oil pressure NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 124 of 4331

AT

N

O P

DTC P0734 A/T 4TH GEAR FUNCTION

Description INFOID:0000000004305383

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis malfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305384

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305385

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0734 A/T 4TH GR FNCTN” with CONSULT-III is detected when A/T cannot be

shifted to the 4th gear position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve A is stuck open or shift solenoid valve B is stuck

closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve A stuck open: 2, 2, 3 and 3* positions

In case of gear position with shift solenoid valve B stuck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0734 A/T 4TH GR FNCTN” is detected.

Possible Cause INFOID:0000000004305386

• Shift solenoid valve A

• Shift solenoid valve B

• Line pressure solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation Procedure INFOID:0000000004305387

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated. Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open) Item name Condition Display value (Approx.)

LINE PRES DTY Small throttle opening (Low line pressure)

⇔ Large

throttle opening (High line pressure) 0%

⇔ 94%

Page 134 of 4331

AT

N

O P

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

Description INFOID:0000000004305397

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis malfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock-up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305398

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305399

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744 A/T TCC S/V FNCTN” wi th CONSULT-III is detected when A/T cannot per-

form lock-up even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve B is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stu ck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0744 A/T TCC S/V FNCTN” is detected.

Possible Cause INFOID:0000000004305400

• Line pressure solenoid valve

• Torque converter clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation Procedure INFOID:0000000004305401

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage

(cool down the fluid).

4. Select “TCC S/V FNCTN P0744” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

Item name Condition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Page 190 of 4331

AT

N

O P

OK or NG OK >> GO TO 5.

NG >> GO TO 4. Disassembly " .

2. Check the following items:

- Forward clutch assembly. Refer to AT-306, " Forward and Overrun Clutches " .

- Overrun clutch assembly. Refer to AT-306, " Forward and Overrun Clutches " .

- Reverse clutch assembly. Refer to AT-296, " Reverse Clutch " .

OK or NG OK >> GO TO 5.

NG >> Repair or replace damaged parts. Check at Idle " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 6. TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Large Shock "N" → "R" Position INFOID:0000000004305476

SYMPTOM: There is a large shock when changing from “N” to “R” position.

DIAGNOSTIC PROCEDURE CONSULT-III Functi

on (TRANSMISSION) " or

AT-83, " Diagnosis Pro-

cedure without CONSULT-III " .

Is any malfunction detected by self-diagnostic results? YES >> Check the malfuncti

oning system. Refer to AT-79, " CONSULT-III Functi

on (TRANSMISSION) " or

AT-83, " Diagnosis Procedure without CONSULT-III " .

NO >> GO TO 2. Inspections Before Trouble

Diagnosis " .

OK or NG OK >> GO TO 4.

NG >> GO TO 3. Control Valve Assembly and Accumulators " .

2. Check the following items:

- Valves to control line pressure (Pressure regulator valv e, pressure modifier valve, pilot valve and pilot fil-

ter)

- Line pressure solenoid valve

- Oil pump assembly. Refer to AT-277, " Oil Pump " .

OK or NG OK >> GO TO 4.

Page 191 of 4331

Check at Idle " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 5. TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Vehicle Does Not Creep Ba ckward in "R" Position INFOID:0000000004305477

SYMPTOM:

Vehicle does not creep backward when selecting “R” position.

DIAGNOSTIC PROCEDURE Checking A/T Fluid " .

OK or NG OK >> GO TO 2.

NG >> Refill ATF. Inspections Before Trouble

Diagnosis " .

OK or NG OK >> GO TO 4.

NG >> GO TO 3. Control Valve Assembly and Accumulators " .

2. Check the following items:

- Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- ter)

- Line pressure solenoid valve

3. Disassemble A/T. Refer to AT-256, " Disassembly " .

4. Check the following item:

- Oil pump assembly. Refer to AT-277, " Oil Pump " .

OK or NG OK >> GO TO 4.

NG >> Repair or replace damaged parts. Inspections Before Trouble

Diagnosis " .

OK or NG OK >> GO TO 6.

OK in “1” position, NG in “R” position>>GO TO 5.

NG in both “1” and “R” positions>>GO TO 7. Disassembly " .

Page 193 of 4331

Control Valve Assembly and Accumulators " .

2. Check the following items:

- Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- ter)

- Line pressure solenoid valve

3. Disassemble A/T. Refer to AT-256, " Disassembly " .

4. Check the following item:

- Oil pump assembly. Refer to AT-277, " Oil Pump " .

OK or NG OK >> GO TO 4.

NG >> Repair or replace damaged parts. Inspections Before Trouble Diagno-

sis " .

OK or NG OK >> GO TO 6.

NG >> GO TO 5. Disassembly " .

2. Check the following items:

- Oil pump assembly. Refer to AT-277, " Oil Pump " .

- Forward clutch assembly. Refer to AT-306, " Forward and Overrun Clutches " .

- Forward one-way clutch. Refer to AT-317, " Rear Internal Gear and Forward Clutch Hub " .

- Low one-way clutch. Refer to AT-256, " Disassembly " .

- Torque converter. Refer to AT-256, " Disassembly " .

OK or NG OK >> GO TO 7.

NG >> Repair or replace damaged parts. Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 7.

NG >> GO TO 5. Check at Idle " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 8. TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Vehicle Cannot Be Started from D 1 INFOID:0000000004305479

SYMPTOM:

Vehicle cannot be started from D 1 on “Cruise Test — Part 1”.

Page 226 of 4331

AT

N

O P

ON-VEHICLE SERVICE

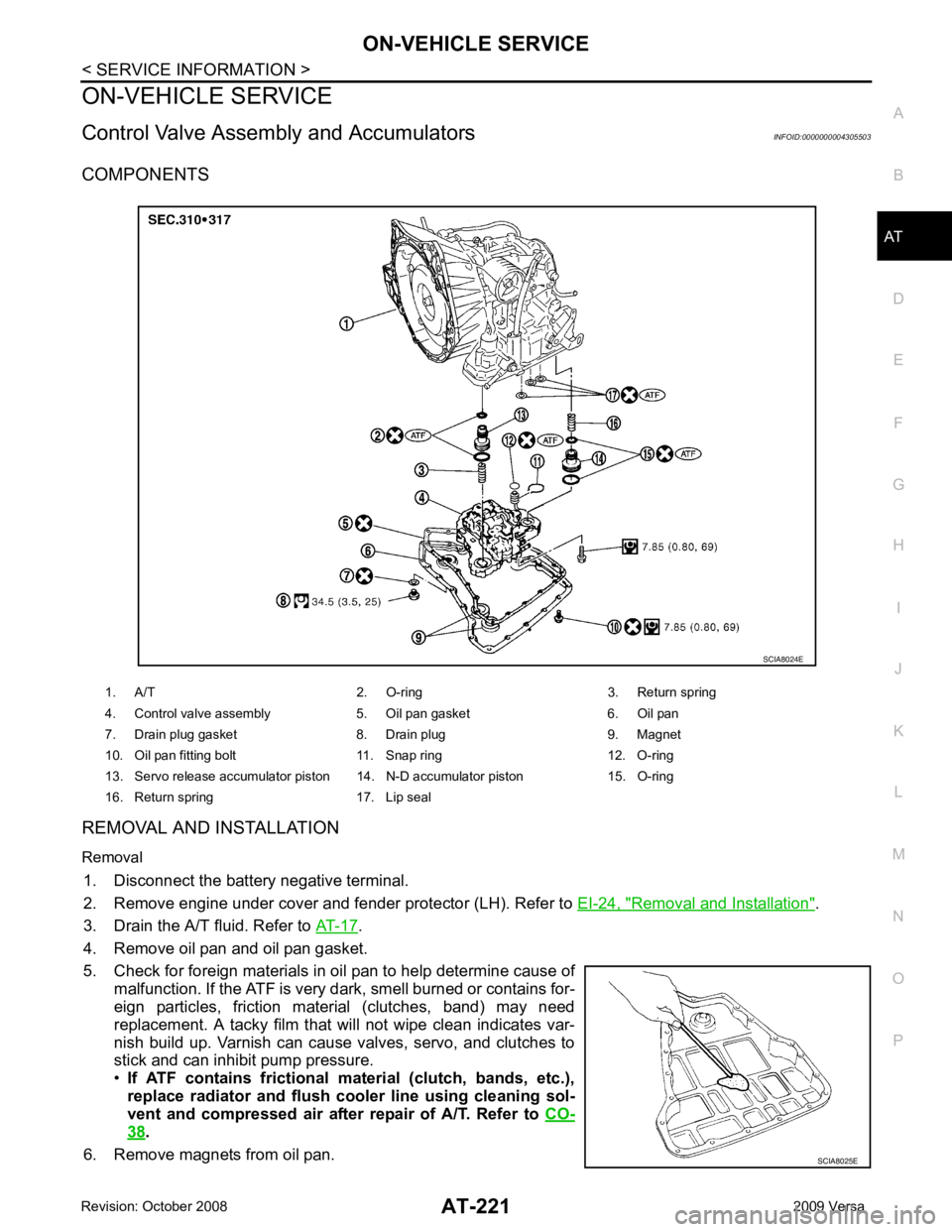

Control Valve Assembly and Accumulators INFOID:0000000004305503

COMPONENTS

REMOVAL AND INSTALLATION

Removal 1. Disconnect the battery negative terminal.

2. Remove engine under cover and fender protector (LH). Refer to EI-24, " Removal and Installation " .

3. Drain the A/T fluid. Refer to AT-17 .

4. Remove oil pan and oil pan gasket.

5. Check for foreign materials in oil pan to help determine cause of malfunction. If the ATF is very dark, smell burned or contains for-

eign particles, friction material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

• If ATF contains frictional material (clutch, bands, etc.),

replace radiator and flush cooler line using cleaning sol-

vent and compressed air after repair of A/T. Refer to CO-38 .

6. Remove magnets from oil pan. 1. A/T 2. O-ring 3. Return spring

4. Control valve assembly 5. Oil pan gasket 6. Oil pan

7. Drain plug gasket 8. Drain plug 9. Magnet

10. Oil pan fitting bolt 11. Snap ring 12. O-ring

13. Servo release accumulator piston 14. N-D accumulator piston 15. O-ring

16. Return spring 17. Lip seal SCIA8025E

Page 286 of 4331

AT

N

O P

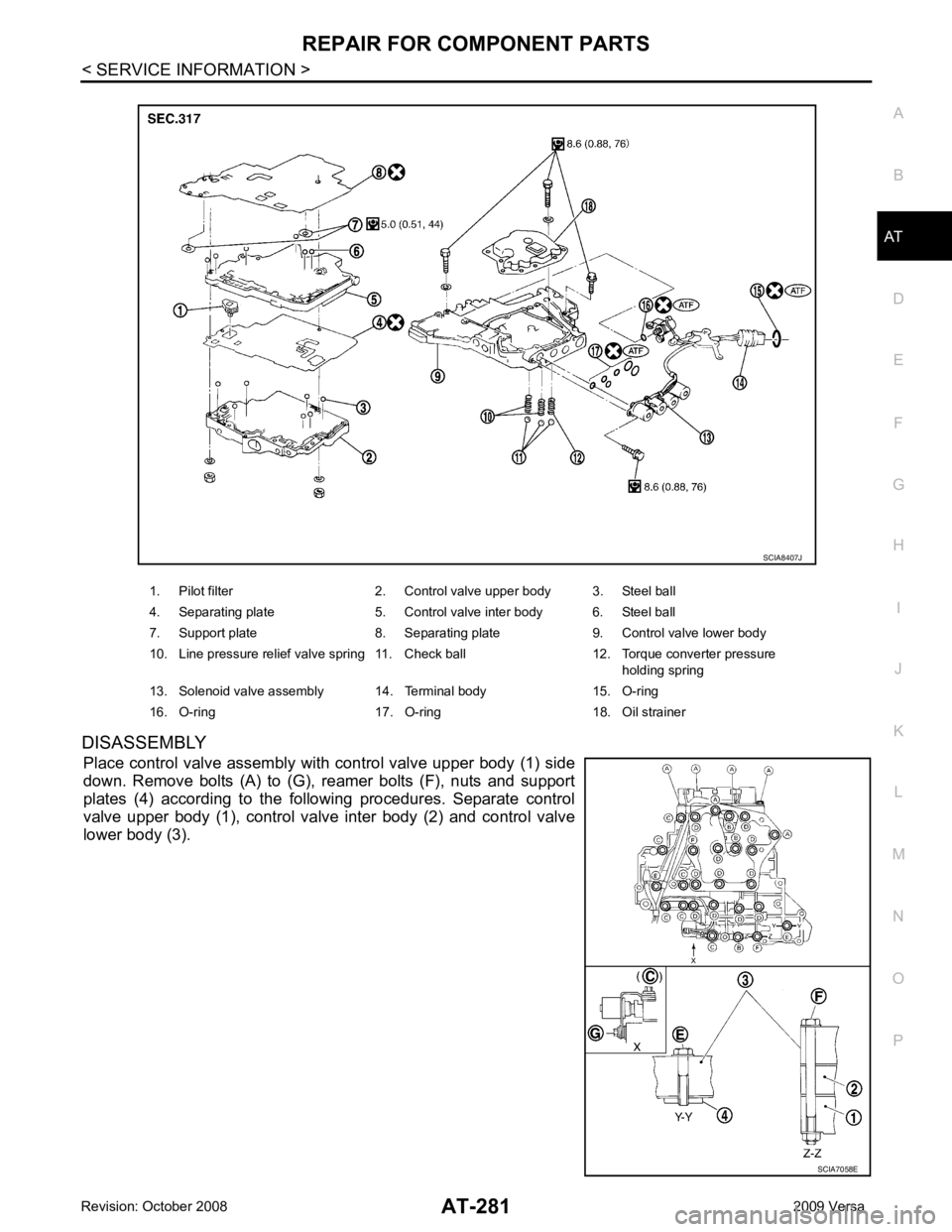

DISASSEMBLY

Place control valve assembly with control valve upper body (1) side

down. Remove bolts (A) to (G), reamer bolts (F), nuts and support

plates (4) according to the following procedures. Separate control

valve upper body (1), control valve inter body (2) and control valve

lower body (3). 1. Pilot filter 2. Control valve upper body 3. Steel ball

4. Separating plate 5. Control valve inter body 6. Steel ball

7. Support plate 8. Separating plate 9. Control valve lower body

10. Line pressure relief valve spring 11. Check ball 12. Torque converter pressure holding spring

13. Solenoid valve assembly 14. Terminal body 15. O-ring

16. O-ring 17. O-ring 18. Oil strainer SCIA7058E

Page 290 of 4331

AT

N

O P

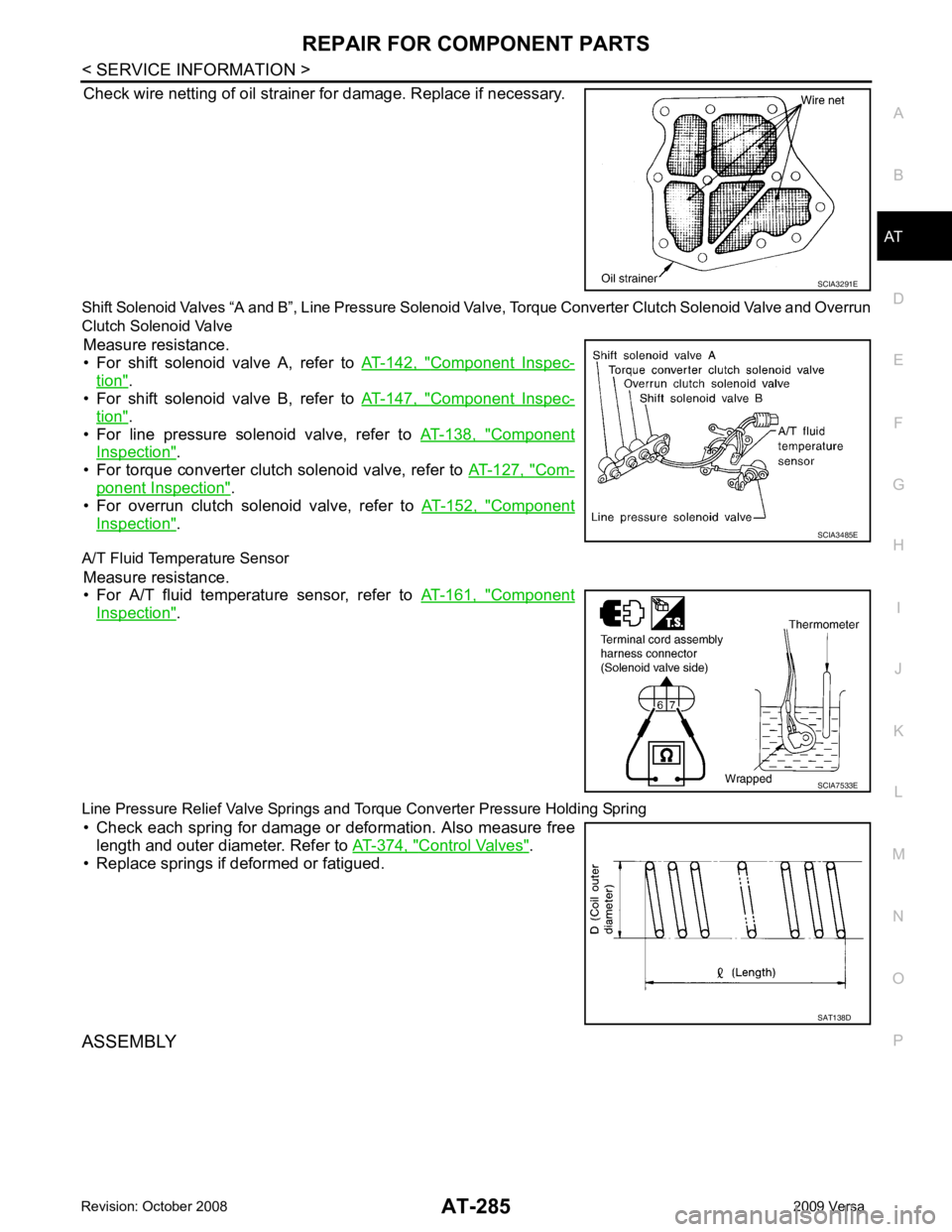

Check wire netting of oil strainer for damage. Replace if necessary.

Shift Solenoid Valves “A and B”, Line Pressure Solenoid Valve, Torque Conv erter Clutch Solenoid Valve and Overrun

Clutch Solenoid Valve

Measure resistance.

• For shift solenoid valve A, refer to AT-142, " Component Inspec-

tion " .

• For shift solenoid valve B, refer to AT-147, " Component Inspec-

tion " .

• For line pressure solenoid valve, refer to AT-138, " Component

Inspection " .

• For torque converter clutch solenoid valve, refer to AT-127, " Com-

ponent Inspection " .

• For overrun clutch solenoid valve, refer to AT-152, " Component

Inspection " .

A/T Fluid Temperature Sensor Measure resistance.

• For A/T fluid temperature sensor, refer to AT-161, " Component

Inspection " .

Line Pressure Relief Valve Springs and To rque Converter Pressure Holding Spring

• Check each spring for damage or deformation. Also measure free length and outer diameter. Refer to AT-374, " Control Valves " .

• Replace springs if deformed or fatigued.

ASSEMBLY SCIA3485E

SAT138D

Page 880 of 4331

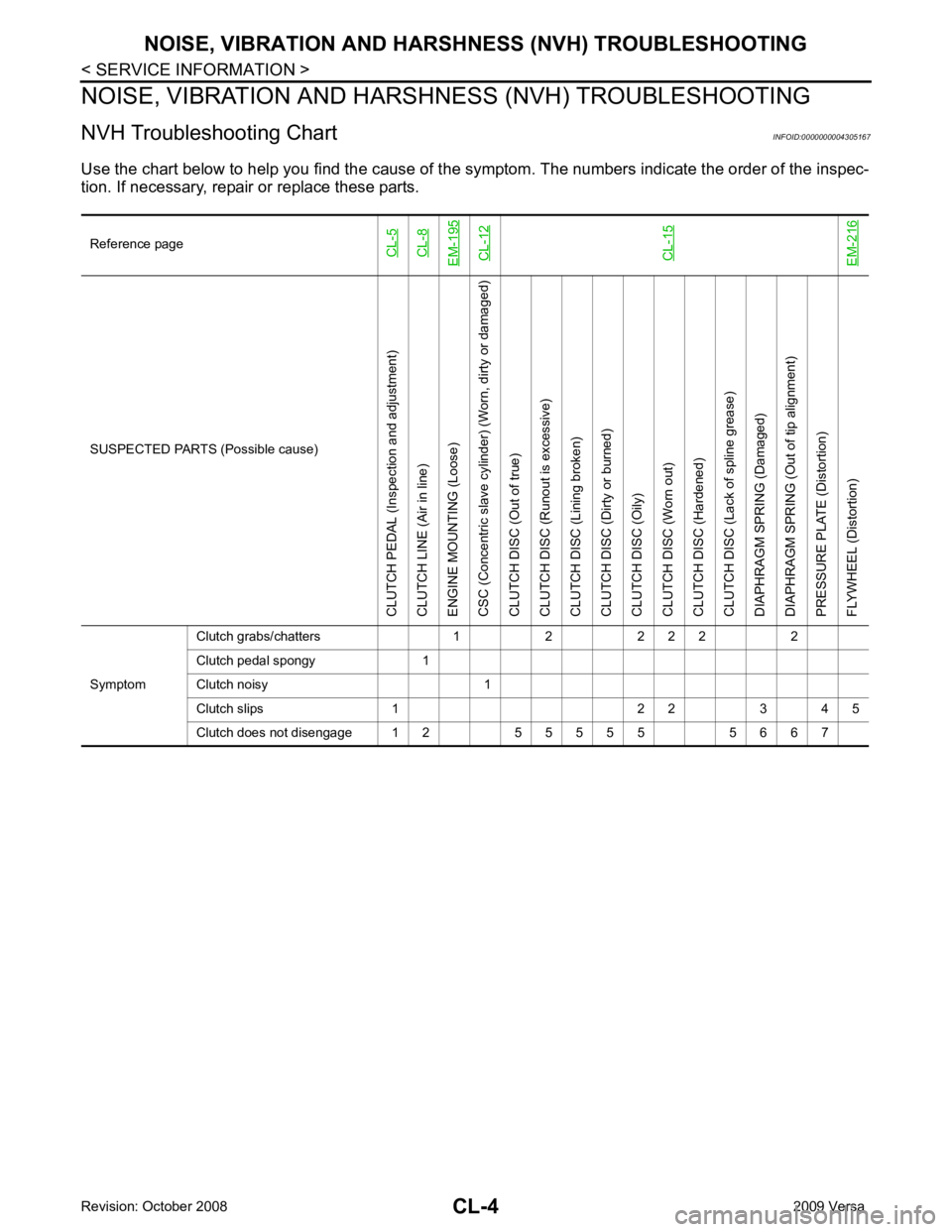

CL-8EM-195CL-12CL-15EM-216SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Inspection and adjustment)

CLUTCH LINE (Air in line)

ENGINE MOUNTING (Loose)

CSC (Concentric slave cylinder) (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runou t is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

Symptom Clutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 5 5 5 5 5 5 6 6 7

Page 891 of 4331

CL

N

O P

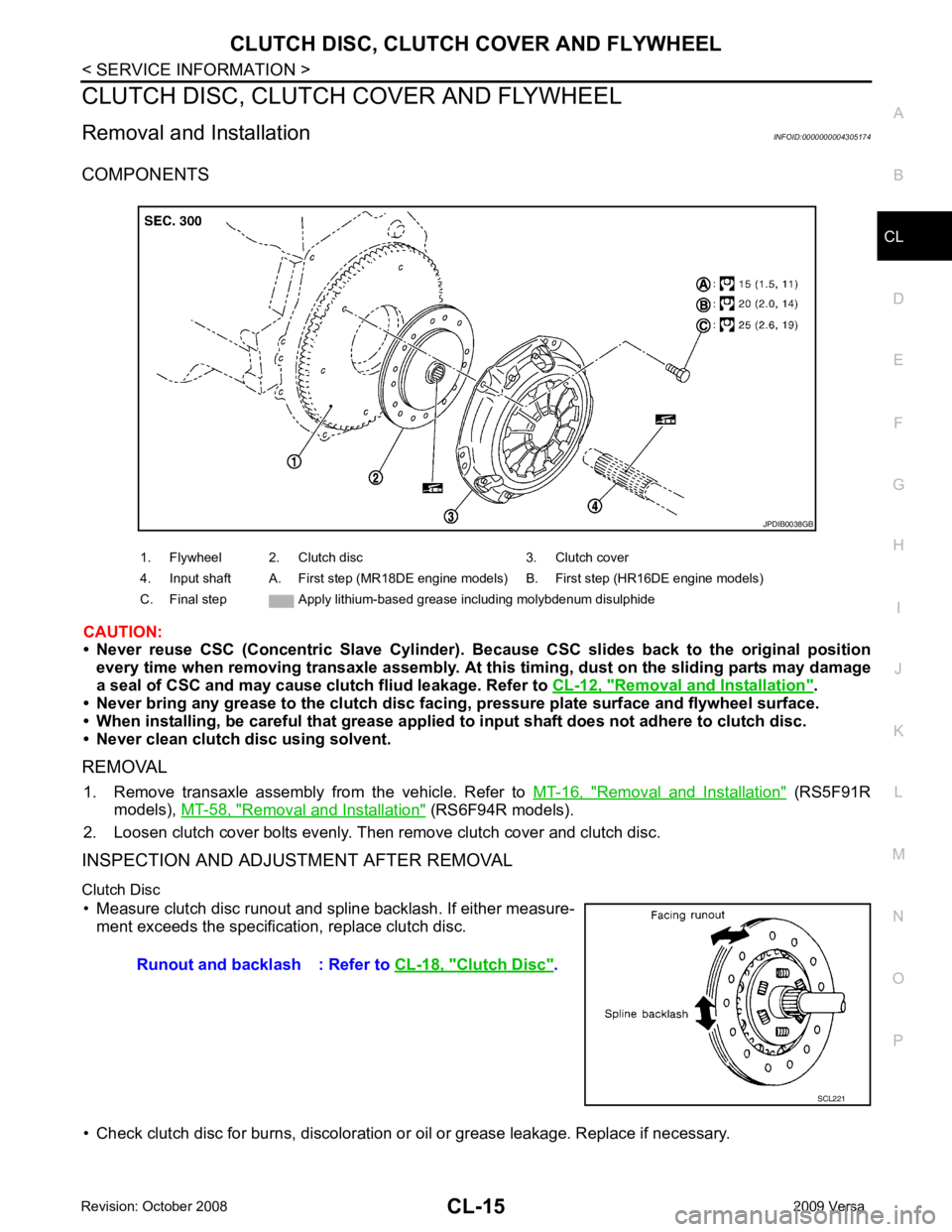

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Removal and Installation INFOID:0000000004305174

COMPONENTS

CAUTION:

• Never reuse CSC (Concentric Slave Cylinder). B ecause CSC slides back to the original position

every time when removing transaxle assembly. At th is timing, dust on the sliding parts may damage

a seal of CSC and may cause clut ch fliud leakage. Refer to CL-12, " Removal and Installation " .

• Never bring any grease to the clutch disc faci ng, pressure plate surface and flywheel surface.

• When installing, be careful that grease applied to input shaft does not adhere to clutch disc.

• Never clean clutch disc using solvent.

REMOVAL 1. Remove transaxle assembly from the vehicle. Refer to MT-16, " Removal and Installation " (RS5F91R

models), MT-58, " Removal and Installation " (RS6F94R models).

2. Loosen clutch cover bolts evenly. Then remove clutch cover and clutch disc.

INSPECTION AND ADJUSTMENT AFTER REMOVAL

Clutch Disc • Measure clutch disc runout and spline backlash. If either measure- ment exceeds the specificat ion, replace clutch disc.

• Check clutch disc for burns, discoloration or oil or grease leakage. Replace if necessary.

1. Flywheel 2. Clutch disc 3. Clutch cover

4. Input shaft A. First step (MR18DE engine models) B. First step (HR16DE engine models)

C. Final step Apply lithium-based grease including molybdenum disulphide Clutch Disc " .