................................................... 1411

Diagnosis Procedure ........................................... 1412

Main 13 Causes of Overheating .......................... 1415

Component Inspection ........................................ 1416

DTC P1225 TP SENSOR ............................... 1417

Component Description ....................................... 1417

On Board Diagnosis Logic .................................. 1417

DTC Confirmation Procedure .............................. 1417

Diagnosis Procedure ........................................... 1417

Removal and Installation .....................................1418

DTC P1226 TP SENSOR ............................... 1419

Component Description ....................................... 1419

On Board Diagnosis Logic .................................. 1419

DTC Confirmation Procedure .............................. 1419

Diagnosis Procedure ........................................... 1419

Removal and Installation .....................................1420

DTC P1421 COLD START CONTROL .......... 1421

Description .......................................................... 1421

On Board Diagnosis Logic .................................. 1421

DTC Confirmation Procedure .............................. 1421

Diagnosis Procedure ........................................... 1421

DTC P1564 ASCD STEERING SWITCH ....... 1423

Component Description ....................................... 1423

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1423

On Board Diagnosis Logic .................................. 1423

DTC Confirmation Procedure .............................. 1424

Wiring Diagram ................................................... 1425

Diagnosis Procedure ........................................... 1426

Component Inspection ........................................ 1428

DTC P1572 ASCD BRAKE SWITCH ............. 1429

Component Description ....................................... 1429

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... 1429

On Board Diagnosis Logic .................................. 1429

DTC Confirmation Procedure .............................. 1430Wiring Diagram ....................................................

1431

Diagnosis Procedure ........................................... 1432

Component Inspection ......................................... 1436

DTC P1574 ASCD VEH ICLE SPEED SEN-

SOR ................................................................ 1438

Component Description ....................................... 1438

On Board Diagnosis Logic ................................... 1438

DTC Confirmation Procedure .............................. 1438

Diagnosis Procedure ........................................... 1438

DTC P1715 INPUT SPEED SENSOR (TUR-

BINE REVOLUTION SENSOR) ..................... 1440

Description ........................................................... 1440

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1440

On Board Diagnosis Logic ................................... 1440

Diagnosis Procedure ........................................... 1440

DTC P1715 INPUT SPEED SENSOR (PRIMA-

RY SPEED SENSOR) ....................................

1441

Description ........................................................... 1441

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1441

On Board Diagnosis Logic ................................... 1441

DTC Confirmation Procedure .............................. 1441

Diagnosis Procedure ........................................... 1441

DTC P1805 BRAKE SWITCH ........................ 1443

Description ........................................................... 1443

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1443

On Board Diagnosis Logic ................................... 1443

DTC Confirmation Procedure .............................. 1443

Wiring Diagram .................................................... 1444

Diagnosis Procedure ........................................... 1445

Component Inspection ......................................... 1446

DTC P2100, P2103 THROTTLE CONTROL

MOTOR RELAY ............................................. 1447

Component Description ....................................... 1447

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... 1447

On Board Diagnosis Logic ................................... 1447

DTC Confirmation Procedure .............................. 1447

Wiring Diagram .................................................... 1448

Diagnosis Procedure ........................................... 1449

DTC P2101 ELECTRIC THROTTLE CON-

TROL FUNCTION .......................................... 1451

Description ........................................................... 1451

On Board Diagnosis Logic ................................... 1451

DTC Confirmation Procedure .............................. 1451

Wiring Diagram .................................................... 1452

Diagnosis Procedure ........................................... 1453

Component Inspection ......................................... 1456

Removal and Installation ..................................... 1456

DTC P2118 THROTTLE CONTROL MOTOR 1457

Component Description ....................................... 1457

Page 1391 of 4331

EC

NP

O

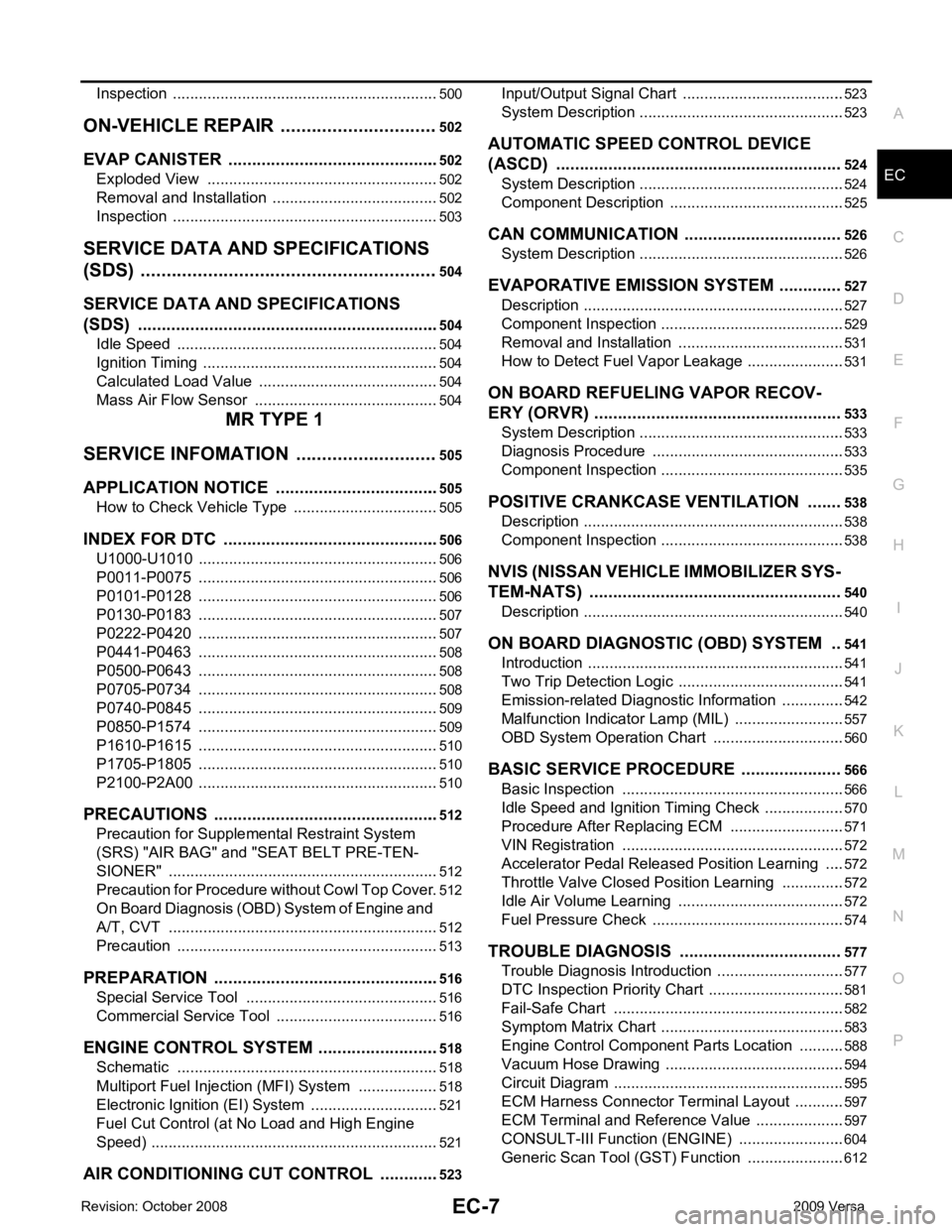

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System Diagram INFOID:0000000004780006

Page 1397 of 4331

EC

NP

O

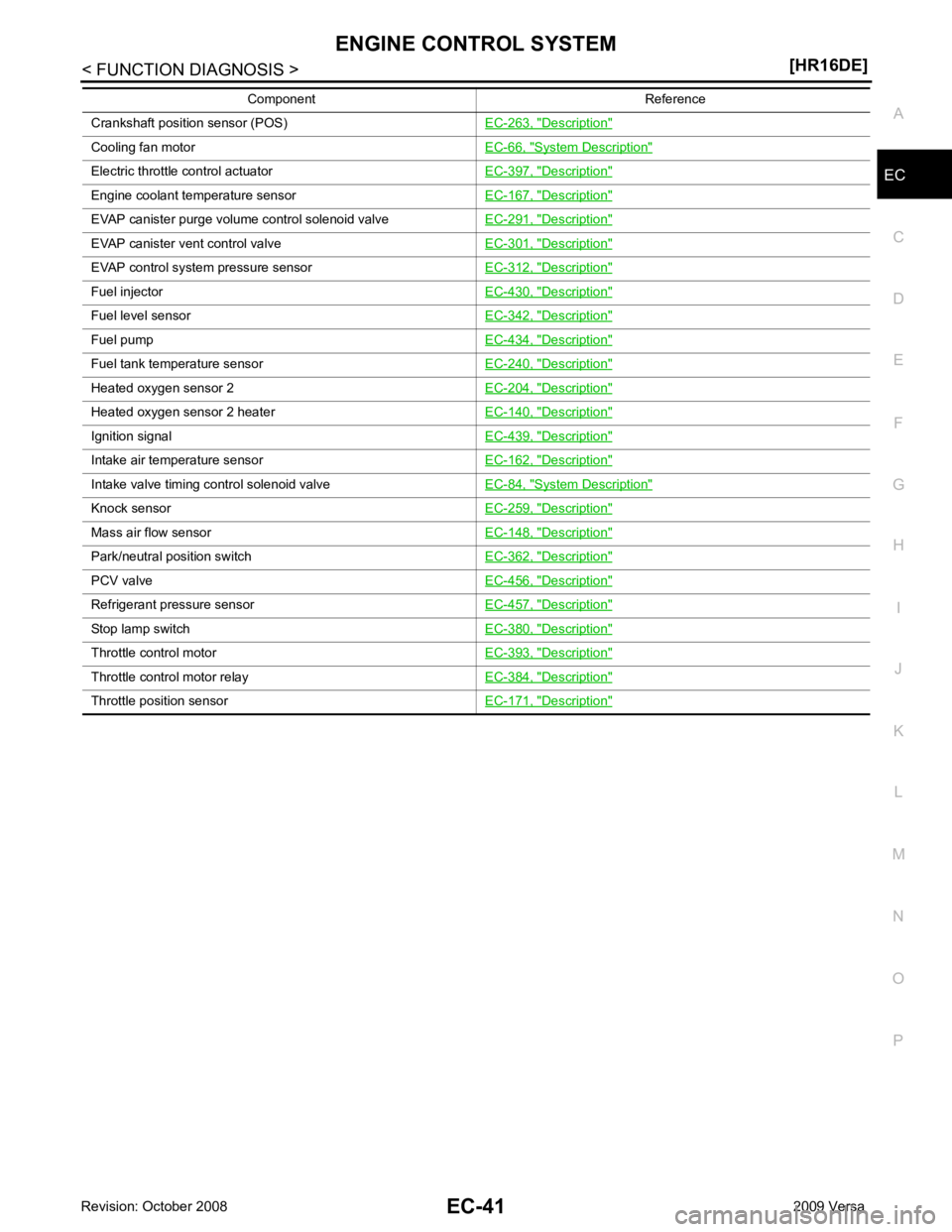

Crankshaft position sensor (POS)

EC-263, " Description "

Cooling fan motor

EC-66, " System Description "

Electric throttle control actuator

EC-397, " Description "

Engine coolant temperature sensor

EC-167, " Description "

EVAP canister purge volume control solenoid valve

EC-291, " Description "

EVAP canister vent control valve

EC-301, " Description "

EVAP control system pressure sensor

EC-312, " Description "

Fuel injector

EC-430, " Description "

Fuel level sensor

EC-342, " Description "

Fuel pump

EC-434, " Description "

Fuel tank temperature sensor

EC-240, " Description "

Heated oxygen sensor 2

EC-204, " Description "

Heated oxygen sensor 2 heater

EC-140, " Description "

Ignition signal

EC-439, " Description "

Intake air temperature sensor

EC-162, " Description "

Intake valve timing control solenoid valve

EC-84, " System Description "

Knock sensor

EC-259, " Description "

Mass air flow sensor

EC-148, " Description "

Park/neutral position switch

EC-362, " Description "

PCV valve

EC-456, " Description "

Refrigerant pressure sensor

EC-457, " Description "

Stop lamp switch

EC-380, " Description "

Throttle control motor

EC-393, " Description "

Throttle control motor relay

EC-384, " Description "

Throttle position sensor

EC-171, " Description "Component Reference

Page 1399 of 4331

EC

NP

O

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). T he amount of fuel injected is a program value in the

ECM memory. The program value is preset by engi ne operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from t he crankshaft position sensor (POS), camshaft position

sensor (PHASE) and the mass air flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION In addition, the amount of fuel injected is compens ated to improve engine performance under various operat-

ing conditions as listed below.

• During warm-up

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D (A/T models)

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

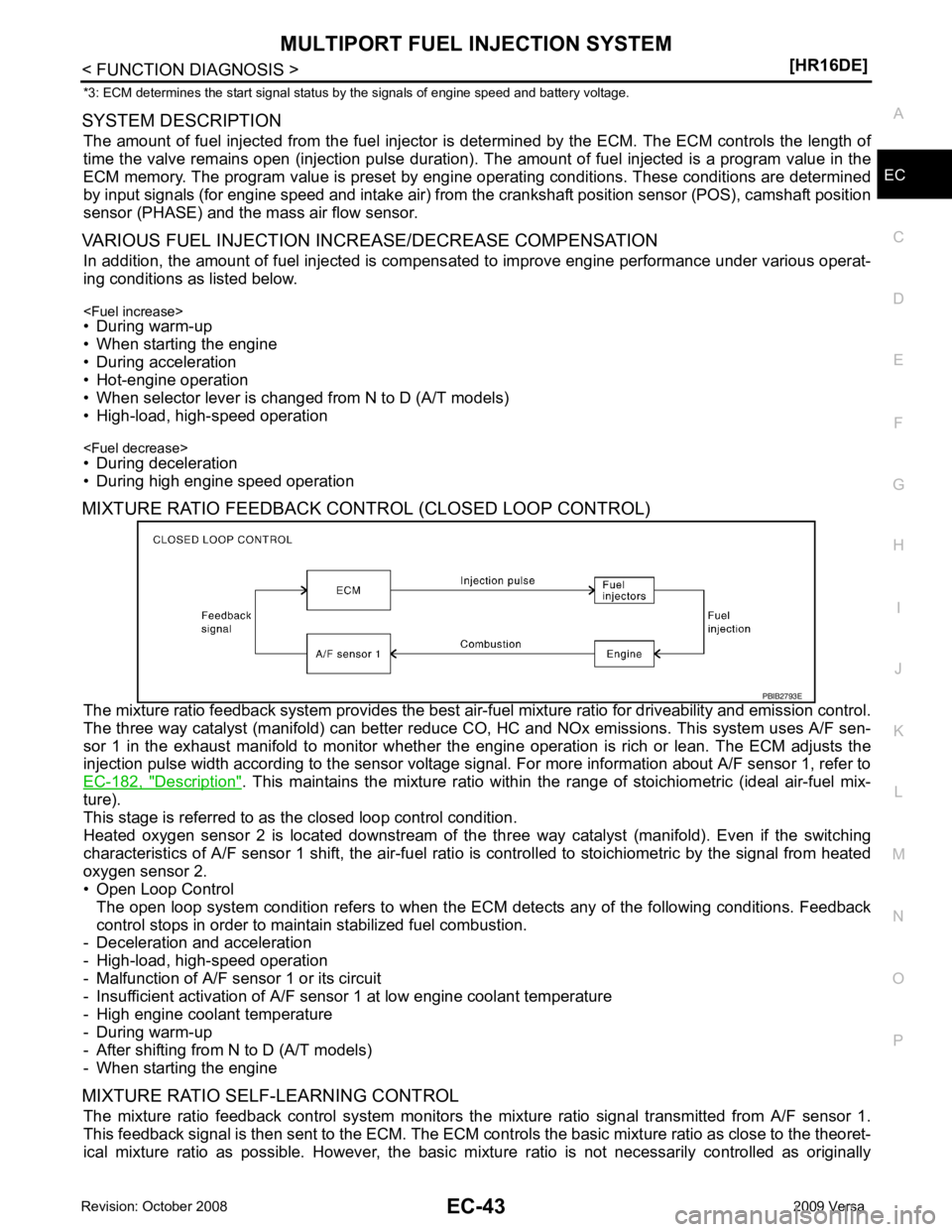

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system prov ides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can better reduce CO, HC and NOx emissions. This system uses A/F sen-

sor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The ECM adjusts the

injection pulse width according to the sensor voltage si gnal. For more information about A/F sensor 1, refer to

EC-182, " Description " . This maintains the mixture ratio within t

he range of stoichiometric (ideal air-fuel mix-

ture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of A/F sensor 1 shift, the air-fuel rati o is controlled to stoichiometric by the signal from heated

oxygen sensor 2.

• Open Loop Control

The open loop system condition refers to when the EC M detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

- Deceleration and acceleration

- High-load, high-speed operation

- Malfunction of A/F sensor 1 or its circuit

- Insufficient activation of A/F sensor 1 at low engine coolant temperature

- High engine coolant temperature

- During warm-up

- After shifting from N to D (A/T models)

- When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL The mixture ratio feedback control system monitors the mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM cont rols the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mi xture ratio is not necessarily controlled as originally

Page 1401 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual MULTIPORT FUEL INJECTION SYSTEM

EC-45

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780012

1. Ignition coil (with power transistor) and spa NISSAN TIIDA 2009 Service Workshop Manual MULTIPORT FUEL INJECTION SYSTEM

EC-45

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780012

1. Ignition coil (with power transistor) and spa](/img/5/57398/w960_57398-1400.png)

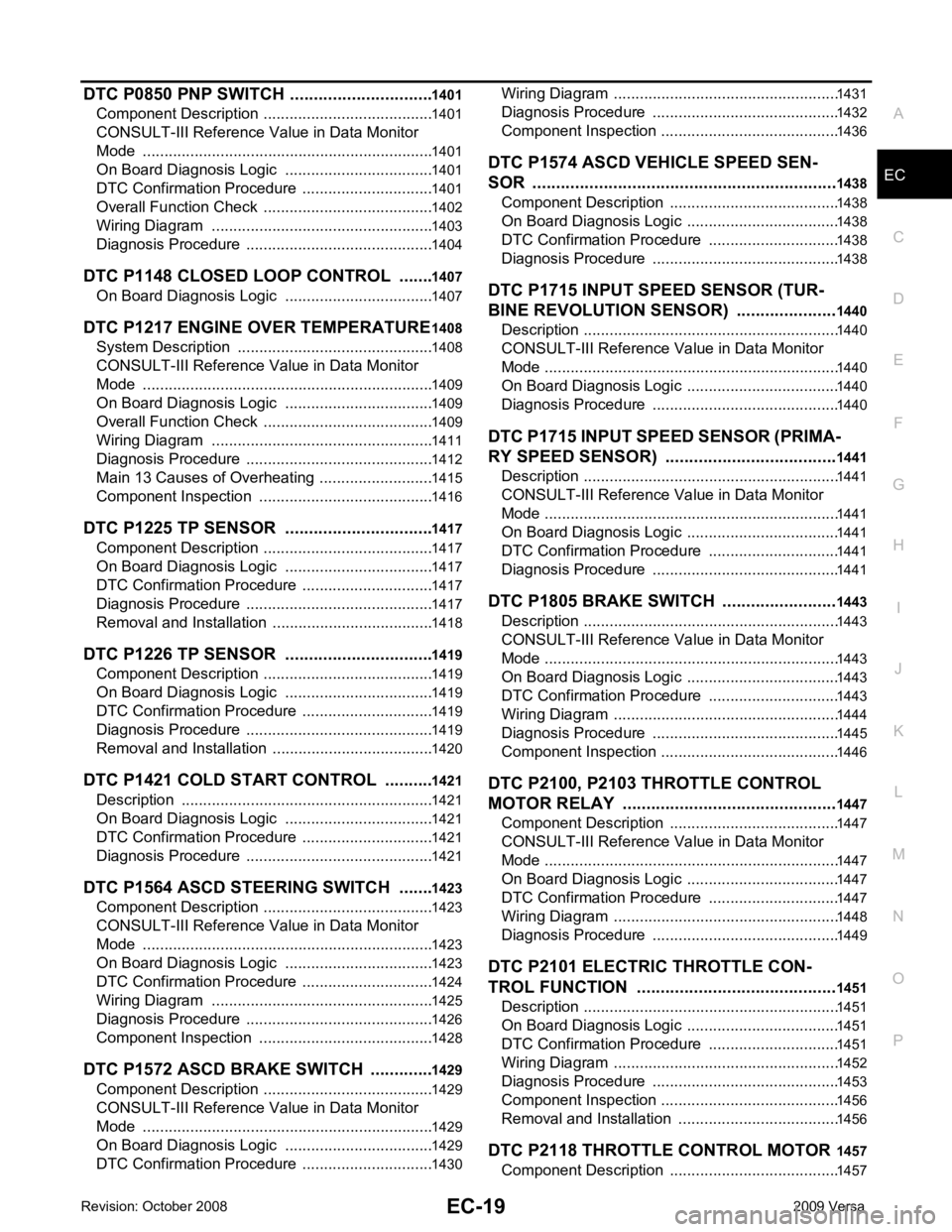

MULTIPORT FUEL INJECTION SYSTEM

EC-45

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780012

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E

Page 1402 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-46< FUNCTION DIAGNOSIS >

[HR16DE]

MULTIPORT FUEL INJECTION SYSTEM

1. Mass air flow sensor (with intake air temperature sensor) 2. Engine coolant temperature sensor 3. Electric throttle control actu NISSAN TIIDA 2009 Service Workshop Manual EC-46< FUNCTION DIAGNOSIS >

[HR16DE]

MULTIPORT FUEL INJECTION SYSTEM

1. Mass air flow sensor (with intake air temperature sensor) 2. Engine coolant temperature sensor 3. Electric throttle control actu](/img/5/57398/w960_57398-1401.png)

EC-46< FUNCTION DIAGNOSIS >

[HR16DE]

MULTIPORT FUEL INJECTION SYSTEM

1. Mass air flow sensor (with intake air temperature sensor) 2. Engine coolant temperature sensor 3. Electric throttle control actuator

4. Camshaft position sensor (PHASE) 5. Ignition coil (with power transistor) 6. Fuel injector

7. EVAP canister purge volume control solenoid valve

Vehicle front PBIB2940E

Page 1407 of 4331

EC

NP

O

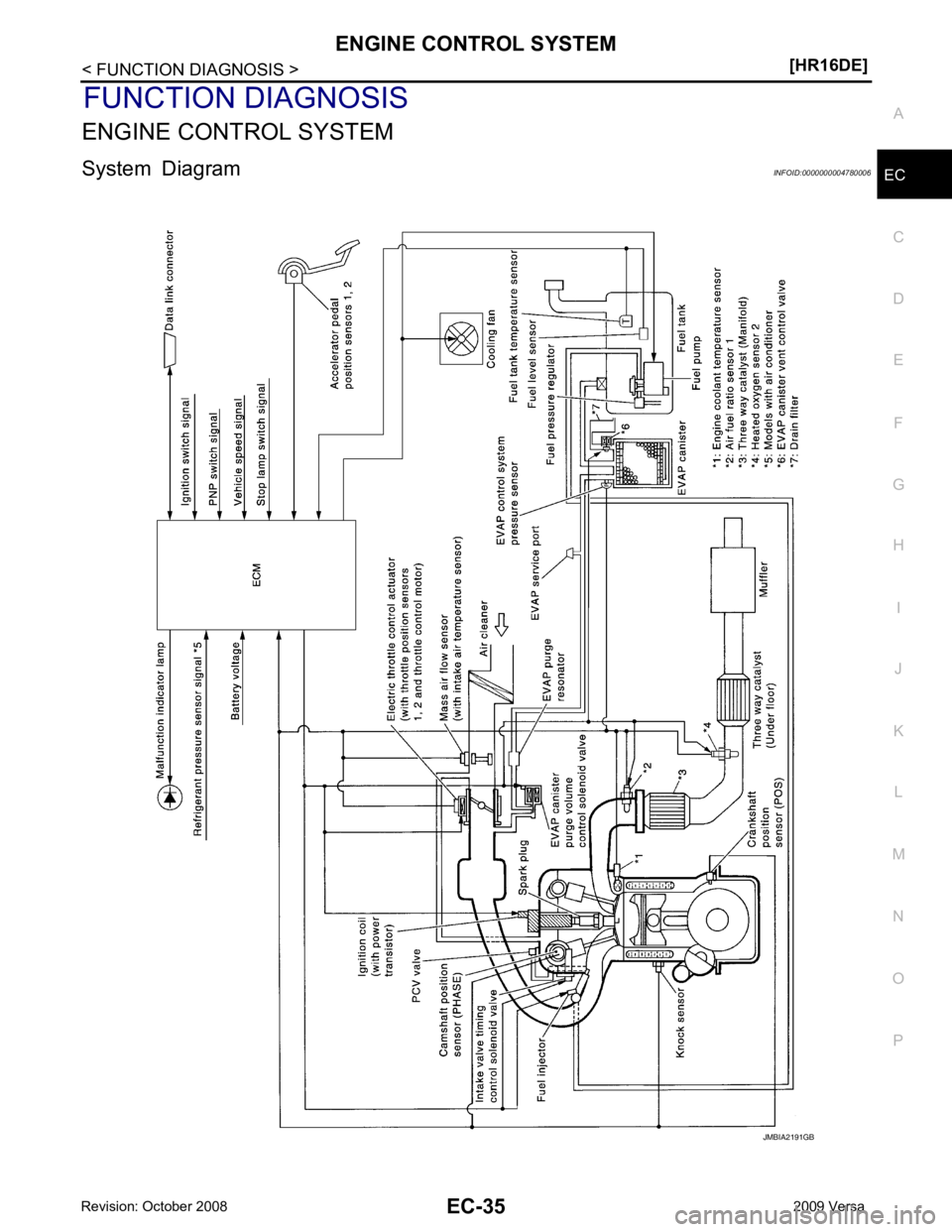

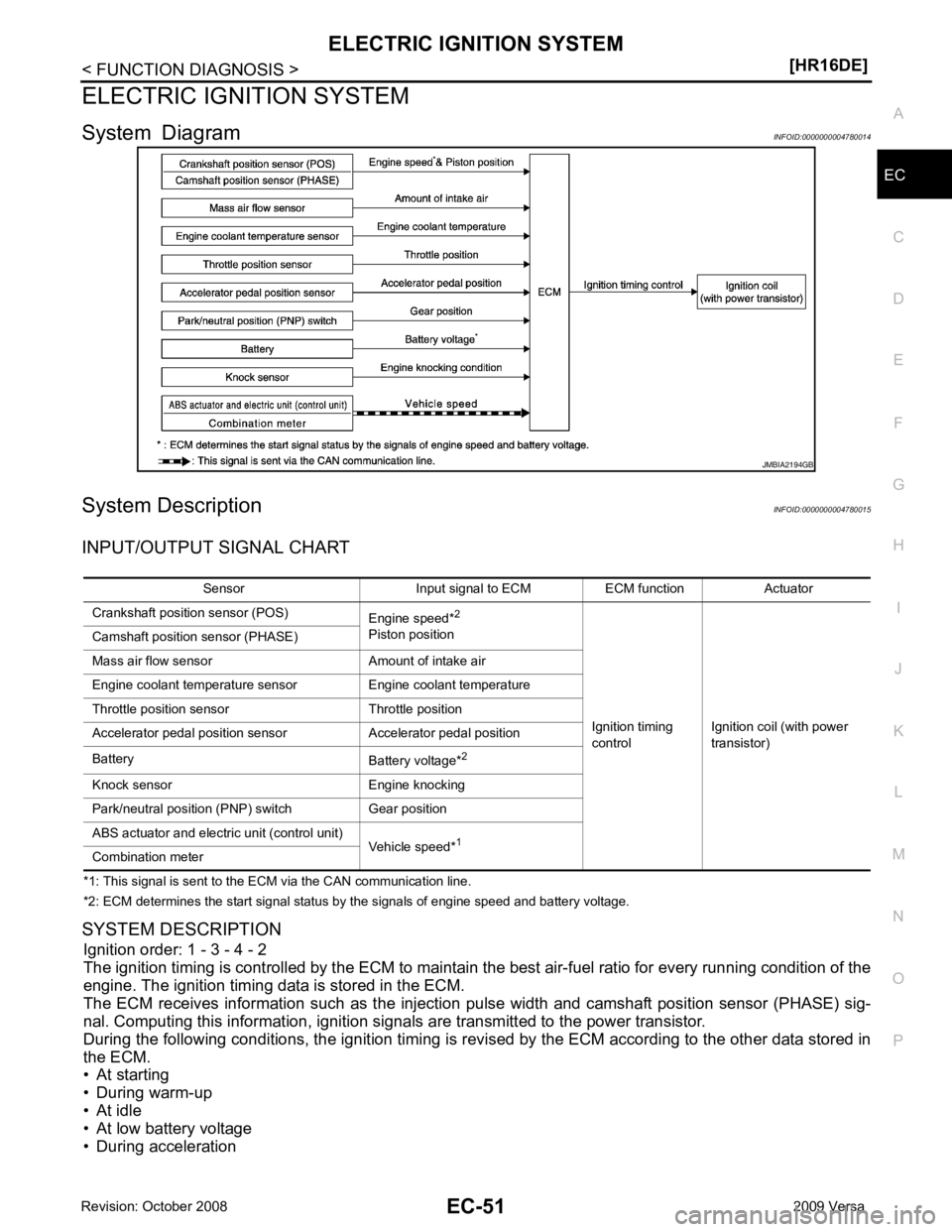

ELECTRIC IGNITION SYSTEM

System Diagram INFOID:0000000004780014

System Description INFOID:0000000004780015

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM via the CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION Ignition order: 1 - 3 - 4 - 2

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injecti on pulse width and camshaft position sensor (PHASE) sig-

nal. Computing this information, ignition si gnals are transmitted to the power transistor.

During the following conditions, the ignition timing is revi sed by the ECM according to the other data stored in

the ECM.

• At starting

• During warm-up

• At idle

• At low battery voltage

• During acceleration

Page 1408 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-52< FUNCTION DIAGNOSIS >

[HR16DE]

ELECTRIC IGNITION SYSTEM

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-k NISSAN TIIDA 2009 Service Workshop Manual EC-52< FUNCTION DIAGNOSIS >

[HR16DE]

ELECTRIC IGNITION SYSTEM

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-k](/img/5/57398/w960_57398-1407.png)

EC-52< FUNCTION DIAGNOSIS >

[HR16DE]

ELECTRIC IGNITION SYSTEM

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Component Parts Location INFOID:0000000004780016

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E