fuel NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1305 of 4331

DI

N

O P

COMBINATION METERS

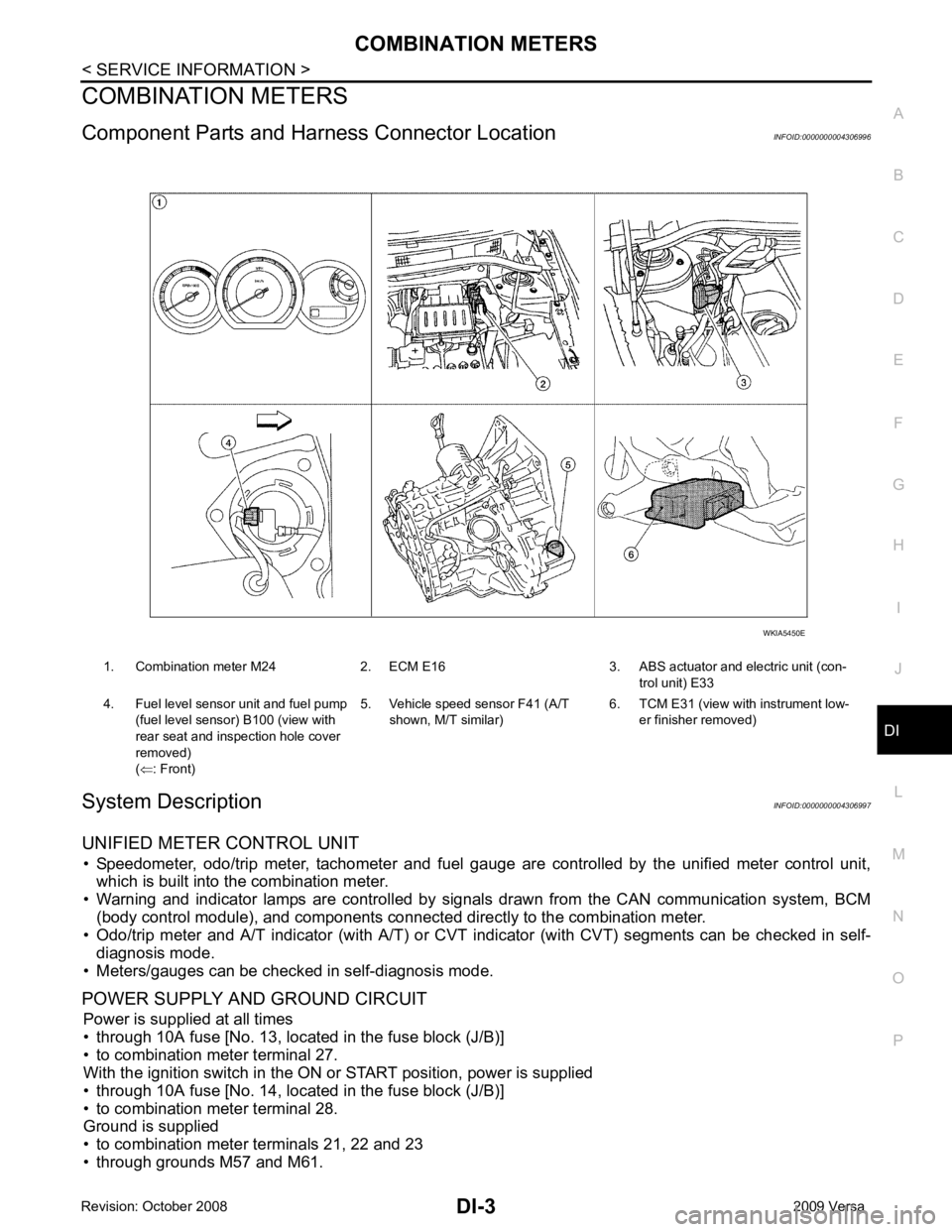

Component Parts and Har ness Connector Location INFOID:0000000004306996

System Description INFOID:0000000004306997

UNIFIED METER CONTROL UNIT • Speedometer, odo/trip meter, tachometer and fuel gauge are controlled by the unified meter control unit,

which is built into the combination meter.

• Warning and indicator lamps are controlled by signal s drawn from the CAN communication system, BCM

(body control module), and components connected directly to the combination meter.

• Odo/trip meter and A/T indicator (with A/T) or CVT i ndicator (with CVT) segments can be checked in self-

diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

POWER SUPPLY AND GROUND CIRCUIT Power is supplied at all times

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61. 1. Combination meter M24 2. ECM E16 3. ABS actuator and electric unit (con-

trol unit) E33

4. Fuel level sensor unit and fuel pump (fuel level sensor) B100 (view with

rear seat and inspection hole cover

removed)

( ⇐ : Front) 5. Vehicle speed sensor F41 (A/T

shown, M/T similar) 6. TCM E31 (view with

instrument low-

er finisher removed)

Page 1312 of 4331

System Description " .

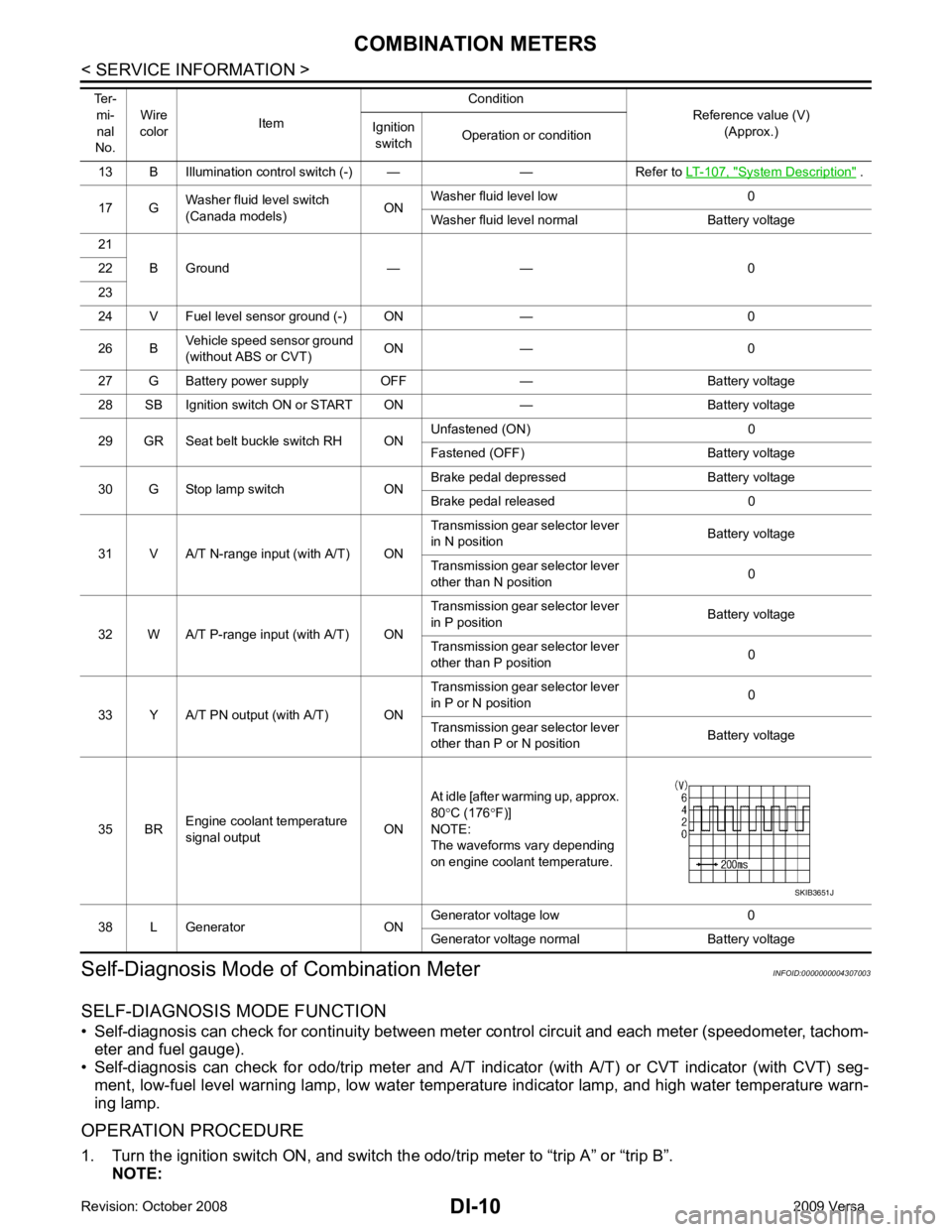

17 G Washer fluid level switch

(Canada models) ONWasher fluid level low 0

Washer fluid level normal Battery voltage

21 B Ground — — 0

22

23

24 V Fuel level sensor ground (-) ON — 0

26 B Vehicle speed sensor ground

(without ABS or CVT) ON — 0

27 G Battery power supply OFF — Battery voltage

28 SB Ignition switch ON or START ON — Battery voltage

29 GR Seat belt buckle switch RH ON Unfastened (ON) 0

Fastened (OFF) Battery voltage

30 G Stop lamp switch ON Brake pedal depressed Battery voltage

Brake pedal released 0

31 V A/T N-range input (with A/T) ON Transmission gear selector lever

in N position Battery voltage

Transmission gear selector lever

other than N position 0

32 W A/T P-range input (with A/T) ON Transmission gear selector lever

in P position Battery voltage

Transmission gear selector lever

other than P position 0

33 Y A/T PN output (with A/T) ON Transmission gear selector lever

in P or N position 0

Transmission gear selector lever

other than P or N position Battery voltage

35 BR Engine coolant temperature

signal output ONAt idle [after warming up, approx.

80 °C (176 °F)]

NOTE:

The waveforms vary depending

on engine coolant temperature.

38 L Generator ON Generator voltage low 0

Generator voltage normal Battery voltage

Ter-

mi-

nal

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

Page 1313 of 4331

DI

N

O P

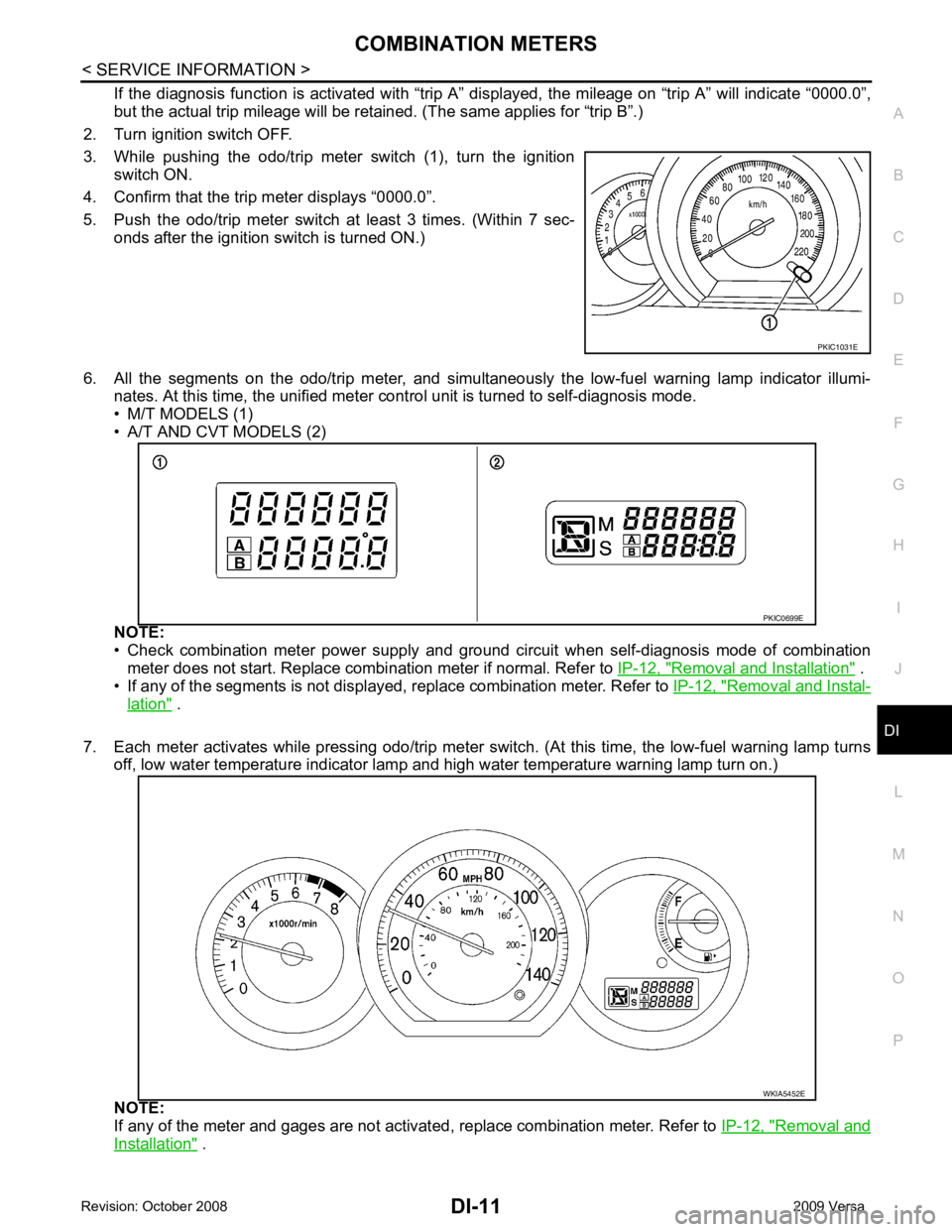

If the diagnosis function is activat

ed with “trip A” displayed, the mileage on “trip A” will indicate “0000.0”,

but the actual trip mileage will be retained. (The same applies for “trip B”.)

2. Turn ignition switch OFF.

3. While pushing the odo/trip meter switch (1), turn the ignition switch ON.

4. Confirm that the trip meter displays “0000.0”.

5. Push the odo/trip meter switch at least 3 times. (Within 7 sec- onds after the ignition switch is turned ON.)

6. All the segments on the odo/trip meter, and simultaneously the low-fuel warning lamp indicator illumi- nates. At this time, the unified meter cont rol unit is turned to self-diagnosis mode.

• M/T MODELS (1)

• A/T AND CVT MODELS (2)

NOTE:

• Check combination meter power supply and ground circuit when self-diagnosis mode of combination

meter does not start. Replace combi nation meter if normal. Refer to IP-12, " Removal and Installation " .

• If any of the segments is not displayed, replace combination meter. Refer to IP-12, " Removal and Instal-

lation " .

7. Each meter activates while pressing odo/trip meter switch. (At this time, the low-fuel warning lamp turns off, low water temperature indicator lamp and high water temperature warning lamp turn on.)

NOTE:

If any of the meter and gages are not activat ed, replace combination meter. Refer to IP-12, " Removal and

Installation " .

Page 1314 of 4331

![NISSAN TIIDA 2009 Service User Guide CONSULT-III display Malfunction Reference page

CAN COMM CIRC [U1000] Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfunct ion on CAN communication system, mal-

f NISSAN TIIDA 2009 Service User Guide CONSULT-III display Malfunction Reference page

CAN COMM CIRC [U1000] Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfunct ion on CAN communication system, mal-

f](/img/5/57398/w960_57398-1313.png)

CONSULT-III display Malfunction Reference page

CAN COMM CIRC [U1000] Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfunct ion on CAN communication system, mal-

function may be misinterpreted when battery has low voltage (when main-

taining 7 - 8 V for about 2 seconds) or 10A fuse [No. 14, located in the fuse

block (J/B)] is removed. DI-18VEHICLE SPEED CIRC [B2205]

Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunctions

may be misinterpreted when battery has low voltage (when maintaining 7

- 8 V for about 2 seconds). DI-15Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Contents

SPEED METER [km/h] X X The value of vehicle speed sign

al, which is input from ABS ac-

tuator and electric unit (control unit).

SPEED OUTPUT [km/h] X X The value of vehicle speed signal, which is transmitted to each

unit with CAN communication.

TACHO METER [rpm] X X The value of engine speed signal, which is input from ECM.

W TEMP METER [ °C] X X The value of engine coolant temperature signal, which is input

from ECM.

FUEL METER [lit.] X X The value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] X X The value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (con trol unit), fuel gauge and fuel

consumption signal from ECM.

FUEL W/L [ON/OFF] X X Indicates [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] X Indicates [ON/OFF] condition of malfunction indicator lamp

(MIL).

AIR PRES W/L X Indicates [ON/OFF] condition of low tire pressure warning lamp.

SEAT BELT W/L X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Indicates [ON/ OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Indicates [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Indicat es [ON/OFF] condition of high beam indicator lamp.

Page 1316 of 4331

Power Supply and

Ground Circuit Inspection " .

" CONSULT-III Function (METER/M&A) " .

Self - diagnostic results content

No malfunction detected>> Refer to

DI-14, " Symptom Chart " .

Malfunction detected>> Refer to DI-12, " CONSULT-III Function (METER/M&A) " .

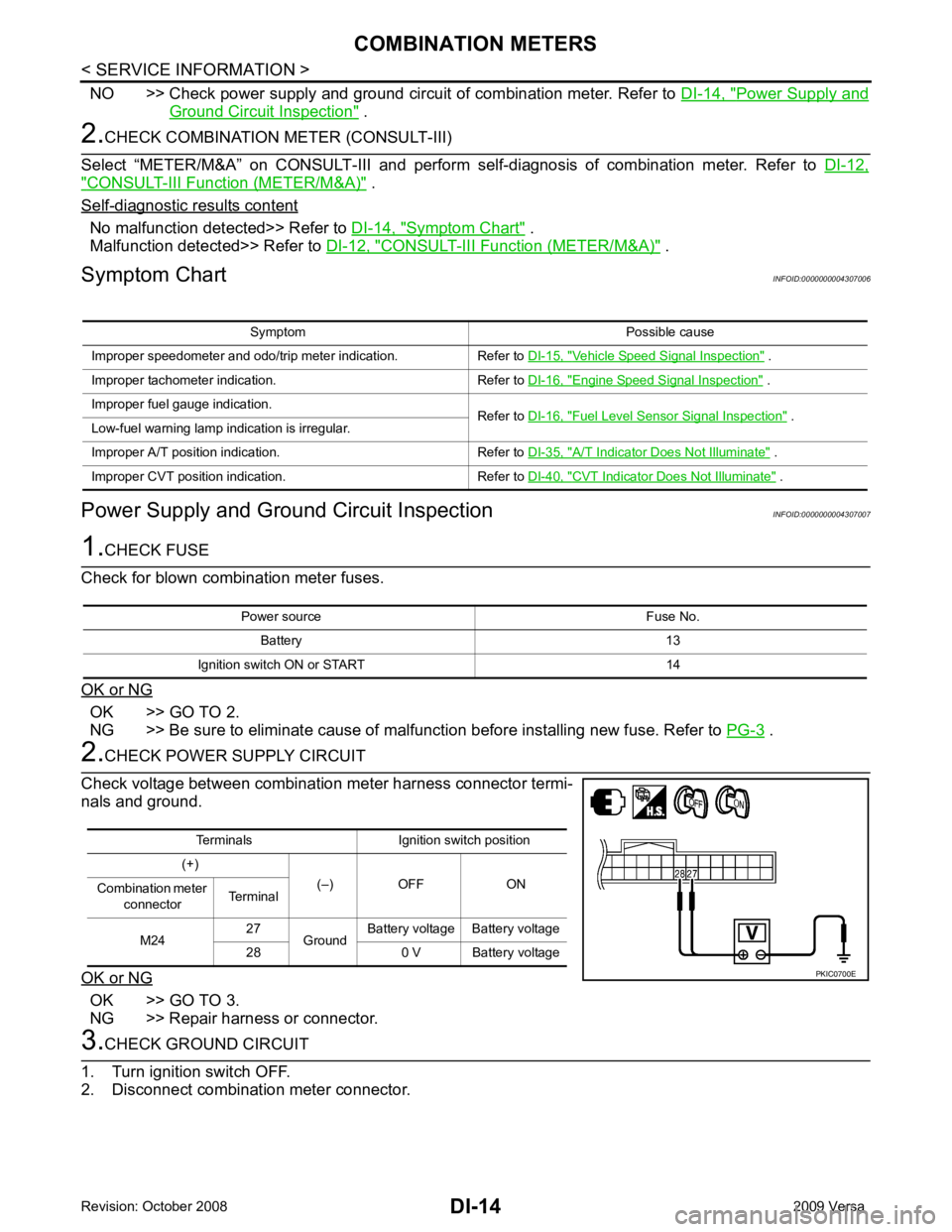

Symptom Chart INFOID:0000000004307006

Power Supply and Ground Circuit Inspection INFOID:0000000004307007OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3 .

OK >> GO TO 3.

NG >> Repair harness or connector. Vehicle Speed Signal Inspection " .

Improper tachometer indication. Refer to DI-16, " Engine Speed Signal Inspection " .

Improper fuel gauge indication. Refer to DI-16, " Fuel Level Sensor Signal Inspection " .

Low-fuel warning lamp indication is irregular.

Improper A/T position indication. Refer to DI-35, " A/T Indicator Does Not Illuminate " .

Improper CVT position indication. Refer to DI-40, " CVT Indicator Does Not Illuminate " .

Power source Fuse No.

Battery 13

Ignition switch ON or START 14 Terminals Ignition switch position

(+) (–) OFF ON

Combination meter

connector Terminal

M24 27

Ground Battery voltage Battery voltage

28 0 V Battery voltage

Page 1318 of 4331

OK >> Check harness or connector between combination meter and vehicle speed sensor.

NG >> Replace vehicle speed sensor.

WITH CVT, WITHOUT ABS OK >> Perform TCM self-diagnosis. Refer to

CVT-230, " CONSULT-III Function (TRANSMISSION) " .

NG >> Replace combination meter. Refer to IP-12, " Removal and Installation " .

Engine Speed Signal Inspection INFOID:0000000004307009

Symptom: Improper tachometer indication. OK >> Perform ECM self-diagnosis. Refer to

EC-604, " CONSULT-III Function (ENGINE) " with (MR

TYPE 1), EC-1116, " CONSULT-III Function (ENGINE) " (MR TYPE 2) or

EC-103, " CONSULT-III

Function " (HR16DE).

NG >> Replace combination meter. Refer to IP-12, " Removal and Installation " .

Fuel Level Sensor Signal Inspection INFOID:0000000004307010

Symptom:

• Improper fuel gauge indication.

• Low-fuel warning lamp indication is irregular.

NOTE:

The following symptoms do not indicate a malfunction.

• Depending on vehicle position or driving circumstance, the fuel level in the tank shifts and the indication may

fluctuate.

• If the vehicle is fueled with the ignition switch ON, the indication will update slowly.

• If the vehicle is tilted when the ignition switch is turned ON, fuel in the tank may flow to one direction result-

ing in a change of reading.

Page 1319 of 4331

DI

N

O P

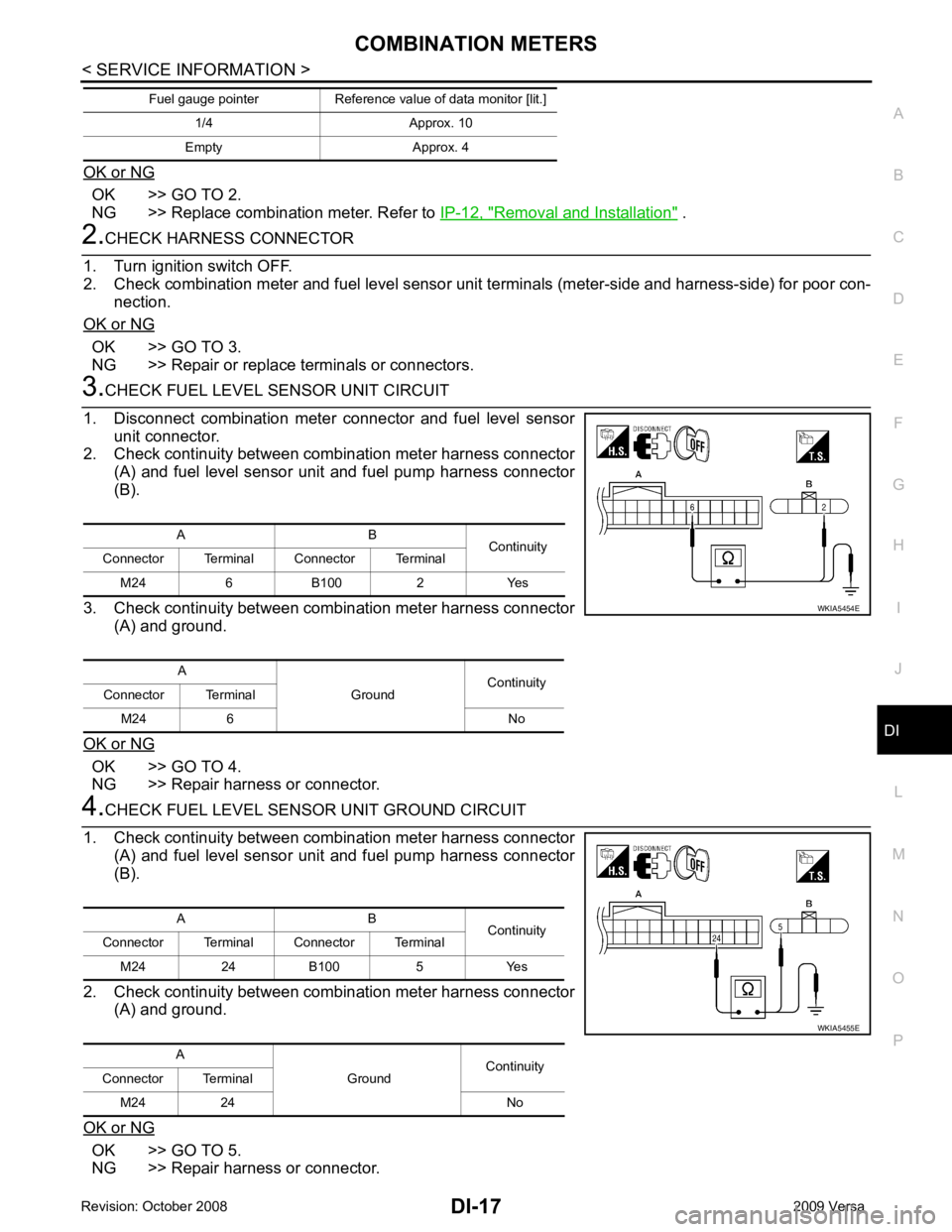

OK or NG OK >> GO TO 2.

NG >> Replace combination meter. Refer to IP-12, " Removal and Installation " .

OK >> GO TO 3.

NG >> Repair or replace terminals or connectors. OK >> GO TO 4.

NG >> Repair harness or connector. OK >> GO TO 5.

NG >> Repair harness or connector. 1/4 Approx. 10

Empty Approx. 4

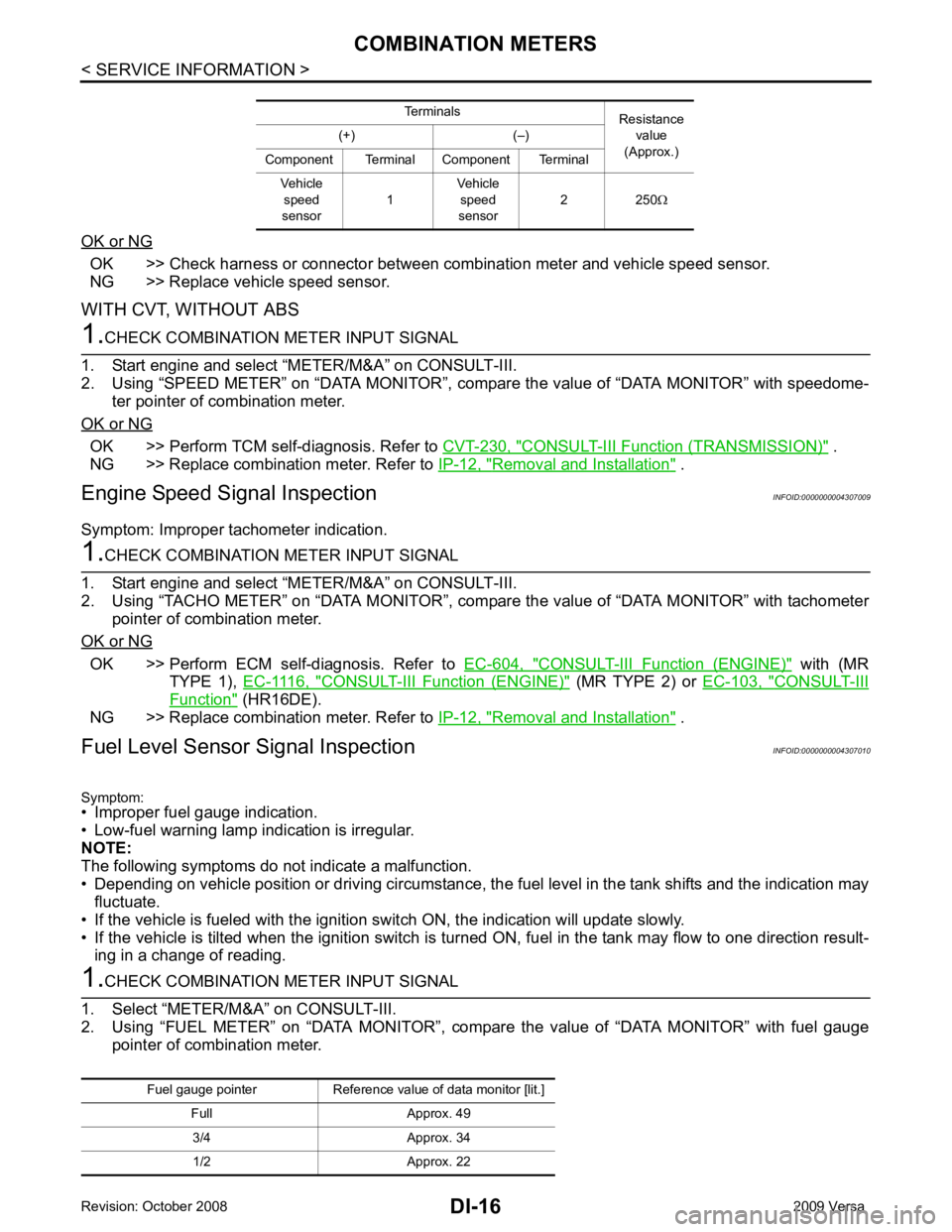

Fuel gauge pointer Reference value of data monitor [lit.] A B

Continuity

Connector Terminal Connector Terminal

M24 6 B100 2 Yes

A GroundContinuity

Connector Terminal

M24 6 No

Page 1320 of 4331

Electrical Component Inspection " .

OK or NG OK >> Check fuel level sensor unit installation, and c

heck whether the float arm interferes or binds with

any of the internal components in the fuel tank. Repair or replace malfunctioning part, if neces-

sary.

NG >> Replace fuel level sensor unit.

Fuel Gauge Fluctuat es, Indicates Wrong Value, or Varies INFOID:0000000004307011YES >> The pointer fluctuation may be caused by fuel

level change in the fuel tank. Condition is normal.

NO >> Ask the customer about the situation when the symptom occurs in detail, and perform the trouble

diagnosis.

Fuel Gauge Does Not Mo ve to Full-position INFOID:0000000004307012YES >> GO TO 2.

NO >> GO TO 3. YES >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise, it will take a long time to move

to FULL position because of the c haracteristic of the fuel gauge.

NO >> GO TO 3. YES >> Check the fuel level indication with vehicle on a level surface.

NO >> GO TO 4. YES >> Check the components. Refer to

DI-19, " Electrical Component Inspection " .

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

DTC [U1000] CAN Communication Circuit INFOID:0000000004307013

Symptom: Display CAN COMM CIRC [U1000] at the re sult of self-diagnosis for combination meter. Trouble Diagnosis Flow Chart " .

Page 1321 of 4331

DI

N

O P

Electrical Component Inspection

INFOID:0000000004307014

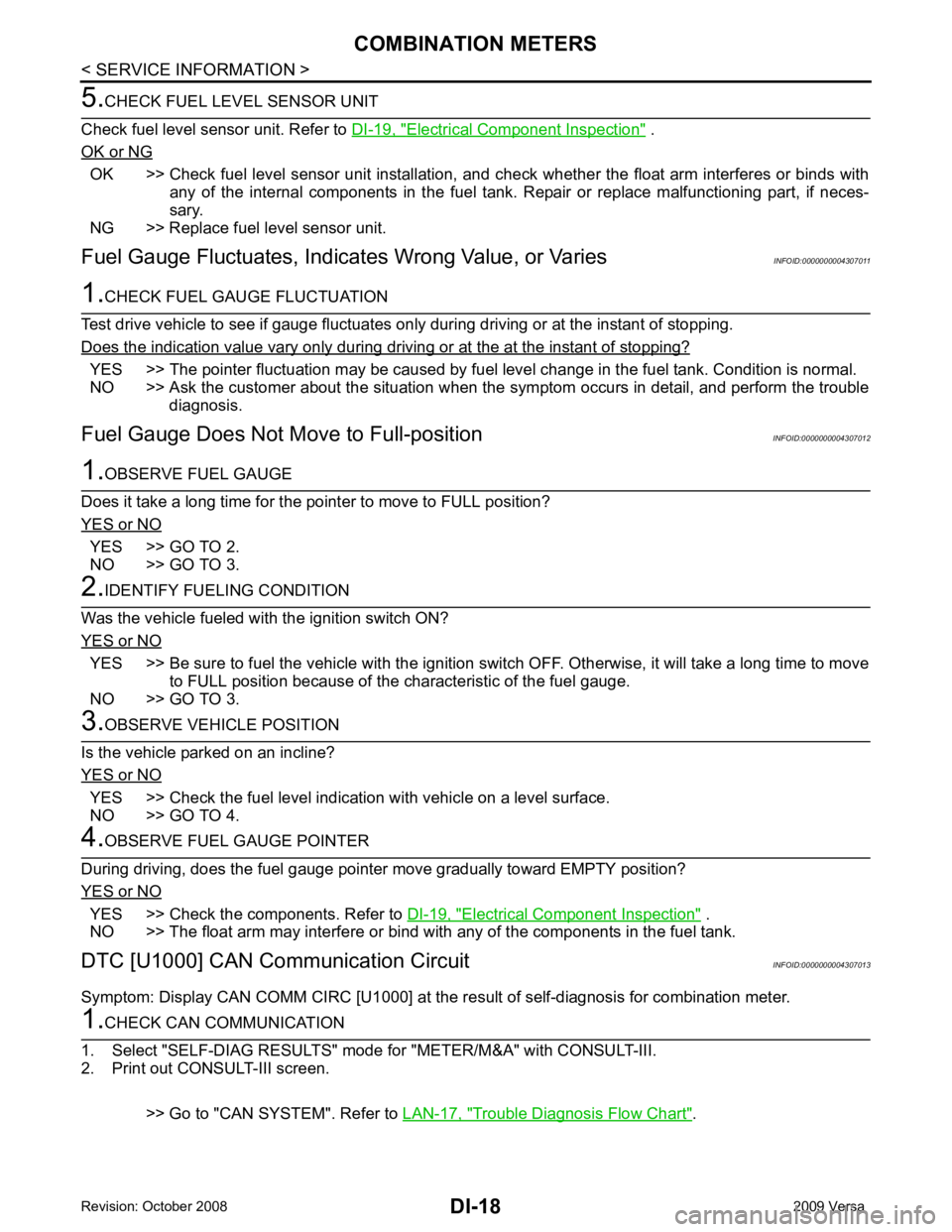

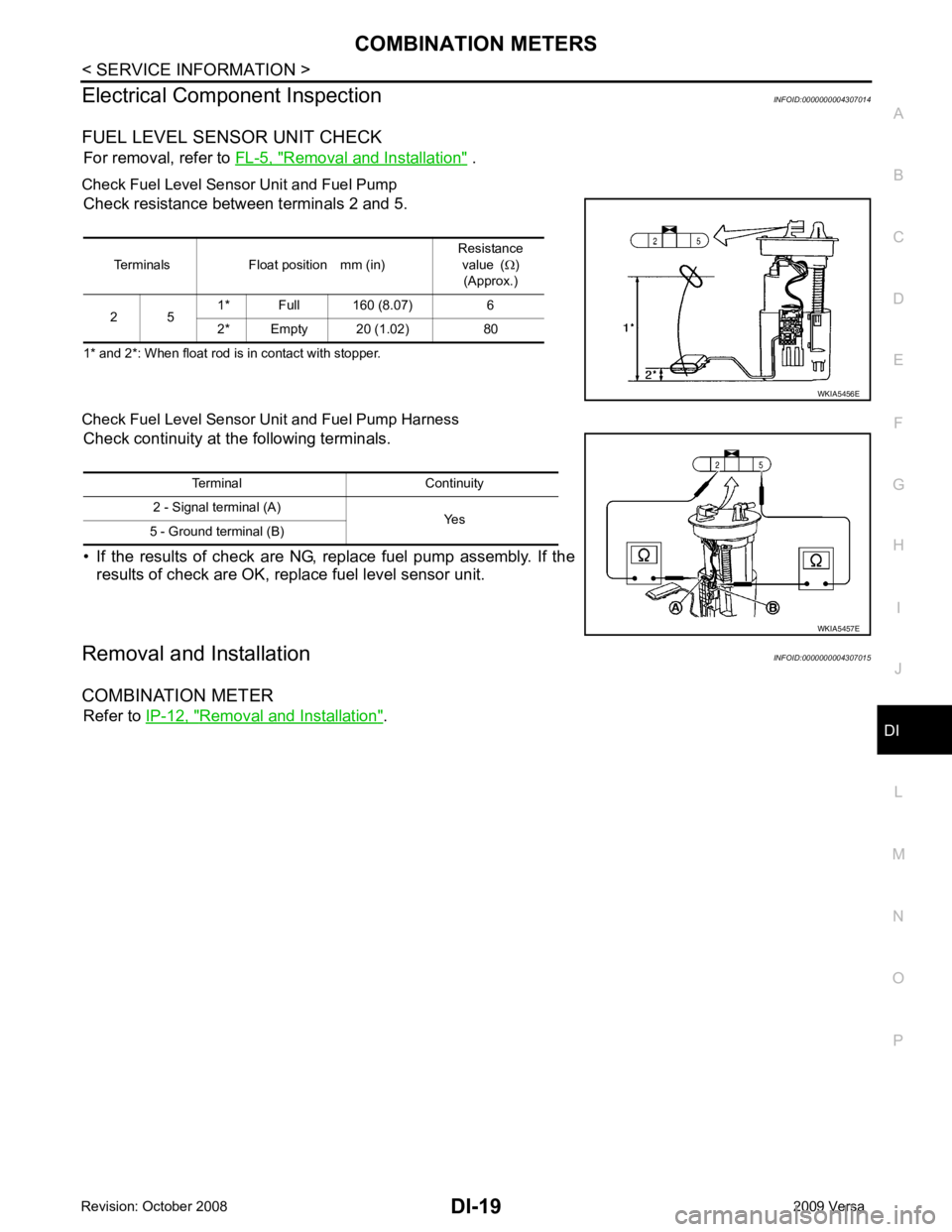

FUEL LEVEL SENSOR UNIT CHECK For removal, refer to FL-5, " Removal and Installation " .

Check Fuel Level Sensor Unit and Fuel Pump Check resistance between terminals 2 and 5.

1* and 2*: When float rod is in contact with stopper.

Check Fuel Level Sensor Unit and Fuel Pump Harness Check continuity at the following terminals.

• If the results of check are NG, replace fuel pump assembly. If the results of check are OK, replace fuel level sensor unit.

Removal and Installation INFOID:0000000004307015

COMBINATION METER Refer to IP-12, " Removal and Installation " .

Terminals Float position mm (in)

Resistance

value ( Ω)

(Approx.)

2 5 1* Full 160 (8.07) 6

2* Empty 20 (1.02) 80

Page 1357 of 4331

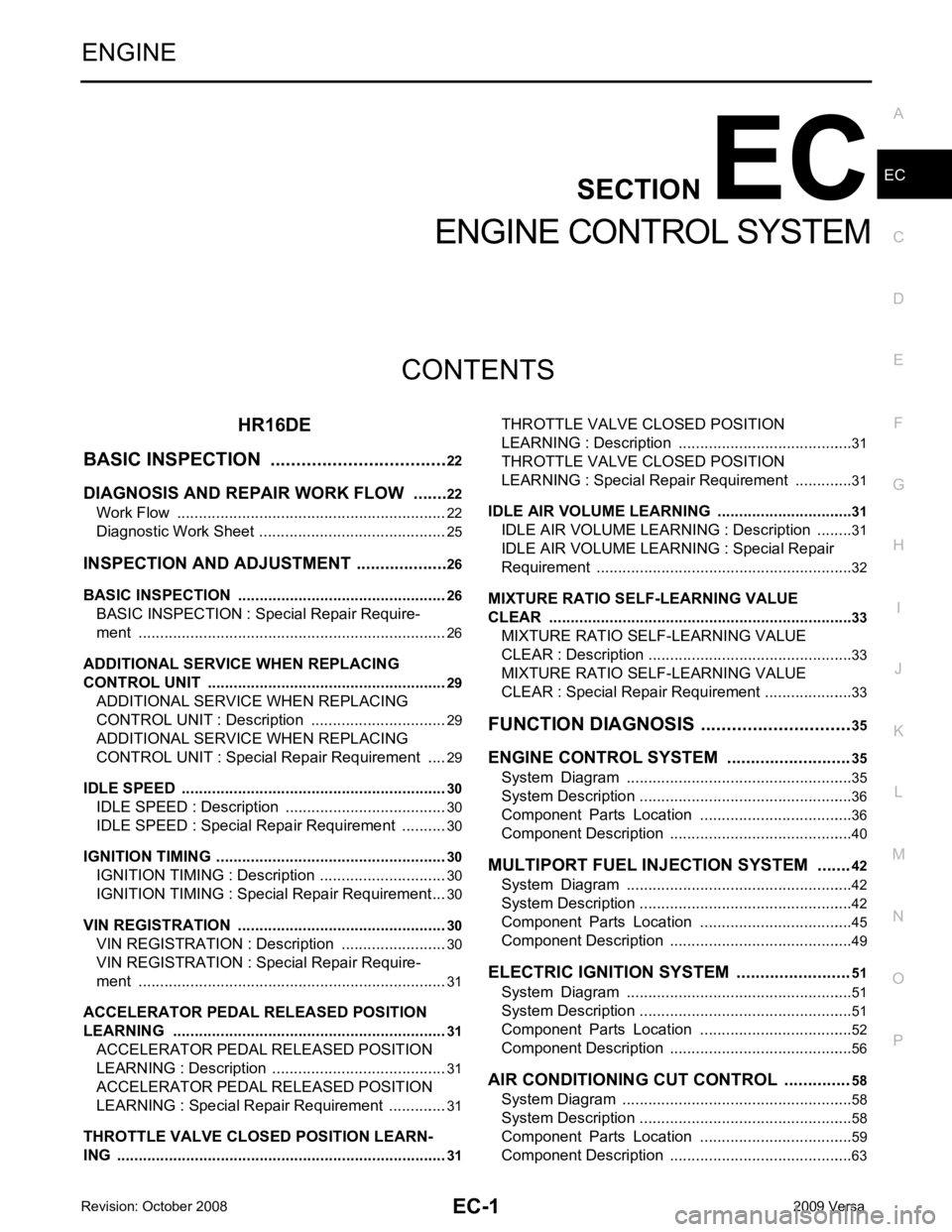

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

HR16DE

BASIC INSPECTION ....... ............................

22

DIAGNOSIS AND REPAIR WORK FLOW .... ....22

Work Flow ........................................................... ....22

Diagnostic Work Sheet ........................................ ....25

INSPECTION AND ADJUSTMENT ................ ....26

BASIC INSPECTION ......... ........................................26

BASIC INSPECTION : Spec ial Repair Require-

ment .................................................................... ....

26

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

29

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ............................ ....

29

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

29

IDLE SPEED .......................................................... ....30

IDLE SPEED : Description ........................ ..............30

IDLE SPEED : Special R epair Requirement ...........30

IGNITION TIMING .................................................. ....30

IGNITION TIMING : Description .......................... ....30

IGNITION TIMING : Special Repair Requirement ....30

VIN REGISTRATION ............................................. ....30

VIN REGISTRATION : Description ..................... ....30

VIN REGISTRATION : Special Repair Require-

ment .................................................................... ....

31

ACCELERATOR PEDAL RE LEASED POSITION

LEARNING ............................................................ ....

31

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Description ..................................... ....

31

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement .......... ....

31

THROTTLE VALVE CLO SED POSITION LEARN-

ING ......................................................................... ....

31 THROTTLE VALVE CLOSED POSITION

LEARNING : Description ..................................... ....

31

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repai r Requirement ..............

31

IDLE AIR VOLUME LEARNING ............................ ....31

IDLE AIR VOLUME LEARNI NG : Description .........31

IDLE AIR VOLUME LEARNI NG : Special Repair

Requirement ........................................................ ....

32

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ................................................................... ....

33

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ............................................ ....

33

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement ................. ....

33

FUNCTION DIAGNOSIS .. ............................35

ENGINE CONTRO L SYSTEM .......................... 35

System Diagram ................................................. ....35

System Description .............................................. ....36

Component Parts Location ................................ ....36

Component Description ....................................... ....40

MULTIPORT FUEL INJECTION SYSTEM ....... 42

System Diagram ................................................. ....42

System Description .............................................. ....42

Component Parts Location ................................ ....45

Component Description ....................................... ....49

ELECTRIC IGNITI ON SYSTEM ........................ 51

System Diagram ................................................. ....51

System Description .............................................. ....51

Component Parts Location ................................ ....52

Component Description ....................................... ....56

AIR CONDITIONING CUT CONTROL .............. 58

System Diagram .................................................. ....58

System Description .............................................. ....58

Component Parts Location ................................ ....59

Component Description ....................................... ....63