Power Window NISSAN TIIDA 2009 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 692 of 4331

BL

N

O P

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

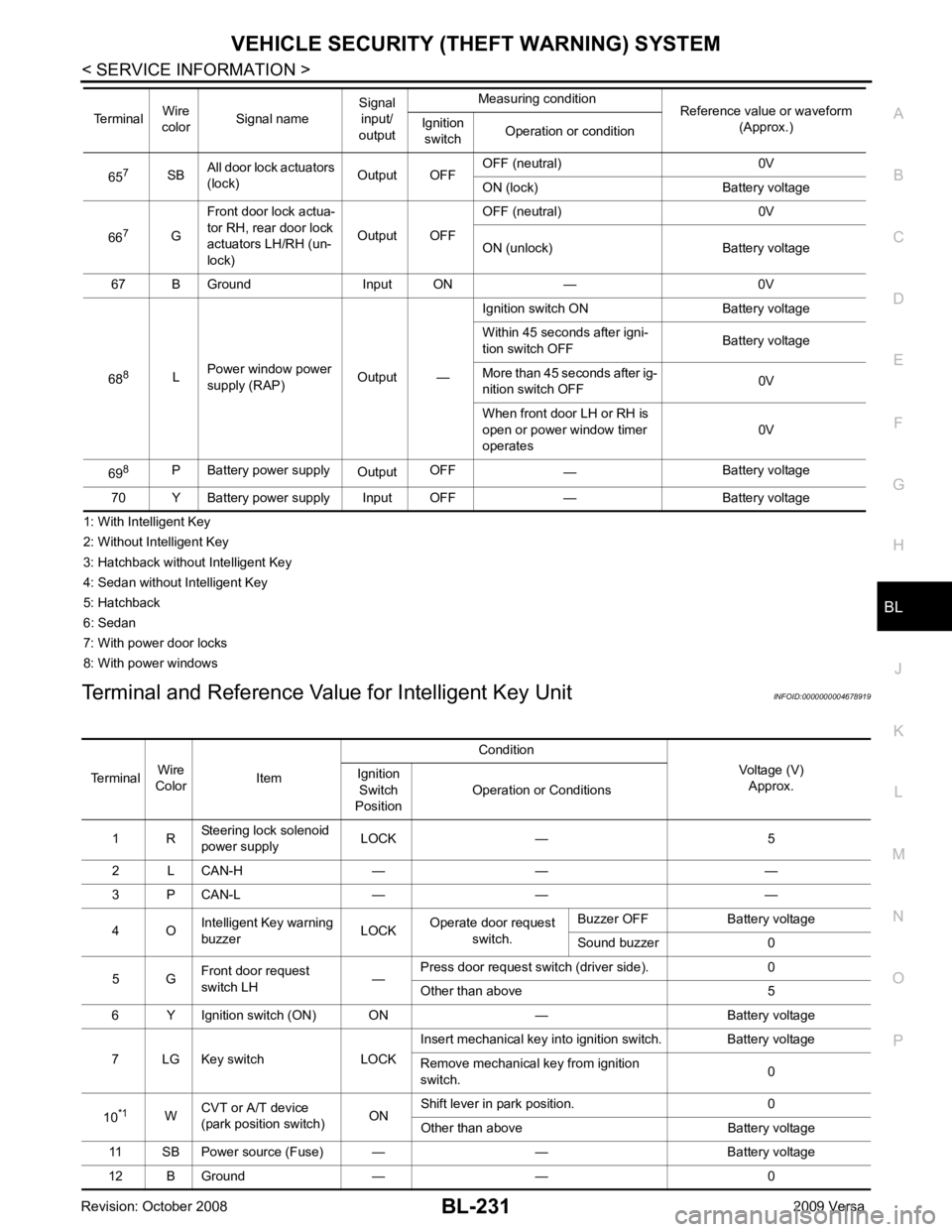

Terminal and Reference Valu e for Intelligent Key Unit INFOID:0000000004678919

65

7

SBAll door lock actuators

(lock) Output OFFOFF (neutral) 0V

ON (lock) Battery voltage

66 7

GFront door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral) 0V

ON (unlock) Battery voltage

67 B Ground Input ON — 0V

68 8

LPower window power

supply (RAP) Output —Ignition switch ON Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69 8

P Battery power supply

OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF — Battery voltage

Terminal

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition Terminal

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

1 R Steering lock solenoid

power supply LOCK — 5

2 L CAN-H — — —

3 P CAN-L — — —

4 O Intelligent Key warning

buzzer LOCKOperate door request

switch. Buzzer OFF Battery voltage

Sound buzzer 0

5 G Front door request

switch LH —Press door request switch (driver side). 0

Other than above 5

6 Y Ignition switch (ON) ON — Battery voltage

7 LG Key switch LOCK Insert mechanical key into ignition switch. Battery voltage

Remove mechanical key from ignition

switch. 0

10 *1

WCVT or A/T device

(park position switch) ONShift lever in park position. 0

Other than above Battery voltage

11 SB Power source (Fus e) — — Battery voltage

12 B Ground — — 0

Page 698 of 4331

BL

N

O P

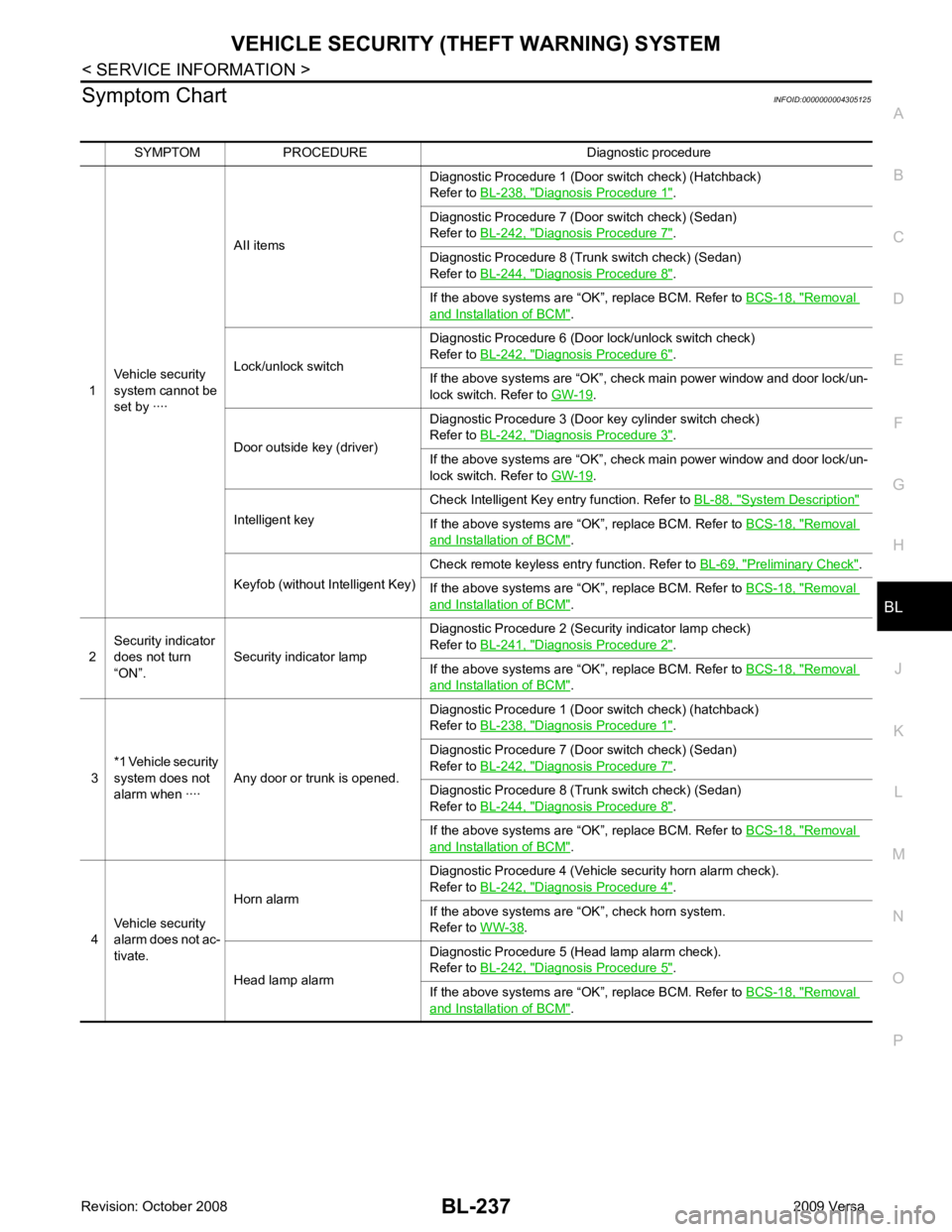

Symptom Chart

INFOID:0000000004305125

SYMPTOM PROCEDURE Diagnostic procedure

1 Vehicle security

system cannot be

set by ···· AII items

Diagnostic Procedure 1 (Door switch check) (Hatchback)

Refer to BL-238, " Diagnosis Procedure 1 " .

Diagnostic Procedure 7 (Door switch check) (Sedan)

Refer to BL-242, " Diagnosis Procedure 7 " .

Diagnostic Procedure 8 (Trunk switch check) (Sedan)

Refer to BL-244, " Diagnosis Procedure 8 " .

If the above systems are “OK”, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

Lock/unlock switch Diagnostic Procedure 6 (Door lock/unlock switch check)

Refer to BL-242, " Diagnosis Procedure 6 " .

If the above systems are “OK”, check main power window and door lock/un-

lock switch. Refer to GW-19 .

Door outside key (driver) Diagnostic Procedure 3 (Door key cylinder switch check)

Refer to BL-242, " Diagnosis Procedure 3 " .

If the above systems are “OK”, check main power window and door lock/un-

lock switch. Refer to GW-19 .

Intelligent key Check Intelligent Key entry function. Refer to

BL-88, " System Description "

If the above systems are “OK”, replace BCM. Refer to

BCS-18, " Removal

and Installation of BCM " .

Keyfob (without Intelligent Key) Check remote keyless entry function. Refer to

BL-69, " Preliminary Check " .

If the above systems are “OK”, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

2 Security indicator

does not turn

“ON”. Security indicator lamp Diagnostic Procedure 2 (Security indicator lamp check)

Refer to BL-241, " Diagnosis Procedure 2 " .

If the above systems are “OK”, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

3 *1 Vehicle security

system does not

alarm when ···· Any door or trunk is opened. Diagnostic Procedure 1 (Door switch check) (hatchback)

Refer to BL-238, " Diagnosis Procedure 1 " .

Diagnostic Procedure 7 (Door switch check) (Sedan)

Refer to BL-242, " Diagnosis Procedure 7 " .

Diagnostic Procedure 8 (Trunk switch check) (Sedan)

Refer to BL-244, " Diagnosis Procedure 8 " .

If the above systems are “OK”, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

4 Vehicle security

alarm does not ac-

tivate. Horn alarm

Diagnostic Procedure 4 (Vehicle security horn alarm check).

Refer to BL-242, " Diagnosis Procedure 4 " .

If the above systems are “OK”, check horn system.

Refer to WW-38 .

Head lamp alarm Diagnostic Procedure 5 (Head lamp alarm check).

Refer to BL-242, " Diagnosis Procedure 5 " .

If the above systems are “OK”, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

Page 699 of 4331

BL-238< SERVICE INFORMATION >

VEHICLE SECURITY (T

HEFT WARNING) SYSTEM

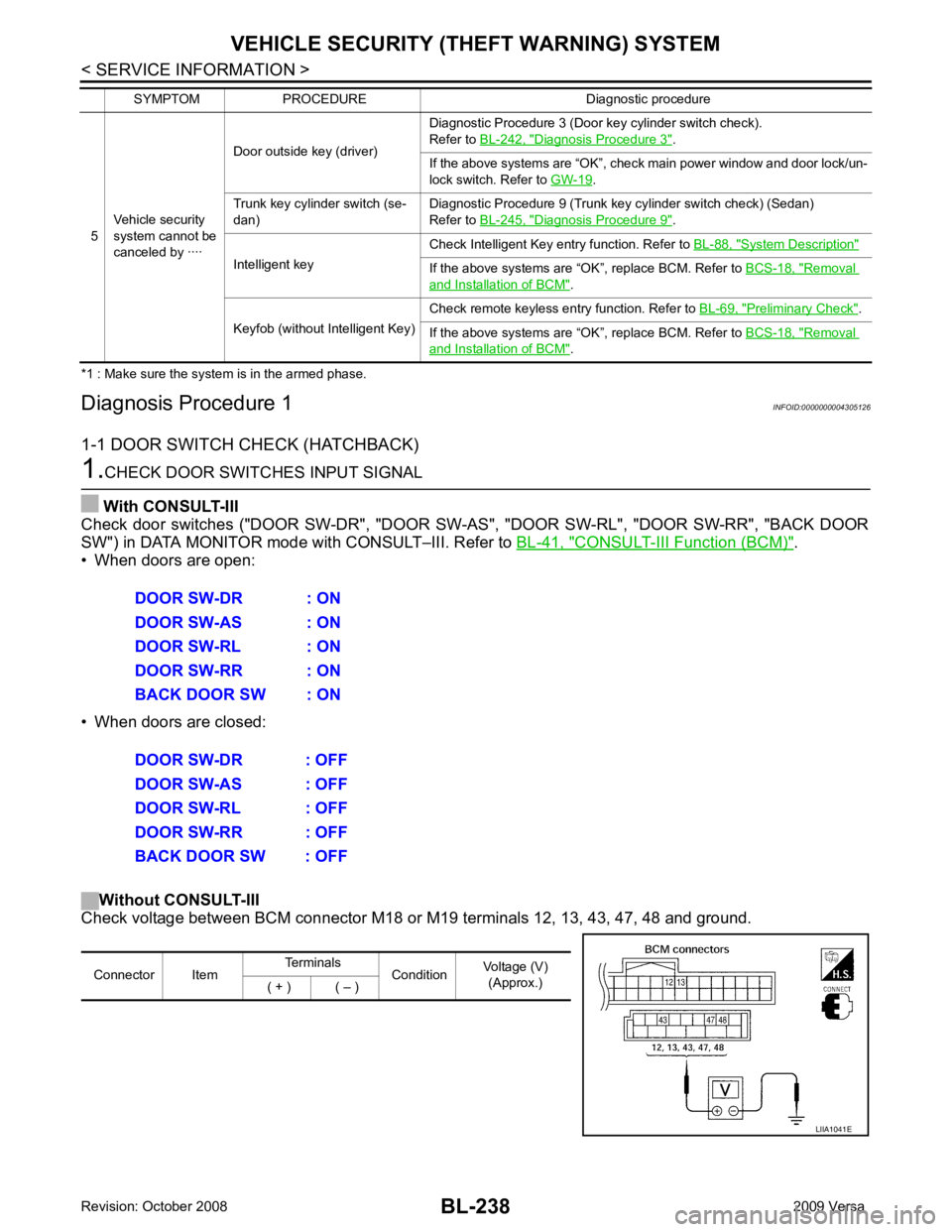

*1 : Make sure the system is in the armed phase.

Diagnosis Procedure 1 INFOID:0000000004305126

1-1 DOOR SWITCH CHECK (HATCHBACK) 1.

CHECK DOOR SWITCHES INPUT SIGNAL

With CONSULT-III

Check door switches ("DOOR SW-DR", "DOOR SW-AS", "DOOR SW-RL", "DOOR SW-RR", "BACK DOOR

SW") in DATA MONITOR mode with CONSULT–III. Refer to BL-41, " CONSULT-III Function (BCM) " .

• When doors are open:

• When doors are closed:

Without CONSULT-III

Check voltage between BCM connector M18 or M19 terminals 12, 13, 43, 47, 48 and ground.

5

Vehicle security

system cannot be

canceled by ···· Door outside key (driver)

Diagnostic Procedure 3 (Door key cylinder switch check).

Refer to BL-242, " Diagnosis Procedure 3 " .

If the above systems are “OK”, check main power window and door lock/un-

lock switch. Refer to GW-19 .

Trunk key cylinder switch (se-

dan) Diagnostic Procedure 9 (Trunk key cylinder switch check) (Sedan)

Refer to BL-245, " Diagnosis Procedure 9 " .

Intelligent key Check Intelligent Key entry function. Refer to

BL-88, " System Description "

If the above systems are “OK”, replace BCM. Refer to

BCS-18, " Removal

and Installation of BCM " .

Keyfob (without Intelligent Key) Check remote keyless entry function. Refer to

BL-69, " Preliminary Check " .

If the above systems are “OK”, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

SYMPTOM PROCEDURE Diagnostic procedure DOOR SW-DR : ON

DOOR SW-AS : ON

DOOR SW-RL : ON

DOOR SW-RR : ON

BACK DOOR SW : ON

DOOR SW-DR : OFF

DOOR SW-AS : OFF

DOOR SW-RL : OFF

DOOR SW-RR : OFF

BACK DOOR SW : OFF Connector Item

Terminals

ConditionVoltage (V)

(Approx.)

( + ) ( – ) LIIA1041E

Page 717 of 4331

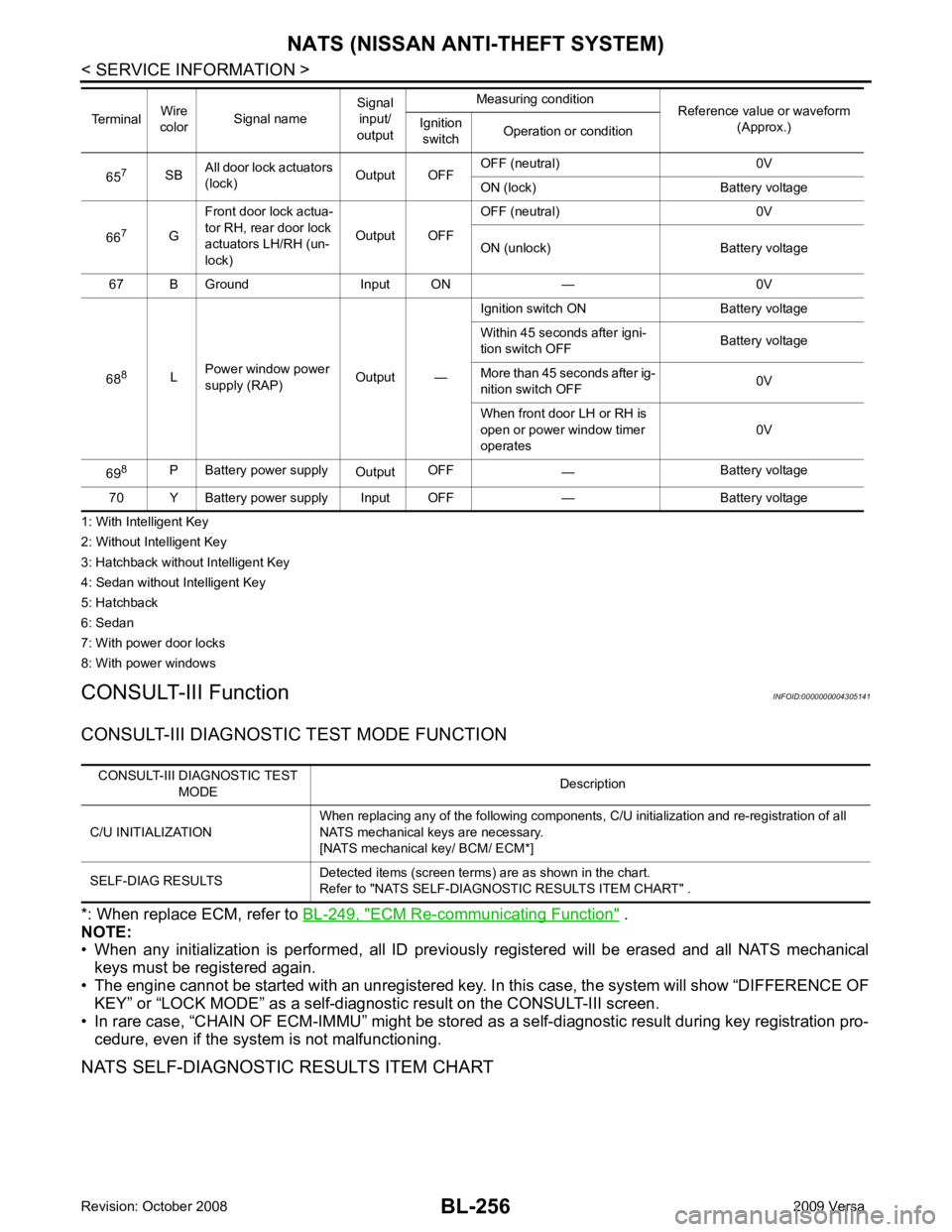

ECM Re-communicating Function " .

NOTE:

• When any initialization is performed, all ID previ ously registered will be erased and all NATS mechanical

keys must be registered again.

• The engine cannot be started with an unregistered key. In this case, the system will show “DIFFERENCE OF

KEY” or “LOCK MODE” as a self-diagnos tic result on the CONSULT-III screen.

• In rare case, “CHAIN OF ECM-IMMU” might be stored as a self-diagnostic result during key registration pro-

cedure, even if the system is not malfunctioning.

NATS SELF-DIAGNOSTIC RESULTS ITEM CHART 65

7

SBAll door lock actuators

(lock) Output OFFOFF (neutral) 0V

ON (lock) Battery voltage

66 7

GFront door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral) 0V

ON (unlock) Battery voltage

67 B Ground Input ON — 0V

68 8

LPower window power

supply (RAP) Output —Ignition switch ON Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69 8

P Battery power supply

OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF — Battery voltage

Terminal

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition CONSULT-III DIAGNOSTIC TEST

MODE Description

C/U INITIALIZATION When replacing any of the following components, C/U initialization and re-registration of all

NATS mechanical keys are necessary.

[NATS mechanical key/ BCM/ ECM*]

SELF-DIAG RESULTS Detected items (screen terms) are as shown in the chart.

Refer to "NATS SELF-DIAGNOSTIC RESULTS ITEM CHART" .

Page 1463 of 4331

EC

NP

O

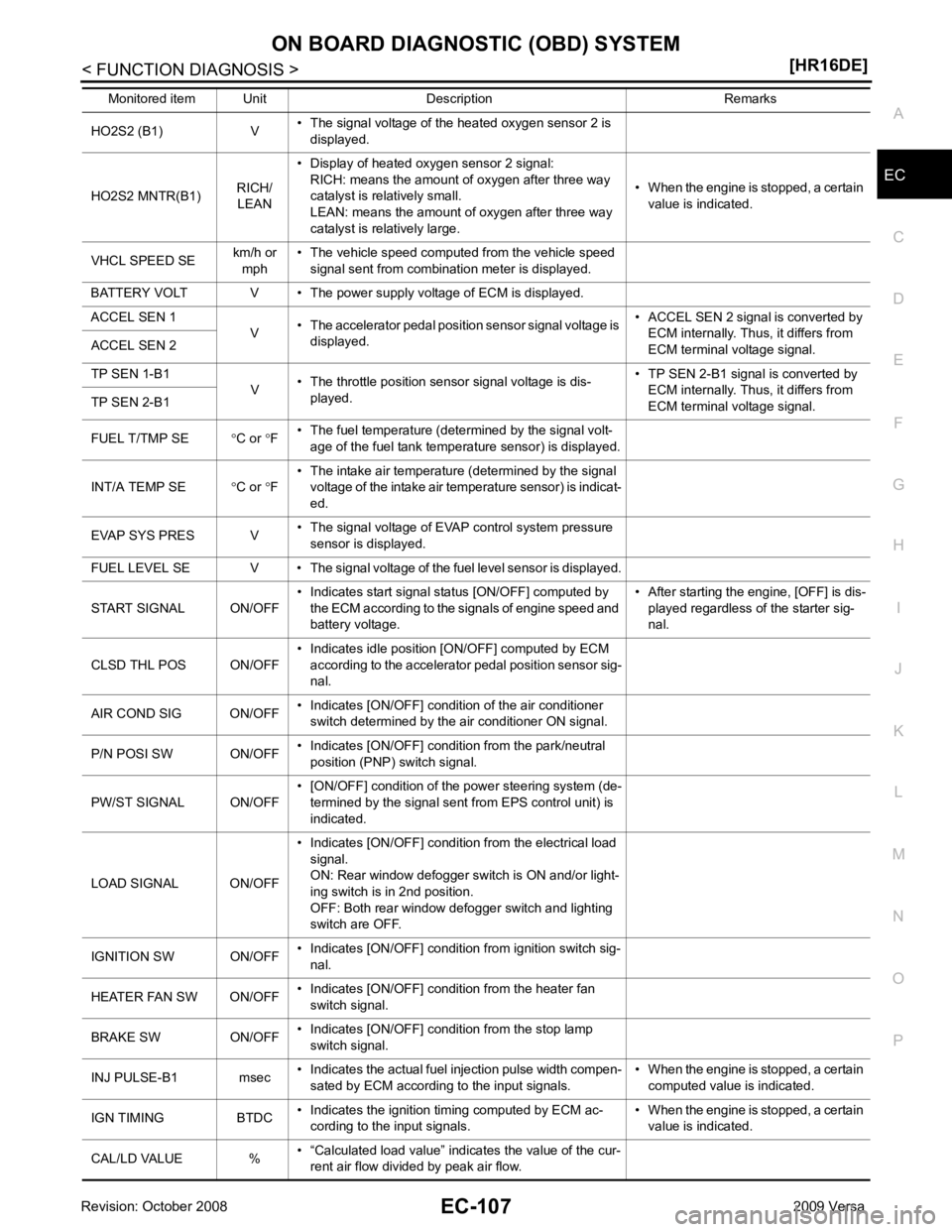

HO2S2 (B1) V

• The signal voltage of the heated oxygen sensor 2 is

displayed.

HO2S2 MNTR(B1) RICH/

LEAN • Display of heated oxygen sensor 2 signal:

RICH: means the amount of oxygen after three way

catalyst is relatively small.

LEAN: means the amount of oxygen after three way

catalyst is relatively large. • When the engine is stopped, a certain

value is indicated.

VHCL SPEED SE km/h or

mph • The vehicle speed computed from the vehicle speed

signal sent from combination meter is displayed.

BATTERY VOLT V • The power supply voltage of ECM is displayed.

ACCEL SEN 1 V• The accelerator pedal position sensor signal voltage is

displayed. • ACCEL SEN 2 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

ACCEL SEN 2

TP SEN 1-B1 V• The throttle position sensor signal voltage is dis-

played. • TP SEN 2-B1 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

TP SEN 2-B1

FUEL T/TMP SE °C or °F • The fuel temperature (determined by the signal volt-

age of the fuel tank temperature sensor) is displayed.

INT/A TEMP SE °C or °F • The intake air temperature (determined by the signal

voltage of the intake air temperature sensor) is indicat-

ed.

EVAP SYS PRES V • The signal voltage of EVAP control system pressure

sensor is displayed.

FUEL LEVEL SE V • The signal voltage of the fuel level sensor is displayed.

START SIGNAL ON/OFF • Indicates start signal status [ON/OFF] computed by

the ECM according to the signals of engine speed and

battery voltage. • After starting the engine, [OFF] is dis-

played regardless of the starter sig-

nal.

CLSD THL POS ON/OFF • Indicates idle position [ON/OFF] computed by ECM

according to the accelerator pedal position sensor sig-

nal.

AIR COND SIG ON/OFF • Indicates [ON/OFF] condition of the air conditioner

switch determined by the air conditioner ON signal.

P/N POSI SW ON/OFF • Indicates [ON/OFF] condit

ion from the park/neutral

position (PNP) switch signal.

PW/ST SIGNAL ON/OFF • [ON/OFF] condition of the power steering system (de-

termined by the signal sent from EPS control unit) is

indicated.

LOAD SIGNAL ON/OFF • Indicates [ON/OFF] condition from the electrical load

signal.

ON: Rear window defogger switch is ON and/or light-

ing switch is in 2nd position.

OFF: Both rear window defogger switch and lighting

switch are OFF.

IGNITION SW ON/OFF • Indicates [ON/OFF] condition from ignition switch sig-

nal.

HEATER FAN SW ON/OFF • Indicates [ON/OFF] condition from the heater fan

switch signal.

BRAKE SW ON/OFF • Indicates [ON/OFF] condition from the stop lamp

switch signal.

INJ PULSE-B1 msec • Indicates the actual fuel injection pulse width compen-

sated by ECM according to the input signals. • When the engine is stopped, a certain

computed value is indicated.

IGN TIMING BTDC • Indicates the ignition timing computed by ECM ac-

cording to the input signals. • When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE % • “Calculated load value” indicates the value of the cur-

rent air flow divided by peak air flow.

Monitored item Unit Description Remarks

Page 1965 of 4331

![NISSAN TIIDA 2009 Service Owners Manual EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake ai NISSAN TIIDA 2009 Service Owners Manual EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake ai](/img/5/57398/w960_57398-1964.png)

EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake air temperature (determined by the signal voltage

of the intake air temperature sensor) is indicated.

EVAP SYS PRES

[V] • The signal voltage of EVAP control system pressure sensor

is displayed.

FUEL LEVEL SE

[V] • The signal voltage of the fuel level sensor is displayed.

START SIGNAL

[ON/OFF] • Indicates start signal status [ON/OFF] computed by the ECM

according to the signals of engine speed and battery voltage. • After starting the engine, [OFF] is displayed

regardless of the starter signal.

CLSD THL POS

[ON/OFF] • Indicates idle position [ON/OFF] computed by the ECM ac-

cording to the accelerator pedal position sensor signal.

AIR COND SIG

[ON/OFF] • Indicates [ON/OFF] condition of the air conditioner switch as

determined by the air conditioner signal.

P/N POSI SW

[ON/OFF] • Indicates [ON/OFF] condition from the park/neutral position

(PNP) switch signal.

PW/ST SIGNAL

[ON/OFF] • [ON/OFF] condition of the power steering system (deter-

mined by the signal sent from EPS control unit) is indicated.

LOAD SIGNAL

[ON/OFF] • Indicates [ON/OFF] condition from the electrical load signal.

ON: Rear window defogger switch is ON and/or lighting

switch is in 2nd position.

OFF: Both rear window defogger switch and lighting switch

are OFF.

IGNITION SW

[ON/OFF] • Indicates [ON/OFF] condition from ignition switch.

HEATER FAN SW

[ON/OFF] • Indicates [ON/OFF] condition from the heater fan switch sig-

nal.

BRAKE SW

[ON/OFF] • Indicates [ON/OFF] condition from the stop lamp switch sig-

nal.

INJ PULSE-B1

[msec] • Indicates the actual fuel injection pulse width compensated

by ECM according to the input signals. • When the engine is stopped, a certain com-

puted value is indicated.

IGN TIMING

[BTDC] • Indicates the ignition timing computed by ECM according to

the input signals. • When the engine is stopped, a certain value

is indicated.

CAL/LD VALUE

[%] • “Calculated load value” indicates the value of the current air-

flow divided by peak airflow.

MASS AIRFLOW

[g·m/s] • Indicates the mass airflow computed by ECM according to

the signal voltage of the mass air flow sensor.

PURG VOL C/V

[%] • Indicates the EVAP canister purge volume control solenoid

valve control value computed by the ECM according to the in-

put signals.

• The opening becomes larger as the value increases.

INT/V TIM (B1)

[ ° CA] • Indicates [

°CA] of intake camshaft advanced angle.

INT/V SOL (B1)

[%] • The control value of the intake valve timing control solenoid

valve (determined by ECM according to the input signal) is in-

dicated.

• The advance angle becomes larger as the value increases

AIR COND RLY

[ON/OFF] • The air conditioner relay control condition (determined by

ECM according to the input signals) is indicated.

FUEL PUMP RLY

[ON/OFF] • Indicates the fuel pump relay control condition determined by

ECM according to the input signals.

Monitored item [Unit] Description Remarks

Page 2477 of 4331

![NISSAN TIIDA 2009 Service Owners Manual EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake ai NISSAN TIIDA 2009 Service Owners Manual EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake ai](/img/5/57398/w960_57398-2476.png)

EC

NP

O

FUEL T/TMP SE

[ ° C] or [ °F] • The fuel temperature (determined by the signal voltage of the

fuel tank temperature sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] • The intake air temperature (determined by the signal voltage

of the intake air temperature sensor) is indicated.

EVAP SYS PRES

[V] • The signal voltage of EVAP control system pressure sensor

is displayed.

FUEL LEVEL SE

[V] • The signal voltage of the fuel level sensor is displayed.

START SIGNAL

[ON/OFF] • Indicates start signal status [ON/OFF] computed by the ECM

according to the signals of engine speed and battery voltage. • After starting the engine, [OFF] is displayed

regardless of the starter signal.

CLSD THL POS

[ON/OFF] • Indicates idle position [ON/OFF] computed by the ECM ac-

cording to the accelerator pedal position sensor signal.

AIR COND SIG

[ON/OFF] • Indicates [ON/OFF] condition of the air conditioner switch as

determined by the air conditioner signal.

P/N POSI SW

[ON/OFF] • Indicates [ON/OFF] condition from the park/neutral position

(PNP) switch signal.

PW/ST SIGNAL

[ON/OFF] • [ON/OFF] condition of the power steering system (deter-

mined by the signal sent from EPS control unit) is indicated.

LOAD SIGNAL

[ON/OFF] • Indicates [ON/OFF] condition from the electrical load signal.

ON: Rear window defogger switch is ON and/or lighting

switch is in 2nd position.

OFF: Both rear window defogger switch and lighting switch

are OFF.

IGNITION SW

[ON/OFF] • Indicates [ON/OFF] condition from ignition switch.

HEATER FAN SW

[ON/OFF] • Indicates [ON/OFF] condition from the heater fan switch sig-

nal.

BRAKE SW

[ON/OFF] • Indicates [ON/OFF] condition from the stop lamp switch sig-

nal.

INJ PULSE-B1

[msec] • Indicates the actual fuel injection pulse width compensated

by ECM according to the input signals. • When the engine is stopped, a certain com-

puted value is indicated.

IGN TIMING

[BTDC] • Indicates the ignition timing computed by ECM according to

the input signals. • When the engine is stopped, a certain value

is indicated.

CAL/LD VALUE

[%] • “Calculated load value” indicates the value of the current air-

flow divided by peak airflow.

MASS AIRFLOW

[g·m/s] • Indicates the mass airflow computed by ECM according to

the signal voltage of the mass air flow sensor.

PURG VOL C/V

[%] • Indicates the EVAP canister purge volume control solenoid

valve control value computed by the ECM according to the in-

put signals.

• The opening becomes larger as the value increases.

INT/V TIM (B1)

[ ° CA] • Indicates [

°CA] of intake camshaft advanced angle.

INT/V SOL (B1)

[%] • The control value of the intake valve timing control solenoid

valve (determined by ECM according to the input signal) is in-

dicated.

• The advance angle becomes larger as the value increases

AIR COND RLY

[ON/OFF] • The air conditioner relay control condition (determined by

ECM according to the input signals) is indicated.

FUEL PUMP RLY

[ON/OFF] • Indicates the fuel pump relay control condition determined by

ECM according to the input signals.

Monitored item [Unit] Description Remarks

Page 2926 of 4331

EI

N

O P

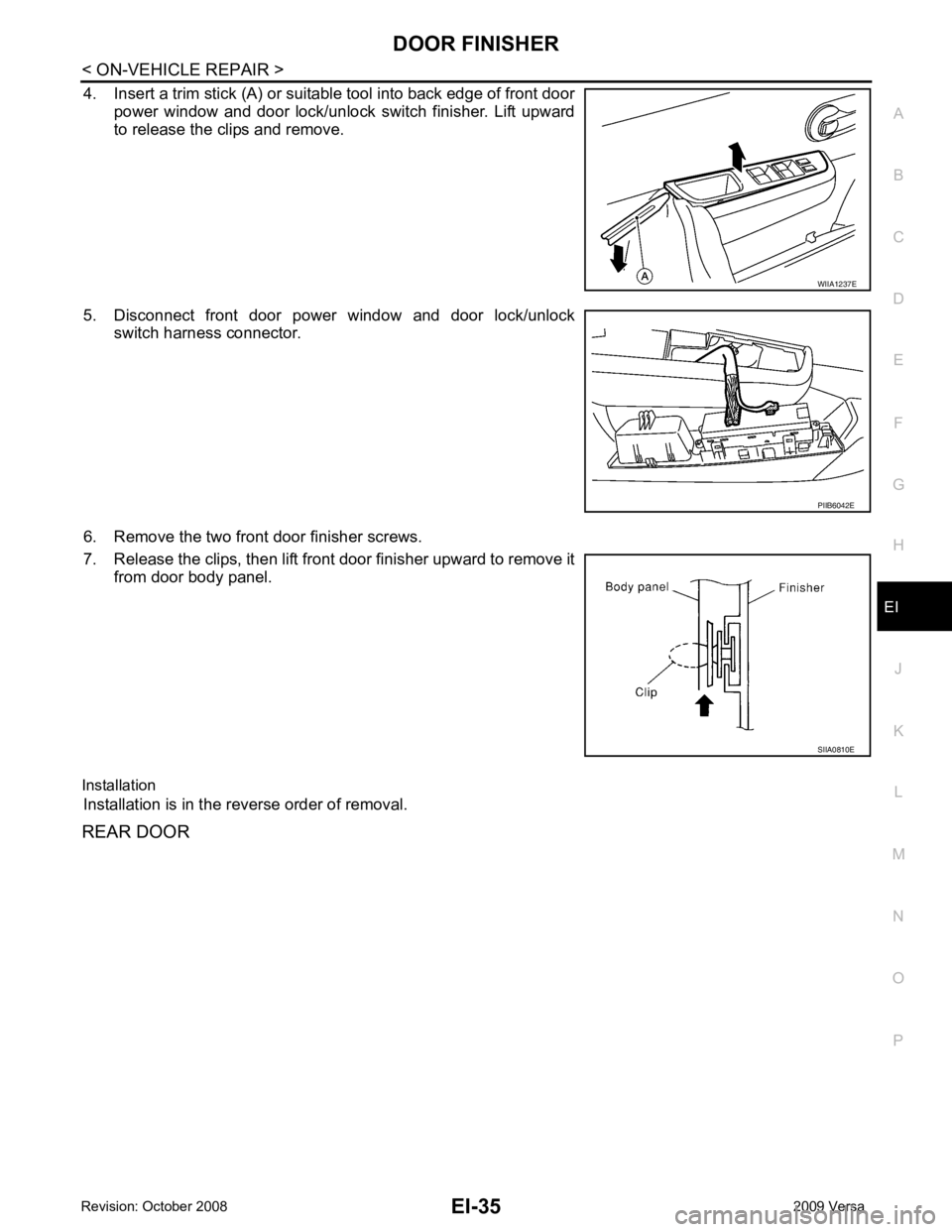

4. Insert a trim stick (A) or suitable tool into back edge of front door

power window and door lock/unlock switch finisher. Lift upward

to release the clips and remove.

5. Disconnect front door power window and door lock/unlock switch harness connector.

6. Remove the two front door finisher screws.

7. Release the clips, then lift front door finisher upward to remove it from door body panel.

Installation Installation is in the reverse order of removal.

REAR DOOR PIIB6042E

Page 3304 of 4331

GW

N

O P

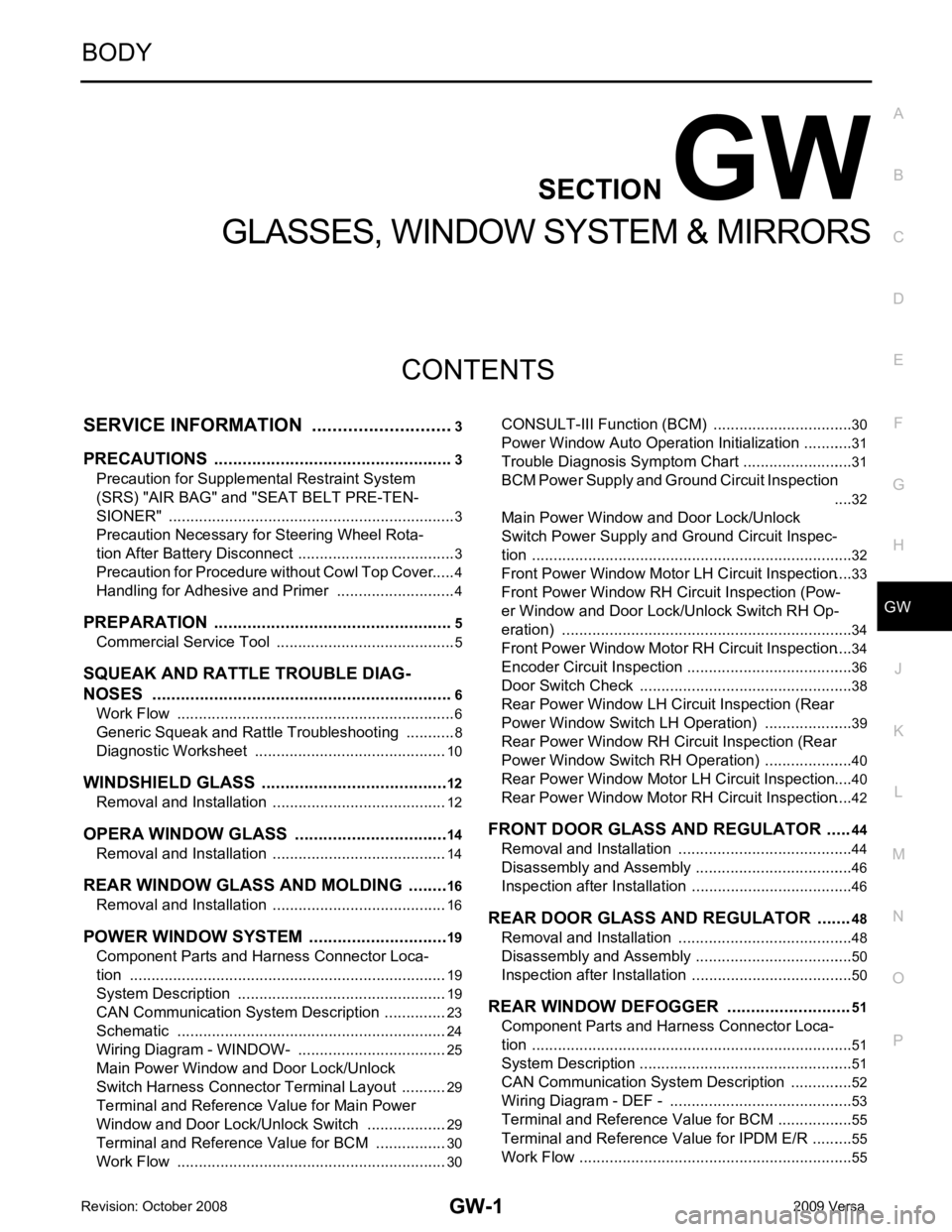

CONTENTS

GLASSES, WINDOW SYSTEM & MIRRORS

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Handling for Adhesive and Primer ...................... ......4

PREPARATION .............................................. .....5

Commercial Service Tool .................................... ......5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................6

Work Flow ........................................................... ......6

Generic Squeak and Rattle Troubleshooting ...... ......8

Diagnostic Worksheet ......................................... ....10

WINDSHIELD GLASS .................................... ....12

Removal and Installation .........................................12

OPERA WINDOW GLASS ............................. ....14

Removal and Installation .........................................14

REAR WINDOW GLASS AND MOLDING ..... ....16

Removal and Installation .........................................16

POWER WINDOW SYST EM ..............................19

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

19

System Description ............................................. ....19

CAN Communication System Description ........... ....23

Schematic ........................................................... ....24

Wiring Diagram - WINDOW- ............................... ....25

Main Power Window and Door Lock/Unlock

Switch Harness Connector Terminal Layout ....... ....

29

Terminal and Reference Value for Main Power

Window and Door Lock/Unlock Switch ............... ....

29

Terminal and Reference Value for BCM ............. ....30

Work Flow ........................................................... ....30 CONSULT-III Function (B

CM) .................................30

Power Window Auto Operat ion Initialization ............31

Trouble Diagnosis Symptom Chart ...................... ....31

BCM Power Supply and Ground Circuit Inspection ....32

Main Power Window and Door Lock/Unlock

Switch Power Supply and Ground Circuit Inspec-

tion ....................................................................... ....

32

Front Power Window Motor LH Circuit Inspection ....33

Front Power Window RH Circuit Inspection (Pow-

er Window and Door Lock/Unlock Switch RH Op-

eration) ................................................................ ....

34

Front Power Window Motor RH Circuit Inspection ....34

Encoder Circuit Inspection ................................... ....36

Door Switch Check .............................................. ....38

Rear Power Window LH Circuit Inspection (Rear

Power Window Switch LH Operation) ................. ....

39

Rear Power Window RH Circu it Inspection (Rear

Power Window Switch RH Operation) ................. ....

40

Rear Power Window Motor LH Circuit Inspection ....40

Rear Power Window Motor RH Circuit Inspection ....42

FRONT DOOR GLASS AND REGULATOR ..... 44

Removal and Installation ..................................... ....44

Disassembly and Assembly ................................. ....46

Inspection after Installati on ......................................46

REAR DOOR GLASS AND REGULATOR ....... 48

Removal and Installation ..................................... ....48

Disassembly and Assembly ................................. ....50

Inspection after Installati on ......................................50

REAR WINDOW DEFOGGER .......................... 51

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

51

System Description .............................................. ....51

CAN Communication System Description ........... ....52

Wiring Diagram - DEF - ....................................... ....53

Terminal and Reference Value for BCM ..................55

Terminal and Reference Va lue for IPDM E/R ..........55

Work Flow ............................................................ ....55

Page 3316 of 4331

GW

N

O P

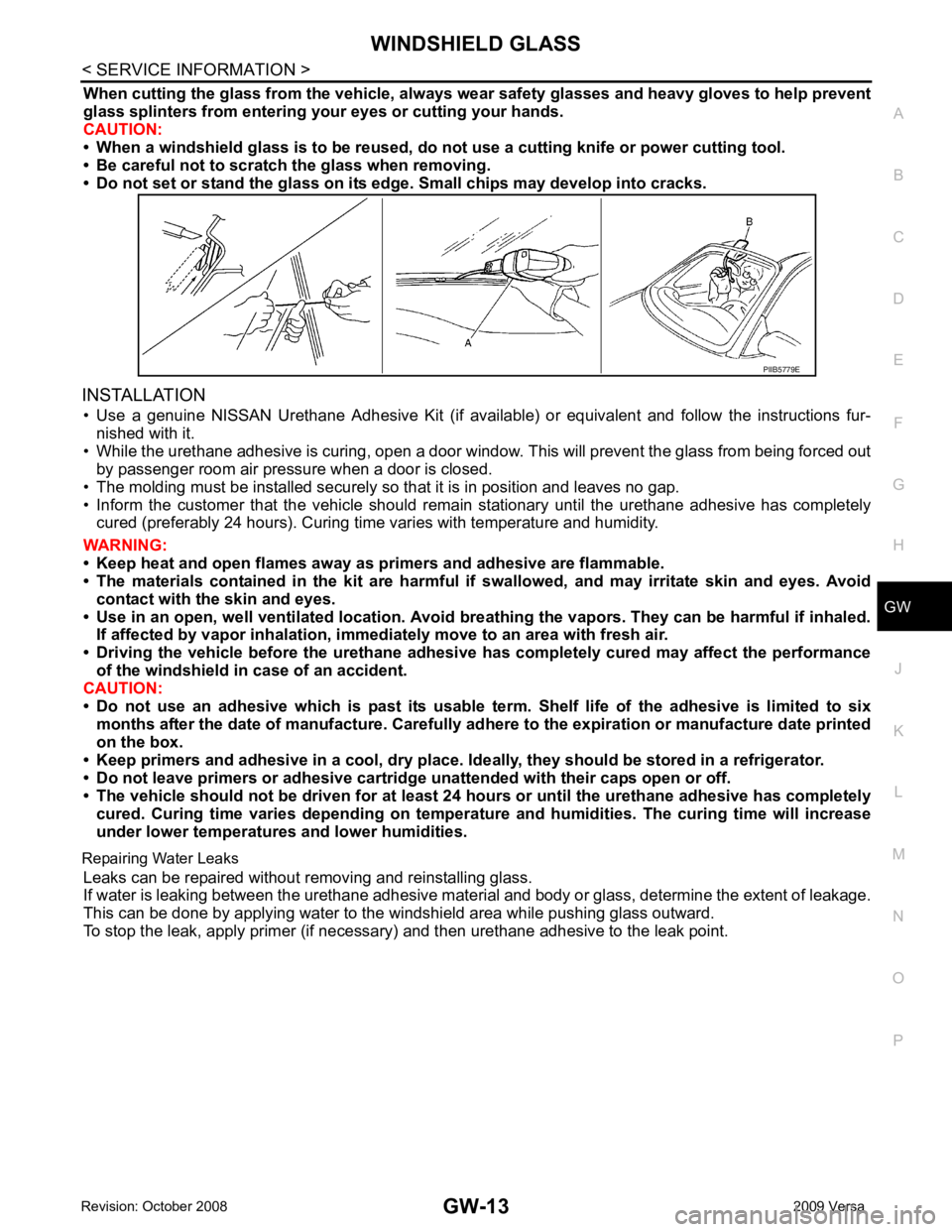

When cutting the glass from the vehicle, always

wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

• When a windshield glass is to be reused, do no t use a cutting knife or power cutting tool.

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

INSTALLATION • Use a genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger room air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated lo cation. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of the adhesive is limited to six

months after the date of manufacture. Carefully ad here to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depend ing on temperature and humidities. The curing time will increase

under lower temperatures and lower humidities.

Repairing Water Leaks Leaks can be repaired without removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the windshield area while pushing glass outward.

To stop the leak, apply primer (if necessary ) and then urethane adhesive to the leak point.