engine control unit NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 858 of 4331

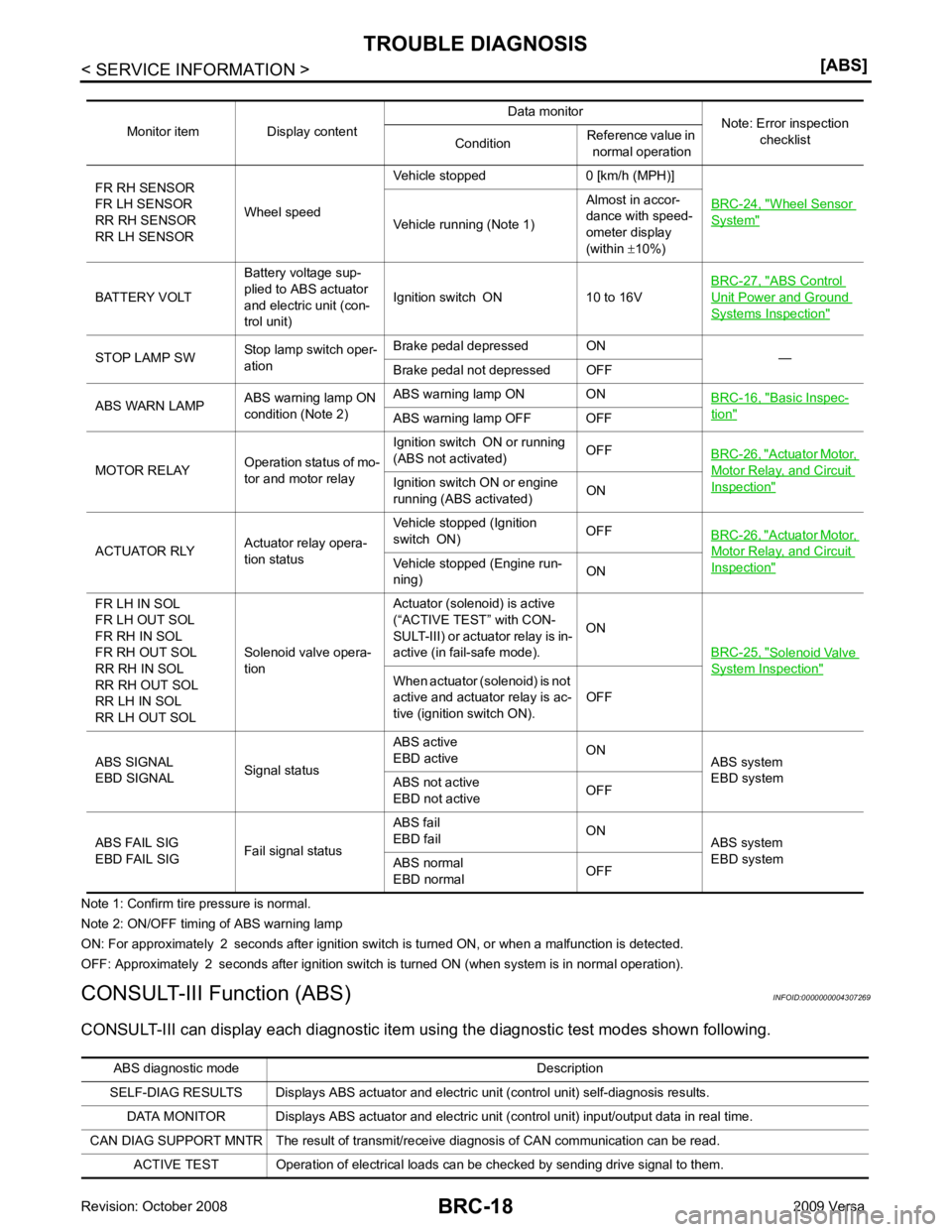

Wheel Sensor

System "

Vehicle running (Note 1)

Almost in accor-

dance with speed-

ometer display

(within ±10%)

BATTERY VOLT Battery voltage sup-

plied to ABS actuator

and electric unit (con-

trol unit) Ignition switch ON 10 to 16V

BRC-27, " ABS Control

Unit Power and Ground

Systems Inspection "

STOP LAMP SW

Stop lamp switch oper-

ation Brake pedal depressed ON

—

Brake pedal not depressed OFF

ABS WARN LAMP ABS warning lamp ON

condition (Note 2) ABS warning lamp ON ON

BRC-16, " Basic Inspec-

tion "

ABS warning lamp OFF OFF

MOTOR RELAY Operation status of mo-

tor and motor relay Ignition switch ON or running

(ABS not activated) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Ignition switch ON or engine

running (ABS activated) ON

ACTUATOR RLY Actuator relay opera-

tion status Vehicle stopped (Ignition

switch ON) OFF

BRC-26, " Actuator Motor,

Motor Relay, and Circuit

Inspection "Vehicle stopped (Engine run-

ning) ON

FR LH IN SOL

FR LH OUT SOL

FR RH IN SOL

FR RH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL Solenoid valve opera-

tion Actuator (solenoid) is active

(“ACTIVE TEST” with CON-

SULT-III) or actuator relay is in-

active (in fail-safe mode). ON

BRC-25, " Solenoid Valve

System Inspection "

When actuator (solenoid) is not

active and actuator relay is ac-

tive (ignition switch ON). OFF

ABS SIGNAL

EBD SIGNAL Signal statusABS active

EBD active ON

ABS system

EBD system

ABS not active

EBD not active OFF

ABS FAIL SIG

EBD FAIL SIG Fail signal statusABS fail

EBD fail ON

ABS system

EBD system

ABS normal

EBD normal OFFABS diagnostic mo

de Description

SELF-DIAG RESULTS Displays ABS actuator and electric unit (control unit) self-diagnosis results.

DATA MONITOR Displays ABS actuator and electric unit (control unit) input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Page 859 of 4331

BRC

N

O P

SELF-DIAGNOSIS

Description If an error is detected in the system, the ABS warning lamp will turn on. In this case, perform self-diagnosis as

follows:

Operation Procedure 1. Turn ignition switch OFF.

2. Connect CONSULT-III to the data link connector.

3. Turn ignition switch ON.

4. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

5. After stopping the vehicle, with the engine running, t ouch “ABS”, “SELF-DIAG RESULTS” in order on the

CONSULT-III screen.

6. The self-diagnostic results are displayed. (If nece ssary, the self-diagnostic results can be printed out by

touching “PRINT”.)

• When “NO DTC IS DETECTED” is displayed, check the ABS warning lamp.

7. Conduct the appropriate inspection from the display item list, and repair or replace the malfunctioning

component.

8. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

• When a wheel sensor “short-circuit” is detected, if the vehicle is not driven at 30 km/h (19 MPH)

for at least 1 minute, the ABS warn ing lamp will not turn off even if the malfunction is repaired.

9. Turn ignition switch OFF to prepare for erasing the memory.

10. Start the engine and touch “ABS”, “SELF-DIAG RESU LTS”, “ERASE” in order on the CONSULT-III screen

to erase the error memory.

If “ABS” is not indicated, go to GI-36, " CONSULT-III Data Link Connector (DLC) Circuit " .

CAUTION:

If the error memory is not erased, re -conduct the operation from step 5.

11. For the final inspection, drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute and

confirm that the ABS warning lamp is off.

Display Item List FUNCTION TEST Conducted by CONSULT-III in

stead of a technician to determine whether each sy stem is "OK" or "NG".

ECU PART NUMBER ABS actuator and electric unit (control unit) part number can be read.

ABS diagnostic mode Description

Page 875 of 4331

BRC

N

O P

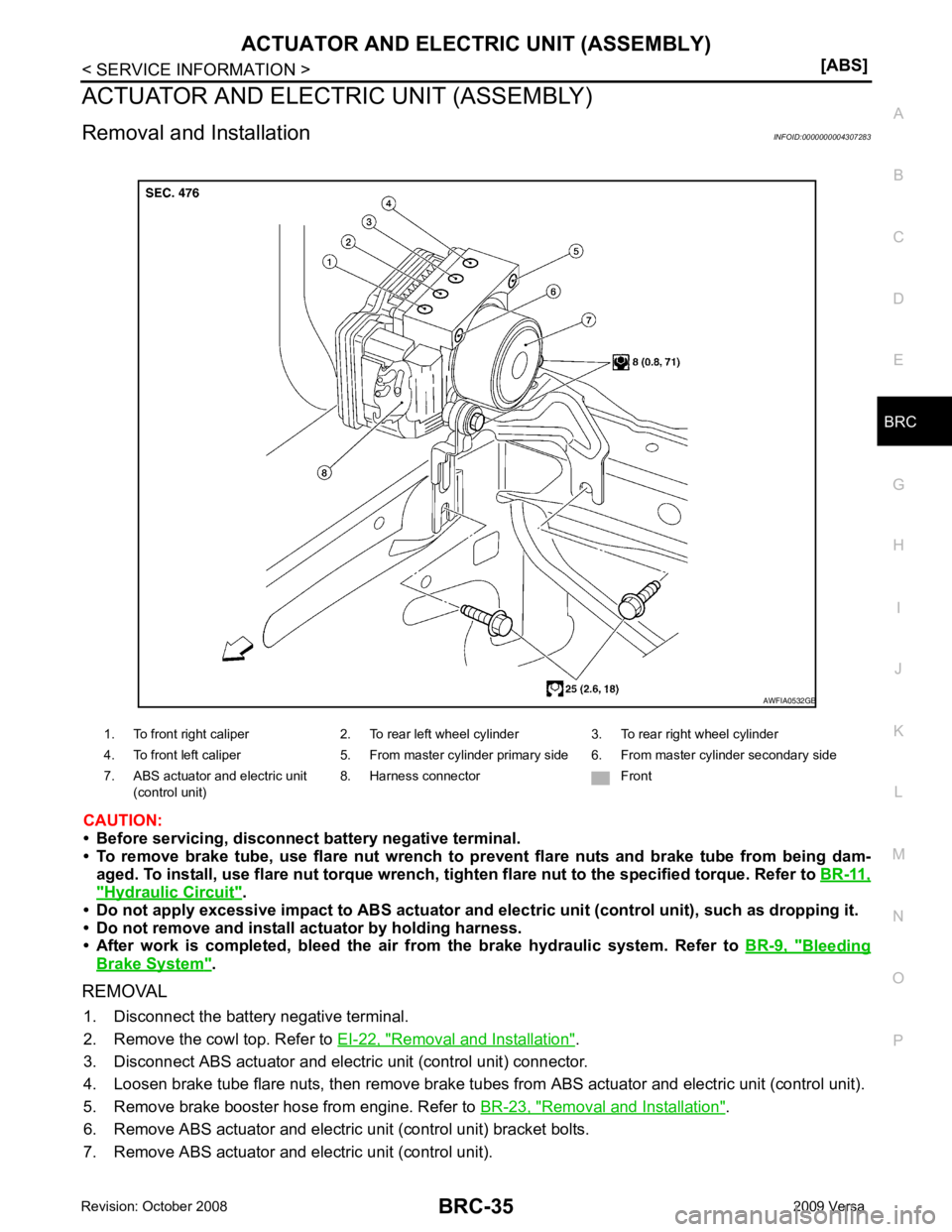

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and Installation INFOID:0000000004307283

CAUTION:

• Before servicing, disconnect battery negative terminal.

• To remove brake tube, use flare nut wrench to pr event flare nuts and brake tube from being dam-

aged. To install, use flare nut torque wrench, ti ghten flare nut to the specified torque. Refer to BR-11," Hydraulic Circuit " .

• Do not apply excessive impact to ABS actuator and elect ric unit (control unit), such as dropping it.

• Do not remove and install actuator by holding harness.

• After work is completed, bleed the air from the brake hydraulic system. Refer to BR-9, " Bleeding

Brake System " .

REMOVAL 1. Disconnect the battery negative terminal.

2. Remove the cowl top. Refer to EI-22, " Removal and Installation " .

3. Disconnect ABS actuator and electric unit (control unit) connector.

4. Loosen brake tube flare nuts, then remove brake tubes from ABS actuator and electric unit (control unit).

5. Remove brake booster hose from engine. Refer to BR-23, " Removal and Installation " .

6. Remove ABS actuator and electric unit (control unit) bracket bolts.

7. Remove ABS actuator and electric unit (control unit). 1. To front right caliper 2. To rear left wheel cylinder 3. To rear right wheel cylinder

4. To front left caliper 5. From master cylinder primary side 6. From master cylinder secondary side

7. ABS actuator and electric unit (control unit) 8. Harness connector Front

Page 897 of 4331

CO

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784387

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004784348

NOTE:

• This Procedure is applied only to models with Inte lligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 945 of 4331

CVT

N

O P

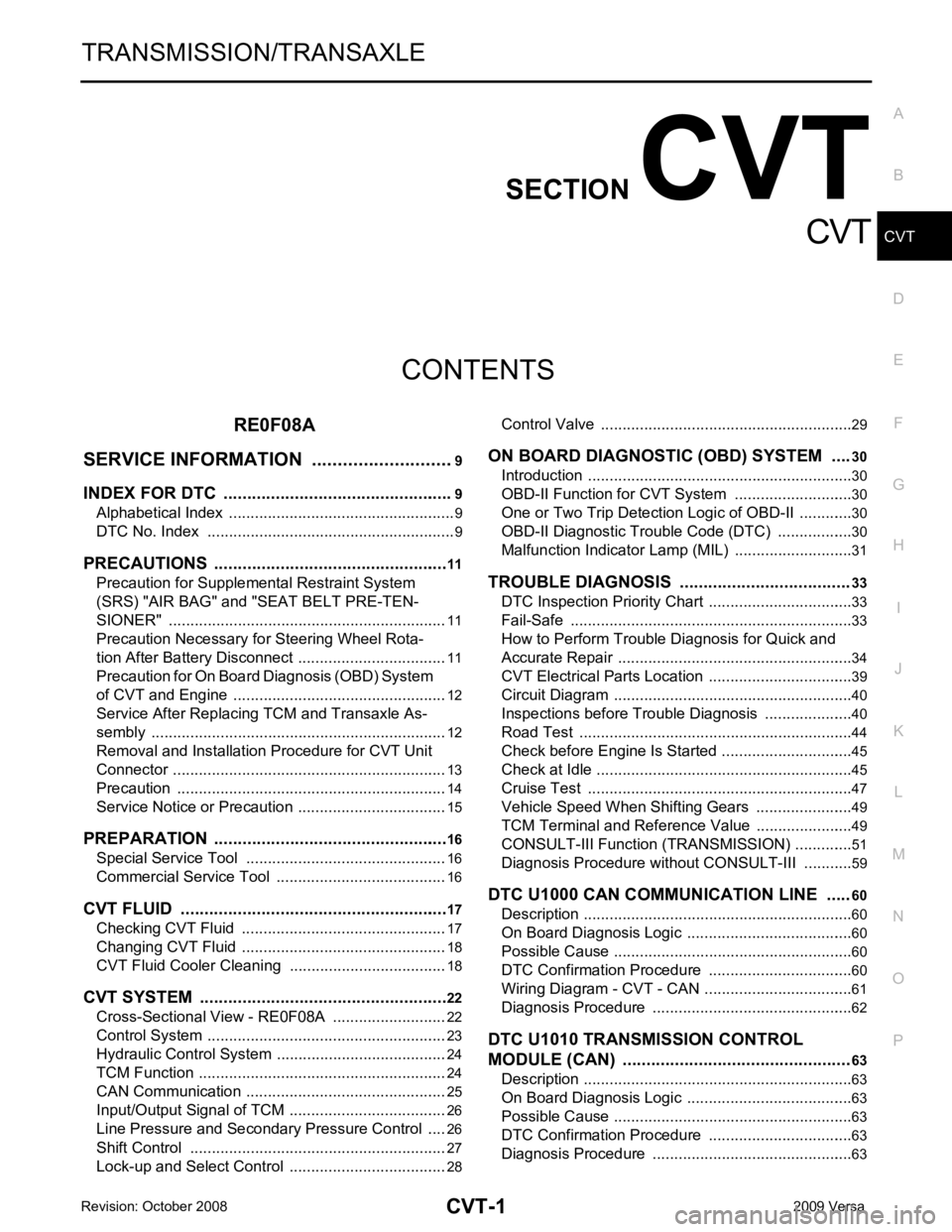

CONTENTS

CVT

RE0F08A

SERVICE INFORMATION .. ..........................

9

INDEX FOR DTC ............................................ .....9

Alphabetical Index ............................................... ......9

DTC No. Index .................................................... ......9

PRECAUTIONS .............................................. ....11

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

11

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ....

11

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine .............................................. ....

12

Service After Replacing TCM and Transaxle As-

sembly ................................................................. ....

12

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ....

13

Precaution ........................................................... ....14

Service Notice or Precaution ............................... ....15

PREPARATION .............................................. ....16

Special Service Tool ........................................... ....16

Commercial Service Tool .................................... ....16

CVT FLUID ..................................................... ....17

Checking CVT Fluid ............................................ ....17

Changing CVT Fluid ............................................ ....18

CVT Fluid Cooler Cleanin g .....................................18

CVT SYSTEM ... .............................................. ....22

Cross-Sectional View - RE0F08A ....................... ....22

Control System .................................................... ....23

Hydraulic Control System ........................................24

TCM Function ...................................................... ....24

CAN Communication ........................................... ....25

Input/Output Signal of TCM ................................. ....26

Line Pressure and Secondary Pressure Control . ....26

Shift Control ........................................................ ....27

Lock-up and Select Control ................................. ....28 Control Valve .......................................................

....29

ON BOARD DIAGNOSTIC (OBD) SYSTEM .... 30

Introduction .......................................................... ....30

OBD-II Function for CVT System ........................ ....30

One or Two Trip Detection Logic of OBD-II ......... ....30

OBD-II Diagnostic Trouble Code (DTC) .............. ....30

Malfunction Indicator Lamp (MIL) ............................31

TROUBLE DIAGNOSIS .................................... 33

DTC Inspection Priority Chart .............................. ....33

Fail-Safe .............................................................. ....33

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ....

34

CVT Electrical Parts Location .............................. ....39

Circuit Diagram .................................................... ....40

Inspections before Trouble Diagnosis ................. ....40

Road Test ............................................................ ....44

Check before Engine Is Started ........................... ....45

Check at Idle ........................................................ ....45

Cruise Test .......................................................... ....47

Vehicle Speed When Shifting Gears ................... ....49

TCM Terminal and Refere nce Value .......................49

CONSULT-III Function (TRANSMISSION) .......... ....51

Diagnosis Procedure withou t CONSULT-III ............59

DTC U1000 CAN COMMUNICATION LINE ..... 60

Description ........................................................... ....60

On Board Diagnosis Logic ................................... ....60

Possible Cause .................................................... ....60

DTC Confirmation Procedure .............................. ....60

Wiring Diagram - CVT - CAN ............................... ....61

Diagnosis Procedure ........................................... ....62

DTC U1010 TRANSMISSION CONTROL

MODULE (CAN) ................................................ 63

Description ........................................................... ....63

On Board Diagnosis Logic ................................... ....63

Possible Cause .................................................... ....63

DTC Confirmation Procedure .............................. ....63

Diagnosis Procedure ........................................... ....63

Page 949 of 4331

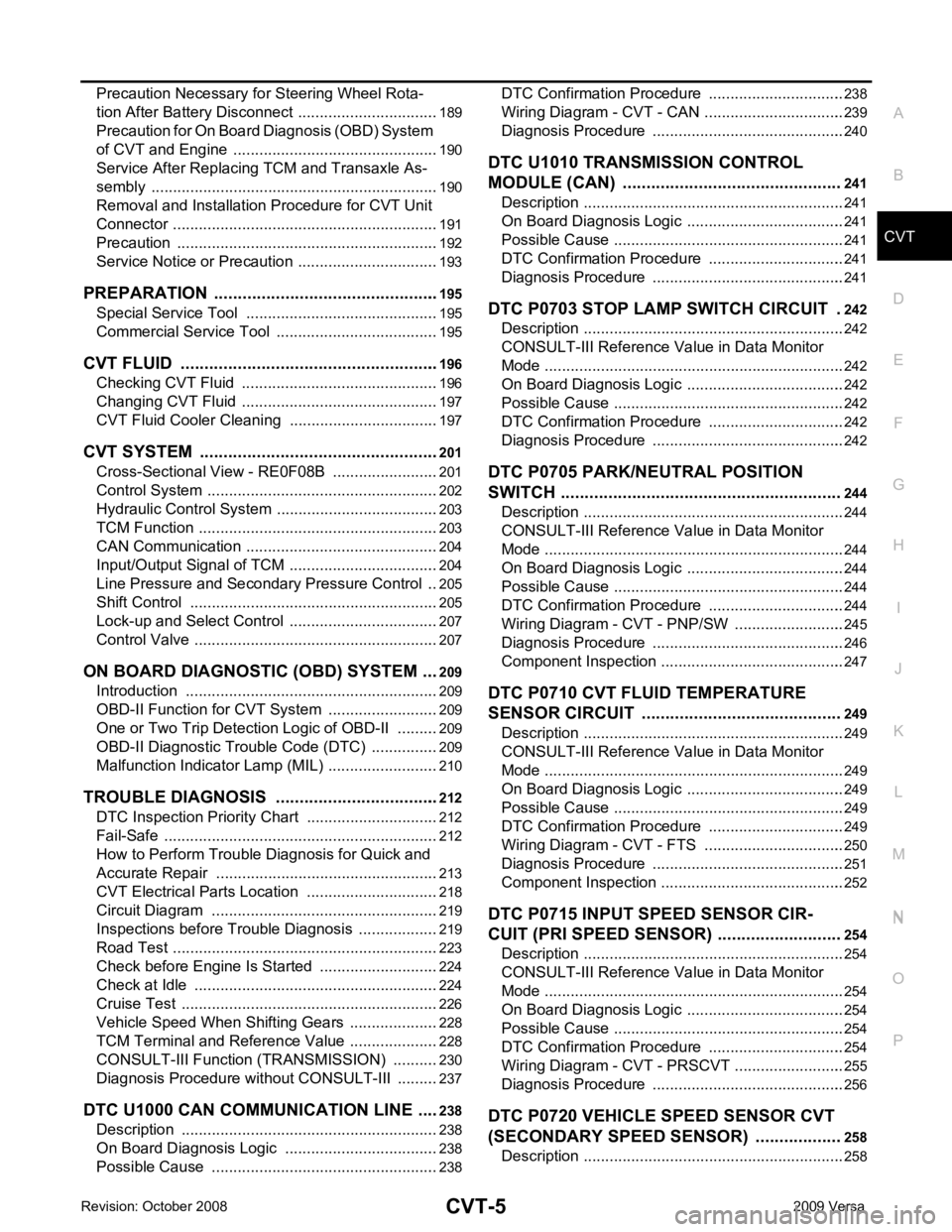

CVT

N

O

P

N

Precaution Necessary fo

r Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

189

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine .............................................. ..

190

Service After Replacing TCM and Transaxle As-

sembly ................................................................. ..

190

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ..

191

Precaution ........................................................... ..192

Service Notice or Precaution ............................... ..193

PREPARATION .............................................. ..195

Special Service Tool ........................................... ..195

Commercial Service Tool .................................... ..195

CVT FLUID ..................................................... ..196

Checking CVT Fluid ............................................ ..196

Changing CVT Fluid ............................................ ..197

CVT Fluid Cooler Cleanin g ...................................197

CVT SYSTEM ... .............................................. ..201

Cross-Sectional View - RE0F08B ....................... ..201

Control System .................................................... ..202

Hydraulic Control System ......................................203

TCM Function ...................................................... ..203

CAN Communication ........................................... ..204

Input/Output Signal of TCM ................................. ..204

Line Pressure and Secondary Pressure Control . ..205

Shift Control ........................................................ ..205

Lock-up and Select Control ................................. ..207

Control Valve ....................................................... ..207

ON BOARD DIAGNOSTIC (OBD) SYSTEM .. ..209

Introduction ......................................................... ..209

OBD-II Function for CVT System ........................ ..209

One or Two Trip Detection Logic of OBD-II ........ ..209

OBD-II Diagnostic Trouble Code (DTC) .............. ..209

Malfunction Indicator Lamp (MIL) ........................ ..210

TROUBLE DIAGNOSIS ................................. ..212

DTC Inspection Priority Chart ............................. ..212

Fail-Safe .............................................................. ..212

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........... .........................................

213

CVT Electrical Parts Location ............................. ..218

Circuit Diagram ................................................... ..219

Inspections before Trouble Diagnosis ................. ..219

Road Test ............................................................ ..223

Check before Engine Is Started ............................224

Check at Idle ....................................................... ..224

Cruise Test .......................................................... ..226

Vehicle Speed When Shifting Gears ................... ..228

TCM Terminal and Reference Value ................... ..228

CONSULT-III Function (TRANSMISSION) ......... ..230

Diagnosis Procedu re without CONSULT-III ........ ..237

DTC U1000 CAN COMMUNICATION LINE ... ..238

Description .......................................................... ..238

On Board Diagnosis Logic .................................. ..238

Possible Cause ................................................... ..238 DTC Confirmation Procedure ..............................

..238

Wiring Diagram - CVT - CAN ............................... ..239

Diagnosis Procedure ........................................... ..240

DTC U1010 TRANSMISSION CONTROL

MODULE (CAN) .............................................. 241

Description ........................................................... ..241

On Board Diagnosis Logic ................................... ..241

Possible Cause .................................................... ..241

DTC Confirmation Procedure .............................. ..241

Diagnosis Procedure ........................................... ..241

DTC P0703 STOP LAMP SWITCH CIRCUIT . 242

Description ........................................................... ..242

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

242

On Board Diagnosis Logic ................................... ..242

Possible Cause .................................................... ..242

DTC Confirmation Procedure .............................. ..242

Diagnosis Procedure ........................................... ..242

DTC P0705 PARK/NEUTRAL POSITION

SWITCH ........................................................... 244

Description ........................................................... ..244

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

244

On Board Diagnosis Logic ................................... ..244

Possible Cause .................................................... ..244

DTC Confirmation Procedure .............................. ..244

Wiring Diagram - CVT - PNP/SW ........................ ..245

Diagnosis Procedure ........................................... ..246

Component Inspection ......................................... ..247

DTC P0710 CVT FLUID TEMPERATURE

SENSOR CIRCUIT .......................................... 249

Description ........................................................... ..249

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

249

On Board Diagnosis Logic ................................... ..249

Possible Cause .................................................... ..249

DTC Confirmation Procedure .............................. ..249

Wiring Diagram - CVT - FTS ............................... ..250

Diagnosis Procedure ........................................... ..251

Component Inspection ......................................... ..252

DTC P0715 INPUT SPEED SENSOR CIR-

CUIT (PRI SPEED SENSOR) .......................... 254

Description ........................................................... ..254

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

254

On Board Diagnosis Logic ................................... ..254

Possible Cause .................................................... ..254

DTC Confirmation Procedure .............................. ..254

Wiring Diagram - CVT - PRSCVT ........................ ..255

Diagnosis Procedure ........................................... ..256

DTC P0720 VEHICLE SPEED SENSOR CVT

(SECONDARY SPEED SENSOR) .................. 258

Description ........................................................... ..258

Page 953 of 4331

CVT

N

O P

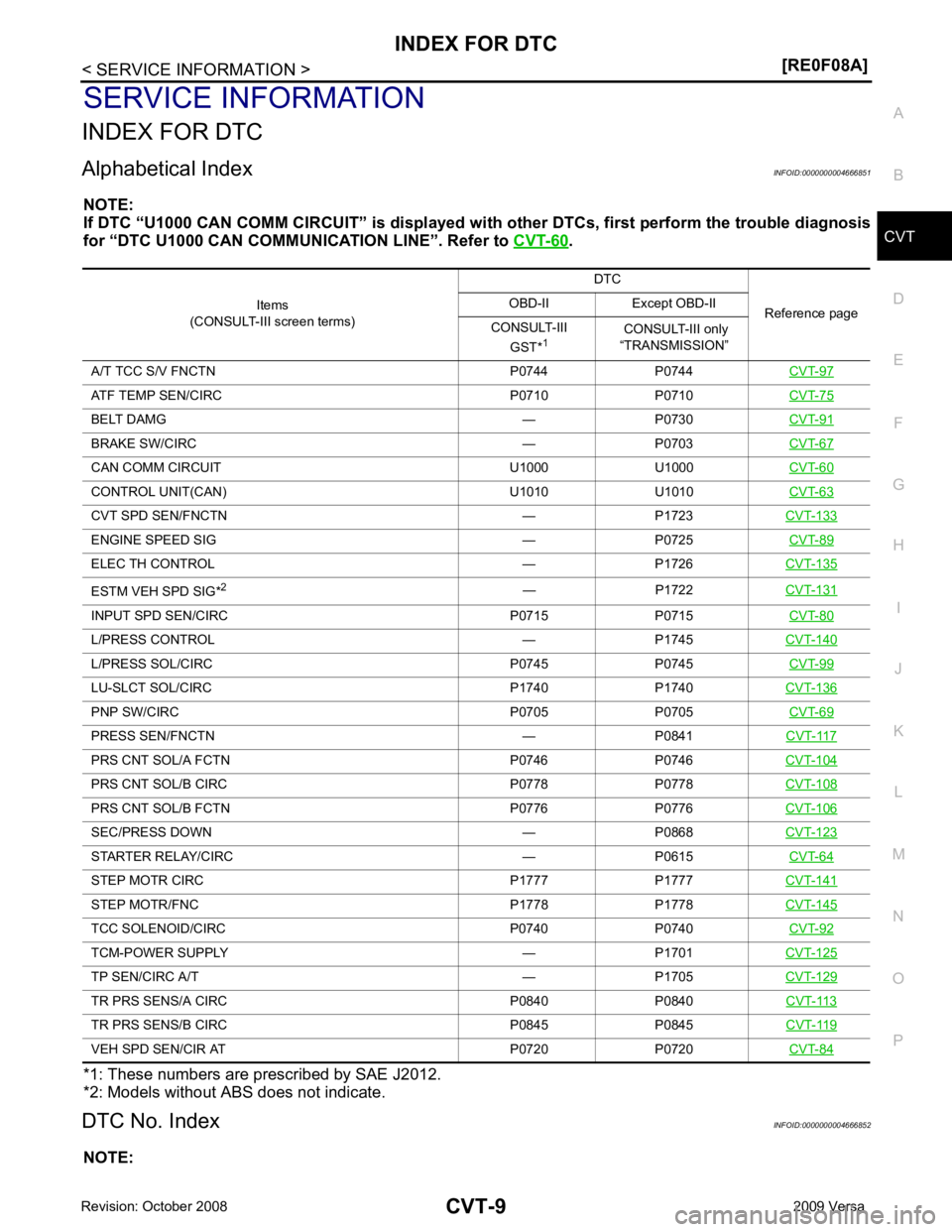

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical Index INFOID:0000000004666851

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-60 .

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC No. Index INFOID:0000000004666852

NOTE: Items

(CONSULT-III screen terms) DTC

Reference page

OBD-II Except OBD-II

CONSULT-III GST* 1 CONSULT-III only

“TRANSMISSION”

A/T TCC S/V FNCTN P0744 P0744 CVT-97ATF TEMP SEN/CIRC P0710 P0710

CVT-75BELT DAMG — P0730

CVT-91BRAKE SW/CIRC — P0703

CVT-67CAN COMM CIRCU

IT U1000 U1000 CVT-60CONTROL UNIT(CAN) U1010 U1010

CVT-63CVT SPD SEN/FNCTN — P1723

CVT-133ENGINE SPEED SIG — P0725

CVT-89ELEC TH CONTROL — P1726

CVT-135ESTM VEH SPD SIG*

2

— P1722CVT-131INPUT SPD SEN/CIRC P0715 P0715

CVT-80L/PRESS CONTROL — P1745

CVT-140L/PRESS SOL/CIRC P0745 P0745

CVT-99LU-SLCT SOL/CIRC P1740 P1740

CVT-136PNP SW/CIRC P0705 P0705

CVT-69PRESS SEN/FNCTN — P0841

CVT-117PRS CNT SOL/A FCTN P0746 P0746

CVT-104PRS CNT SOL/B CIRC P0778 P0778

CVT-108PRS CNT SOL/B FCTN P0776 P0776

CVT-106SEC/PRESS DOWN — P0868

CVT-123STARTER RELAY/CIRC — P0615

CVT-64STEP MOTR CIRC P1777 P1777

CVT-141STEP MOTR/FNC P1778 P1778

CVT-145TCC SOLENOID/CIRC P0740 P0740

CVT-92TCM-POWER SUPPLY — P1701

CVT-125TP SEN/CIRC A/T — P1705

CVT-129TR PRS SENS/A CIRC P0840 P0840

CVT-113TR PRS SENS/B CIRC P0845 P0845

CVT-119VEH SPD SEN/CIR AT P0720 P0720

CVT-84

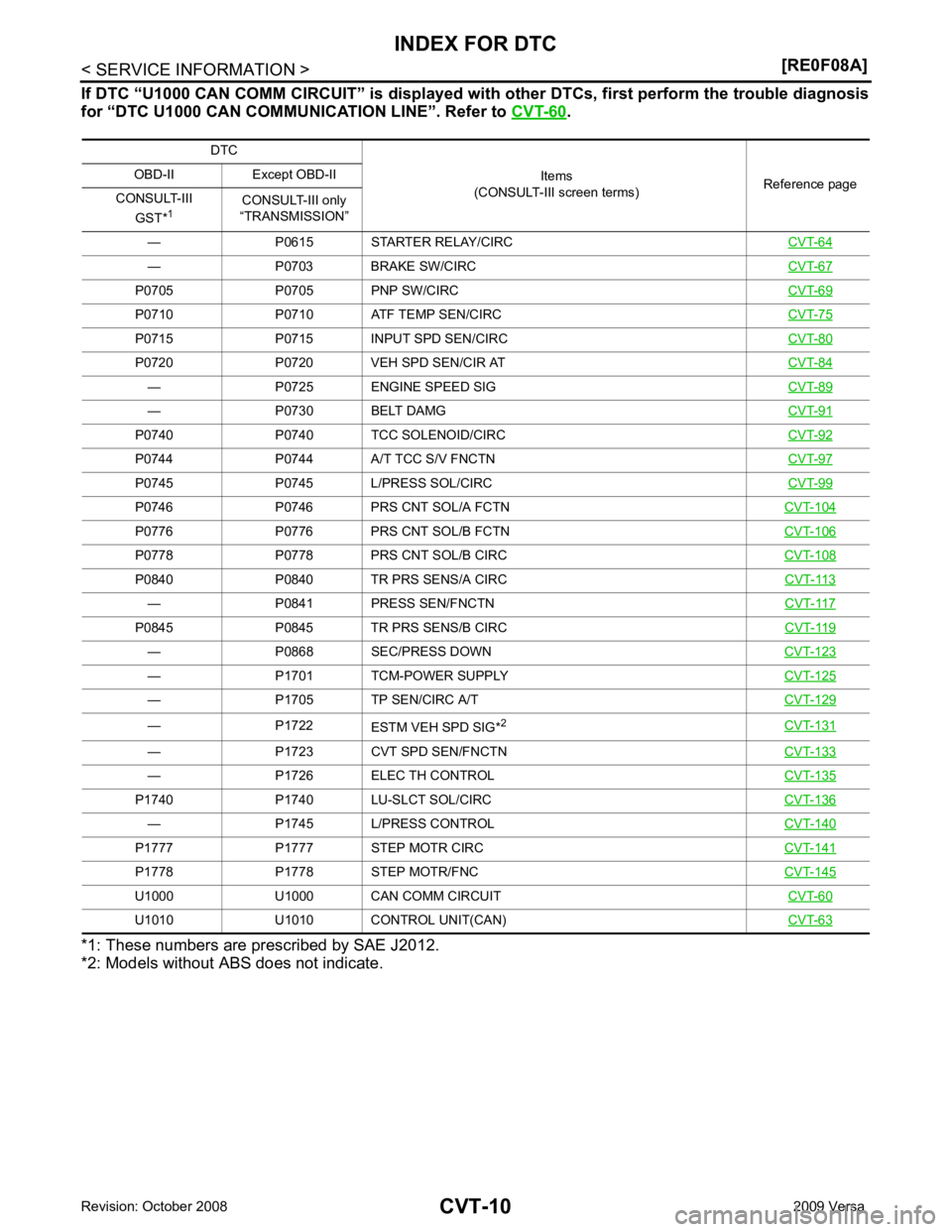

Page 954 of 4331

.

*1: These numbers are pr escribed by SAE J2012.

*2: Models without ABS does not indicate. DTC

Items

(CONSULT-III screen terms) Reference page

OBD-II Except OBD-II

CONSULT-III GST* 1 CONSULT-III only

“TRANSMISSION”

— P0615 STARTER RELAY/CIRC CVT-64— P0703 BRAKE SW/CIRC

CVT-67P0705 P0705 PNP SW/CIRC

CVT-69P0710 P0710 ATF TEMP SEN/CIRC

CVT-75P0715 P0715 INPUT SPD SEN/CIRC

CVT-80P0720 P0720 VEH SPD SEN/CIR AT

CVT-84— P0725 ENGINE SPEED SIG

CVT-89— P0730 BELT DAMG

CVT-91P0740 P0740 TCC SOLENOID/CIRC

CVT-92P0744 P0744 A/T TCC S/V FNCTN

CVT-97P0745 P0745 L/PRESS SOL/CIRC

CVT-99P0746 P0746 PRS CNT SOL/A FCTN

CVT-104P0776 P0776 PRS CNT SOL/B FCTN

CVT-106P0778 P0778 PRS CNT SOL/B CIRC

CVT-108P0840 P0840 TR PRS SENS/A CIRC

CVT-113— P0841 PRESS SEN/FNCTN

CVT-117P0845 P0845 TR PRS SENS/B CIRC

CVT-119— P0868 SEC/PRESS DOWN

CVT-123— P1701 TCM-POWER SUPPLY

CVT-125— P1705 TP SEN/CIRC A/T

CVT-129— P1722

ESTM VEH SPD SIG*2

CVT-131— P1723 CVT SPD SEN/FNCTN

CVT-133— P1726 ELEC TH CONTROL

CVT-135P1740 P1740 LU-SLCT SOL/CIRC

CVT-136— P1745 L/PRESS CONTROL

CVT-140P1777 P1777 STEP MOTR CIRC

CVT-141P1778 P1778 STEP MOTR/FNC

CVT-145U1000 U1000 CAN COMM CIRCUIT

CVT-60U1010 U1010 CONTROL UNIT(CAN)

CVT-63

Page 955 of 4331

CVT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004800719

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004666854

NOTE:

• This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 998 of 4331

How to Perform Trouble Diag-

nosis for Quick and Accurate Repair " . Reference pages are provided following the items.

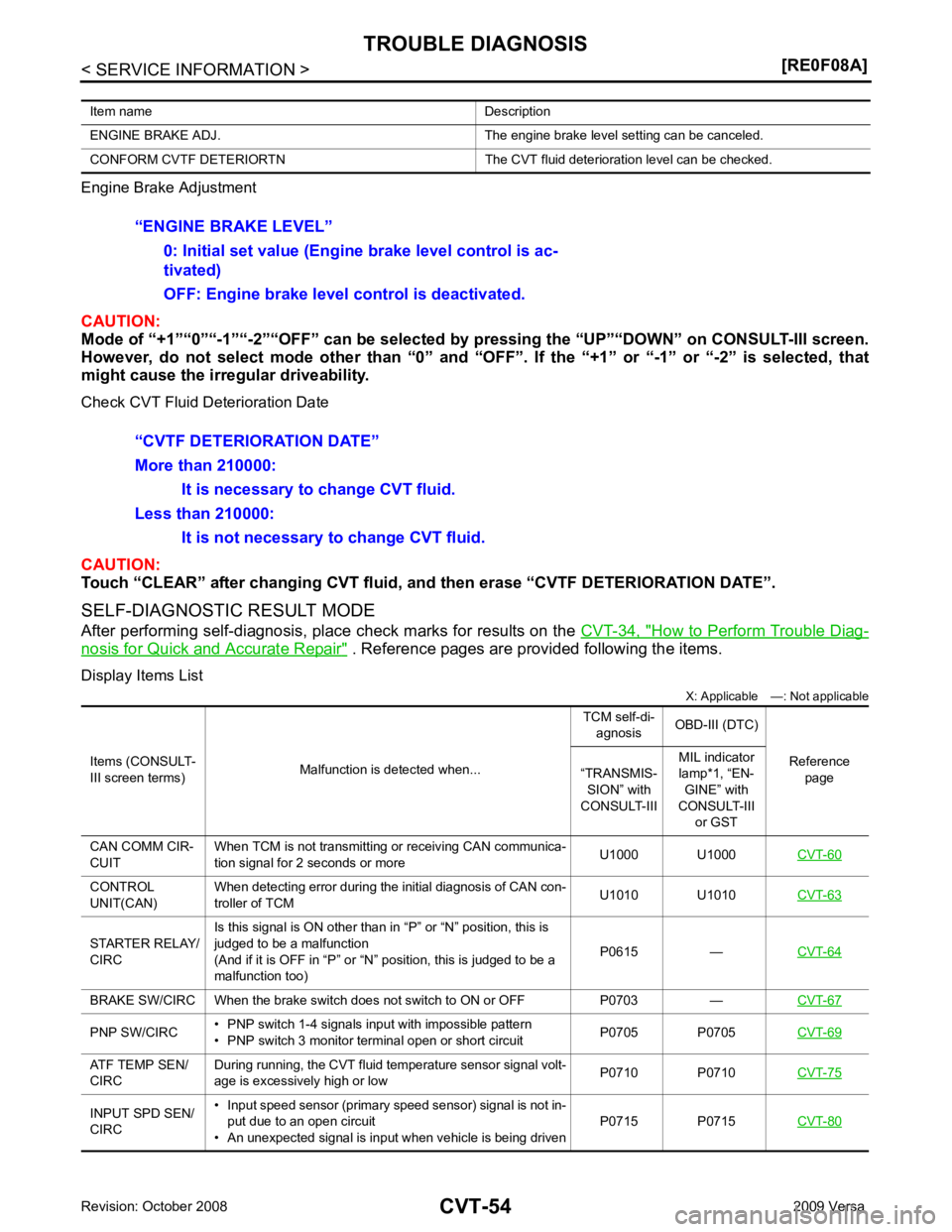

Display Items List X: Applicable —: Not applicable

Item name Description

ENGINE BRAKE ADJ. The engine brake level setting can be canceled.

CONFORM CVTF DETERIORTN The CVT fluid deterioration level can be checked. CONTROL

UNIT(CAN) When detecting error during the initial diagnosis of CAN con-

troller of TCM U1010 U1010

CVT-63STARTER RELAY/

CIRC Is this signal is ON other than in “P” or “N” position, this is

judged to be a malfunction

(And if it is OFF in “P” or “N” position, this is judged to be a

malfunction too) P0615 —

CVT-64BRAKE SW/CIRC When the brake switch does

not switch to ON or OFF P0703 — CVT-67PNP SW/CIRC

• PNP switch 1-4 signals input with impossible pattern

• PNP switch 3 monitor terminal open or short circuit P0705 P0705

CVT-69ATF TEMP SEN/

CIRC During running, the CVT fluid temperature sensor signal volt-

age is excessively high or low P0710 P0710

CVT-75INPUT SPD SEN/

CIRC • Input speed sensor (primary speed sensor) signal is not in-

put due to an open circuit

• An unexpected signal is input when vehicle is being driven P0715 P0715

CVT-80