oil pressure NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2124 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-768< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

OK or NG OK >> GO TO 7.

NG >> Check ignition coil, power transistor and their circui NISSAN TIIDA 2009 Service Manual PDF EC-768< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

OK or NG OK >> GO TO 7.

NG >> Check ignition coil, power transistor and their circui](/img/5/57398/w960_57398-2123.png)

EC-768< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

OK or NG OK >> GO TO 7.

NG >> Check ignition coil, power transistor and their circuits. Refer to EC-996 .

7.

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

OK or NG OK >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-227, " Standard and Limit " .

NG >> 1. Repair or clean spark plug.

2. GO TO 8. 8.

CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about three seconds, and recheck whether spark is generated between the spark plug

and the grounded portion.

OK or NG OK >>

INSPECTION END

NG >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-227, " Standard

and Limit " .

9.

CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-185, " On-Vehicle Service " .

OK or NG OK >> GO TO 10.

NG >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets. 10.

CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-574, " Fuel Pressure Check " .

3. Install fuel pressure gauge and check fuel pressure. Refer to EC-574, " Fuel Pressure Check " .

OK or NG OK >> GO TO 12.

NG >> GO TO 11. 11.

DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-991 .)

• Fuel pressure regulator (Refer to EC-574, " Fuel Pressure Check " .)

• Fuel lines (Refer to EM-156 .)

• Fuel filter for clogging

>> Repair or replace. 12.

CHECK IGNITION TIMING

Check the following items. Refer to EC-566, " Basic Inspection " .

Spark should be generated.

SEF156I

Spark should be generated.

At idling: Approximately 350 kPa (3.57 kg/cm 2

, 51 psi)

Page 2145 of 4331

![NISSAN TIIDA 2009 Service Manual PDF DTC P0420 THREE WAY CATALYST FUNCTION

EC-789

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 5.

NG >> Follow the EC-566, " Basic Inspection " .

5.

CHECK FUEL I NISSAN TIIDA 2009 Service Manual PDF DTC P0420 THREE WAY CATALYST FUNCTION

EC-789

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 5.

NG >> Follow the EC-566, " Basic Inspection " .

5.

CHECK FUEL I](/img/5/57398/w960_57398-2144.png)

DTC P0420 THREE WAY CATALYST FUNCTION

EC-789

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 5.

NG >> Follow the EC-566, " Basic Inspection " .

5.

CHECK FUEL INJECTOR

1. Stop engine and turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Turn ignition switch ON.

4. Check voltage between ECM terminals 25, 29, 30, 31 and ground with CONSULT-III or tester.

Refer to Wiring Diagram for fuel injectors, EC-987, " Wiring Diagram " .

OK or NG OK >> GO TO 6.

NG >> Perform EC-988, " Diagnosis Procedure " .

6.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump (1) fuse in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electri- cal discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm between the edge of the spark plug and grounded metal portion

as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20kV or more. Items Specifications

Target idle speed A/T: 700

± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

Ignition timing A/T: 13

± 5 ° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position)

M/T: 13 ± 5 ° BTDC (in Neutral position) Voltage: Battery voltage

Spark should be generated. PBIB2958E

PBIB2325E

Page 2173 of 4331

![NISSAN TIIDA 2009 Service Manual PDF DTC P0447 EVAP CANISTER

VENT CONTROL VALVE

EC-817

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0447 EVAP CANISTER VENT CONTROL VALVE

Component Description INFOID:0000000004 NISSAN TIIDA 2009 Service Manual PDF DTC P0447 EVAP CANISTER

VENT CONTROL VALVE

EC-817

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0447 EVAP CANISTER VENT CONTROL VALVE

Component Description INFOID:0000000004](/img/5/57398/w960_57398-2172.png)

DTC P0447 EVAP CANISTER

VENT CONTROL VALVE

EC-817

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0447 EVAP CANISTER VENT CONTROL VALVE

Component Description INFOID:0000000004537308

The EVAP canister vent control valve (3) is located on the EVAP

canister (2) and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal

the vent is necessary for the on board diagnosis of other evaporative

emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the evapo-

rative emission control system is depressurized and allows EVAP

control system diagnoses.

• EVAP control system pressure sensor (1)

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004537309

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004537310

DTC Confirmation Procedure INFOID:0000000004537311

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, conf irm battery voltage is more than 11V at idle.

1. Start engine and wait at least 8 seconds.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-819, " Diagnosis Procedure " . PBIB1263E

BBIA0693E

MONITOR ITEM CONDITION SPECIFICATION

VENT CONT/V • Ignition switch: ON OFF DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0447

0447 EVAP canister vent con-

trol valve circuit open An improper voltage signal is sent to ECM

through EVAP canister vent control valve. • Harness or connectors

(EVAP canister vent control valve circuit

is open or shorted.)

• EVAP canister vent control valve

Page 2179 of 4331

![NISSAN TIIDA 2009 Service Manual PDF DTC P0448 EVAP CANISTER

VENT CONTROL VALVE

EC-823

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

Component Description INFOID:0000000004 NISSAN TIIDA 2009 Service Manual PDF DTC P0448 EVAP CANISTER

VENT CONTROL VALVE

EC-823

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

Component Description INFOID:0000000004](/img/5/57398/w960_57398-2178.png)

DTC P0448 EVAP CANISTER

VENT CONTROL VALVE

EC-823

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

Component Description INFOID:0000000004537315

The EVAP canister vent control valve (3) is located on the EVAP

canister (2) and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal

the vent is necessary for the on board diagnosis of other evaporative

emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the evapo-

rative emission control system is depressurized and allows EVAP

control system diagnoses.

• EVAP control system pressure sensor (1)

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004537316

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004537317

DTC Confirmation Procedure INFOID:0000000004537318

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and let it idle for at least 1 minute.

4. Repeat next procedures three times.

a. Increase the engine speed up to 3,000 to 3,500 rpm and keep it for 2 minutes and 50 seconds to 3 min- utes. PBIB1263E

BBIA0693E

MONITOR ITEM CONDITION SPECIFICATION

VENT CONT/V • Ignition switch: ON OFF DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0448

0448 EVAP canister vent con-

trol valve close EVAP canister vent control valve remains

closed under specified driving conditions. • EVAP canister vent control valve

• EVAP control system pressure sensor and the circuit

• Blocked rubber tube to EVAP canister

vent control valve

• EVAP canister is saturated with water

Page 2360 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-1004< SERVICE INFOMATION >

[MR TYPE 1]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or f NISSAN TIIDA 2009 Service Manual PDF EC-1004< SERVICE INFOMATION >

[MR TYPE 1]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or f](/img/5/57398/w960_57398-2359.png)

EC-1004< SERVICE INFOMATION >

[MR TYPE 1]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel

pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be checked.

13. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm between the edge of the spark plug and grounded metal portion

as shown in the figure.

16. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20kV or more.

• It might cause to damage the ignition coil if the gap of more than 17 mm is taken.

NOTE:

When the gap is less than 13 mm, the spark might be generated even if the coil is malfunctioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER-2

1. Turn ignition switch OFF.

2. Disconnect condenser-2 harness connector.

3. Check resistance between condenser-2 terminals 1 and 2.

4. If NG, replace condenser-2.

Removal and Installation INFOID:0000000004537539

IGNITION COIL WITH POWER TRANSISTOR

Refer to EM-153 .

Spark should be generated. PBIB2958E

PBIB2325E

Resistance: Above 1 M

Ω [at 25 °C (77 °F)] PBIB0794E

Page 2443 of 4331

![NISSAN TIIDA 2009 Service Manual PDF BASIC SERVICE PROCEDURE

EC-1087

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After e NISSAN TIIDA 2009 Service Manual PDF BASIC SERVICE PROCEDURE

EC-1087

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After e](/img/5/57398/w960_57398-2442.png)

BASIC SERVICE PROCEDURE

EC-1087

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because C11 models do not have fuel return system.

• The fuel hose connection method u sed when taking fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains seal abil ity with O-rings inside.

• Do not perform fuel pressure check with electrical syst ems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check B and fuel tube adapter (KV10118400) D, then connect fuel pressure gauge A.

• : To quick connector

• : To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine

NISSAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder- ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam- age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer to EM-156, " Removal and Installation " .

• Do not twist or kink fuel hose because it is plastic hose.

4. Connect fuel hose for fuel pressure check (1) to fuel tube (engine side) with clamp (2) as shown in the figure.

• No.2 spool (5)

• Wipe off oil or dirt from hose insertion part using cloth moist-

ened with gasoline.

• Apply proper amount of gasoline between top of the fuel tube (3) and No.1 spool (4).

• Insert fuel hose for fuel pressure check until it touches the No.1 spool on fuel tube.

• Use NISSAN genuine hose clamp (part number: 16439 N4710

or 16439 40U00).

• When reconnecting fuel line, always use new clamps.

• Use a torque driver to tighten clamps.

• Install hose clamp to the positi on within 1 - 2 mm (0.04 - 0.08 in).

• Make sure that clamp screw does not contact adjacent parts. PBIB2958E

Tightening torque: 1 - 1.5 N·m

(0.1 - 0.15 kg-m, 9 - 13 in-lb) PBIB2982E

PBIB2983E

Page 2453 of 4331

EC

NP

O

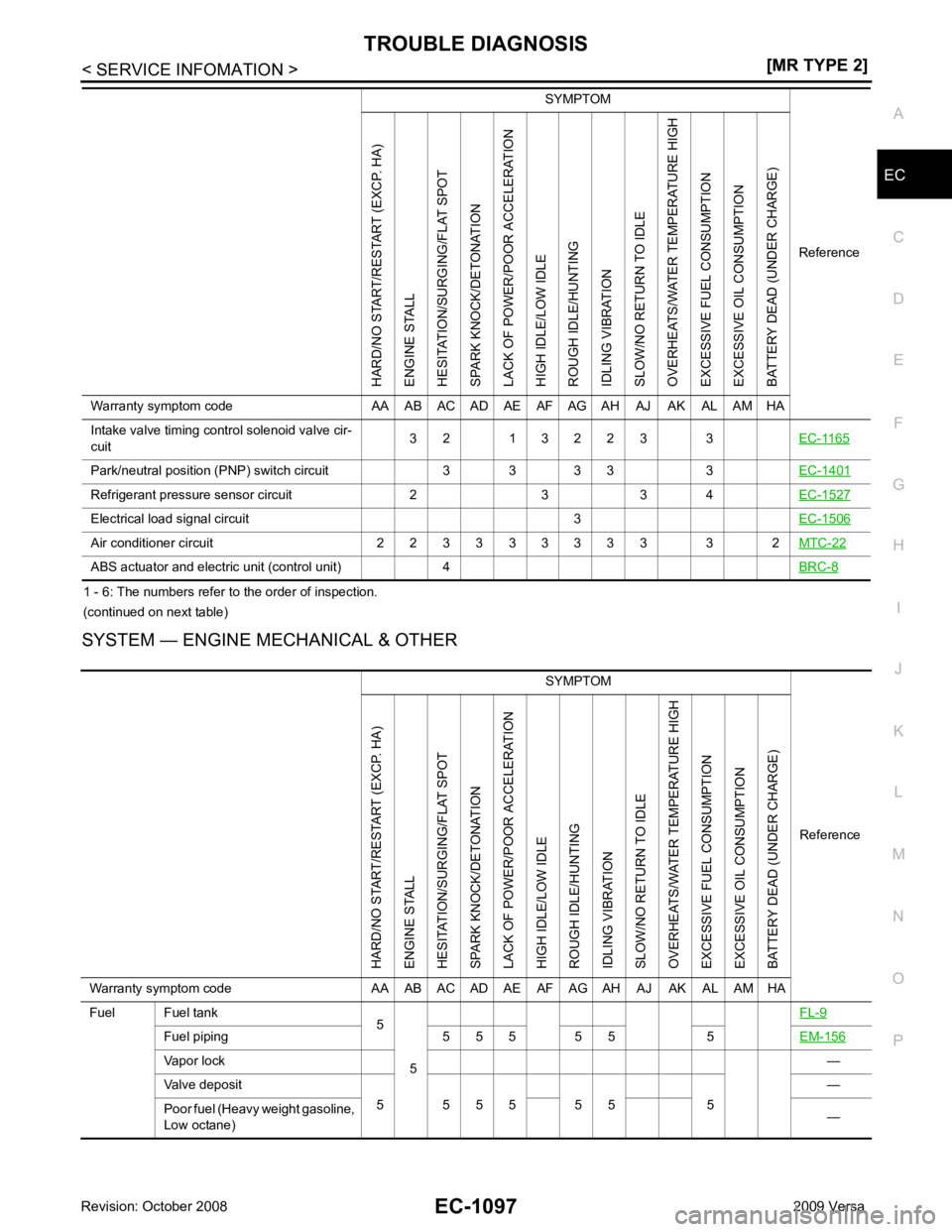

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & OTHER Intake valve timing control solenoid valve cir-

cuit 3 2 1 3 2 2 3 3

EC-1165Park/neutral position (P

NP) switch circuit 3 3 3 3 3 EC-1401Refrigerant pressure sensor circuit 2 3 3 4

EC-1527Electrical load signal circuit 3

EC-1506Air conditioner circuit 2 2 3 3 3 3 3 3 3 3 2

MTC-22ABS actuator and electric unit (control unit) 4

BRC-8SYMPTOM

ReferenceHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA SYMPTOM

Reference

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-9Fuel piping 5 5 5 5 5 5

EM-156Vapor lock

—

Valve deposit 5 5 5 5 5 5 5 —

Poor fuel (Heavy weight gasoline,

Low octane) —

Page 2456 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-1100< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

Engine Control Comp onent Parts Location INFOID:0000000004499941

1. Ignition coil (with power transistor) and spark plug 2. Intake valve ti NISSAN TIIDA 2009 Service Manual PDF EC-1100< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

Engine Control Comp onent Parts Location INFOID:0000000004499941

1. Ignition coil (with power transistor) and spark plug 2. Intake valve ti](/img/5/57398/w960_57398-2455.png)

EC-1100< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

Engine Control Comp onent Parts Location INFOID:0000000004499941

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector 6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built-in throttle position sensor,

throttle control motor)

13. EVAP canister purge volume control solenoid valve PBIB3261E

Page 2458 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-1102< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

: Vehicle front

1. Intake valve timing control solenoid valve 2. Knock sensor 3. IPDM E/R

4. Fuel pump fuse (15A) 5. Fuel level sensor u NISSAN TIIDA 2009 Service Manual PDF EC-1102< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

: Vehicle front

1. Intake valve timing control solenoid valve 2. Knock sensor 3. IPDM E/R

4. Fuel pump fuse (15A) 5. Fuel level sensor u](/img/5/57398/w960_57398-2457.png)

EC-1102< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

: Vehicle front

1. Intake valve timing control solenoid valve 2. Knock sensor 3. IPDM E/R

4. Fuel pump fuse (15A) 5. Fuel level sensor unit and fuel pump harness connector (view with in-

spection hole cover removed) 6. Fuel level sensor unit and fuel pump

7. Fuel pressure regulator 8. Fuel level sensor 9. Fuel tank temperature sensor

10. Ignition coil (with power transistor) and spark plug 11. Fuel injector BBIA0725E

Page 2489 of 4331

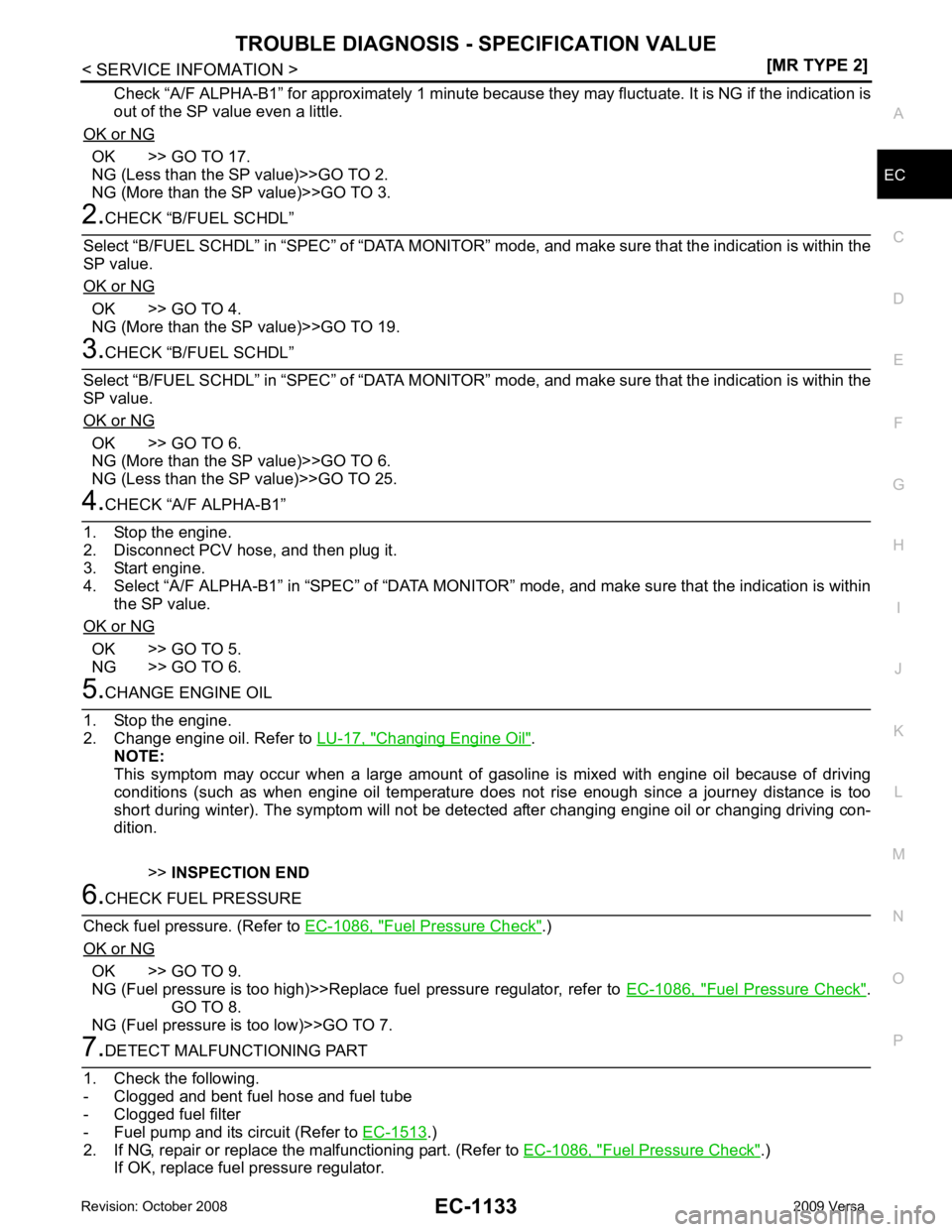

EC

NP

O

Check “A/F ALPHA-B1” for approximately 1 minute because t

hey may fluctuate. It is NG if the indication is

out of the SP value even a little.

OK or NG OK >> GO TO 17.

NG (Less than the SP value)>>GO TO 2.

NG (More than the SP value)>>GO TO 3. OK >> GO TO 4.

NG (More than the SP value)>>GO TO 19. OK >> GO TO 6.

NG (More than the SP value)>>GO TO 6.

NG (Less than the SP value)>>GO TO 25. OK >> GO TO 5.

NG >> GO TO 6. Changing Engine Oil " .

NOTE:

This symptom may occur when a large amount of gas oline is mixed with engine oil because of driving

conditions (such as when engine oil temperature does not rise enough since a journey distance is too

short during winter). The symptom will not be detect ed after changing engine oil or changing driving con-

dition.

>>INSPECTION END Fuel Pressure Check " .)

OK or NG OK >> GO TO 9.

NG (Fuel pressure is too high)>>Replace fuel pressure regulator, refer to EC-1086, " Fuel Pressure Check " .

GO TO 8.

NG (Fuel pressure is too low)>>GO TO 7. .)

2. If NG, repair or replace the malfunctioning part. (Refer to EC-1086, " Fuel Pressure Check " .)

If OK, replace fuel pressure regulator.