engine control unit NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2167 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual DTC P0444, P0445 EVAP CANISTER P

URGE VOLUME CONTROL SOLENOID

VALVE

EC-811

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0444, P0445 EVAP CANISTER

PURGE VOLUME CONTROL SOLE NISSAN TIIDA 2009 Service Workshop Manual DTC P0444, P0445 EVAP CANISTER P

URGE VOLUME CONTROL SOLENOID

VALVE

EC-811

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0444, P0445 EVAP CANISTER

PURGE VOLUME CONTROL SOLE](/img/5/57398/w960_57398-2166.png)

DTC P0444, P0445 EVAP CANISTER P

URGE VOLUME CONTROL SOLENOID

VALVE

EC-811

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0444, P0445 EVAP CANISTER

PURGE VOLUME CONTROL SOLE-

NOID VALVE

Description INFOID:0000000004537300

SYSTEM DESCRIPTION

*1: The ECM determines the start signal status by the signal of engine speed and battery voltage.

*2: This signal is sent to the ECM through CAN communication line.

This system controls flow rate of fuel vapor from the EVAP canister. The opening of the vapor by-pass pas-

sage in the EVAP canister purge volume control solenoi d valve changes to control the flow rate. The EVAP

canister purge volume control solenoid valve repeats ON/O FF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engi ne control. The optimum value stored in the ECM is

determined by considering various engine conditions. When t he engine is operating, the flow rate of fuel vapor

from the EVAP canister is regulated as the air flow changes.

COMPONENT DESCRIPTION The EVAP canister purge volume control solenoid valve uses a ON/

OFF duty to control the flow rate of fuel vapor from the EVAP canis-

ter. The EVAP canister purge volume control solenoid valve is

moved by ON/OFF pulses from the ECM. The longer the ON pulse,

the greater the amount of fuel vapor that will flow through the valve.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004537301

Specification data are reference values. Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

1

EVAP canister

purge flow

control EVAP canister purge volume

control solenoid valve

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Battery Battery voltage*1

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

(Mixture ratio feedback signal)

Fuel tank temperature sensor Fuel temperature in fuel tank

ABS actuator and electric unit (control unit)

Vehicle speed*2

Combination meter PBIA9215J

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/V • Engine: After warming up

• Shift lever: N (A/T, CVT), Neutral (M/T)

• Air conditioner switch: OFF

• No load Idle

(Accelerator pedal is not depressed

even slightly, after engine starting) 0%

2,000 rpm 0 - 50%

Page 2222 of 4331

.

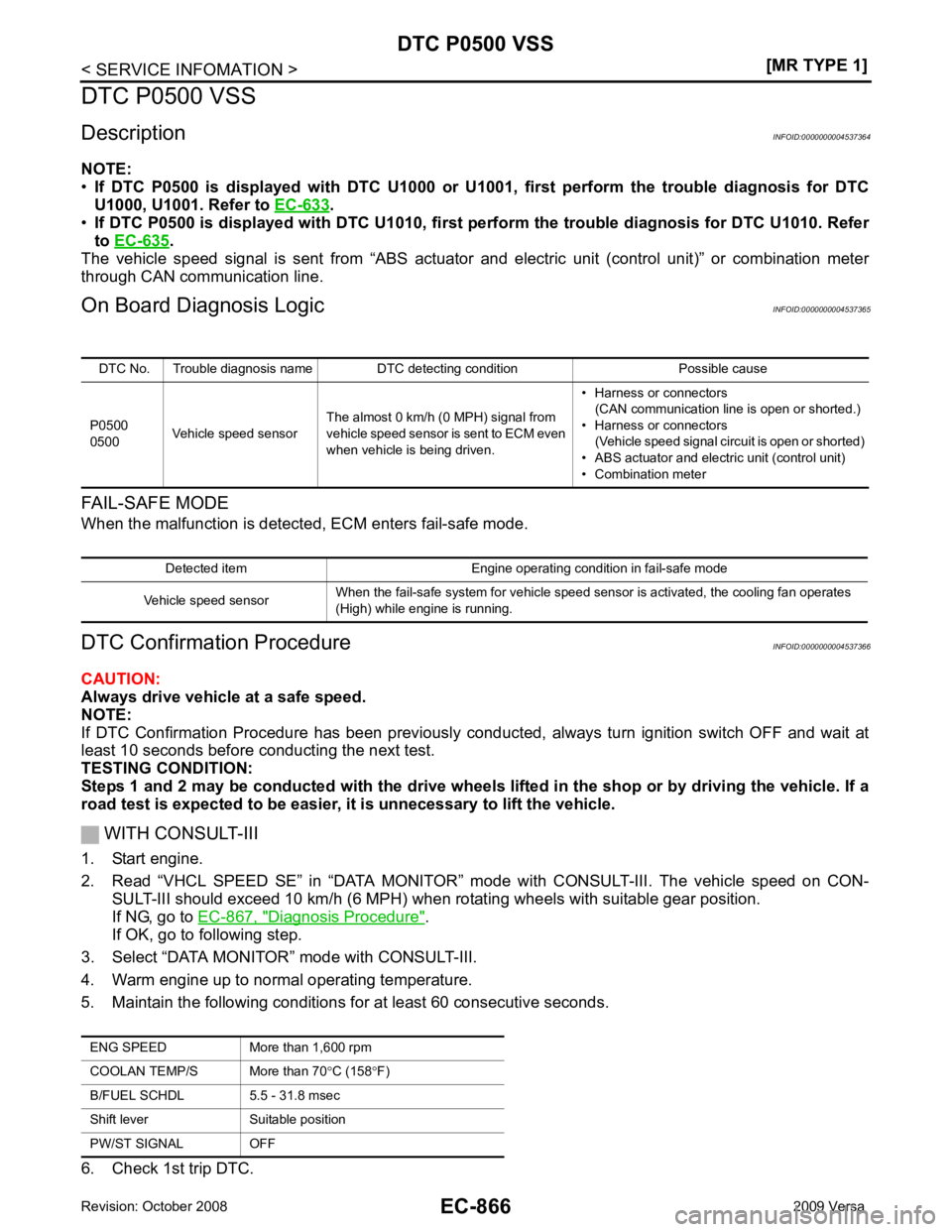

• If DTC P0500 is displayed with DTC U1010, first pe rform the trouble diagnosis for DTC U1010. Refer

to EC-635 .

The vehicle speed signal is sent from “ABS actuator and electric unit (control unit)” or combination meter

through CAN communication line.

On Board Diagn osis Logic INFOID:0000000004537365

FAIL-SAFE MODE

When the malfunction is detected, ECM enters fail-safe mode.

DTC Confirmation Procedure INFOID:0000000004537366

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels li fted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-III

1. Start engine.

2. Read “VHCL SPEED SE” in “DATA MONITOR” m ode with CONSULT-III. The vehicle speed on CON-

SULT-III should exceed 10 km/h (6 MPH) when rotating wheels with suitable gear position.

If NG, go to EC-867, " Diagnosis Procedure " .

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Warm engine up to normal operating temperature.

5. Maintain the following conditions for at least 60 consecutive seconds.

6. Check 1st trip DTC. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0500

0500 Vehicle speed sensor The almost 0 km/h (0 MPH) signal from

vehicle speed sensor is sent to ECM even

when vehicle is being driven. • Harness or connectors

(CAN communication line is open or shorted.)

• Harness or connectors (Vehicle speed signal circuit is open or shorted)

• ABS actuator and electric unit (control unit)

• Combination meter Detected item Engine operating condition in fail-safe mode

Vehicle speed sensor When the fail-safe system for vehicle speed sensor is activated, the cooling fan operates

(High) while engine is running. ENG SPEED More th

an 1,600 rpm

COOLAN TEMP/S More than 70 °C (158 °F)

B/FUEL SCHDL 5.5 - 31.8 msec

Shift lever Suitable position

PW/ST SIGNAL OFF

Page 2242 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-886< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004537393

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is NISSAN TIIDA 2009 Service Workshop Manual EC-886< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004537393

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is](/img/5/57398/w960_57398-2241.png)

EC-886< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

DTC P1217 ENGINE OVER TEMPERATURE

System Description INFOID:0000000004537393

SYSTEM DESCRIPTION

NOTE:

• If DTC P1217 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-633 .

• If DTC P1217 is displayed with DTC U1010, first pe rform the trouble diagnosis for DTC U1010. Refer

to EC-635 .

Cooling Fan Control

*1: The ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to ECM through CAN communication line.

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The contro l system has 3-step control [HIGH/LOW/OFF].

Cooling Fan Operation

Models with A/C

Models without A/C Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

1

Cooling fan

control IPDM E/R

(Cooling fan relays)

Battery

Battery voltage*1

ABS actuator and electric unit (control unit)

Vehicle speed*2

Combination meter

Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ON signal*2

Refrigerant pressure sensor Refrigerant pressure PBIB2483E

PBIB3335E

Page 2347 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual FUEL PUMP

EC-991

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004537529

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the si NISSAN TIIDA 2009 Service Workshop Manual FUEL PUMP

EC-991

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004537529

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the si](/img/5/57398/w960_57398-2346.png)

FUEL PUMP

EC-991

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

FUEL PUMP

Description INFOID:0000000004537529

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

startability. If the ECM receives a engine speed signal from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engi ne is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition s witch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The ECM does not directly drive the fuel

pump. It controls the ON/OFF fuel pump rela y, which in turn controls the fuel pump.

COMPONENT DESCRIPTION A turbine type design fuel pump is used in the fuel tank.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

• Fuel tank temperature sensor (4)

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004537530

Specification data are reference values. Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage* Condition Fuel pump operation

Ignition switch is turned to ON Operates for 1 second

Engine running and cranking Operates

Engine: Stopped Stops in 1.5 seconds

Except as shown above Stops BBIA0704E

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY • For 1 second after turning ignition switch ON

• Engine running or cranking ON

• Except above conditions OFF

Page 2380 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-1024< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and NISSAN TIIDA 2009 Service Workshop Manual EC-1024< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and](/img/5/57398/w960_57398-2379.png)

EC-1024< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine just prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it m ay adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possi ble from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body. BBIA0704E

SEF709Y

SEF708Y

Page 2384 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-1028< SERVICE INFOMATION >

[MR TYPE 2]

ENGINE CONTROL SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communi NISSAN TIIDA 2009 Service Workshop Manual EC-1028< SERVICE INFOMATION >

[MR TYPE 2]

ENGINE CONTROL SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communi](/img/5/57398/w960_57398-2383.png)

EC-1028< SERVICE INFOMATION >

[MR TYPE 2]

ENGINE CONTROL SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). T he amount of fuel injected is a program value in the

ECM memory. The program value is preset by engi ne operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from t he crankshaft position sensor (POS), camshaft position

sensor (PHASE) and the ma ss air flow sensor.

VARIOUS FUEL INJECTION I NCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compens ated to improve engine performance under various operat-

ing conditions as listed below.

• During warm-up

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D (A/T and CVT models)

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL) Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*3

Piston position

Fuel injection

& mixture ratio

control Fuel injector

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Battery Battery voltage*3

Knock sensor Engine knocking condition

EPS control unit Power steering operation*2

Heated oxygen sensor 2* 1

Density of oxygen in exhaust gas

Air conditioner switch Air conditioner operation*2

ABS actuator and electric unit (control unit)

Vehicle speed*2

Combination meter PBIB3020E

Page 2386 of 4331

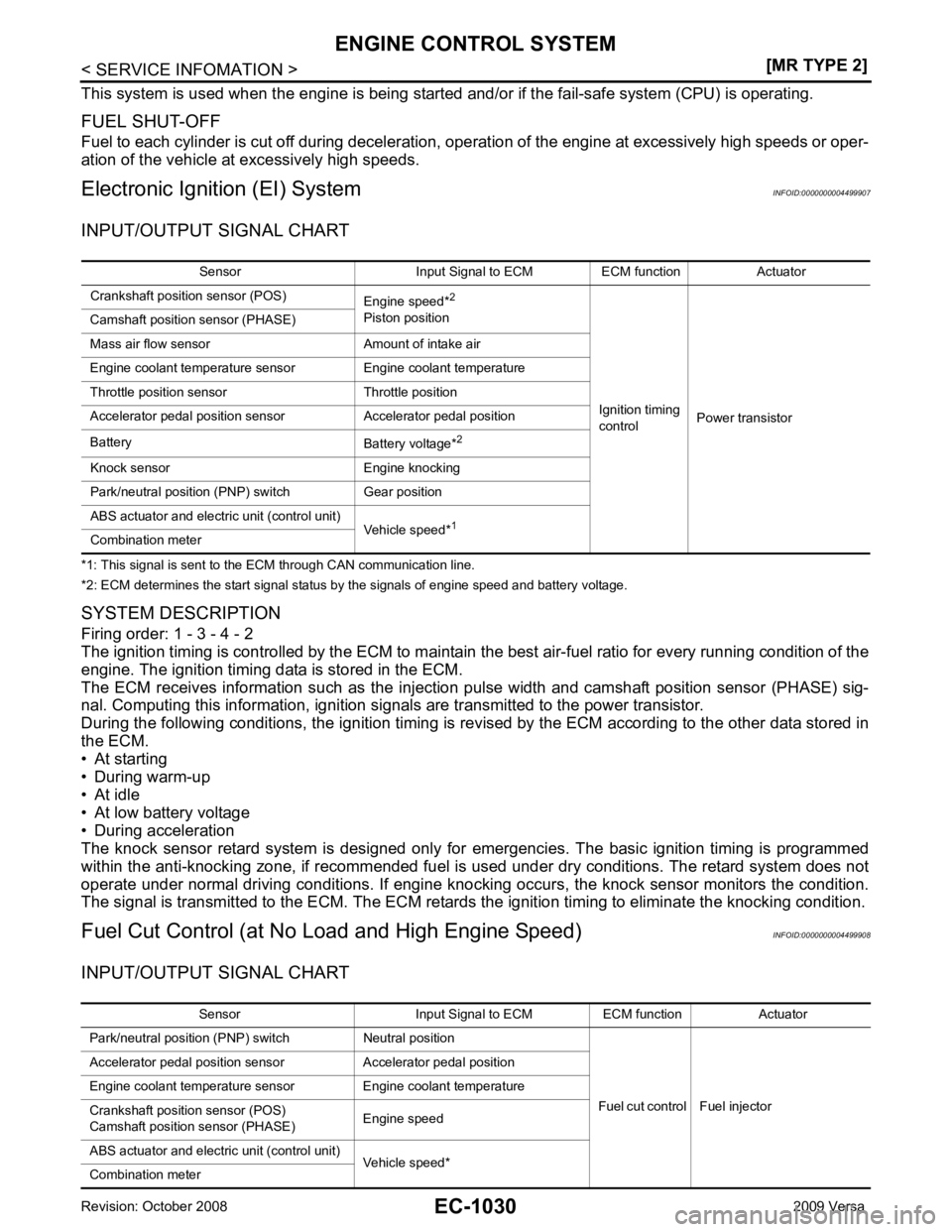

Sensor Input Signal to ECM ECM function Actuator

Park/neutral position (P NP) switch Neutral position

Fuel cut control Fuel injector

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed

ABS actuator and electric unit (control unit) Vehicle speed*

Combination meter

Page 2389 of 4331

EC

NP

O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System Description INFOID:0000000004499911

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.

BASIC ASCD SYSTEM Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric thro ttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE i ndicator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION Press MAIN switch. (The CRUISE indicato r in combination meter illuminates.)

When vehicle speed reaches a desired speed between appr oximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET indi cator in combination meter illuminates.)

ACCELERATE OPERATION If the RESUME/ACCELERATE switch is depressed during cruise control driving, increase the vehicle speed

until the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION When any of following conditions exis t, cruise operation will be canceled.

• CANCEL switch is pressed

• More than two switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Clutch pedal is depressed or gear position is changed to the neutral position (M/T models)

• Selector lever is changed to N, P, R position (A/T and CVT models)

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

• Engine coolant temperature is slightly higher than the normal operating temperature, CRUISE lamp may

blink slowly.

When the engine coolant temperature decreases to t he normal operating temperature, CRUISE lamp will

stop blinking and the cruise operation will be able to work by pressing SET/COAST switch or RESUME/

ACCELERATE switch.

• Malfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed controlElectric throttle control

actuator

Stop lamp switch Brake pedal operation

ASCD clutch switch (M/T models) Clutch pedal operation

ASCD steering switch ASCD steering switch operation

Park/neutral position (PNP) switch Gear position

ABS actuator and electric unit (con-

trol unit) Vehicle speed*

Combination meter

TCM Powertrain revolution*

Page 2453 of 4331

EC

NP

O

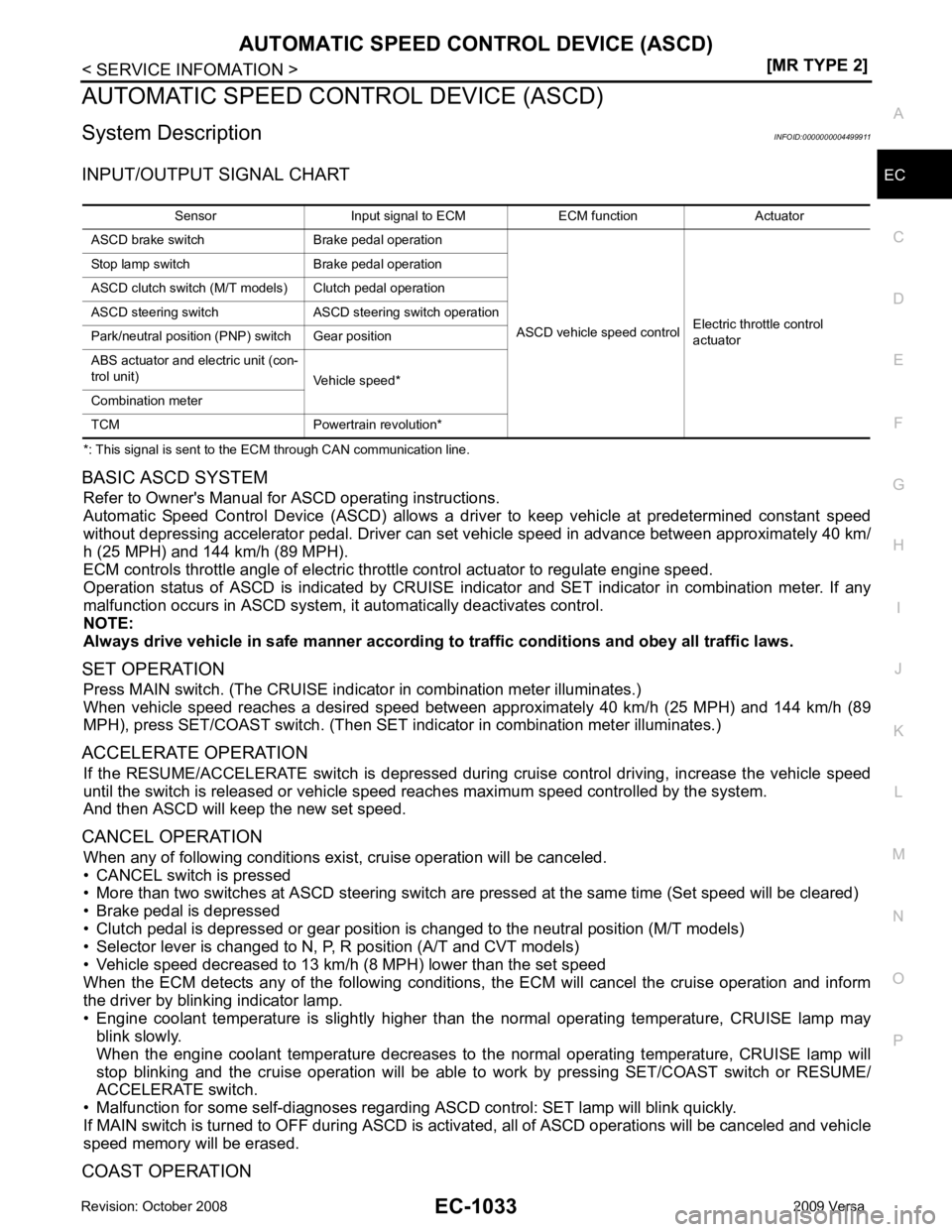

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & OTHER Intake valve timing control solenoid valve cir-

cuit 3 2 1 3 2 2 3 3

EC-1165Park/neutral position (P

NP) switch circuit 3 3 3 3 3 EC-1401Refrigerant pressure sensor circuit 2 3 3 4

EC-1527Electrical load signal circuit 3

EC-1506Air conditioner circuit 2 2 3 3 3 3 3 3 3 3 2

MTC-22ABS actuator and electric unit (control unit) 4

BRC-8SYMPTOM

ReferenceHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA SYMPTOM

Reference

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-9Fuel piping 5 5 5 5 5 5

EM-156Vapor lock

—

Valve deposit 5 5 5 5 5 5 5 —

Poor fuel (Heavy weight gasoline,

Low octane) —

Page 2476 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual Monitored item [Unit] Description Remarks

ENG SPEED

[rpm] • Indicates the engine speed computed from the signals of the

crankshaft position sensor (POS) and camshaft position sen-

sor (PHASE). • NISSAN TIIDA 2009 Service Workshop Manual Monitored item [Unit] Description Remarks

ENG SPEED

[rpm] • Indicates the engine speed computed from the signals of the

crankshaft position sensor (POS) and camshaft position sen-

sor (PHASE). •](/img/5/57398/w960_57398-2475.png)

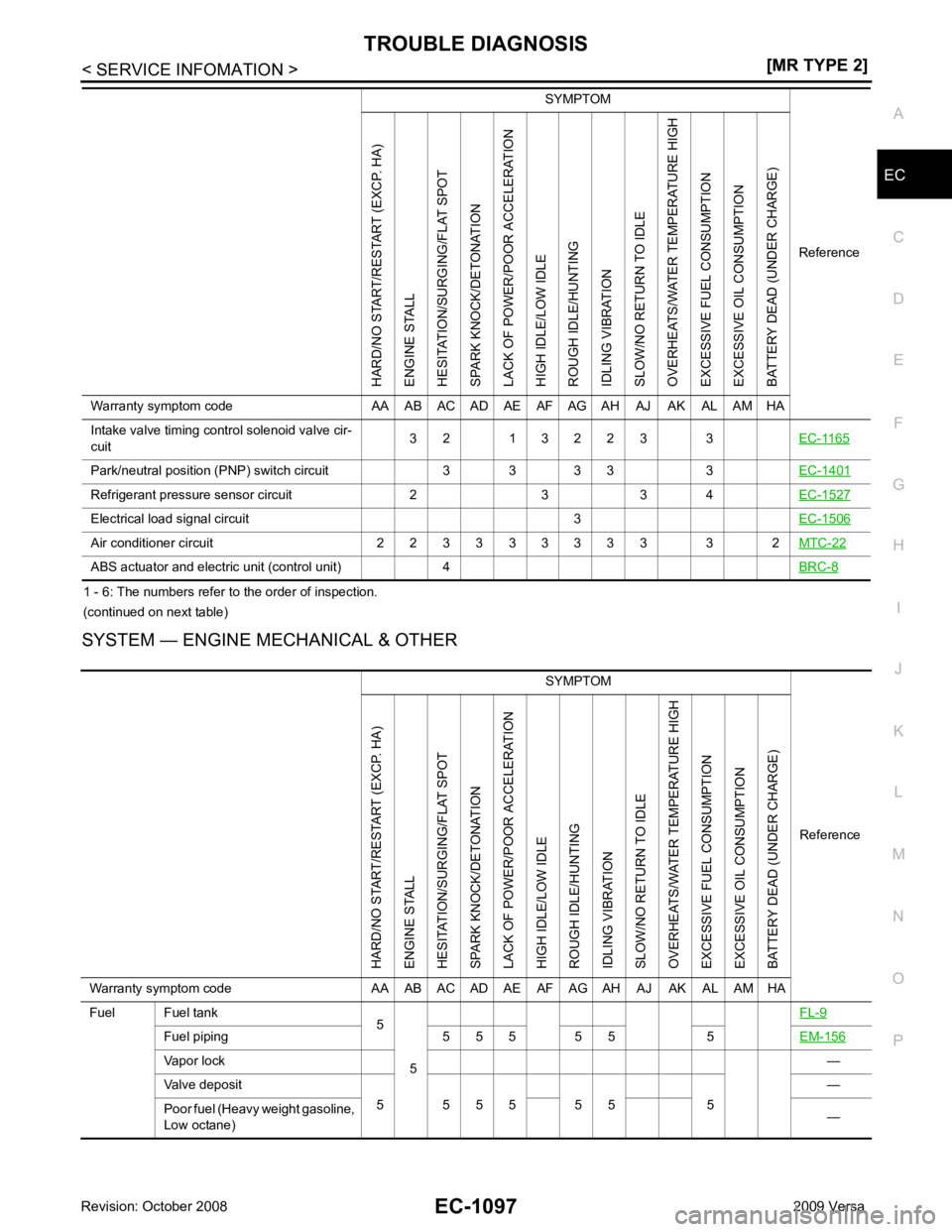

Monitored item [Unit] Description Remarks

ENG SPEED

[rpm] • Indicates the engine speed computed from the signals of the

crankshaft position sensor (POS) and camshaft position sen-

sor (PHASE). • Accuracy becomes poor if engine speed

drops below the idle rpm.

• If the signal is interrupted while the engine is running, an abnormal value may be indicat-

ed.

MAS A/F SE-B1

[V] • The signal voltage of the mass air flow sensor is displayed. • When the engine is stopped, a certain value

is indicated.

• When engine is running, specification range is indicated in "SPEC".

B/FUEL SCHDL

[msec] • “Base fuel schedule” indicates the fuel injection pulse width

programmed into ECM, prior to any learned on board correc-

tion. • When engine is running, specification range

is indicated in "SPEC".

A/F ALPHA-B1

[%] • The mean value of the air-fuel ratio feedback correction fac-

tor per cycle is indicated. • When the engine is stopped, a certain value

is indicated.

• This data also includes the data for the air/ fuel ratio learning control.

• When engine is running, specification range

is indicated in "SPEC".

COOLAN TEMP/S

[ ° C] or [ °F] • The engine coolant temperature (determined by the signal

voltage of the engine coolant temperature sensor) is dis-

played. • When the engine coolant temperature sen-

sor is open or short-circuited, ECM enters

fail-safe mode. The engine coolant temper-

ature determined by the ECM is displayed.

A/F SEN1 (B1)

[V] • The A/F signal computed from the input signal of the A/F sen-

sor 1 is displayed.

HO2S2 (B1)

[V] • The signal voltage of the heated oxygen sensor 2 is dis-

played.

HO2S2 MNTR (B1)

[RICH/LEAN] • Display of heated oxygen sensor 2 signal:

RICH: means the amount of oxygen after three way catalyst

is relatively small.

LEAN: means the amount of oxygen after three way catalyst

is relatively large. • When the engine is stopped, a certain value

is indicated.

VHCL SPEED SE

[km/h] or [mph] • The vehicle speed computed from the vehicle speed signal is

displayed.

BATTERY VOLT

[V] • The power supply voltage of ECM is displayed.

ACCEL SEN 1

[V] • The accelerator pedal position sensor signal voltage is dis-

played. • ACCEL SEN 2 signal is converted by ECM

internally. Thus, it differs from ECM terminal

voltage signal.

ACCEL SEN 2

[V]

TP SEN 1-B1

[V] • The throttle position sensor signal voltage is displayed. • TP SEN 2-B1 signal is converted by ECM in-

ternally. Thus, it differs from ECM terminal

voltage signal.

TP SEN 2-B1

[V]