check engine NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1724 of 4331

DTC Logic " .

If the cooling fan or another component in the coo ling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnorma lly high temperature condition, a malfunction is

indicated.

CAUTION:

When a malfunction is indicated, be su re to replace the coolant. Refer to CO-11, " Changing Engine

Coolant " . Also, replace the engine oil. Refer to

LU-8, " Draining " and

LU-8, " Refilling " .

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

2. After refilling coolant, run engine to en sure that no water-flow noise is emitted.

DTC CONFIRMATION PROCEDURE Component Function Check " .

NOTE:

Use component function check to check the overall functi on of the cooling fan. During this check, a DTC might

not be confirmed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-369, " Diagnosis Procedure " .

Component Function Check INFOID:0000000004780251

Page 1725 of 4331

EC

NP

O

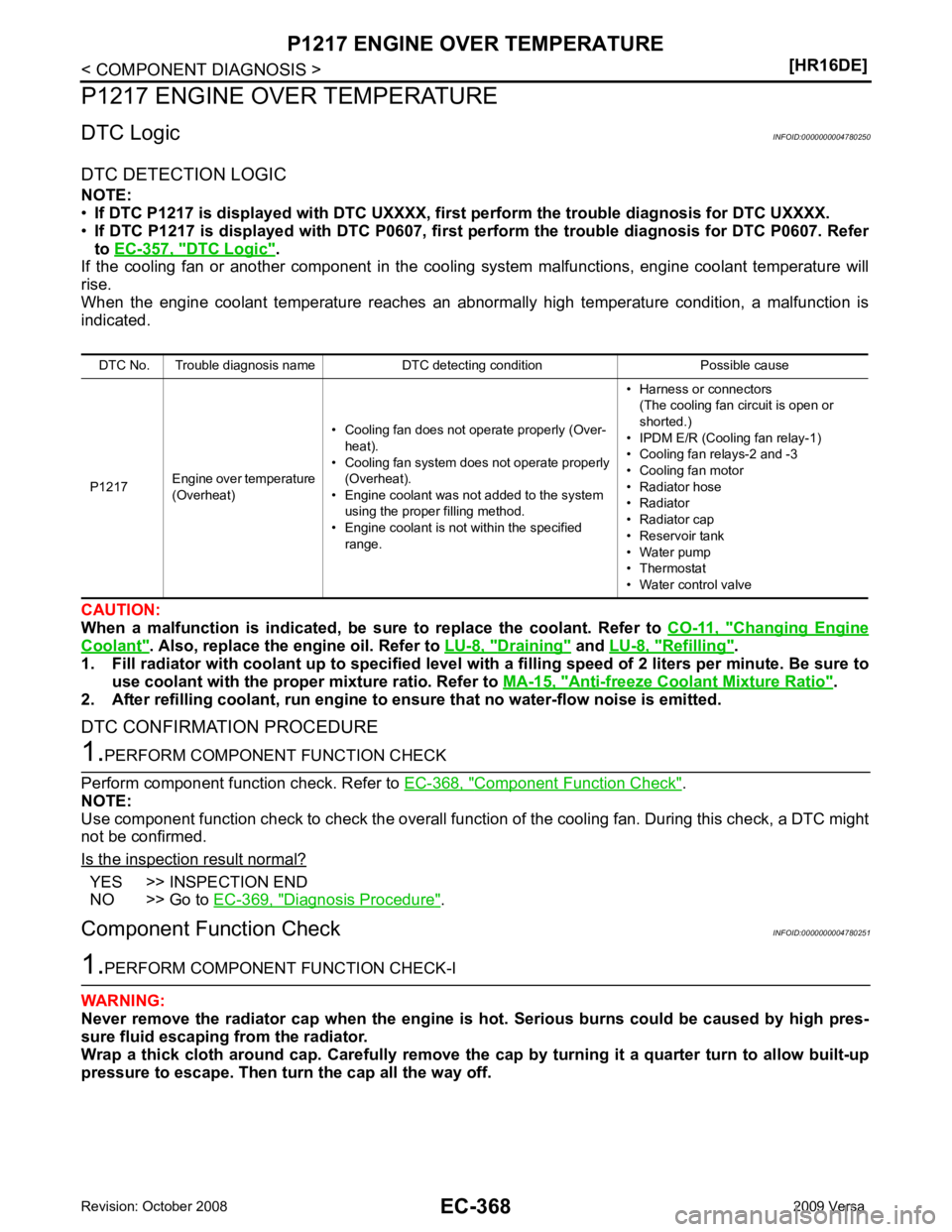

Check the coolant level in the reservoir tank and radiator.

Allow engine to cool befo re checking coolant level.

Is the coolant level in the reservoir tank and/or radiator below the proper range?

YES >> Go to

EC-369, " Diagnosis Procedure " .

NO >> GO TO 2. YES >> Go to

EC-369, " Diagnosis Procedure " .

NO >> GO TO 3. Auto Active Test " .

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-369, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004780252 Auto Active

Test " .

2. Make sure that cooling fan motor operates at each speed (Low/High).

Is the inspection result normal? YES >> GO TO 2.

NO >> Go to EC-424, " Diagnosis Procedure " .

Inspection " .

Is leakage detected? YES >> GO TO 3.

NO >> GO TO 4. Inspection " .)

• Radiator (Refer to CO-14, " Checking Radiator " .)

• Water pump (Refer to CO-21, " Inspection " .)

>> Repair or replace malfunctioning part.

Page 1726 of 4331

Checking Radiator Cap " .

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace radiator cap. Inspection " .

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace thermostat. Inspection " .

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace water control valve Component Inspection " .

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace engine coolant temperature sensor. Anti-freeze Coolant Mixture Ratio "

3 • Coolant level • Visual Coolant up to MAX level in

reservoir tank and radiator

filler neck CO-11, " Inspection "

4 • Radiator cap • Pressure tester

CO-14, " Checking Radiator Cap "

ON*

2

5 • Coolant leaks • Visual No leaks CO-11, " Inspection "

ON*

2

6 • Thermostat • Touch the upper and

lower radiator hosesBoth hoses should be hot

CO-23, " Inspection "

ON*

1

7 • Cooling fan motor • CONSULT-III Operating EC-422, " Component

Function Check "

OFF 8 • Combustion gas leak • Color checker chemical

tester 4 Gas analyzerNegative —

ON* 3

9 • Coolant temperature

gauge • Visual Gauge less than 3/4 when

driving —

• Coolant overflow to res- ervoir tank • Visual No overflow during driving

and idling CO-11, " Inspection "

OFF*

4

10 • Coolant return from res-

ervoir tank to radiator • Visual Should be initial level in

reservoir tank CO-25, " Inspection "

OFF 11 • Cylinder head • Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping) EM-82, " Disassembly and

Assembly "

12 • Cylinder block and pis-

tons • Visual No scuffing on cylinder

walls or piston EM-103, " Inspection "

Page 1759 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P2127, P2128 APP SENSOR

EC-403

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2127, P2128 APP SENSOR

Description INFOID:0000000004780323

The accelerator pedal position sensor i NISSAN TIIDA 2009 Service Repair Manual P2127, P2128 APP SENSOR

EC-403

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2127, P2128 APP SENSOR

Description INFOID:0000000004780323

The accelerator pedal position sensor i](/img/5/57398/w960_57398-1758.png)

P2127, P2128 APP SENSOR

EC-403

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2127, P2128 APP SENSOR

Description INFOID:0000000004780323

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometer which transform the accelerator pedal

position into output voltage, and emit the voltage signal to the ECM.

The ECM judges the current opening angle of the accelerator pedal

from these signals and controls the throttle control motor based on

these signals.

Idle position of the accelerato r pedal is determined by the ECM

receiving the signal from the acce lerator pedal position sensor. The

ECM uses this signal for the engine operation such as fuel cut.

DTC Logic INFOID:0000000004780324

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to

EC-404, " Diagnosis Procedure " .

NO >> INSPECTION END PBIB1741E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2127 Accelerator pedal position

sensor 2 circuit low input An excessively low voltage from the APP

sensor 2 is sent to ECM. • Harness or connectors

(APP sensor 2 circuit is open or shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.]

(Refrigerant pressure sensor circuit is

shorted.)

(EVAP control system pressure sensor

circuit is shorted.)

• Accelerator pedal position sensor (APP sensor 2)

• Crankshaft position sensor (POS)

• Refrigerant pressure sensor

• EVAP control system pressure sensor

P2128

Accelerator pedal position

sensor 2 circuit high input An excessively high voltage from the APP

sensor 2 is sent to ECM.

Page 1764 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-408< COMPONENT DIAGNOSIS >

[HR16DE]

P2135 TP SENSOR

P2135 TP SENSOR

Description INFOID:0000000004780448

Electric throttle control actuator consists of throttle control motor,

throttle posit NISSAN TIIDA 2009 Service Repair Manual EC-408< COMPONENT DIAGNOSIS >

[HR16DE]

P2135 TP SENSOR

P2135 TP SENSOR

Description INFOID:0000000004780448

Electric throttle control actuator consists of throttle control motor,

throttle posit](/img/5/57398/w960_57398-1763.png)

EC-408< COMPONENT DIAGNOSIS >

[HR16DE]

P2135 TP SENSOR

P2135 TP SENSOR

Description INFOID:0000000004780448

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometer which transform the throttle valve position into

output voltage, and emit the voltage signals to the ECM. The ECM

judges the current opening angle of the throttle valve from these sig-

nals and controls the throttle valve opening angle in response to

driving conditions via the throttle control motor.

DTC Logic INFOID:0000000004780329

DTC DETECTION LOGIC

NOTE:

If DTC P2135 is displayed with DTC P0643, first pe rform the trouble diagnosis for DTC P0643. Refer to

EC-358, " DTC Logic " .

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to

EC-409, " Diagnosis Procedure " .

NO >> INSPECTION END PBIB0145E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2135 Throttle position sensor

circuit range/perfor-

mance Rationally incorrect voltage is sent to ECM

compared with the signals from TP sensor 1

and TP sensor 2. • Harness or connector

(TP sensor 1 or 2 circuit is open or shorted.)

• Electric throttle control actuator (TP sensor 1 or 2)

Page 1768 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-412< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

P2138 APP SENSOR

Description INFOID:0000000004780333

The accelerator pedal position sensor is installed on the upper end

of the accele NISSAN TIIDA 2009 Service Repair Manual EC-412< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

P2138 APP SENSOR

Description INFOID:0000000004780333

The accelerator pedal position sensor is installed on the upper end

of the accele](/img/5/57398/w960_57398-1767.png)

EC-412< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

P2138 APP SENSOR

Description INFOID:0000000004780333

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometer which transform the accelerator pedal

position into output voltage, and emit the voltage signal to the ECM.

The ECM judges the current opening angle of the accelerator pedal

from these signals and controls the throttle control motor based on

these signals.

Idle position of the accelerator pedal is determined by the ECM

receiving the signal from the accelerator pedal position sensor. The

ECM uses this signal for the engine operation such as fuel cut.

DTC Logic INFOID:0000000004780334

DTC DETECTION LOGIC

NOTE:

If DTC P2138 is displayed with DTC P0643, first pe rform the trouble diagnosis for DTC P0643. Refer to

EC-358, " DTC Logic " .

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to

EC-413, " Diagnosis Procedure " .

NO >> INSPECTION END PBIB1741E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2138 Accelerator pedal position

sensor circuit range/per-

formance Rationally incorrect voltage is sent to ECM

compared with the signals from APP sensor

1 and APP sensor 2. • Harness or connector

(APP sensor 1 or 2 circuit is open or

shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

(EVAP control system sensor circuit is

shorted.)

• Accelerator pedal position sensor

(APP sensor 1 or 2)

• Crankshaft position sensor (POS)

• Refrigerant pressure sensor

• EVAP control system pressure sensor

Page 1775 of 4331

![NISSAN TIIDA 2009 Service Repair Manual P2A00 A/F SENSOR 1

EC-419

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000047803401.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check g NISSAN TIIDA 2009 Service Repair Manual P2A00 A/F SENSOR 1

EC-419

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000047803401.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check g](/img/5/57398/w960_57398-1774.png)

P2A00 A/F SENSOR 1

EC-419

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000047803401.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connections E15, E24. Refer to EC-125, " Ground Inspection " .

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK HARNESS CONNECTOR

1. Disconnect A/F sensor 1 harness connector.

2. Check harness connector for water.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness connector. 3.

RETIGHTEN A/F SENSOR 1

1. Loosen and retighten the A/F sensor 1. Refer to EM-31, " Exploded View " .

>> GO TO 4. 4.

CHECK FOR INTAKE AIR LEAK

1. Reconnect A/F sensor 1 harness connector.

2. Start engine and run it at idle.

3. Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected? YES >> GO TO 5.

NO >> Repair or replace. 5.

CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

1. Clear the mixture ratio self-learning value. Refer to EC-33, " MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement " .

2. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 or P0172 detected? Is it difficult to start engine? YES >> Perform trouble diagnosis for DTC P0171or P0172. Refer to

EC-229, " DTC Logic " or

EC-235, " DTC Logic " .

NO >> GO TO 6. 6.

CHECK A/F SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F sensor 1 harness connector.

2. Turn ignition switch ON.

3. Check the voltage between A/F sensor 1 harness connector and

ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7. 7.

DETECT MALFUNCTIONING PART

Check the following. Water should not exit.

A/F sensor 1 Ground Voltage

Connector Terminal

F12 4 Ground Battery voltage PBIB3308E

Page 1801 of 4331

![NISSAN TIIDA 2009 Service Repair Manual IGNITION SIGNAL

EC-445

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

10. Connect spark plug and harness connector to ignition coil.

11. Fix ignition coil using a rope etc. with gap NISSAN TIIDA 2009 Service Repair Manual IGNITION SIGNAL

EC-445

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

10. Connect spark plug and harness connector to ignition coil.

11. Fix ignition coil using a rope etc. with gap](/img/5/57398/w960_57398-1800.png)

IGNITION SIGNAL

EC-445

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

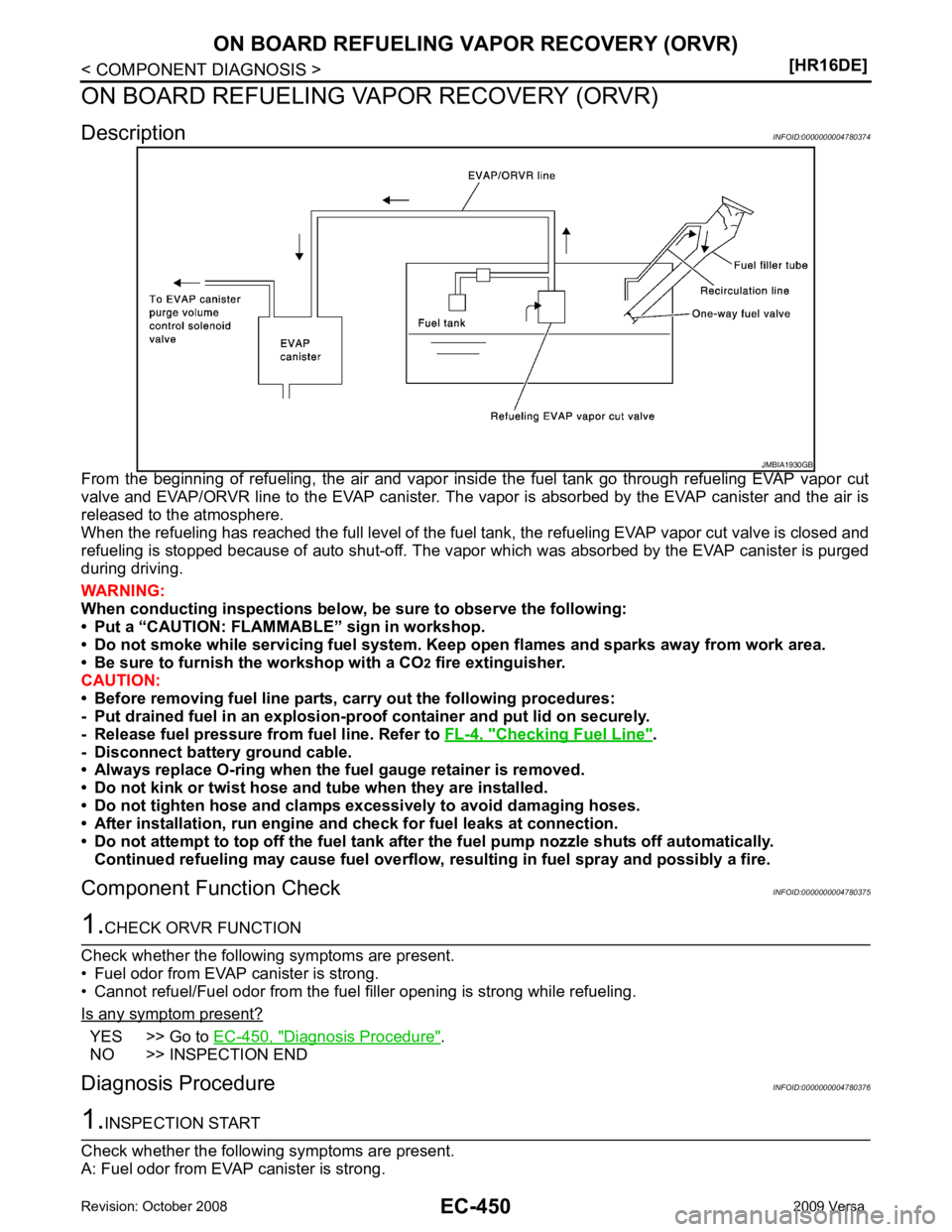

10. Connect spark plug and harness connector to ignition coil.

11. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

12. Crank engine for about three seconds, and check whether spark is generated between the spark plug and the grounded metal

portion.

CAUTION:

• During the operation, alw ays stay 0.5 cm (19.7 in) away

from the spark plug and the igni tion coil. Be careful not to

get an electrical shock wh ile checking, because the elec-

trical discharge voltage becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunctioning ignition coil with power transistor.

Component Inspection (Condenser-2) INFOID:00000000047803701.

CHECK CONDENSER-2

1. Turn ignition switch OFF.

2. Disconnect condenser-2 harness connector.

3. Check resistance between condenser-2 terminals as per the fol- lowing.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace condenser-2. Spark should be generated. JMBIA0066GB

Terminals Resistance

1 and 2 Above 1 M Ω [at 25 °C (77 °F)] PBIB0794E

Page 1802 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-446< COMPONENT DIAGNOSIS >

[HR16DE]

MALFUNCTION INDICATOR LAMP

MALFUNCTION INDICATOR LAMP

Description INFOID:0000000004780371

The Malfunction Indicator Lamp (MIL) is located on the combination

mete NISSAN TIIDA 2009 Service Repair Manual EC-446< COMPONENT DIAGNOSIS >

[HR16DE]

MALFUNCTION INDICATOR LAMP

MALFUNCTION INDICATOR LAMP

Description INFOID:0000000004780371

The Malfunction Indicator Lamp (MIL) is located on the combination

mete](/img/5/57398/w960_57398-1801.png)

EC-446< COMPONENT DIAGNOSIS >

[HR16DE]

MALFUNCTION INDICATOR LAMP

MALFUNCTION INDICATOR LAMP

Description INFOID:0000000004780371

The Malfunction Indicator Lamp (MIL) is located on the combination

meter.

The MIL will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

When the engine is started, the MIL should go off. If the MIL remains

on, the on board diagnostic system has detected an engine system

malfunction.

For details, refer to EC-90, " Diagnosis Description " .

Component Function Check INFOID:00000000047803721.

CHECK MIL FUNCTION

1. Turn ignition switch ON.

2. Make sure that MIL lights up.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-448, " Diagnosis Procedure " . SEF217U

Page 1806 of 4331

Checking Fuel Line " .

- Disconnect battery ground cable.

• Always replace O-ring when the fu el gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine an d check for fuel leaks at connection.

• Do not attempt to top off the fuel tank afte r the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, r esulting in fuel spray and possibly a fire.

Component Function Check INFOID:0000000004780375YES >> Go to

EC-450, " Diagnosis Procedure " .

NO >> INSPECTION END

Diagnosis Procedure INFOID:0000000004780376