check engine NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2623 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1267

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Do not use ECM ground terminals wh

en measuring input/output voltage. Doing so may NISSAN TIIDA 2009 Service Repair Manual DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1267

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Do not use ECM ground terminals wh

en measuring input/output voltage. Doing so may](/img/5/57398/w960_57398-2622.png)

DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1267

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Do not use ECM ground terminals wh

en measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis Procedure INFOID:00000000045001171.

CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before three way catalyst (manifold).

OK or NG OK >> GO TO 2.

NG >> Repair or replace. 2.

CHECK FOR INTAKE AIR LEAK

TERMI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

3 G A/F sensor 1 heater [Engine is running]

• Warm-up condition

• Idle speed (More than 140 seconds after starting engine) Approximately 2.9 - 8.8V

25

29

30

31 V

Y

O

L Fuel injector No. 4

Fuel injector No. 3

Fuel injector No. 2

Fuel injector No. 1 [Engine is running]

• Warm-up condition

• Idle speed NOTE:

The pulse cycle changes depending on rpm at

idle BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

• Warm-up condition

• Engine speed: 2,000 rpm BATTERY VOLTAGE

(11 - 14V)

49 W A/F sensor 1 [Engine is running]

• Warm-up condition

• Engine speed: 2,000 rpm Approximately 1.8V

Output voltage varies with air

fuel ratio.

53 B A/F sensor 1 [Ignition switch: ON] Approximately 2.2V PBIA8148J

PBIB0529E

PBIA4943J

PBIB1216E

Page 2624 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1268< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

Listen for an intake air leak after the mass air flow sensor.

OK or NG OK >> GO TO 3.

NG >> Repair or replace. 3.

CHE NISSAN TIIDA 2009 Service Repair Manual EC-1268< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

Listen for an intake air leak after the mass air flow sensor.

OK or NG OK >> GO TO 3.

NG >> Repair or replace. 3.

CHE](/img/5/57398/w960_57398-2623.png)

EC-1268< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

Listen for an intake air leak after the mass air flow sensor.

OK or NG OK >> GO TO 3.

NG >> Repair or replace. 3.

CHECK AIR FUEL RATIO (A/F) SENS OR 1 CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect air fuel ratio (A/F) sensor 1 harness connector (1).

- Air fuel ratio (A/F) sensor 1 (2)

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals. Refer to Wiring Diagram.

5. Check harness continuity between ECM terminals 49, 53 or A/F sensor 1 terminals 1, 2 and ground. Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-1086, " Fuel Pressure Check " .

2. Install fuel pressure gauge and check fuel pressure. Refer to EC-1086, " Fuel Pressure Check " .

OK or NG OK >> GO TO 6.

NG >> GO TO 5. 5.

DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-1513 .)

• Fuel pressure regulator (Refer to EC-1086, " Fuel Pressure Check " .)

>> Repair or replace. 6.

CHECK MASS AIR FLOW SENSOR

With CONSULT-III

1. Install all removed parts.

2. Start engine and warm it up to normal operating temperature.

3. Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT-III.

With GST

1. Install all removed parts.

2. Start engine and warm it up to normal operating temperature.

3. Check mass air flow sensor signal in Service $01 with GST. A/F sensor 1 terminal ECM terminal

1 49

2 53

Continuity should exist.

Continuity should not exist. BBIA0699E

At idling: Approximately 350 kPa (3.57 kg/cm2, 51 psi)

at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec

Page 2625 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1269

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 7.

NG >> Check connectors for rusted terminals or loose c onne NISSAN TIIDA 2009 Service Repair Manual DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1269

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 7.

NG >> Check connectors for rusted terminals or loose c onne](/img/5/57398/w960_57398-2624.png)

DTC P0172 FUEL INJECT

ION SYSTEM FUNCTION

EC-1269

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 7.

NG >> Check connectors for rusted terminals or loose c onnections in the mass air flow sensor circuit or

ground. Refer to EC-1170 .

7.

CHECK FUNCTION OF FUEL INJECTORS

With CONSULT-III

1. Let engine idle.

2. Perform “POWER BALANCE” in “A CTIVE TEST” mode with CONSULT-III.

3. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-III

1. Let engine idle.

2. Listen to each fuel injector operating sound.

OK or NG OK >> GO TO 8.

NG >> Perform trouble diagnosis for EC-1508 .

8.

CHECK FUEL INJECTOR

1. Remove fuel injector assembly. Refer to EM-156 .

Keep fuel hose and all fuel injector connected to fuel tube.

2. Confirm that the engine is cooled down and t here are no fire hazards near the vehicle.

3. Reconnect all harness connectors disconnected.

4. Disconnect all injector harness connectors.

5. Disconnect all ignition coil harness connectors.

6. Prepare pans or saucers under each fuel injector.

7. Crank engine for about 3 seconds.

Make sure fuel does not drip from fuel injector.

OK or NG OK (Does not drip.)>>GO TO 9.

NG (Drips.)>>Replace the fuel injectors from which fuel is dripping. Always replace O-ring with new one.9.

CHECK INTERMITTENT INCIDENT

Refer to EC-1138 .

>> INSPECTION END

at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec Clicking noise should be heard.

PBIB3332E

Page 2626 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1270< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0181 FTT SENSOR

DTC P0181 FTT SENSOR

Component Description INFOID:0000000004500118

The fuel tank temperature sensor (4) is used to detect the fuel tem-

NISSAN TIIDA 2009 Service Repair Manual EC-1270< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0181 FTT SENSOR

DTC P0181 FTT SENSOR

Component Description INFOID:0000000004500118

The fuel tank temperature sensor (4) is used to detect the fuel tem-](/img/5/57398/w960_57398-2625.png)

EC-1270< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0181 FTT SENSOR

DTC P0181 FTT SENSOR

Component Description INFOID:0000000004500118

The fuel tank temperature sensor (4) is used to detect the fuel tem-

perature inside the fuel tank. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the fuel

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The elec trical resistance of the ther-

mistor decreases as temperature increases.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

*: This data is reference values and is measured between ECM terminal 43 (Fuel

tank temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result da mage the ECM's transistor. Use

ground other than ECM, such as ground.

On Board Diagn osis Logic INFOID:0000000004500119

DTC Confirmation Procedure INFOID:0000000004500120

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-III

1. Turn ignition switch ON and wait at least 10 seconds.

2. Check 1st trip DTC. If 1st trip DTC is detected, go to EC-1271, " Diagnosis Procedure " .

If 1st trip DTC is not det ected, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Check “COOLAN TEMP/S” value.

If the “COOLAN TEMP/S” is less than 60 °C (140 °F), the result will be OK.

If the “COOLAN TEMP/S” is above 60 °C (140 °F), go to the following step.

5. Cool engine down until “COOLAN TEMP/S” signal is less than 60 °C (140 °F).

6. Wait at least 10 seconds.

7. Check 1st trip DTC.

8. If 1st trip DTC is detected, go to EC-1271, " Diagnosis Procedure " .

WITH GST BBIA0704E

Fluid temperature

°C ( °F) Voltage*

V Resistance

kΩ

20 (68) 3.5 2.3 - 2.7

50 (122) 2.2 0.79 - 0.90 SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0181

0181 Fuel tank temperature

sensor circuit range/per-

formance Rationally incorrect voltage from the sensor is

sent to ECM, compared with the voltage signals

from engine coolant temperature sensor and in-

take air temperature sensor. • Harness or connectors

(Fuel tank temperature sensor circuit is

open or shorted)

• Fuel tank temperature sensor

Page 2628 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1272< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0181 FTT SENSOR

2. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or repl NISSAN TIIDA 2009 Service Repair Manual EC-1272< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0181 FTT SENSOR

2. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or repl](/img/5/57398/w960_57398-2627.png)

EC-1272< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0181 FTT SENSOR

2. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK FUEL TANK TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness con- nector (1).

- : Vehicle front

3. Turn ignition switch ON.

4. Check voltage between “fuel level sensor unit and fuel pump” terminal 4 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 4.

NG >> GO TO 3. 3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness connectors M69, E7

• Harness connectors B102, M13

• Harness for open or short between ECM and “fuel level sensor unit and fuel pump”

>> Repair open circuit or short to ground or short to power in harness or connector. 4.

CHECK FUEL TANK TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF. :

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

BBIA0702E

Voltage: Approximately 5V

PBIB0932E

Page 2632 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1276< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0182, P0183 FTT SENSOR

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK FUEL TANK TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. NISSAN TIIDA 2009 Service Repair Manual EC-1276< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0182, P0183 FTT SENSOR

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK FUEL TANK TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1.](/img/5/57398/w960_57398-2631.png)

EC-1276< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0182, P0183 FTT SENSOR

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK FUEL TANK TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness con-

nector (1).

- : Vehicle front

3. Turn ignition switch ON.

4. Check voltage between “fuel level sensor unit and fuel pump” terminal 4 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 4.

NG >> GO TO 3. 3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness connectors M69, E7

• Harness connectors B102, M13

• Harness for open or short between ECM and “fuel level sensor unit and fuel pump”

>> Repair open circuit or short to ground or short to power in harness or connector. 4.

CHECK FUEL TANK TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect combination meter harness connector. :

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

BBIA0702E

Voltage: Approximately 5V

PBIB0932E

Page 2636 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1280< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECMs transistor. Use NISSAN TIIDA 2009 Service Repair Manual EC-1280< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECMs transistor. Use](/img/5/57398/w960_57398-2635.png)

EC-1280< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0222, P0223 TP SENSOR

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground.

Diagnosis Procedure INFOID:00000000045001371.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. 2.

CHECK THROTTLE POSITION SE NSOR 1 POWER SUPPLY CIRCUIT-I

TERMI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

33 LG Throttle position sensor 1 [Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully released More than 0.36V

[Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully depressed Less than 4.75V

34 O Throttle position sensor 2 [Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully released Less than 4.75V

[Ignition switch: ON]

• Engine stopped

• Shift lever: D (A/T, CVT), 1st (M/T)

• Accelerator pedal: Fully depressed More than 0.36V

36 Y Sensor ground

(Throttle position sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

72 V Sensor power supply

(Throttle position sensor) [Ignition switch: ON]

Approximately 5V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2639 of 4331

EC

NP

O

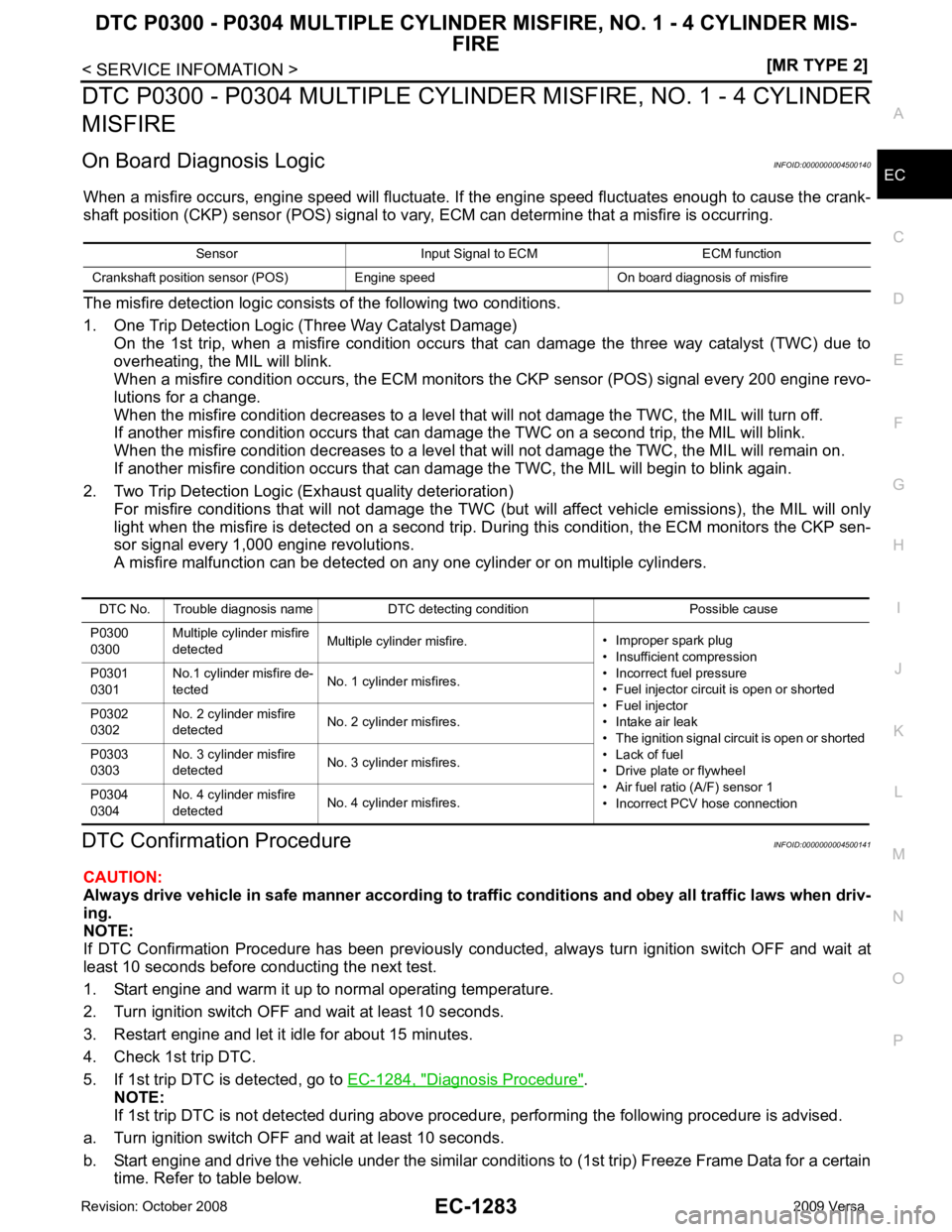

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER

MISFIRE

On Board Diagnosis Logic INFOID:0000000004500140

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary , ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage) On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor (POS) signal every 200 engine revo-

lutions for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. Du ring this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC Confirmation Procedure INFOID:0000000004500141

CAUTION:

Always drive vehicle in safe manner according to traf fic conditions and obey all traffic laws when driv-

ing.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Restart engine and let it idle for about 15 minutes.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to EC-1284, " Diagnosis Procedure " .

NOTE:

If 1st trip DTC is not detected during above proc edure, performing the following procedure is advised.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Start engine and drive the vehicle under the similar conditi ons to (1st trip) Freeze Frame Data for a certain

time. Refer to table below. Sensor Input Signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300

0300 Multiple cylinder misfire

detected Multiple cylinder misfire.

• Improper spark plug

• Insufficient compression

• Incorrect fuel pressure

• Fuel injector circuit is open or shorted

• Fuel injector

• Intake air leak

• The ignition signal circuit is open or shorted

• Lack of fuel

• Drive plate or flywheel

• Air fuel ratio (A/F) sensor 1

• Incorrect PCV hose connection

P0301

0301 No.1 cylinder misfire de-

tected No. 1 cylinder misfires.

P0302

0302 No. 2 cylinder misfire

detected No. 2 cylinder misfires.

P0303

0303 No. 3 cylinder misfire

detected No. 3 cylinder misfires.

P0304

0304 No. 4 cylinder misfire

detected No. 4 cylinder misfires.

Page 2640 of 4331

![NISSAN TIIDA 2009 Service Repair Manual EC-1284< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

Hold the accelerator pedal as steady as possible.

The similar conditions to (1st tr NISSAN TIIDA 2009 Service Repair Manual EC-1284< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

Hold the accelerator pedal as steady as possible.

The similar conditions to (1st tr](/img/5/57398/w960_57398-2639.png)

EC-1284< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

Hold the accelerator pedal as steady as possible.

The similar conditions to (1st trip) Freeze Frame Da ta means the vehicle operation that the following con-

dition should be satisfied at the same time:

The time to driving varies according to the engine speed in the freeze frame data.

Refer to the following table.

Diagnosis Procedure INFOID:00000000045001421.

CHECK FOR INTAKE AIR LEAK AND PCV HOSE

1. Start engine and run it at idle speed.

2. Listen for the sound of the intake air leak.

3. Check PCV hose connection.

OK or NG OK >> GO TO 2.

NG >> Repair or replace. 2.

CHECK FOR EXHAUST SYSTEM CLOGGING

Stop engine and visually check exhaust tube, three way catalyst and muffler for dents.

OK or NG OK >> GO TO 3.

NG >> Repair or replace. 3.

PERFORM POWER BALANCE TEST

With CONSULT-III

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode.

2. Is there any cylinder which does not produce a momentary engine speed drop?

Without CONSULT-III

When disconnecting each fuel inje ctor (1) harness connector one at

a time, is there any cylinder which does not produce a momentary

engine speed drop?

Yes or No Engine speed Engine speed in the freeze frame data

± 400 rpm

Vehicle speed Vehicle speed in the freeze frame data ± 10 km/h (6 MPH)

Basic fuel schedule Basic fuel schedule in the freeze frame data × (1 ± 0.1)

Engine coolant temperature

(T) condition When the freeze frame data shows lower than 70

°C (158 °F), T should be lower than 70 °C (158 °F)

When the freeze frame data shows higher than or equal to 70 °C (158 °F), T should be higher than or

equal to 70 °C (158 °F) Engine speed Time

Around 1,000 rpm Approximately 10 minutes

Around 2,000 rpm Approximately 5 minutes

More than 3,000 rpm Approximately 3.5 minutes PBIA9870J

Page 2641 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1285

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 4.

No >> GO TO 9. 4.

CHECK FUEL INJEC NISSAN TIIDA 2009 Service Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1285

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 4.

No >> GO TO 9. 4.

CHECK FUEL INJEC](/img/5/57398/w960_57398-2640.png)

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-1285

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Yes >> GO TO 4.

No >> GO TO 9. 4.

CHECK FUEL INJECTOR

Does each fuel injector make an operating sound at idle?

Yes or No Yes >> GO TO 5.

No >> Check fuel injector(s) and circuit(s). Refer to EC-1508 .

5.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

OK or NG OK >> GO TO 9.

NG >> GO TO 6. 6.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug. PBIB3332E

Spark should be generated. PBIB2958E

PBIB2325E