oil pressure NISSAN TIIDA 2009 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1331 of 4331

DI

N

O P

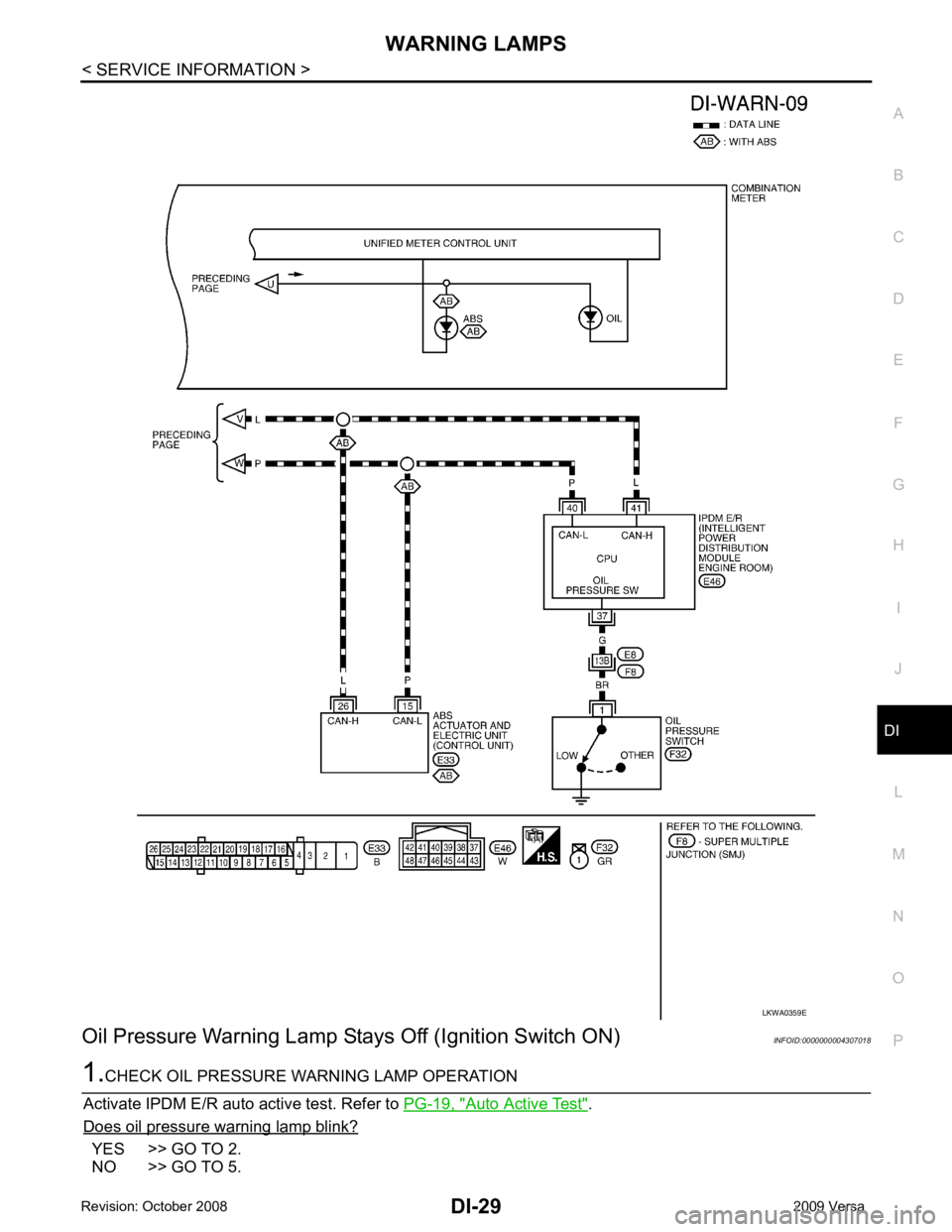

Oil Pressure Warning Lamp Stay

s Off (Ignition Switch ON) INFOID:0000000004307018 Auto Active Test " .

Does oil pressure warning lamp blink? YES >> GO TO 2.

NO >> GO TO 5.

Page 1332 of 4331

OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and

Installation of IPDM E/R " .

NG >> GO TO 3. Component Inspection " .

OK or NG OK >> GO TO 4.

NG >> Replace oil pressure switch. OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and

Installation of IPDM E/R " .

NG >> Repair harness or connector. - diagnostic results content

No malfunction detected>>GO TO 6.

Malfunction detected>> Check applicable parts, and repair or replace as necessary. OK >> Replace combination meter. Refer to

IP-12, " Removal and Installation " .

NG >> Replace IPDM E/R. Refer to PG-27, " Removal and Installation of IPDM E/R " .

Terminals

ConditionVoltage (Ap-

prox.)

(+)

(–)

IPDM E/R

connector Terminal

E46 37 Ground Engine stopped 0 V

Page 1333 of 4331

DI

N

O P

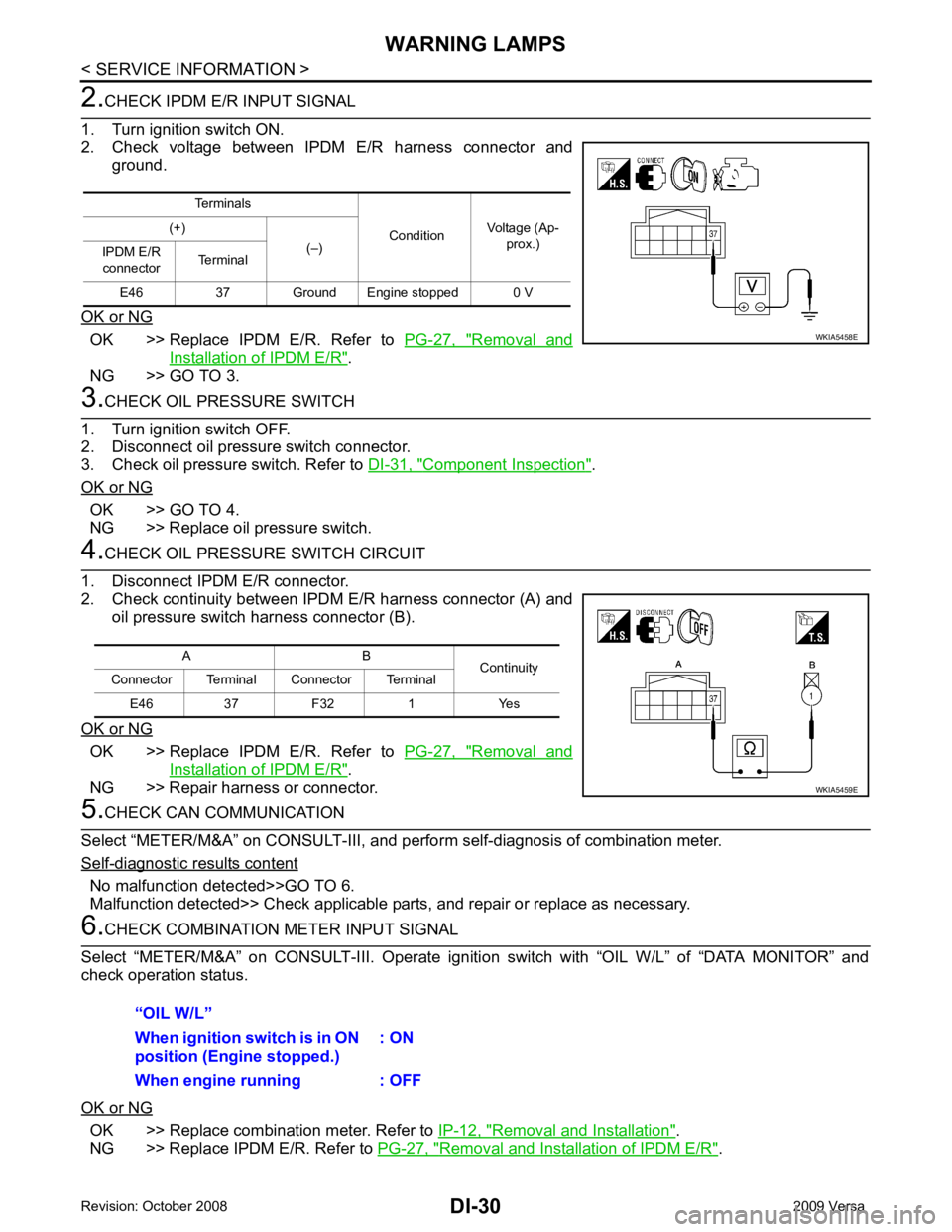

Oil Pressure Warning Lamp Does Not

Turn Off (Oil Pressure Is Normal)INFOID:0000000004307019

NOTE:

For oil pressure inspection, refer to LU-16, " Inspection " .

Auto Active Test " .

Does oil pressure warning lamp blink? YES >> GO TO 2.

NO >> GO TO 5. OK >> GO TO 3.

NG >> GO TO 4. Component Inspection " .

OK or NG OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

NG >> Replace oil pressure switch. OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and

Installation of IPDM E/R " .

NG >> Repair harness or connector. CONSULT-III Function (IPDM E/R) " .

Self - diagnostic results content

No malfunction detected>>Replace combination meter. Refer to

IP-12, " Removal and Installation " .

Malfunction detected>> Check applicable parts, and repair or replace as necessary.

Component Inspection INFOID:0000000004307020

OIL PRESSURE SWITCH Terminals

Voltage (Approx.)

(+)

(–)

Oil pressure switch

connector Terminal

F32 1 Ground 12 V

Page 1401 of 4331

![NISSAN TIIDA 2009 Service Service Manual MULTIPORT FUEL INJECTION SYSTEM

EC-45

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780012

1. Ignition coil (with power transistor) and spa NISSAN TIIDA 2009 Service Service Manual MULTIPORT FUEL INJECTION SYSTEM

EC-45

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780012

1. Ignition coil (with power transistor) and spa](/img/5/57398/w960_57398-1400.png)

MULTIPORT FUEL INJECTION SYSTEM

EC-45

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780012

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E

Page 1408 of 4331

![NISSAN TIIDA 2009 Service Service Manual EC-52< FUNCTION DIAGNOSIS >

[HR16DE]

ELECTRIC IGNITION SYSTEM

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-k NISSAN TIIDA 2009 Service Service Manual EC-52< FUNCTION DIAGNOSIS >

[HR16DE]

ELECTRIC IGNITION SYSTEM

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-k](/img/5/57398/w960_57398-1407.png)

EC-52< FUNCTION DIAGNOSIS >

[HR16DE]

ELECTRIC IGNITION SYSTEM

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Component Parts Location INFOID:0000000004780016

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E

Page 1415 of 4331

![NISSAN TIIDA 2009 Service Service Manual AIR CONDITIONING CUT CONTROL

EC-59

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed NISSAN TIIDA 2009 Service Service Manual AIR CONDITIONING CUT CONTROL

EC-59

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed](/img/5/57398/w960_57398-1414.png)

AIR CONDITIONING CUT CONTROL

EC-59

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high.

Component Parts Location INFOID:0000000004780020

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E

Page 1424 of 4331

![NISSAN TIIDA 2009 Service Service Manual EC-68< FUNCTION DIAGNOSIS >

[HR16DE]

COOLING FAN CONTROL

Component Parts Location INFOID:0000000004780029

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control soleno NISSAN TIIDA 2009 Service Service Manual EC-68< FUNCTION DIAGNOSIS >

[HR16DE]

COOLING FAN CONTROL

Component Parts Location INFOID:0000000004780029

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control soleno](/img/5/57398/w960_57398-1423.png)

EC-68< FUNCTION DIAGNOSIS >

[HR16DE]

COOLING FAN CONTROL

Component Parts Location INFOID:0000000004780029

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E

Page 1434 of 4331

![NISSAN TIIDA 2009 Service Service Manual EC-78< FUNCTION DIAGNOSIS >

[HR16DE]

EVAPORATIVE EMISSION SYSTEM

Component Parts Location INFOID:0000000004780033

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing contro NISSAN TIIDA 2009 Service Service Manual EC-78< FUNCTION DIAGNOSIS >

[HR16DE]

EVAPORATIVE EMISSION SYSTEM

Component Parts Location INFOID:0000000004780033

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing contro](/img/5/57398/w960_57398-1433.png)

EC-78< FUNCTION DIAGNOSIS >

[HR16DE]

EVAPORATIVE EMISSION SYSTEM

Component Parts Location INFOID:0000000004780033

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E

Page 1441 of 4331

![NISSAN TIIDA 2009 Service Service Manual INTAKE VALVE TIMING CONTROL

EC-85

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780037

1. Ignition coil (with power transistor) and spark p NISSAN TIIDA 2009 Service Service Manual INTAKE VALVE TIMING CONTROL

EC-85

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780037

1. Ignition coil (with power transistor) and spark p](/img/5/57398/w960_57398-1440.png)

INTAKE VALVE TIMING CONTROL

EC-85

< FUNCTION DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Parts Location

INFOID:0000000004780037

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB2939E

Page 1611 of 4331

![NISSAN TIIDA 2009 Service Service Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES NISSAN TIIDA 2009 Service Service Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES](/img/5/57398/w960_57398-1610.png)

P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES >> GO TO 5.

NO >> Perform trouble diagnosis for FUEL INJECTOR, refer to EC-432, " Component Inspection " .

5.

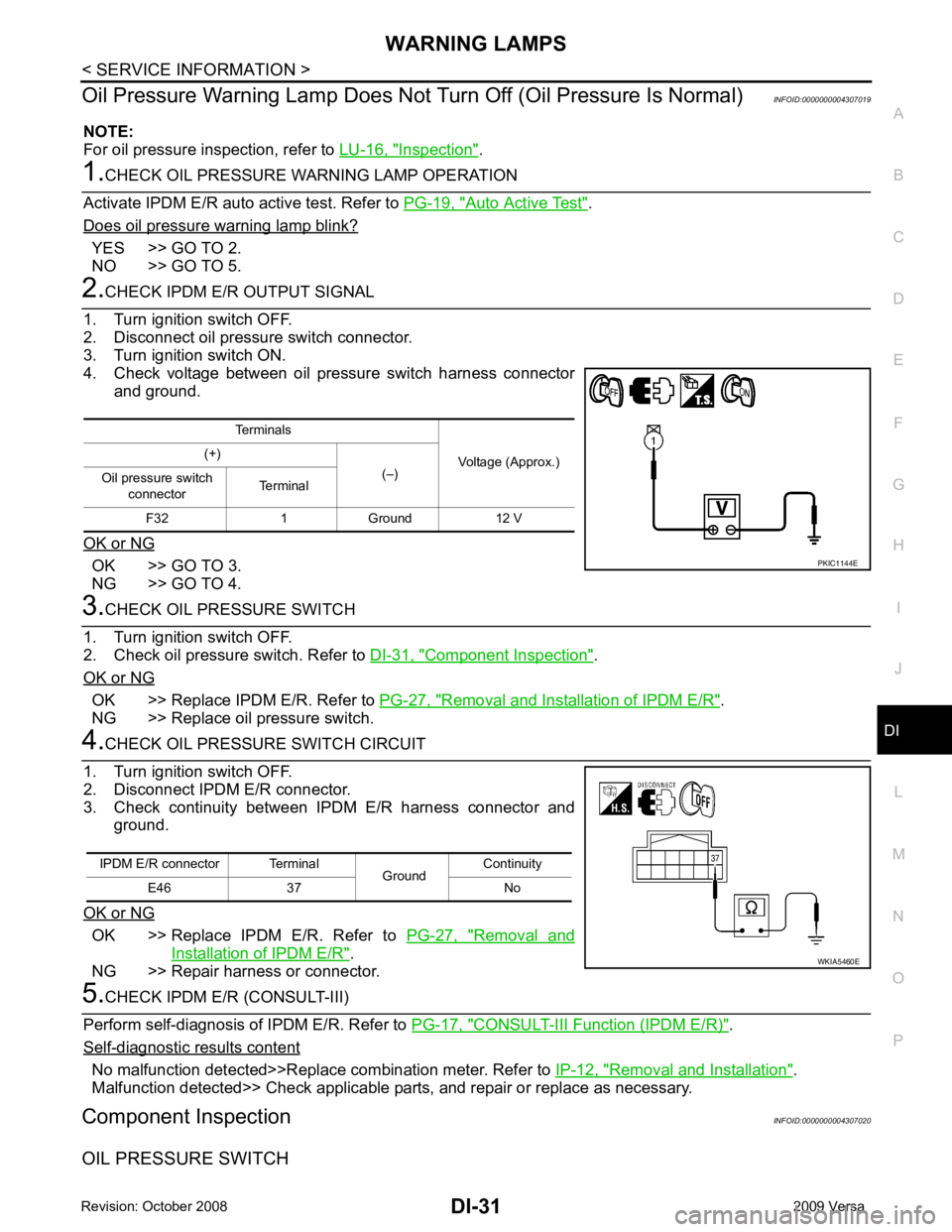

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure. NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pressure applies again during the following pro-

cedure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 -

0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• During the operation, alw ays stay 0.5 m (19.7 in) away

from the spark plug and the ig nition coil within. Be careful

not to get an electrical sh ock while checking, because the

electrical discharge voltage becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 6. 6.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Is the inspection result normal? YES >> GO TO 7.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-439, " Component Function

Check " .

Clicking noise should be heard.

PBIB3332E

Spark should be generated.

JMBIA0066GB

Spark should be generated.