engine control NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2604 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1248< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0138 HO2S2

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CLEAR THE SELF-LEARNING DATA

With CONSULT-III

1. Start engine and war NISSAN TIIDA 2009 Service Repair Manual EC-1248< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0138 HO2S2

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CLEAR THE SELF-LEARNING DATA

With CONSULT-III

1. Start engine and war](/img/5/57398/w960_57398-2603.png)

EC-1248< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0138 HO2S2

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CLEAR THE SELF-LEARNING DATA

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “WORK SUPPORT” mode with CONSULT-III.

3. Clear the self-learning control coefficient by touching “CLEAR”.

4. Run engine for at least 10 minutes at idle speed. Is the 1st trip DTC P0172 detected?

Is it difficult to start engine?

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF.

3. Disconnect mass air flow sensor (1) harness connector, and restart and run engine for at least 5 seconds at idle speed.

4. Stop engine and reconnect mass air flow sensor harness con-

nector.

5. Make sure that DTC P0102 is displayed.

6. Erase the DTC memory. Refer to EC-1052, " Emission-related

Diagnostic Information " .

7. Make sure that DTC P0000 is displayed.

8. Run engine for at least 10 minutes at idle speed. Is the 1st trip DTC P0172 detected?

Is it difficult to start engine?

Yes or No Yes >> Perform trouble diagnosis for DTC P0172. Refer to

EC-1264 .

No >> GO TO 3. 3.

CHECK HO2S2 GROUND CIRCUI T FOR OPEN AND SHORT

1. Turn ignition switch OFF. :

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

BBIA0701E

Page 2607 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0139 HO2S2

EC-1251

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0139 HO2S2

Component Description INFOID:0000000004501151

The heated oxygen sensor 2, after three NISSAN TIIDA 2009 Service Repair Manual DTC P0139 HO2S2

EC-1251

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0139 HO2S2

Component Description INFOID:0000000004501151

The heated oxygen sensor 2, after three](/img/5/57398/w960_57398-2606.png)

DTC P0139 HO2S2

EC-1251

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0139 HO2S2

Component Description INFOID:0000000004501151

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air/fuel ratio is c ontrolled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004501152

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004500103

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity before the three way catalyst (manifold) causes

the longer switching time. To judge the malfunctions of heated oxy-

gen sensor 2, ECM monitors whether the switching response of the

sensor's voltage is faster than specified during the various driving

condition such as fuel-cut.

DTC Confirmation Procedure INFOID:0000000004500104

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-III

TESTING CONDITION:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30 °C (32 to 86 °F). SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1) • Revving engine from idle to 3,000 rpm quickly after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load 0 - 0.3V

←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1) LEAN ←→ RICH SEF302U

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0139

0139 Heated oxygen sensor 2

circuit slow response It takes more time for the sensor to respond be-

tween rich and lean than the specified time. • Harness or connectors

(Heated oxygen sensor circuit is open or

shorted.)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

• Intake air leaks

Page 2611 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0139 HO2S2

EC-1255

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “W OR NISSAN TIIDA 2009 Service Repair Manual DTC P0139 HO2S2

EC-1255

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “W OR](/img/5/57398/w960_57398-2610.png)

DTC P0139 HO2S2

EC-1255

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “W ORK SUPPORT” mode with CONSULT-III.

3. Clear the self-learning control coefficient by touching “CLEAR”.

4. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 or P0172 detected?

Is it difficult to start engine?

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF.

3. Disconnect mass air flow sensor (1) harness connector, and

restart and run engine for at least 5 seconds at idle speed.

4. Stop engine and reconnect mass air flow sensor harness con- nector.

5. Make sure that DTC P0102 is displayed.

6. Erase the DTC memory. Refer to EC-1052, " Emission-related

Diagnostic Information " .

7. Make sure that DTC P0000 is displayed.

8. Run engine for at least 10 minutes at idle speed. Is the 1st trip DTC P0171 or P0172 detected?

Is it difficult to start engine?

Yes or No Yes >> Perform trouble diagnosis for DTC P0171 or P0172. Refer to

EC-1258 or

EC-1264 .

No >> GO TO 3. 3.

CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect heated oxygen sensor 2 harness connector (2).

- : Vehicle front

- Heated oxygen sensor 2 (1)

3. Disconnect ECM harness connector.

4. Check harness continuity between HO2S2 terminal 1 and ECM

terminal 59. Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between HO2S2 terminal 4 and ECM terminal 50. Refer to Wiring Diagram.

2. Check harness continuity between ECM terminal 50 or HO2S2 terminal 4 and ground. Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 5.

CHECK HEATED OXYGEN SENSOR 2

Refer to EC-1256, " Component Inspection " .

OK or NG BBIA0701E

Continuity should exist.

BBIA0700E

Continuity should exist.

Continuity should not exist.

Page 2614 of 4331

Diagnosis Procedure " .

If engine does not start, check exhaus t and intake air leak visually.

6. Keep engine at idle for at least 5 minutes.

7. Check 1st trip DTC. The 1st trip DTC P0171 should be detected at this stage, if a malfunction exists. If so, go to EC-1261," Diagnosis Procedure " .

NOTE:

If 1st trip DTC is not detected during above proc edure, performing the following procedure is advised.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Start engine.

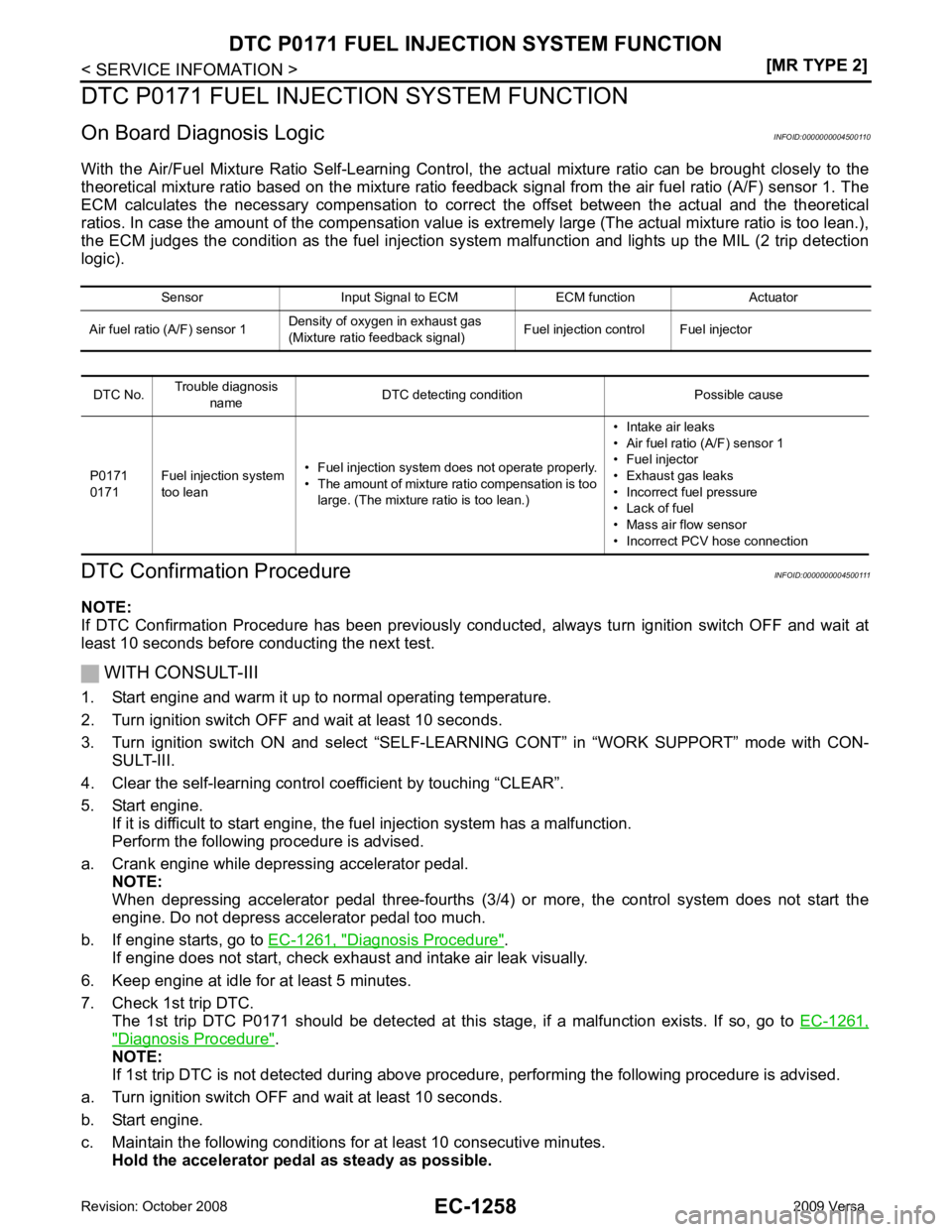

c. Maintain the following conditions for at least 10 consecutive minutes. Hold the accelerator pedal as steady as possible. Sensor Input Signal to ECM ECM function Actuator

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

(Mixture ratio fe edback signal) Fuel injection control Fuel injectorDTC No.

Trouble diagnosis

name DTC detecting condition Possible cause

P0171

0171 Fuel injection system

too lean • Fuel injection system does not operate properly.

• The amount of mixture ratio compensation is too large. (The mixture ratio is too lean.) • Intake air leaks

• Air fuel ratio (A/F) sensor 1

• Fuel injector

• Exhaust gas leaks

• Incorrect fuel pressure

• Lack of fuel

• Mass air flow sensor

• Incorrect PCV hose connection

Page 2615 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0171 FUEL INJECT

ION SYSTEM FUNCTION

EC-1259

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st tri NISSAN TIIDA 2009 Service Repair Manual DTC P0171 FUEL INJECT

ION SYSTEM FUNCTION

EC-1259

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st tri](/img/5/57398/w960_57398-2614.png)

DTC P0171 FUEL INJECT

ION SYSTEM FUNCTION

EC-1259

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st trip DTC is detected, go to EC-1261, " Diagnosis Procedure " .

WITH GST

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Disconnect mass air flow sensor (1) harness connector.

4. Restart engine and let idle for at least 5 seconds.

5. Stop engine and reconnect mass air flow sensor (1) harness connector.

6. Select Service $03 with GST. Make sure DTC P0102 is detected.

7. Select Service $04 with GST and erase the DTC P0102.

8. Start engine. If it is difficult to start engine, the fuel injection system has a mal-

function.

Perform the following procedure is advised.

a. Crank engine while depressing accelerator pedal. NOTE:

When depressing accelerator pedal three-fourths (3/4) or more, the control system does not start the

engine. Do not depress accelerator pedal too much.

b. If engine starts, go to EC-1261, " Diagnosis Procedure " .

If engine does not start, check exhaust and intake air leak visually.

9. Keep engine at idle for at least 5 minutes.

10. Check 1st trip DTC. The 1st trip DTC P0171 should be det ected at this stage, if a malfunction exists. If so, go to EC-1261," Diagnosis Procedure " .

NOTE:

If 1st trip DTC is not detected during above proc edure, performing the following procedure is advised.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Start engine.

c. Maintain the following conditions for at least 10 consecutive minutes. Hold the accelerator pedal as steady as possible.

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st trip DTC is detected, go to EC-1261, " Diagnosis Procedure " .

VHCL SPEED SE 50 – 120 km/h (31 – 75 MPH)

VHCL SPEED SE 50 – 120 km/h (31 – 75 MPH) BBIA0701E

Page 2620 of 4331

Diagnosis Procedure " .

If engine does not start, remove ignition plugs and check for fouling, etc.

6. Keep engine at idle for at least 5 minutes.

7. Check 1st trip DTC. The 1st trip DTC P0172 should be detected at this stage, if a malfunction exists. If so, go to EC-1267," Diagnosis Procedure " .

NOTE:

If 1st trip DTC is not detected during above proc edure, performing the following procedure is advised.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Start engine.

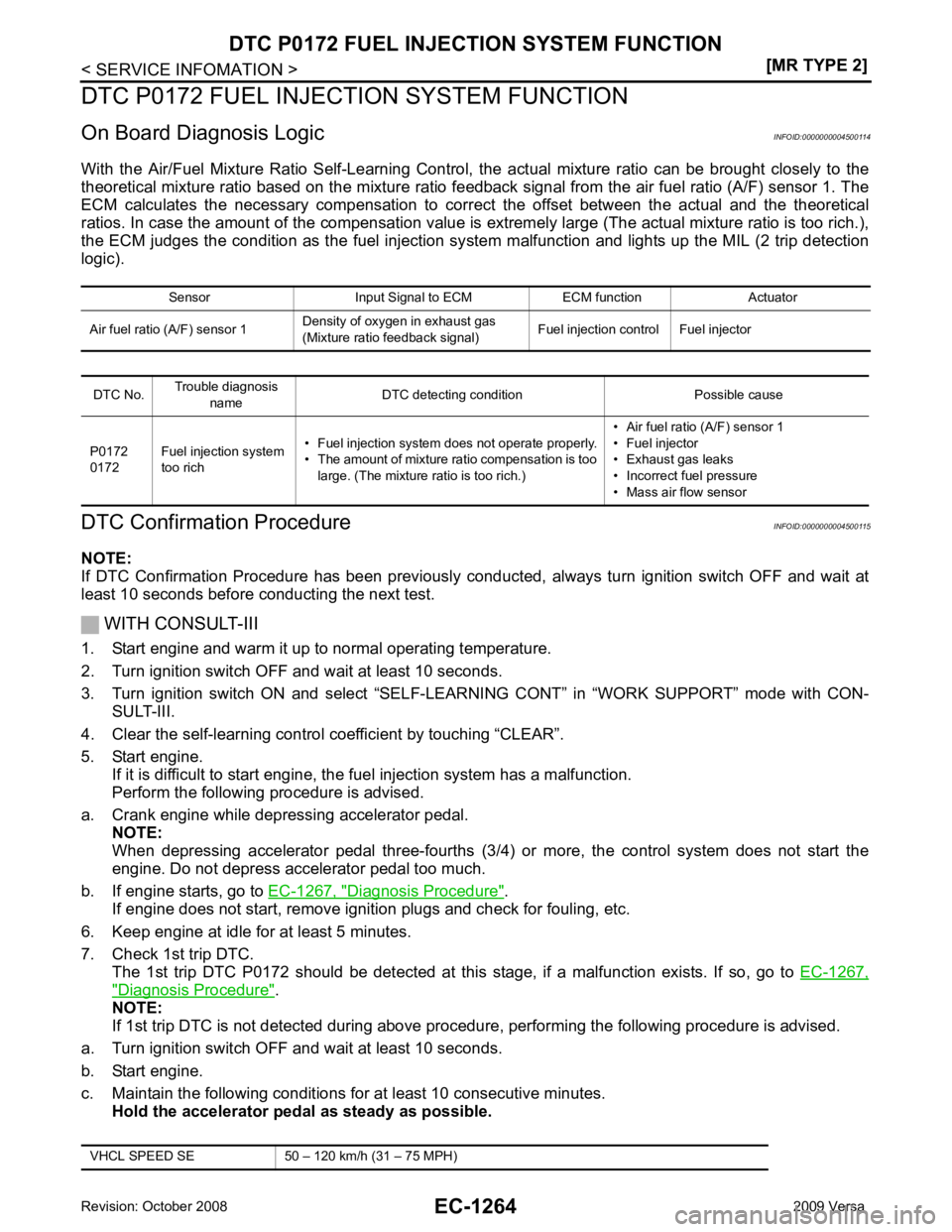

c. Maintain the following conditions for at least 10 consecutive minutes. Hold the accelerator pedal as steady as possible. Sensor Input Signal to ECM ECM function Actuator

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

(Mixture ratio feedback signal) Fuel injection control Fuel injectorDTC No.

Trouble diagnosis

name DTC detecting condition Possible cause

P0172

0172 Fuel injection system

too rich • Fuel injection system does not operate properly.

• The amount of mixture ratio compensation is too large. (The mixture ratio is too rich.) • Air fuel ratio (A/F) sensor 1

• Fuel injector

• Exhaust gas leaks

• Incorrect fuel pressure

• Mass air flow sensor VHCL SPEED SE 50 – 120 km/h (31 – 75 MPH)

Page 2621 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1265

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st tri NISSAN TIIDA 2009 Service Repair Manual DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1265

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st tri](/img/5/57398/w960_57398-2620.png)

DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1265

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st trip DTC is detected, go to EC-1267, " Diagnosis Procedure " .

WITH GST

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Disconnect mass air flow sensor (1) harness connector.

4. Restart engine and let idle for at least 5 seconds.

5. Stop engine and reconnect mass air flow sensor harness con- nector.

6. Select Service $03 with GST. Make sure DTC P0102 is detected.

7. Select Service $04 with GST and erase the DTC P0102.

8. Start engine. If it is difficult to start engine, the fuel injection system has a mal-

function.

Perform the following procedure is advised.

a. Crank engine while depressing accelerator pedal. NOTE:

When depressing accelerator pedal three-fourths (3/4) or more, the control system does not start the

engine. Do not depress accelerator pedal too much.

b. If engine starts, go to EC-1267, " Diagnosis Procedure " .

If engine does not start, remove ignition plugs and check for fouling, etc.

9. Keep engine at idle for at least 5 minutes.

10. Check 1st trip DTC. The 1st trip DTC P0172 should be det ected at this stage, if a malfunction exists. If so, go to EC-1267," Diagnosis Procedure " .

NOTE:

If 1st trip DTC is not detected during above proc edure, performing the following procedure is advised.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Start engine.

c. Maintain the following conditions for at least 10 consecutive minutes. Hold the accelerator pedal as steady as possible.

CAUTION:

Always drive vehicle at a safe speed.

d. Check 1st trip DTC.

e. If 1st trip DTC is detected, go to EC-1267, " Diagnosis Procedure " .VHCL SPEED SE 50 – 120 km/h (31 – 75 MPH) BBIA0701E

Page 2634 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1278< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

DTC P0222, P0223 TP SENSOR

Component Description INFOID:0000000004501170

Electric throttle control actuator consists of throt NISSAN TIIDA 2009 Service Repair Manual EC-1278< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

DTC P0222, P0223 TP SENSOR

Component Description INFOID:0000000004501170

Electric throttle control actuator consists of throt](/img/5/57398/w960_57398-2633.png)

EC-1278< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

DTC P0222, P0223 TP SENSOR

Component Description INFOID:0000000004501170

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometers which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. In addition,

these sensors detect the opening and closing speed of the throttle

valve and feed the voltage signals to the ECM. The ECM judges the

current opening angle of the throttle valve from these signals and the

ECM controls the throttle control motor to make the throttle valve

opening angle properly in response to driving condition.

CONSULT-III Reference Value in Data Monitor Mode INFOID:0000000004501171

Specification data are reference values.

*: Throttle position sensor 2 signal is converted by ECM internally. Thus, it differs from ECM terminal voltage signal.

On Board Diagn osis Logic INFOID:0000000004500134

These self-diagnoses have the one trip detection logic.

NOTE:

If DTC P0222 or P0223 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-1396 .

FAIL-SAFE MODE

When the malfunction is detected, the ECM enters fail-safe mode and the MIL lights up.

DTC Confirmation Procedure INFOID:0000000004500135

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

1. Start engine and let it idle for 1 second. PBIB0145E

MONITOR ITEM CONDITION SPECIFICATION

TP SEN 1-B1

TP SEN 2-B1* • Ignition switch: ON

(Engine stopped)

• Shift lever: D (A/T, CVT),

1st (M/T) Accelerator pedal: Fully released More than 0.36V

Accelerator pedal: Fully depressed Less than 4.75V DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0222

0222 Throttle position sensor

1 circuit low input An excessively low voltage from the TP sensor

1 is sent to ECM. • Harness or connectors

(TP sensor 1 circuit is open or shorted.)

(APP sensor 2 circuit is shorted.)

• Electric throttle control actuator (TP sensor 1)

• Accelerator pedal position sensor (APP sensor 2)

P0223

0223 Throttle position sensor

1 circuit high input An excessively high voltage from the TP sensor

1 is sent to ECM. Engine operation condition in fail-safe mode

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor.

Page 2649 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0335 CKP SENSOR (POS)

EC-1293

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0335 CKP SENSOR (POS)

Component Description INFOID:0000000004500150

The crankshaft position NISSAN TIIDA 2009 Service Repair Manual DTC P0335 CKP SENSOR (POS)

EC-1293

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0335 CKP SENSOR (POS)

Component Description INFOID:0000000004500150

The crankshaft position](/img/5/57398/w960_57398-2648.png)

DTC P0335 CKP SENSOR (POS)

EC-1293

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0335 CKP SENSOR (POS)

Component Description INFOID:0000000004500150

The crankshaft position sensor (POS) is located on the cylinder

block rear housing facing the gear t eeth (cogs) of the signal plate at

the end of the crankshaft. It detects the fluctuation of the engine rev-

olution. The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change. The changing gap causes

the magnetic field near the sensor to change. Due to the changing

magnetic field, the voltage from the sensor changes. The ECM

receives the voltage signal and detects the fluctuation of the engine

revolution.

ECM receives the signals as shown in the figure.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500151

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004500152

DTC Confirmation Procedure INFOID:0000000004500153

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION: PBIA9209J

PBIB2997E

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED • Run engine and compare CONSULT-III value with the tachometer indica-

tion. Almost the same speed as the ta-

chometer indication. DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0335

0335 Crankshaft position sen-

sor (POS) circuit • The crankshaft position sensor (POS) signal is not

detected by the ECM during the first few seconds of

engine cranking.

• The proper pulse signal from the crankshaft position sensor (POS) is not sent to ECM while the engine is

running.

• The crankshaft position sensor (POS) signal is not in the normal pattern during engine running. • Harness or connectors

[Crankshaft position sensor (POS)

circuit is open or shorted.]

(Accelerator pedal position sensor

circuit is shorted.)

(Refrigerant pressure sensor circuit

is shorted.)

(EVAP control system pressure

sensor circuit is shorted.)

• Crankshaft position sensor (POS)

• Accelerator pedal position sensor

• Refrigerant pressure sensor

• EVAP control system pressure sen- sor

• Signal plate

Page 2651 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0335 CKP SENSOR (POS)

EC-1295

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Specification data are reference values

and are measured between each terminal and ground.

Pulse NISSAN TIIDA 2009 Service Repair Manual DTC P0335 CKP SENSOR (POS)

EC-1295

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Specification data are reference values

and are measured between each terminal and ground.

Pulse](/img/5/57398/w960_57398-2650.png)

DTC P0335 CKP SENSOR (POS)

EC-1295

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Specification data are reference values

and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-III.

CAUTION:

Do not use ECM ground terminals wh en measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis Procedure INFOID:00000000045001551.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body. Refer to EC-1144, " Ground Inspection " .

TERMI-

NAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

61 W Crankshaft position

sensor (POS) [Engine is running]

• Warm-up condition

• Idle speed NOTE:

The pulse cycle changes depending on rpm

at idle Approximately 4.0V

[Engine is running]

• Engine speed: 2,000 rpm Approximately 4.0V

62 R Sensor ground

[Crankshaft position sensor

(POS)] [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

74 W Sensor power supply

(Refrigerant pressure sen-

sor) [Ignition switch: ON]

Approximately 5V

75 BR Sensor power supply

[Crankshaft position sensor

(POS)] [Ignition switch: ON]

Approximately 5V

76 W EVAP control system pres-

sure sensor power supply [Ignition switch: ON]

Approximately 5V

102 SB Sensor power supply

(APP sensor 2) [Ignition switch: ON]

Approximately 5V PBIB2998E

PBIB2999E

BBIA0698E