oil pressure NISSAN TIIDA 2009 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1149 of 4331

![NISSAN TIIDA 2009 Service Owners Guide CVT SYSTEM

CVT-205

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

*1: Input by CAN communications.

*2: Output by CAN communications.

*3: If these input and output signals are diff NISSAN TIIDA 2009 Service Owners Guide CVT SYSTEM

CVT-205

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

*1: Input by CAN communications.

*2: Output by CAN communications.

*3: If these input and output signals are diff](/img/5/57398/w960_57398-1148.png)

CVT SYSTEM

CVT-205

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

*1: Input by CAN communications.

*2: Output by CAN communications.

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

Line Pressure and Secondary Pressure Control INFOID:0000000004305579

• When an input torque signal equivalent to the engine drive force is sent from the ECM to the TCM, the TCM

controls the line pressure solenoid valve and secondary pressure solenoid valve.

• This line pressure solenoid controls the pressure regulat or valve as the signal pressure and adjusts the pres-

sure of the operating oil discharged from the oil pump to the line pressure most appropriate to the driving

state. Secondary pressure is cont rolled by decreasing line pressure.

NORMAL CONTROL Optimize the line pressure and secondary pressure, dependi ng on driving conditions, on the basis of the throt-

tle position, the engine speed, the primary pulley (input ) revolution speed, the secondary pulley (output) revo-

lution speed, the brake signal, the PNP switch signal, the lock-up signal, the voltage, the target gear ratio, the

fluid temperature, and the fluid pressure.

FEEDBACK CONTROL When controlling the normal fluid pressure or the sele cted fluid pressure, the secondary pressure can be set

more accurately by using the fluid pressure sensor to detect the secondary pressure and controlling the feed-

back.

Shift Control INFOID:0000000004305580

In order to select the gear ratio which can obtain the dr iving force in accordance with driver's intention and the

vehicle condition, TCM monitors the driving conditions, such as the vehicle speed and the throttle position and

selects the optimum gear ratio, and determines the gear change steps to the gear ratio. Then send the com-

Out-

put Step motor X X

TCC solenoid valve X X X

Lock-up select solenoid valve X X X

Line pressure solenoid valve X X X X

Secondary pressure solenoid valve X X X

O/D OFF indicator signal (*2)

X X

Control item

Fluid

pressure

control Select con-

trol Shift control

Lock-up

control CAN com-

munication

control Fail-safe

function

(*3) SCIA1846E

Page 1156 of 4331

.

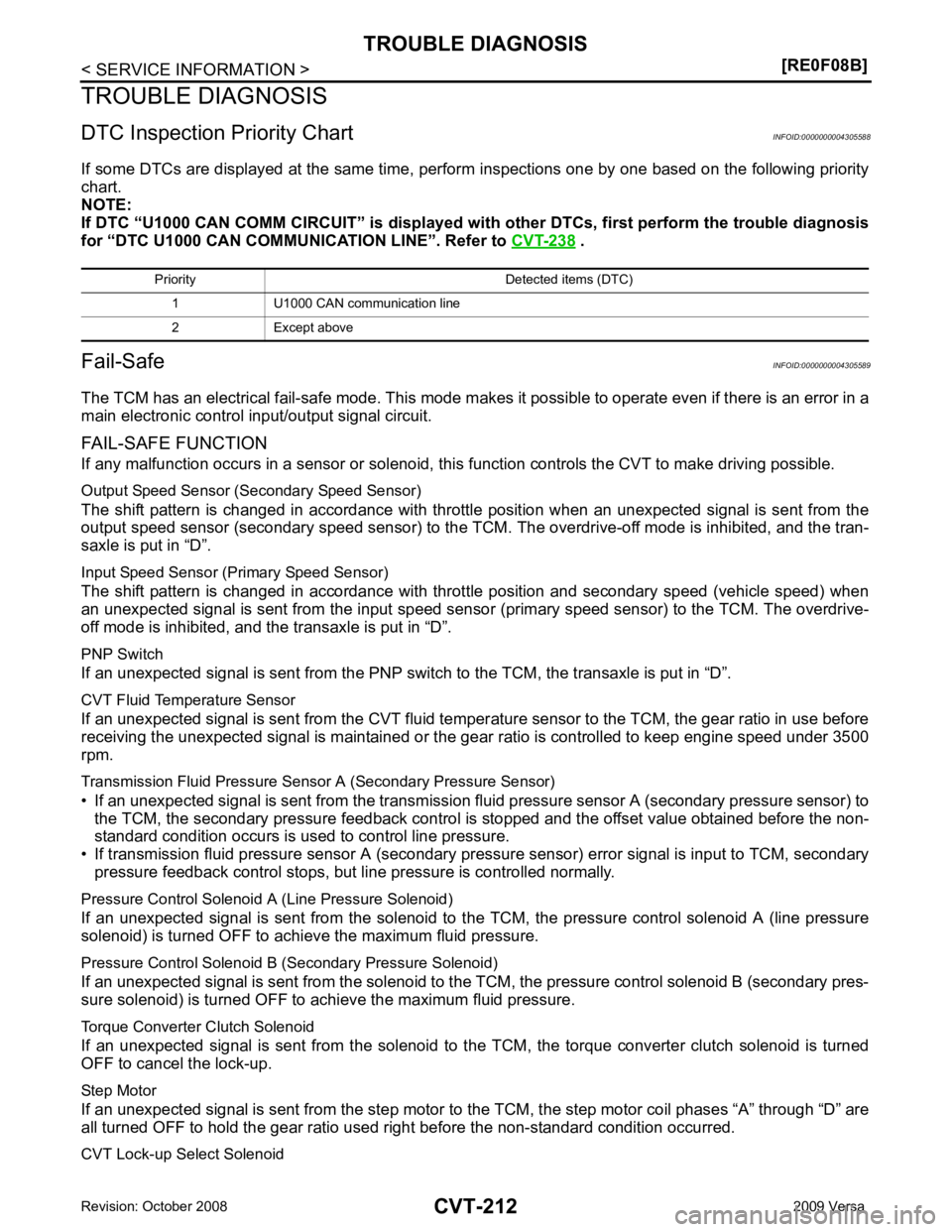

Fail-Safe INFOID:0000000004305589

The TCM has an electrical fail-safe mode. This mode make s it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, th is function controls the CVT to make driving possible.

Output Speed Sensor (S econdary Speed Sensor)

The shift pattern is changed in accordance with thrott le position when an unexpected signal is sent from the

output speed sensor (secondary speed sensor) to the TCM. The overdrive-off mode is inhibited, and the tran-

saxle is put in “D”.

Input Speed Sensor (Primary Speed Sensor)

The shift pattern is changed in accordance with thro ttle position and secondary speed (vehicle speed) when

an unexpected signal is sent from the input speed sensor (primary speed sensor) to the TCM. The overdrive-

off mode is inhibited, and the transaxle is put in “D”.

PNP Switch

If an unexpected signal is sent from the PNP switch to the TCM, the transaxle is put in “D”.

CVT Fluid Temperature Sensor

If an unexpected signal is sent from the CVT fluid temper ature sensor to the TCM, the gear ratio in use before

receiving the unexpected signal is maintained or t he gear ratio is controlled to keep engine speed under 3500

rpm.

Transmission Fluid Pressure Sensor A (Secondary Pressure Sensor)

• If an unexpected signal is sent from the transmission fluid pressure sensor A (secondary pressure sensor) to

the TCM, the secondary pressure feedback control is stopped and the offset value obtained before the non-

standard condition occurs is used to control line pressure.

• If transmission fluid pressure sensor A (secondary pres sure sensor) error signal is input to TCM, secondary

pressure feedback control stops, but line pressure is controlled normally.

Pressure Control Solenoid A (Line Pressure Solenoid)

If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid A (line pressure

solenoid) is turned OFF to achieve the maximum fluid pressure.

Pressure Control Solenoid B (Secondary Pressure Solenoid)

If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid B (secondary pres-

sure solenoid) is turned OFF to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid

If an unexpected signal is sent from the solenoid to t he TCM, the torque converter clutch solenoid is turned

OFF to cancel the lock-up.

Step Motor

If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases “A” through “D” are

all turned OFF to hold the gear ratio used right before the non-standard condition occurred.

CVT Lock-up Select Solenoid Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 1165 of 4331

![NISSAN TIIDA 2009 Service Owners Guide TROUBLE DIAGNOSIS

CVT-221

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

6. While holding down the foot brake, gradually press down the

accelerator pedal.

7. Quickly rea NISSAN TIIDA 2009 Service Owners Guide TROUBLE DIAGNOSIS

CVT-221

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

6. While holding down the foot brake, gradually press down the

accelerator pedal.

7. Quickly rea](/img/5/57398/w960_57398-1164.png)

TROUBLE DIAGNOSIS

CVT-221

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

6. While holding down the foot brake, gradually press down the

accelerator pedal.

7. Quickly read off the stall speed, and then quickly remove your foot from the accelerator pedal.

CAUTION:

Do not hold down the accelerat or pedal for more than 5 sec-

onds during this test.

8. Move the selector lever to the “N” position.

9. Cool down the CVT fluid. CAUTION:

Run the engine at idle for at least 1 minute.

10. Repeat steps 6 through 9 with selector lever in “R” position.

Judgement Stall Test

O: Stall speed within standard value position.

H: Stall speed is higher than standard value.

L: Stall speed is lower than standard value.

LINE PRESSURE TEST

Line Pressure Test Port

Line Pressure Test Procedure 1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the CVT fluid reaches in the range of 50 to 80°C

(122 to 176 °F), then inspect the amount of CVT fluid and replenish if necessary.

NOTE: Stall speed:

CVT-357, " Stall Speed "

SAT514G

SAT771B

Selector lever position

Expected problem location

“D” “R”

Stall rotation H O • Forward clutch

O H • Reverse brake L L • Engine and torque converter one-way clutch

H H • Line pressure low

• Primary pulley

• Secondary pulley

• Steel belt SCIA6184E

Page 1166 of 4331

![NISSAN TIIDA 2009 Service Owners Guide CVT-222< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

The CVT fluid temperature rises in the range of 50 - 80 °C (122 - 176 °F) during 10 minutes of driving.

3. After warming up CVT, remove the NISSAN TIIDA 2009 Service Owners Guide CVT-222< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

The CVT fluid temperature rises in the range of 50 - 80 °C (122 - 176 °F) during 10 minutes of driving.

3. After warming up CVT, remove the](/img/5/57398/w960_57398-1165.png)

CVT-222< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

The CVT fluid temperature rises in the range of 50 - 80 °C (122 - 176 °F) during 10 minutes of driving.

3. After warming up CVT, remove the oil pressure detection plug and install the oil pressure gauge [special service tool: - (OTC3492)].

CAUTION:

When using the oil pressure gauge, be sure to u se the O-ring attached to the oil pressure detec-

tion plug.

4. Securely engage the parking brake so that the tires do not turn.

5. Start the engine, and then measure the line pressure at both idle and the stall speed.

CAUTION:

• Keep the brake pedal pressed all the way down during

measurement.

• When measuring the line pressure at the stall speed, refer

to "STALL TEST" .

6. After the measurements are complete, install the oil pressure detection plug and tighten to the specified torque below.

CAUTION:

• Do not reuse O-ring.

• Apply CVT fluid to O-ring.

Line Pressure

Judgement of Line Pressure Test SAT513G

: 7.5 N·m (0.77 kg-m, 66 in-lb)

SAT493G

Engine speed

Line pressure kPa (kg/cm

2

, psi)

“R”, “D” and “L” positions

At idle CVT-357, " Line Pressure "

At stall

Page 1167 of 4331

![NISSAN TIIDA 2009 Service Owners Guide TROUBLE DIAGNOSIS

CVT-223

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Road Test

INFOID:0000000004305594

DESCRIPTION • The purpose of the test is to determine overall performa NISSAN TIIDA 2009 Service Owners Guide TROUBLE DIAGNOSIS

CVT-223

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Road Test

INFOID:0000000004305594

DESCRIPTION • The purpose of the test is to determine overall performa](/img/5/57398/w960_57398-1166.png)

TROUBLE DIAGNOSIS

CVT-223

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Road Test

INFOID:0000000004305594

DESCRIPTION • The purpose of the test is to determine overall performance of CVT and analyze causes of problems.

• The road test consists of the following three parts:

1. “Check Before Engine Is Started” CVT-224 .

2. “Check at Idle” CVT-224 .

3. “Cruise Test” CVT-226 .

Judgement Possible cause

Idle speed Low for all positions

(“P”, “R”, “N”, “D”, “L”) Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

• Oil pump wear

• Pressure regulator valve or plug sticking or spring fatigue

• Oil strainer ⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

High Possible causes include a sensor malfunction or malfunction in the line pressure adjustment

function.

For example

• Accelerator pedal position signal malfunction

• CVT fluid temperature sensor malfunction

• Pressure control solenoid A (line pressure solenoid) malfunction (sticking in OFF state, filter

clog, cut line)

• Pressure regulator valve or plug sticking

Stall speed Line pressure does

not rise higher than

the line pressure for

idle. Possible causes include a sensor malfunction or malfunction in the pressure adjustment func-

tion.

For example

• Accelerator pedal position signal malfunction

• TCM malfunction

• Pressure control solenoid A (lin e pressure solenoid) malfunction (shorting, sticking in ON

state)

• Pressure regulator valve or plug sticking

The pressure rises,

but does not enter the

standard position. Possible causes include malfunctions in the pressure supply system and malfunction in the pres-

sure adjustment function.

For example

• Accelerator pedal position signal malfunction

• Pressure control solenoid A (l ine pressure solenoid) malfunction (sticking, filter clog)

• Pressure regulator valve or plug sticking

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve. SAT786A

Page 1178 of 4331

Malfunction Indicator Lamp (MIL) " .

*2: Models without ABS does not indicate.

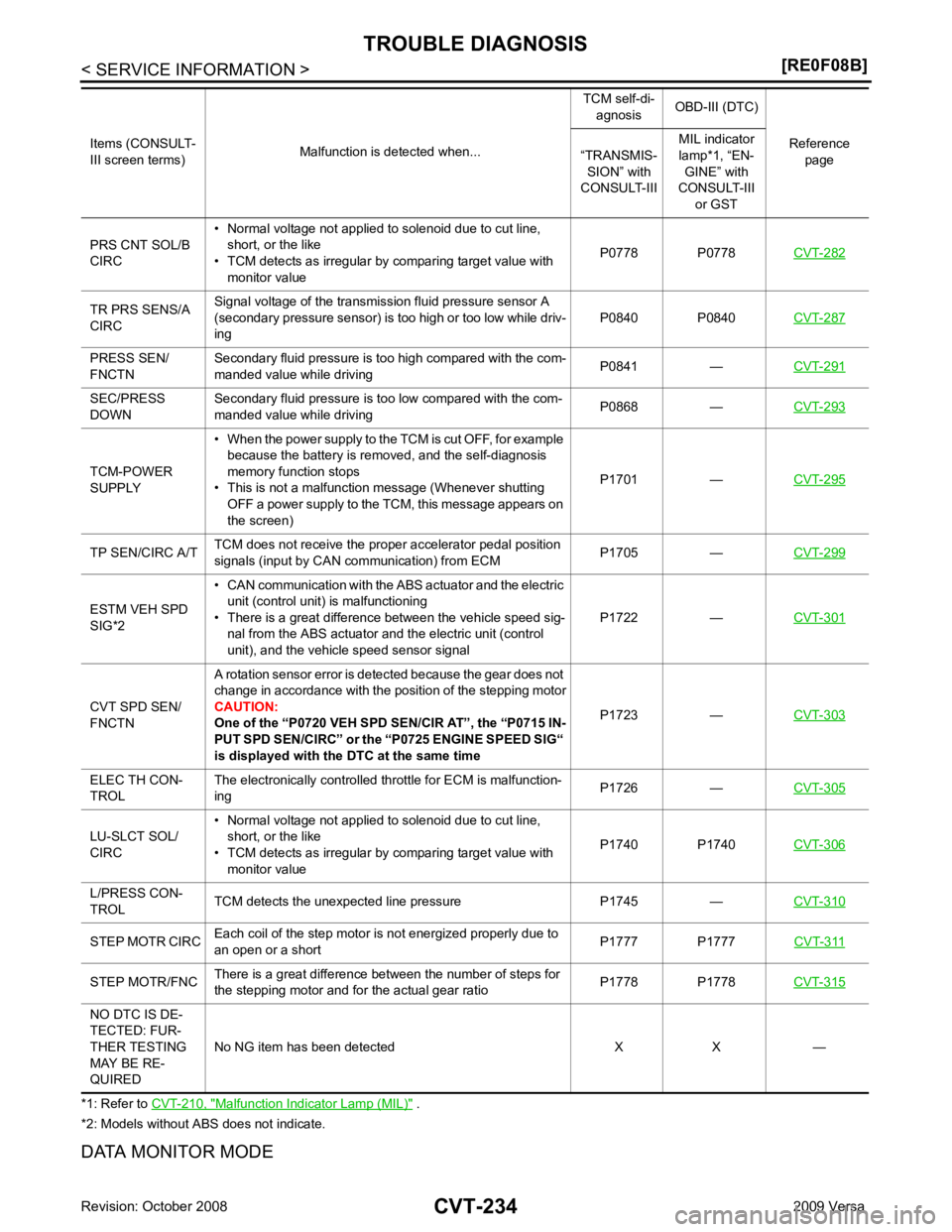

DATA MONITOR MODE PRS CNT SOL/B

CIRC • Normal voltage not applied to solenoid due to cut line,

short, or the like

• TCM detects as irregular by comparing target value with

monitor value P0778 P0778

CVT-282TR PRS SENS/A

CIRC Signal voltage of the transmission fluid pressure sensor A

(secondary pressure sensor) is too high or too low while driv-

ing P0840 P0840

CVT-287PRESS SEN/

FNCTN Secondary fluid pressure is too high compared with the com-

manded value while driving P0841 —

CVT-291SEC/PRESS

DOWN Secondary fluid pressure is too low compared with the com-

manded value while driving P0868 —

CVT-293TCM-POWER

SUPPLY • When the power supply to the TCM is cut OFF, for example

because the battery is removed, and the self-diagnosis

memory function stops

• This is not a malfunction message (Whenever shutting OFF a power supply to the TCM, this message appears on

the screen) P1701 —

CVT-295TP SEN/CIRC A/T

TCM does not receive the proper accelerator pedal position

signals (input by CAN communication) from ECM P1705 —

CVT-299ESTM VEH SPD

SIG*2 • CAN communication with the

ABS actuator and the electric

unit (control unit) is malfunctioning

• There is a great difference between the vehicle speed sig- nal from the ABS actuator and the electric unit (control

unit), and the vehicle speed sensor signal P1722 —

CVT-301CVT SPD SEN/

FNCTN A rotation sensor error is detected because the gear does not

change in accordance with the position of the stepping motor

CAUTION:

One of the “P0720 VEH SPD SEN/CIR AT”, the “P0715 IN-

PUT SPD SEN/CIRC” or the “P0725 ENGINE SPEED SIG“

is displayed with the DTC at the same time P1723 —

CVT-303ELEC TH CON-

TROL The electronically controlled throttle for ECM is malfunction-

ing P1726 —

CVT-305LU-SLCT SOL/

CIRC • Normal voltage not applied to solenoid due to cut line,

short, or the like

• TCM detects as irregular by comparing target value with monitor value P1740 P1740

CVT-306L/PRESS CON-

TROL TCM detects the unexpected line pressure P1745 —

CVT-310STEP MOTR CIRC

Each coil of the step motor is not energized properly due to

an open or a short P1777 P1777

CVT-311STEP MOTR/FNC

There is a great difference between the number of steps for

the stepping motor and for the actual gear ratio P1778 P1778

CVT-315NO DTC IS DE-

TECTED: FUR-

THER TESTING

MAY BE RE-

QUIRED No NG item has been detected X X —

Items (CONSULT-

III screen terms) Malfunction is detected when... TCM self-di-

agnosis OBD-III (DTC)

Reference page

“TRANSMIS-

SION” with

CONSULT-III MIL indicator

lamp*1, “EN- GINE” with

CONSULT-III

or GST

Page 1217 of 4331

CVT

N

O P

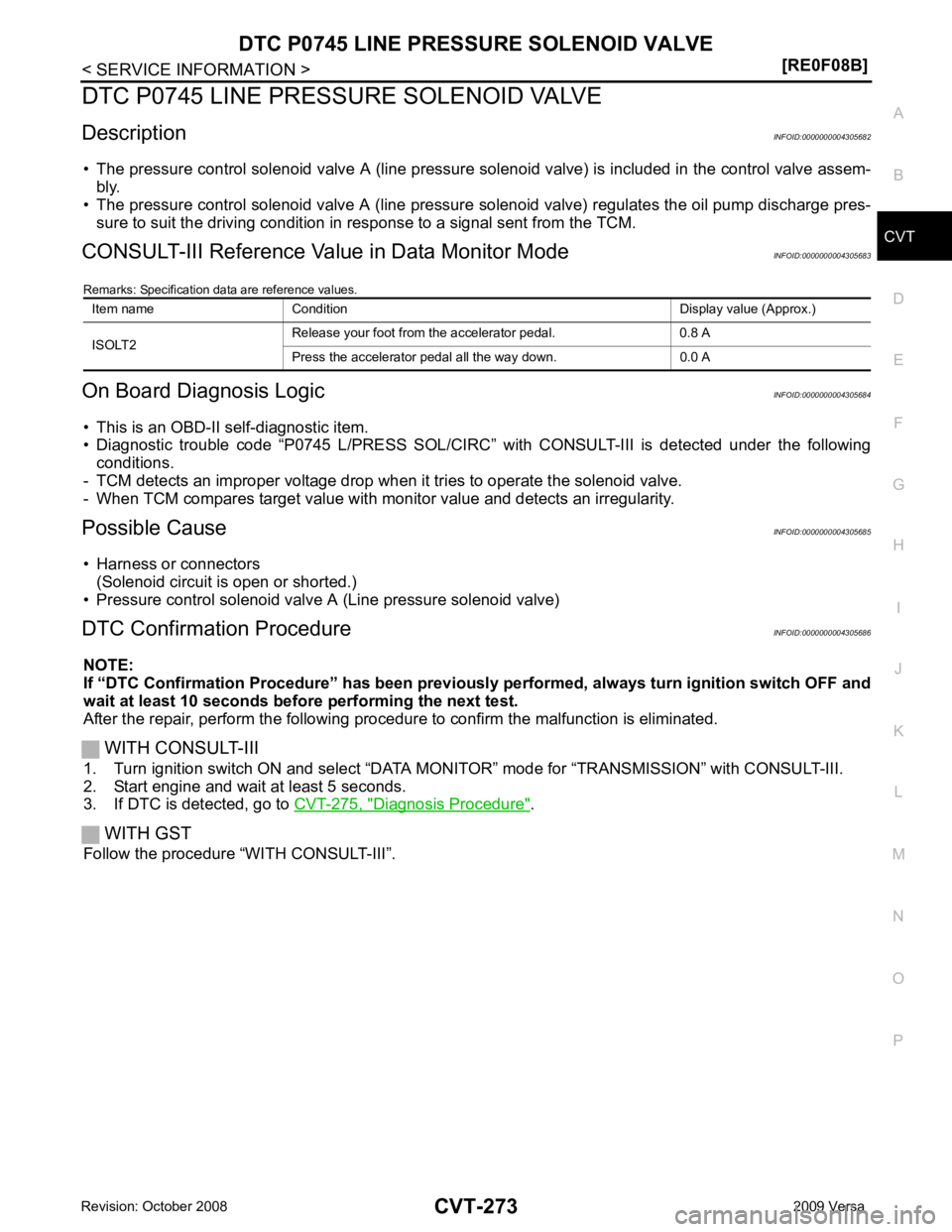

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description INFOID:0000000004305682

• The pressure control solenoid valve A (line pressure solenoid valve) is included in the control valve assem- bly.

• The pressure control solenoid valve A (line pressure solenoid valve) regulates the oil pump discharge pres-

sure to suit the driving condition in response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305683

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305684

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0745 L/PRESS SOL/CIRC” with CONSULT-III is detected under the following

conditions.

- TCM detects an improper voltage drop when it tries to operate the solenoid valve.

- When TCM compares target value with monitor value and detects an irregularity.

Possible Cause INFOID:0000000004305685

• Harness or connectors (Solenoid circuit is open or shorted.)

• Pressure control solenoid valve A (Line pressure solenoid valve)

DTC Confirmation Procedure INFOID:0000000004305686

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Start engine and wait at least 5 seconds.

3. If DTC is detected, go to CVT-275, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value (Approx.)

ISOLT2 Release your foot from the accelerator pedal. 0.8 A

Press the accelerator pedal all the way down. 0.0 A

Page 1255 of 4331

CVT

N

O P

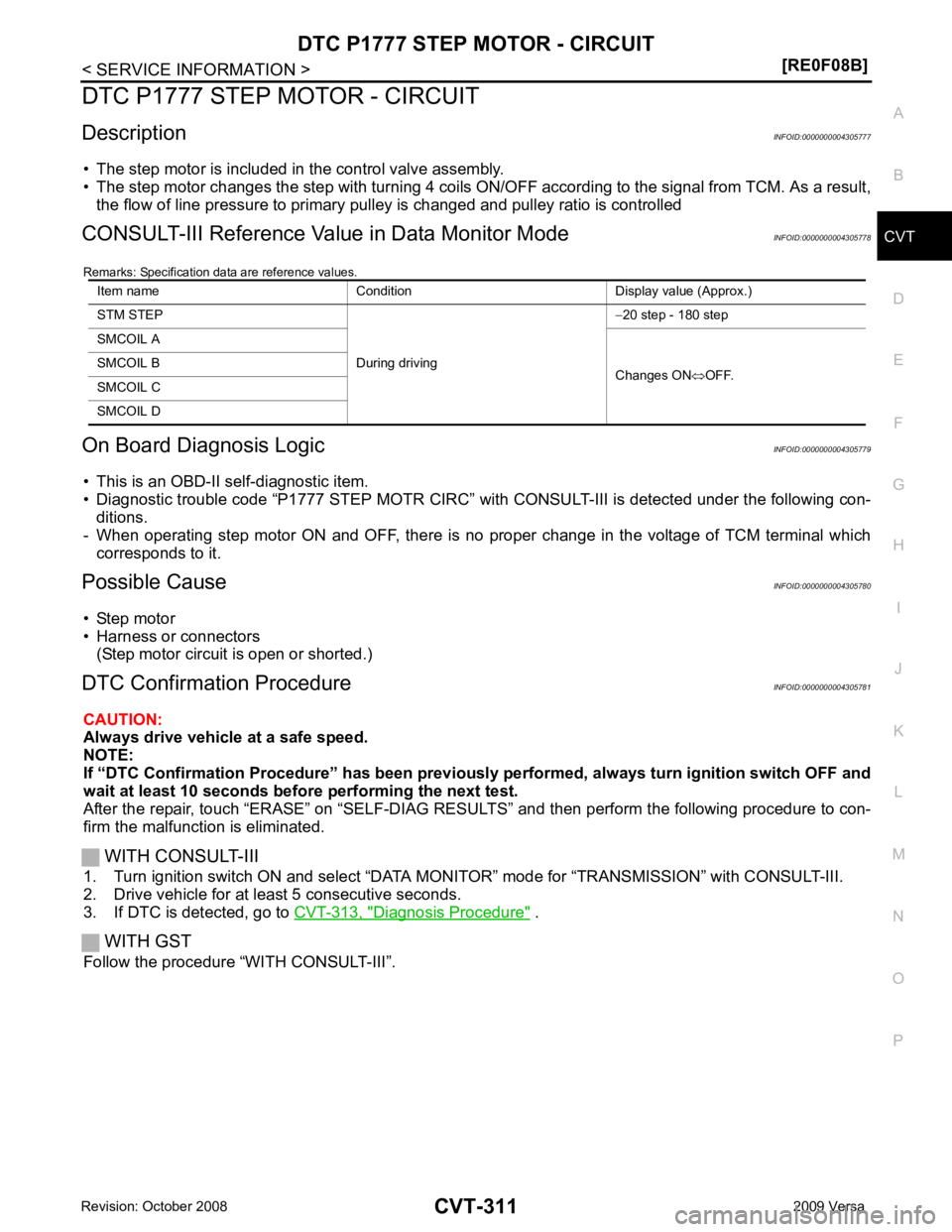

DTC P1777 STEP MOTOR - CIRCUIT

Description INFOID:0000000004305777

• The step motor is included in the control valve assembly.

• The step motor changes the step with turning 4 coils ON/OF F according to the signal from TCM. As a result,

the flow of line pressure to primary pu lley is changed and pulley ratio is controlled

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305778

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305779

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1777 STEP MOTR CIRC” with CONSULT-III is detected under the following con-

ditions.

- When operating step motor ON and OFF, there is no proper change in the voltage of TCM terminal which corresponds to it.

Possible Cause INFOID:0000000004305780

• Step motor

• Harness or connectors

(Step motor circuit is open or shorted.)

DTC Confirmation Procedure INFOID:0000000004305781

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Drive vehicle for at least 5 consecutive seconds.

3. If DTC is detected, go to CVT-313, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value (Approx.)

STM STEP

During driving−

20 step - 180 step

SMCOIL A

Changes ON⇔OFF.

SMCOIL B

SMCOIL C

SMCOIL D

Page 1303 of 4331

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

COMBINATION METERS .............................. .....3

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

3

System Description ............................................. ......3

Arrangement of Combination Meter .................... ......5

Internal Circuit ..................................................... ......6

Wiring Diagram - METER - ................................. ......7

Combination Meter Harness Connector Terminal

Layout ................................................................. ......

9

Terminal and Reference Value for Combination

Meter ................................................................... ......

9

Self-Diagnosis Mode of Combination Meter ........ ....10

CONSULT-III Function (METER/M&A) ............... ....12

Trouble Diagnosis ............................................... ....13

Symptom Chart ................................................... ....14

Power Supply and Ground Circuit Inspection ..... ....14

Vehicle Speed Signal Inspection ......................... ....15

Engine Speed Signal Inspection ......................... ....16

Fuel Level Sensor Signal Inspection ................... ....16

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies .................................................................. ....

18

Fuel Gauge Does Not Move to Full-position ...........18

DTC [U1000] CAN Communication Circuit ......... ....18

Electrical Component Inspection ......................... ....19

Removal and Installation .........................................19

WARNING LAMPS ......................................... ....20

Schematic ........................................................... ....20

Wiring Diagram - WARN - ................................... ....21 Oil Pressure Wa

rning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

29

Oil Pressure Wa rning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

31

Component Inspection ......................................... ....31

A/T INDICATOR ................................................ 33

System Description .............................................. ....33

Wiring Diagram - AT/IND - ................................... ....34

A/T Indicator Does Not Illuminate ........................ ....35

CVT INDICATOR ............................................... 37

System Description .............................................. ....37

Schematic ............................................................ ....37

Wiring Diagram - CVTIND - ................................. ....38

CVT Indicator Does Not Illuminate ...................... ....40

WARNING CHIME ............................................. 42

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

42

System Description .............................................. ....42

Wiring Diagram - CHIME - ................................... ....45

Terminal and Reference Value for BCM ..................46

CONSULT-III Function (B CM) .................................46

Trouble Diagnosis ................................................ ....47

Combination Meter Buzzer Cir cuit Inspection .........48

Front Door Switch LH Signal Inspection .............. ....49

Key Switch Signal Inspec tion (Without Intelligent

Key) ..................................................................... ....

50

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

51

Lighting Switch Signal Inspection ........................ ....53

Parking Brake Switch Signal Inspection .............. ....53

Electrical Component Inspection ......................... ....54

Page 1315 of 4331

DI

N

O P

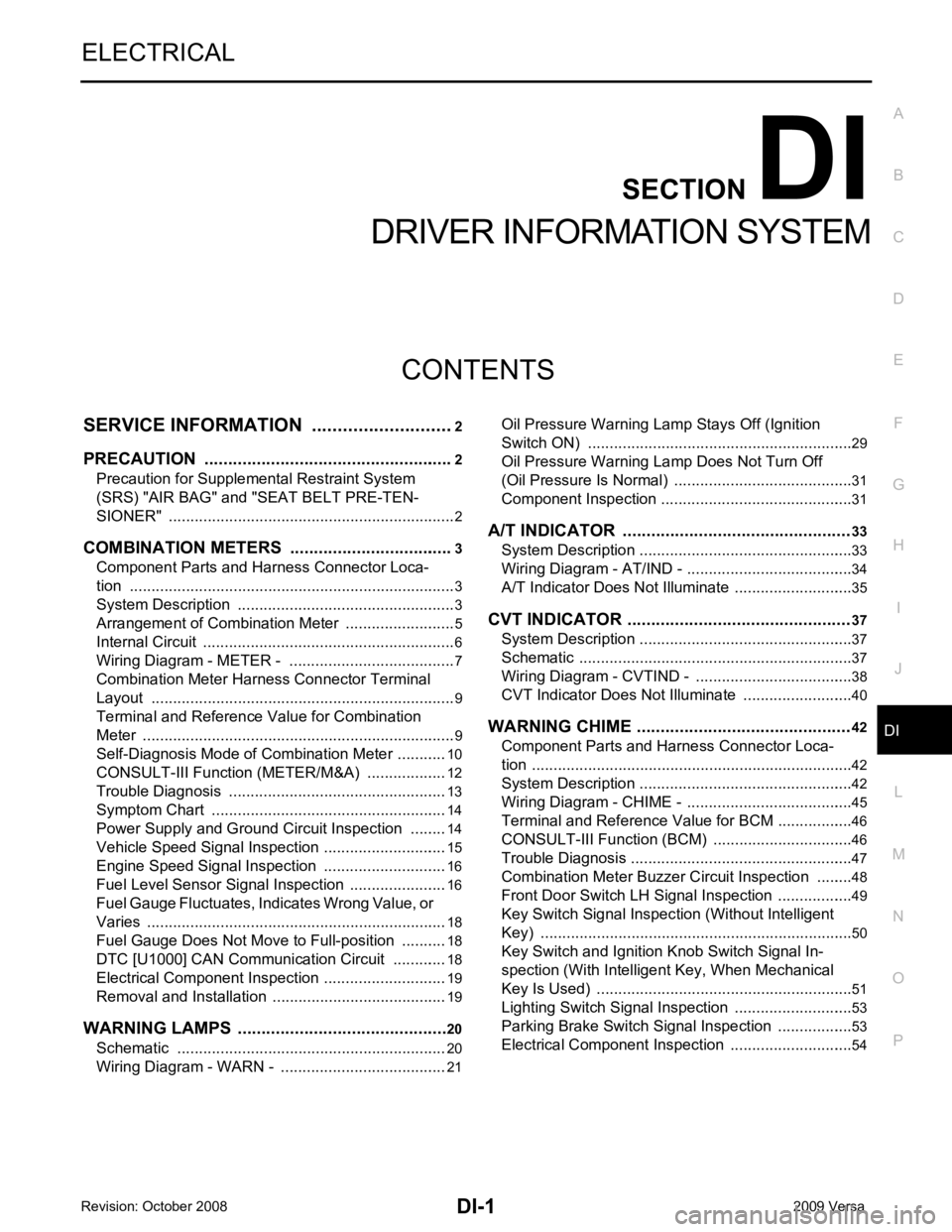

NOTE:

Some items are not available due to vehicle specification.

*: The monitor will indicate “OFF” even though the brake warnin g lamp is on if either of the following conditions exist.

• The parking brake is engaged

• The brake fluid level is low

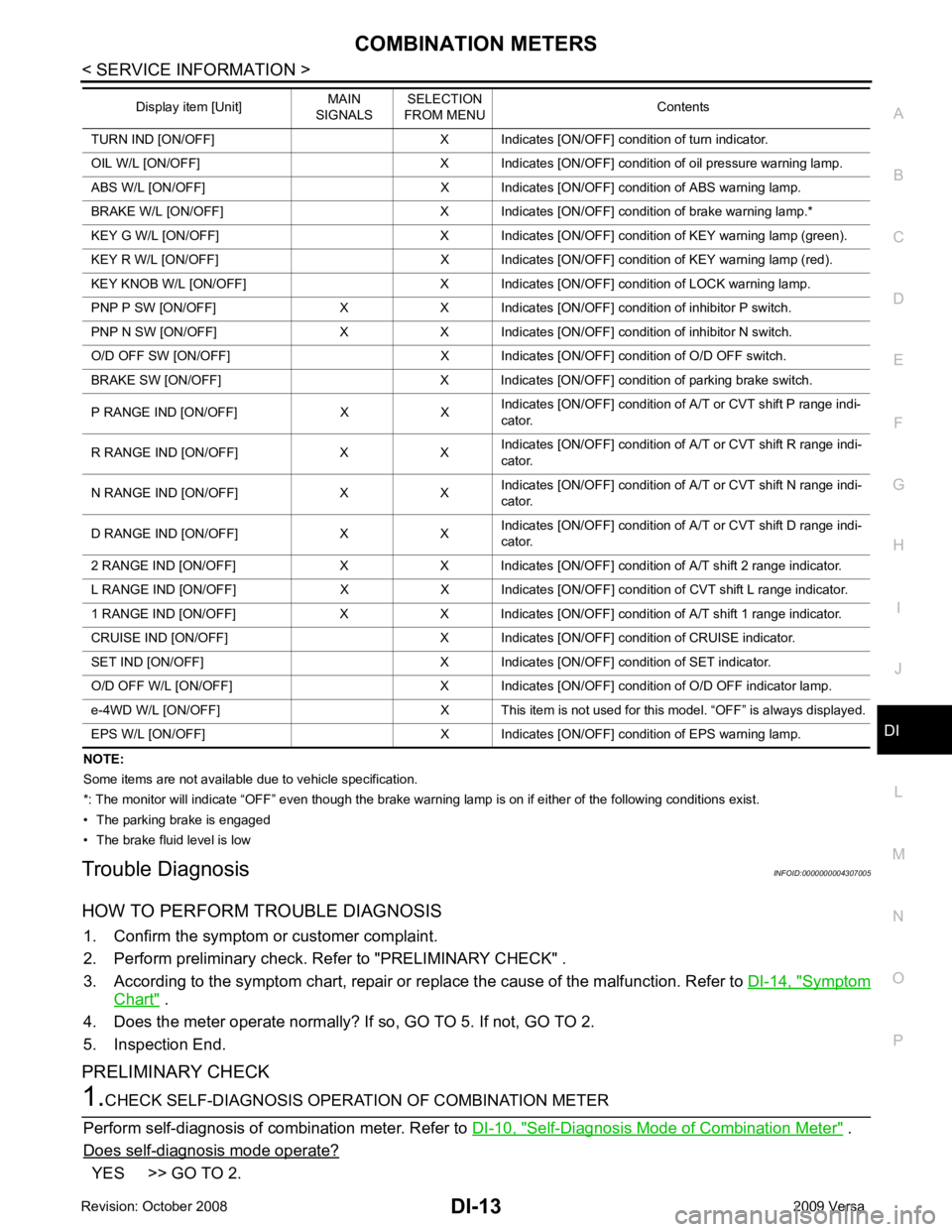

Trouble Diagnosis INFOID:0000000004307005

HOW TO PERFORM TROUBLE DIAGNOSIS 1. Confirm the symptom or customer complaint.

2. Perform preliminary check. Refer to "PRELIMINARY CHECK" .

3. According to the symptom chart, repair or replace the cause of the malfunction. Refer to DI-14, " Symptom

Chart " .

4. Does the meter operate normally? If so, GO TO 5. If not, GO TO 2.

5. Inspection End.

PRELIMINARY CHECK Self-Diagnosis Mode of Combination Meter " .

Does self - diagnosis mode operate?

YES >> GO TO 2.

TURN IND [ON/OFF] X Indicates [ON/O

FF] condition of turn indicator.

OIL W/L [ON/OFF] X Indicates [ON/OFF] condition of oil pressure warning lamp.

ABS W/L [ON/OFF] X Indicates [ON/O FF] condition of ABS warning lamp.

BRAKE W/L [ON/OFF] X Indicates [ON/OFF] condition of brake warning lamp.*

KEY G W/L [ON/OFF] X Indicates [ON/OFF] condition of KEY warning lamp (green).

KEY R W/L [ON/OFF] X Indicates [ON/OFF] condition of KEY warning lamp (red).

KEY KNOB W/L [ON/OFF] X Indicates [ON/OFF] condition of LOCK warning lamp.

PNP P SW [ON/OFF] X X Indicates [ON/OFF] condition of inhibitor P switch.

PNP N SW [ON/OFF] X X Indicates [ON/OFF] condition of inhibitor N switch.

O/D OFF SW [ON/OFF] X Indicates [ON/ OFF] condition of O/D OFF switch.

BRAKE SW [ON/OFF] X Indicates [ON/OFF] condition of parking brake switch.

P RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T or CVT shift P range indi-

cator.

R RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T or CVT shift R range indi-

cator.

N RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T or CVT shift N range indi-

cator.

D RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T or CVT shift D range indi-

cator.

2 RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift 2 range indicator.

L RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of CVT shift L range indicator.

1 RANGE IND [ON/OFF] X X Indicates [ON/OFF] condition of A/T shift 1 range indicator.

CRUISE IND [ON/OFF] X Indicates [ON/O FF] condition of CRUISE indicator.

SET IND [ON/OFF] X Indicates [ON/OFF] condition of SET indicator.

O/D OFF W/L [ON/OFF] X Indicates [ON/OFF] condition of O/D OFF indicator lamp.

e-4WD W/L [ON/OFF] X This item is not used for this model. “OFF” is always displayed.

EPS W/L [ON/OFF] X Indicates [ON/O FF] condition of EPS warning lamp.

Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Contents