Tools NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 4060 of 4331

PS-4< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004305928

The actual shapes of K ent-Moore tools may differ from thos e of special tools illustrated here.

Commercial Service Tool INFOID:0000000004305929

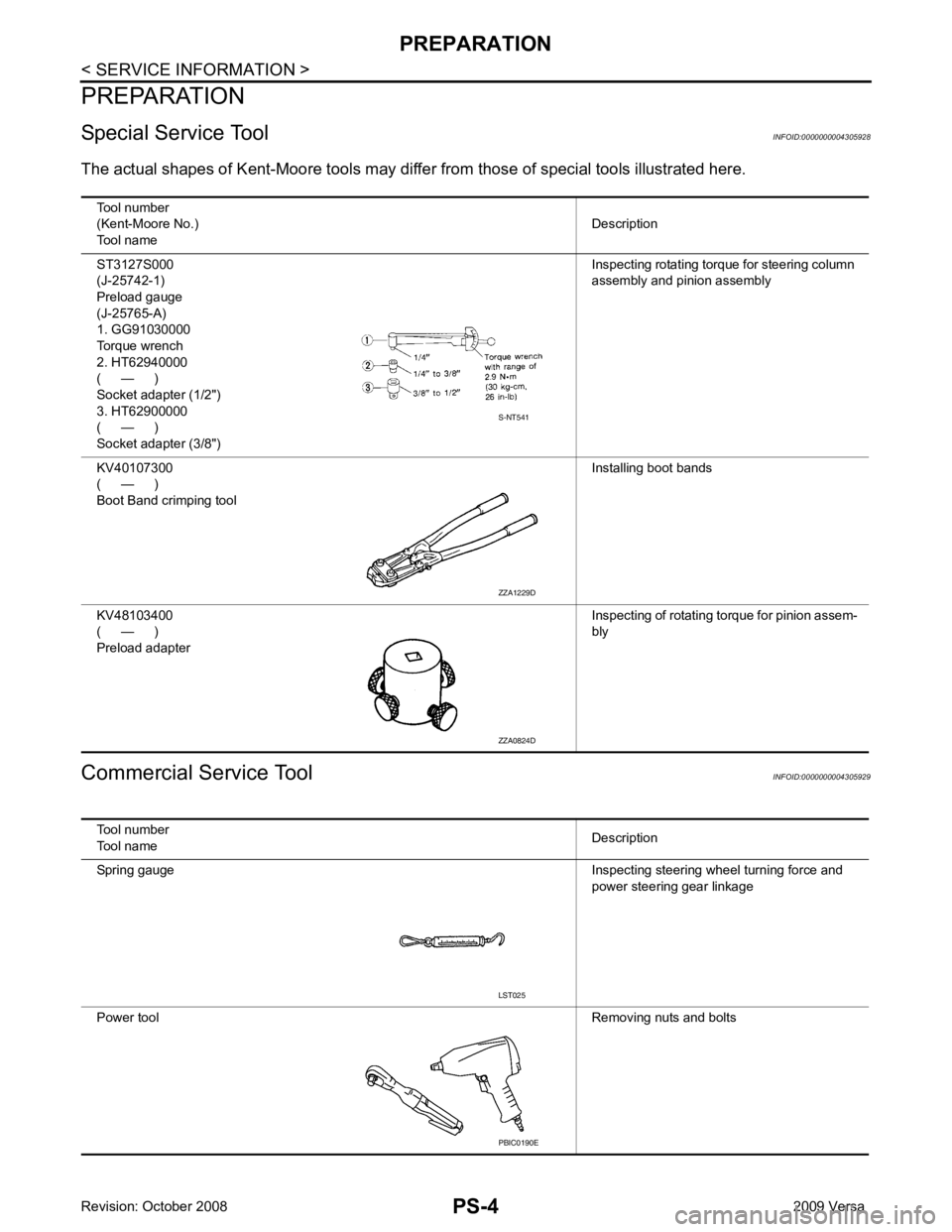

Tool number

(Kent-Moore No.)

Tool name Description

ST3127S000

(J-25742-1)

Preload gauge

(J-25765-A)

1. GG91030000

Torque wrench

2. HT62940000

( — )

Socket adapter (1/2")

3. HT62900000

( — )

Socket adapter (3/8") Inspecting rotating torque for steering column

assembly and pinion assembly

KV40107300

( — )

Boot Band crimping tool Installing boot bands

KV48103400

( — )

Preload adapter Inspecting of rotating torque for pinion assem-

bly S-NT541

ZZA1229D

ZZA0824D

Tool number

Tool name Description

Spring gauge Inspecting steering wheel turning force and

power steering gear linkage

Power tool Removing nuts and bolts LST025

PBIC0190E

Page 4071 of 4331

PS

N

O P

1. Apply recommended grease to teeth part and bush part of rack assembly, if necessary.

2. Apply recommended grease to back of rack assembly, if necessary.

3. Install inner socket to rack assembly. Torque to specified value while holding the flat portion of the rack next to the inner socket using a suitable tool.

4. Apply recommended grease to inner socket.

5. Decide on the neutral position for the rack assembly.

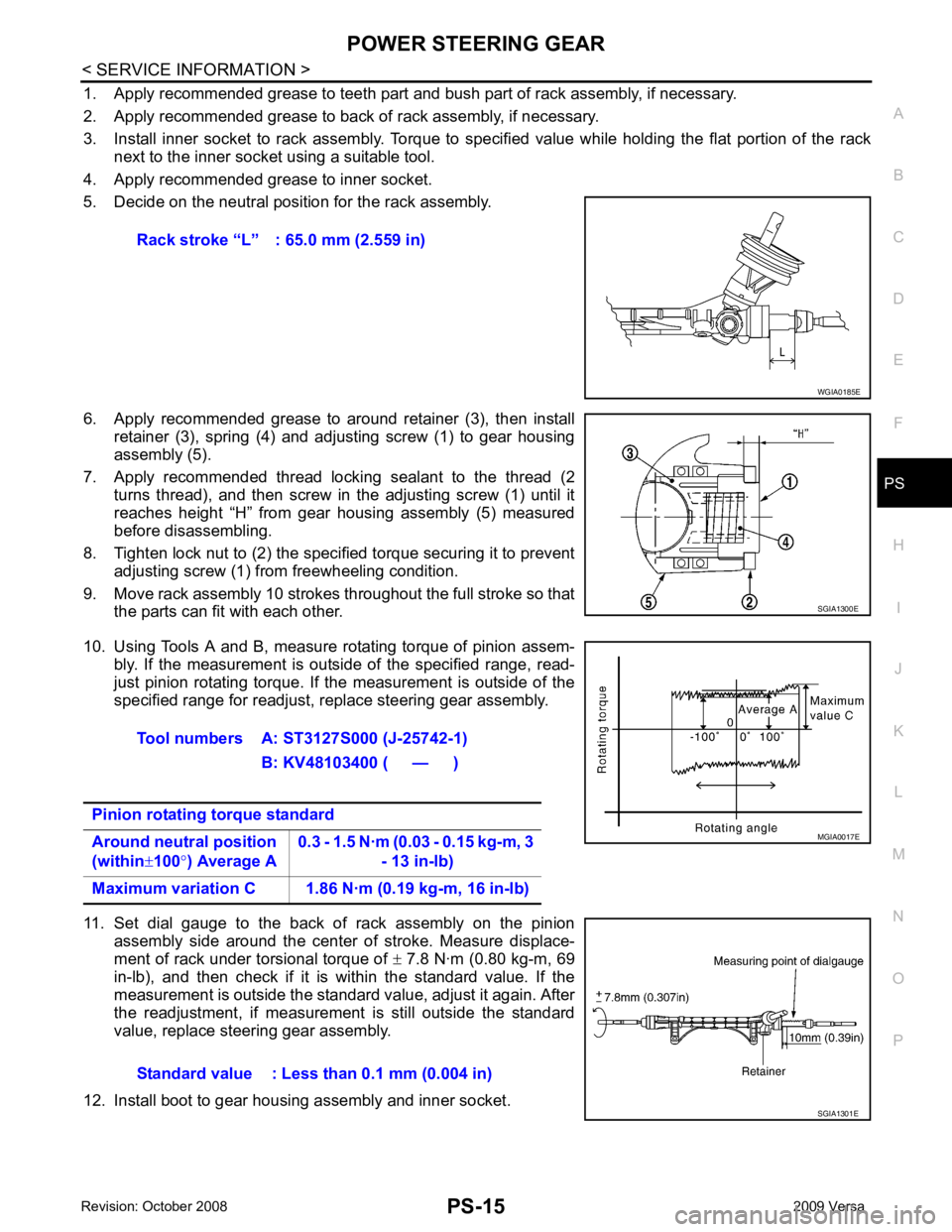

6. Apply recommended grease to around retainer (3), then install retainer (3), spring (4) and adjusting screw (1) to gear housing

assembly (5).

7. Apply recommended thread locking sealant to the thread (2 turns thread), and then screw in the adjusting screw (1) until it

reaches height “H” from gear housing assembly (5) measured

before disassembling.

8. Tighten lock nut to (2) the specified torque securing it to prevent adjusting screw (1) from freewheeling condition.

9. Move rack assembly 10 strokes throughout the full stroke so that the parts can fit with each other.

10. Using Tools A and B, measure rotating torque of pinion assem- bly. If the measurement is outside of the specified range, read-

just pinion rotating torque. If the measurement is outside of the

specified range for readjust, replace steering gear assembly.

11. Set dial gauge to the back of rack assembly on the pinion assembly side around the center of stroke. Measure displace-

ment of rack under torsional torque of ± 7.8 N·m (0.80 kg-m, 69

in-lb), and then check if it is within the standard value. If the

measurement is outside the standard value, adjust it again. After

the readjustment, if measurement is still outside the standard

value, replace steering gear assembly.

12. Install boot to gear housing assembly and inner socket. Rack stroke “L” : 65.0 mm (2.559 in)

Page 4114 of 4331

RSU

N

O P

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Rear Suspension INFOID:0000000004305875

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and l ubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Page 4124 of 4331

RSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

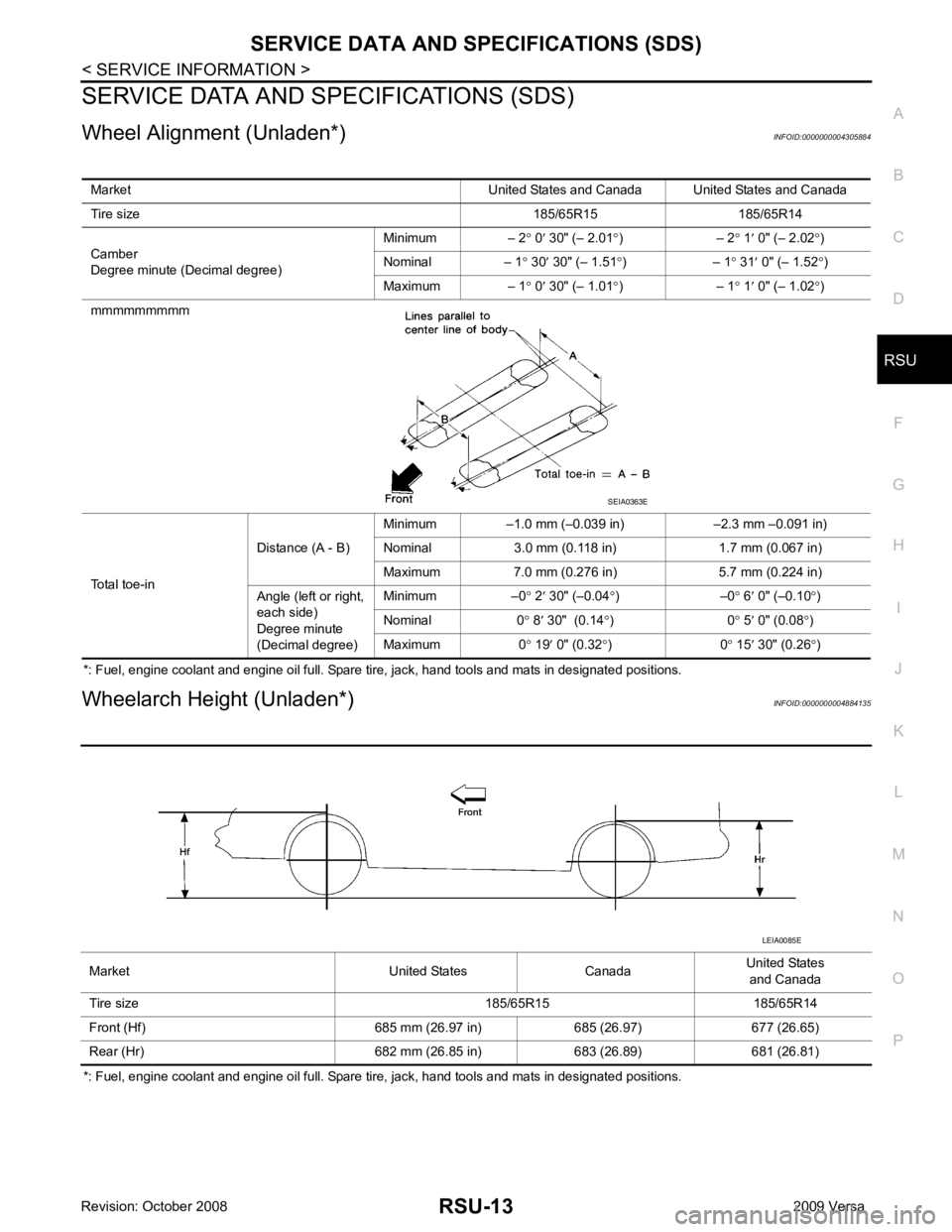

Wheel Alignment (Unladen*) INFOID:0000000004305884

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*) INFOID:0000000004884135

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Market United States and Canada United States and Canada

Tire size 185/65R15 185/65R14

Camber

Degree minute (Decimal degree) Minimum – 2

° 0 ′ 30" (– 2.01 °) – 2 ° 1 ′ 0" (– 2.02 °)

Nominal – 1 ° 30 ′ 30" (– 1.51 °) – 1 ° 31 ′ 0" (– 1.52 °)

Maximum – 1 ° 0 ′ 30" (– 1.01 °) – 1 ° 1 ′ 0" (– 1.02 °)

mmmmmmmmm

Total toe-in Distance (A - B)

Minimum –1.0 mm (–0.039 in) –2.3 mm –0.091 in)

Nominal 3.0 mm (0.118 in) 1.7 mm (0.067 in)

Maximum 7.0 mm (0.276 in) 5.7 mm (0.224 in)

Angle (left or right,

each side)

Degree minute

(Decimal degree) Minimum –0

° 2 ′ 30" (–0.04 °) –0 ° 6 ′ 0" (–0.10 °)

Nominal 0 ° 8 ′ 30" (0.14 °) 0 ° 5 ′ 0" (0.08 °)

Maximum 0 ° 19 ′ 0" (0.32 °) 0 ° 15 ′ 30" (0.26 °)

Page 4166 of 4331

SE

N

O P

• Handle trim, molding instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, member, etc.), be sure to take rust preven-

tion measures.

Precaution INFOID:0000000004306501

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screwdriver or other tool , protect parts by wrapping tools with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an unreusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tight ly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.

Page 4167 of 4331

SE-4< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004306502

The actual shapes of Kent -Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tool INFOID:0000000004306503

Tool number

(Kent-Moore No.)

Tool name Description

—

(J-39570)

Chassis ear Locating the noise

—

(J-43980)

NISSAN Squeak and Rattle

Kit Repairing the cause of noise SIIA0993E

SIIA0994E

(Kent-Moore No.)

Tool name Description

(J-39565)

Engine ear Locating the noiseSIIA0995E