check engine NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1922 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs tha NISSAN TIIDA 2009 Service Repair Manual EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs tha](/img/5/57398/w960_57398-1921.png)

EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs that ma y indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT-III or GST.

OK or NG OK >> GO TO 3.

NG >> GO TO 2. 2.

REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3. 3.

CHECK TARGET IDLE SPEED

With CONSULT-III

1. Run engine at about 2,000 rpm for about 2 minutes under no load. SEF983U

SEF976U

SEF977U

Page 1923 of 4331

EC

NP

O

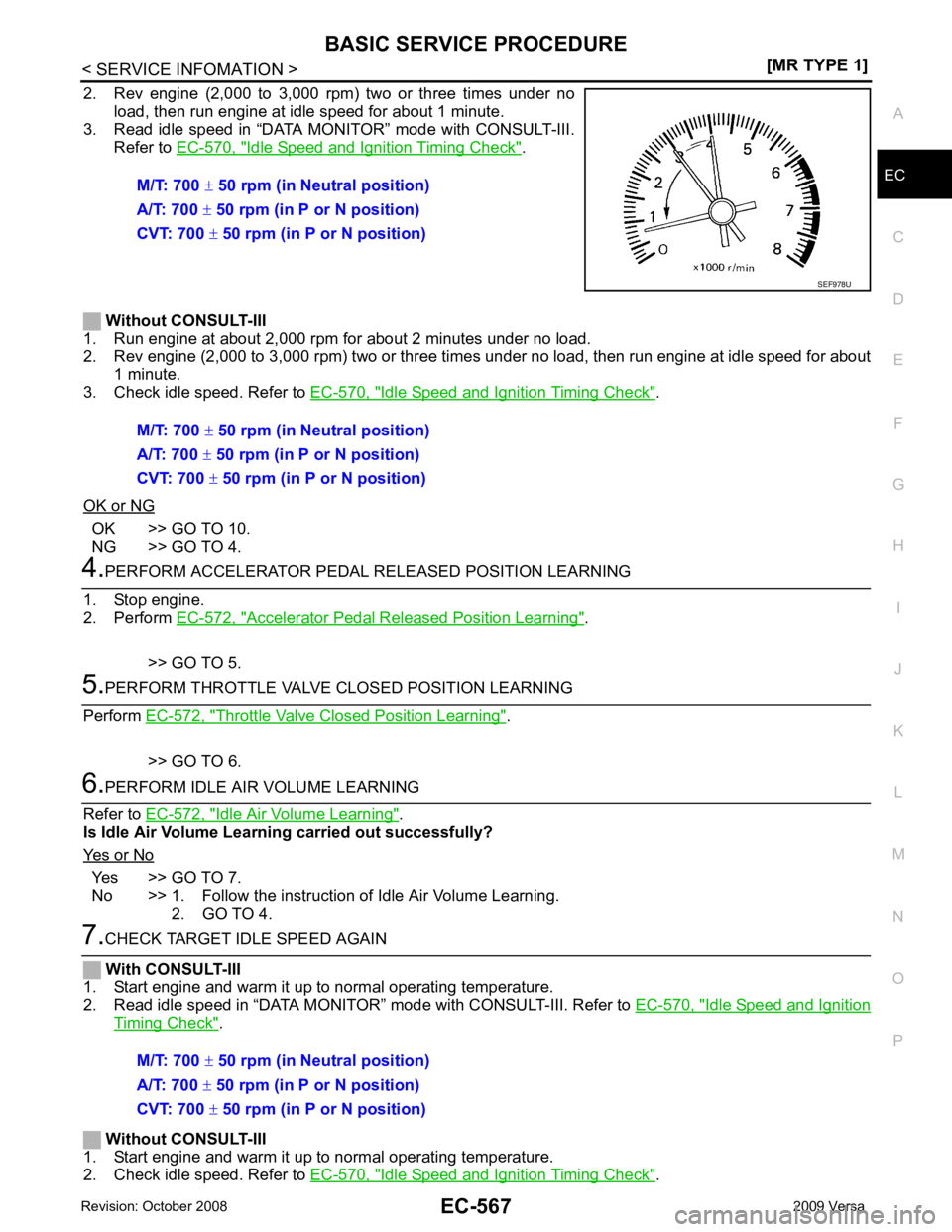

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Read idle speed in “DATA MONITOR” mode with CONSULT-III.

Refer to EC-570, " Idle Speed and Ignition Timing Check " .

Without CONSULT-III

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

2. Rev engine (2,000 to 3,000 rpm) two or three times under no load, then run engine at idle speed for about

1 minute.

3. Check idle speed. Refer to EC-570, " Idle Speed and Ignition Timing Check " .

OK or NG OK >> GO TO 10.

NG >> GO TO 4. Accelerator Pedal Released Position Learning " .

>> GO TO 5. Throttle Valve Closed Position Learning " .

>> GO TO 6. Idle Air Volume Learning " .

Is Idle Air Volume Learning carried out successfully?

Yes or No Yes >> GO TO 7.

No >> 1. Follow the instruction of Idle Air Volume Learning. 2. GO TO 4. Idle Speed and Ignition

Timing Check " .

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed. Refer to EC-570, " Idle Speed and Ignition Timing Check " .

M/T: 700

± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position) M/T: 700

± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

Page 1925 of 4331

![NISSAN TIIDA 2009 Service Repair Manual BASIC SERVICE PROCEDURE

EC-569

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 14.

No >> 1. Follow the instruction of Idle Air Volume Learning. 2. GO TO 4. 14.

CHECK TA NISSAN TIIDA 2009 Service Repair Manual BASIC SERVICE PROCEDURE

EC-569

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 14.

No >> 1. Follow the instruction of Idle Air Volume Learning. 2. GO TO 4. 14.

CHECK TA](/img/5/57398/w960_57398-1924.png)

BASIC SERVICE PROCEDURE

EC-569

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 14.

No >> 1. Follow the instruction of Idle Air Volume Learning. 2. GO TO 4. 14.

CHECK TARGET IDLE SPEED AGAIN

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-III. Refer to EC-570, " Idle Speed and Ignition

Timing Check " .

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed. Refer to EC-570, " Idle Speed and Ignition Timing Check " .

OK or NG OK >> GO TO 15.

NG >> GO TO 17. 15.

CHECK IGNITION TIMING AGAIN

1. Run engine at idle.

2. Check ignition timing with a timing light. Refer to EC-570, " Idle Speed and Ignition Timing Check " .

- Timing indicator (1)

OK or NG OK >> GO TO 19

NG >> GO TO 16. 16.

CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-160 .

OK or NG OK >> GO TO 17.

NG >> 1. Repair the timing chain installation.

2. GO TO 4. 17.

DETECT MALFUNCTIONING PART

Check the following.

• Check crankshaft position sensor (POS) and circuit. Refer to EC-775 .

• Check camshaft position s ensor (PHASE) and circuit.

Refer to EC-781 .

OK or NG OK >> GO TO 18.

NG >> 1. Repair or replace. 2. GO TO 4. 18.

CHECK ECM FUNCTION M/T: 700

± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position) M/T: 13

± 5 ° BTDC (in Neutral position)

A/T: 13 ± 5 ° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position) PBIB3263E

Page 1928 of 4331

Idle Air Volume Learning " .

VIN Registration INFOID:0000000004537046

DESCRIPTION

VIN Registration is an operation to registering VIN in ECM. It must be performed each time ECM is replaced.

NOTE:

Accurate VIN which is registered in ECM ma y be required for Inspection & Maintenance (I/M).

OPERATION PROCEDURE

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to GI-43 .

2. Turn ignition switch ON and engine stopped.

3. Select “VIN REGISTRATION ” in “WORK SUPPORT” mode.

4. Follow the instruction of CONSULT-III display.

Accelerator Pedal Released Position Learning INFOID:0000000004537047

DESCRIPTION

Accelerator Pedal Released Position Learning is an operati on to learn the fully released position of the accel-

erator pedal by monitoring the accelerator pedal positi on sensor output signal. It must be performed each time

harness connector of accelerator pedal pos ition sensor or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

Throttle Valve Clos ed Position Learning INFOID:0000000004537048

DESCRIPTION

Throttle Valve Closed Position Learning is an operation to l earn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal . It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds. Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume Learning INFOID:0000000004537049

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9V (At idle)

• Engine coolant temperature: 70 - 95 °C (158 - 203 °F)

• Park/neutral position (PNP) switch: ON

• Electric load switch: OFF

Page 1929 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC

NP

O

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illumi NISSAN TIIDA 2009 Service Repair Manual EC

NP

O

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illumi](/img/5/57398/w960_57398-1928.png)

EC

NP

O

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- Models with CONSULT-III (A/T and CVT models)

• Drive vehicle until “FLUID TEMP SE” in “DATA MONI TOR” mode of “A/T” or “CVT” system indicates less

than 0.9V.

- Models without CONSULT-III (A/T and CVT models) and M/T models

• Drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-III

1. Perform EC-572, " Accelerator Pedal Released Position Learning " .

2. Perform EC-572, " Throttle Valve Closed Position Learning " .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEA RN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

7. Make sure that “CMPLT” is displayed on CONSULT-III screen. If “CMPLT” is not displayed, Idle Air Vol-

ume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to

the DIAGNOSTIC PROCEDURE below.

8. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications.

Refer to EC-566, " Basic Inspection " .

Without CONSULT-III

NOTE:

• It is better to count the time accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform EC-572, " Accelerator Pedal Released Position Learning " .

2. Perform EC-572, " Throttle Valve Closed Position Learning " .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

7. Repeat the following procedure quick ly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

8. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops

blinking and turned ON.

9. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

10. Start engine and let it idle.

Page 1930 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-574< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are w NISSAN TIIDA 2009 Service Repair Manual EC-574< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are w](/img/5/57398/w960_57398-1929.png)

EC-574< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications. Refer to EC-566, " Basic Inspection " .

13. If idle speed and ignition timing are not within the specification, Idle Air Volume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to the DIAGNOSTIC PROCE-

DURE below.

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1. Check that throttle valve is fully closed.

2. Check PCV valve operation.

3. Check that downstream of throttl e valve is free from air leakage.

4. When the above three items check out OK, engine component parts and their installation condi-

tion are questionable. Check and elim inate the cause of the incident.

It is useful to perform EC-618 .

5. If any of the following conditio ns occur after the engine has st arted, eliminate the cause of the

incident and perform Idle Air Vo lume Learning all over again:

- Engine stalls.

- Erroneous idle.

Fuel Pressure Check INFOID:0000000004537050

FUEL PRESSURE RELEASE With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode with CONSULT-III.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

Without CONSULT-III

ITEM SPECIFICATION

Idle speed M/T: 700 ± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

Ignition timing M/T: 13 ± 5 ° BTDC (in Neutral position)

A/T: 13 ± 5 ° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position) SEC897C

Page 1931 of 4331

EC

NP

O

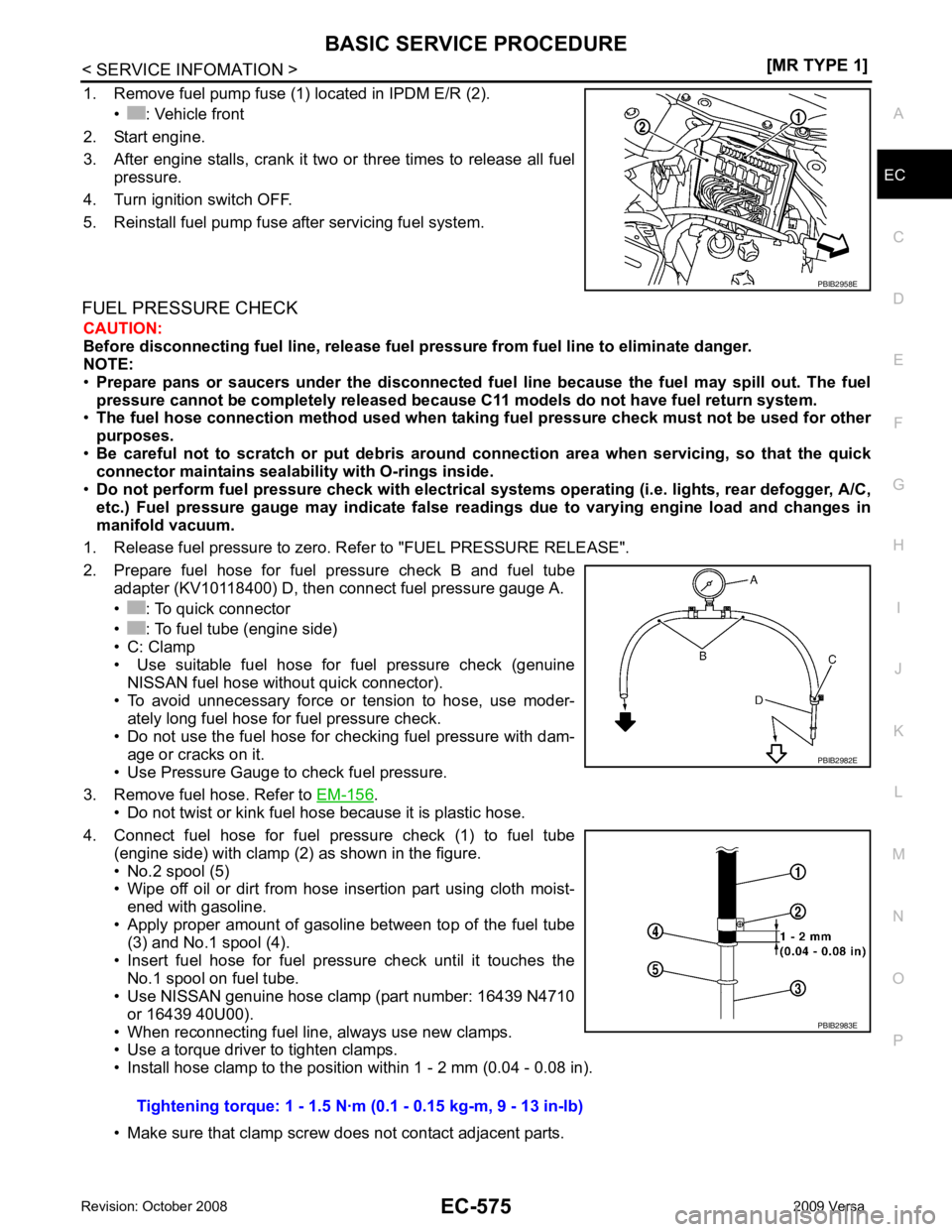

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because C11 models do not have fuel return system.

• The fuel hose connection method u sed when taking fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains sealability with O-rings inside.

• Do not perform fuel pressure check with electrical syst ems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check B and fuel tube adapter (KV10118400) D, then connect fuel pressure gauge A.

• : To quick connector

• : To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine

NISSAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder- ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam- age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer to EM-156 .

• Do not twist or kink fuel hose because it is plastic hose.

4. Connect fuel hose for fuel pressure check (1) to fuel tube (engine side) with clamp (2) as shown in the figure.

• No.2 spool (5)

• Wipe off oil or dirt from hose insertion part using cloth moist-

ened with gasoline.

• Apply proper amount of gasoline between top of the fuel tube (3) and No.1 spool (4).

• Insert fuel hose for fuel pressure check until it touches the No.1 spool on fuel tube.

• Use NISSAN genuine hose clamp (part number: 16439 N4710

or 16439 40U00).

• When reconnecting fuel line, always use new clamps.

• Use a torque driver to tighten clamps.

• Install hose clamp to the positi on within 1 - 2 mm (0.04 - 0.08 in).

• Make sure that clamp screw does not contact adjacent parts.

Page 1933 of 4331

![NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

EC-577

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004537051

INTRODUCTION The engine has an ECM NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS

EC-577

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004537051

INTRODUCTION The engine has an ECM](/img/5/57398/w960_57398-1932.png)

TROUBLE DIAGNOSIS

EC-577

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004537051

INTRODUCTION The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or other malfunctions with the engine.

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find t he cause of the incidents. A road

test with CONSULT-III (or GST) or a circuit tester connected should

be performed. Follow the Work Flow on "WORK FLOW".

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A Diagnostic Worksheet like the example

on "Worksheet Sample" should be used.

Start your diagnosis by looking for conventional malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

cally controlled engine vehicle.

WORK FLOW MEF036D

SEF233G

SEF234G

Page 1967 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC

NP

O

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item AT OD CANCEL

[ON/OFF] • Indicates [ON/OFF] cond NISSAN TIIDA 2009 Service Repair Manual EC

NP

O

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item AT OD CANCEL

[ON/OFF] • Indicates [ON/OFF] cond](/img/5/57398/w960_57398-1966.png)

EC

NP

O

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item AT OD CANCEL

[ON/OFF] • Indicates [ON/OFF] condition of A/T O/D cancel signal sent

from the TCM. • For M/T models always “OFF” is displayed

CRUISE LAMP

[ON/OFF] • Indicates [ON/OFF]

condition of CRUISE lamp determined

by the ECM according to the input signals.

SET LAMP

[ON/OFF] • Indicates [ON/OFF] condition of SET lamp determined by the

ECM according to the input signals.

A/F ADJ-B1 • Indicates the correction factor stored in ECM. The factor is

calculated from the difference between the target air/fuel ratio

stored in ECM and the air/fuel ratio calculated from air fuel ra-

tio (A/F) sensor 1 signal.

Monitored item [Unit] Description Remarks TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION • Engine: Return to the original

trouble condition

• Change the amount of fuel injec- tion using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

IGNITION TIM-

ING • Engine: Return to the original

trouble condition

• Timing light: Set

• Retard the ignition timing using

CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Perform Idle Air Volume Learning.

POWER BAL-

ANCE • Engine: After warming up, idle the

engine.

• A/C switch OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• Cut off each fuel injector signal

one at a time using CONSULT-III. Engine runs rough or dies.

• Harness and connectors

• Compression

• Fuel injector

• Power transistor

• Spark plug

• Ignition coil

COOLING FAN* • Ignition switch: ON

• Turn the cooling fan “LOW”, “HI” and “OFF” with CONSULT-III. Cooling fan moves and stops. • Harness and connectors

• Cooling fan relay

• Cooling fan motor

ENG COOLANT

TEMP • Engine: Return to the original

trouble condition

• Change the engine coolant tem- perature using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Engine coolant temperature sen-

sor

• Fuel injector

FUEL PUMP RE-

LAY • Ignition switch: ON

(Engine stopped)

• Turn the fuel pump relay ON and OFF using CONSULT-III and lis-

ten to operating sound. Fuel pump relay makes the operat-

ing sound. • Harness and connectors

• Fuel pump relay

PURG VOL

CONT/V • Engine: After warming up, run en-

gine at 1,500 rpm.

• Change the EVAP canister purge volume control solenoid valve

opening percent using CON-

SULT-III. Engine speed changes according to

the opening percent. • Harness and connectors

• EVAP canister purge volume con- trol solenoid valve

FUEL/T TEMP

SEN • Change the fuel tank temperature using CONSULT-III.

Page 1968 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-612< SERVICE INFOMATION >

[MR TYPE 1]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS NISSAN TIIDA 2009 Service Repair Manual EC-612< SERVICE INFOMATION >

[MR TYPE 1]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS](/img/5/57398/w960_57398-1967.png)

EC-612< SERVICE INFOMATION >

[MR TYPE 1]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer to EC-542, " Emission-related Diagnostic Information " .

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

DTC WORK SUPPORT Mode

*: DTC P1442 and P1456 does not apply to C11 models but appears in DTC Work Support Mode screens.

Generic Scan Tool (GST) Function INFOID:0000000004537061

DESCRIPTION

Generic Scan Tool (OBDII scan tool) complying with SAE J1978 has

8 different functions explained below.

ISO 15765-4 is used as the protocol.

The name GST or Generic Scan Tool is used in this service manual.

FUNCTION VENT CON-

TROL/V • Ignition switch: ON

(Engine stopped)

• Turn solenoid valve “ON” and “OFF” with the CONSULT-III and

listen to operating sound. Solenoid valve makes an operating

sound. • Harness and connectors

• EVAP canister vent control valve

V/T ASSIGN AN-

GLE • Engine: Return to the original

trouble condition

• Change intake valve timing using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Intake valve timing control sole-

noid valve

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY) Test mode Test item Corresponding DTC No. Reference page

EVAPORATIVE SYS-

TEM PURG FLOW P0441 P0441

EC-792EVP SML LEAK P0442/P1442*

P0442

EC-797 P0455

EC-847 EVP V/S LEAK P0456/P1456* P0456

EC-853PURG VOL CN/V P1444 P0443

EC-804A/F SEN1

A/F SEN1 (B1) P1276 P0130

EC-692A/F SEN1 (B1) P1278/P1279 P0133

EC-710HO2S2

HO2S2 (B1) P0139 P0139

EC-733HO2S2 (B1) P1146 P0138

EC-724HO2S2 (B1) P1147 P0137

EC-717 SEF139P