display NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 989 of 4331

![NISSAN TIIDA 2009 Service Manual PDF TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perfor NISSAN TIIDA 2009 Service Manual PDF TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perfor](/img/5/57398/w960_57398-988.png)

TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perform tests on all items until specified symptom is found. Trou-

bleshoot items which check out No Good after road test.

CONSULT-III START PROCEDURE • Using CONSULT-III, perform a cruise test and record the result.

• Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to CVT-47, " Cruise Test " .

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out.

Check before Engi ne Is Started INFOID:00000000046668871.

CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does O/D OFF indicator lamp come on for about 2 seconds? YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.Refer to CVT-51, " CONSULT-III Function (TRANSMISSION) " .

3. Go to CVT-45, " Check at Idle " .

NO >> Stop “Road Test”. Go to CVT-155, " O/D OFF Indicator Lamp Does Not Come On " .

Check at Idle INFOID:00000000046668881.

CHECK STARTING THE ENGINE

1. Park vehicle on flat surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Turn ignition switch START.

Is engine started? SAT496G

Page 995 of 4331

CVT

N

O P

CONSULT-III Function (TRANSMISSION)

INFOID:0000000004666892

CONSULT-III can display each diagnostic item using the diagnostic test modes shown below.

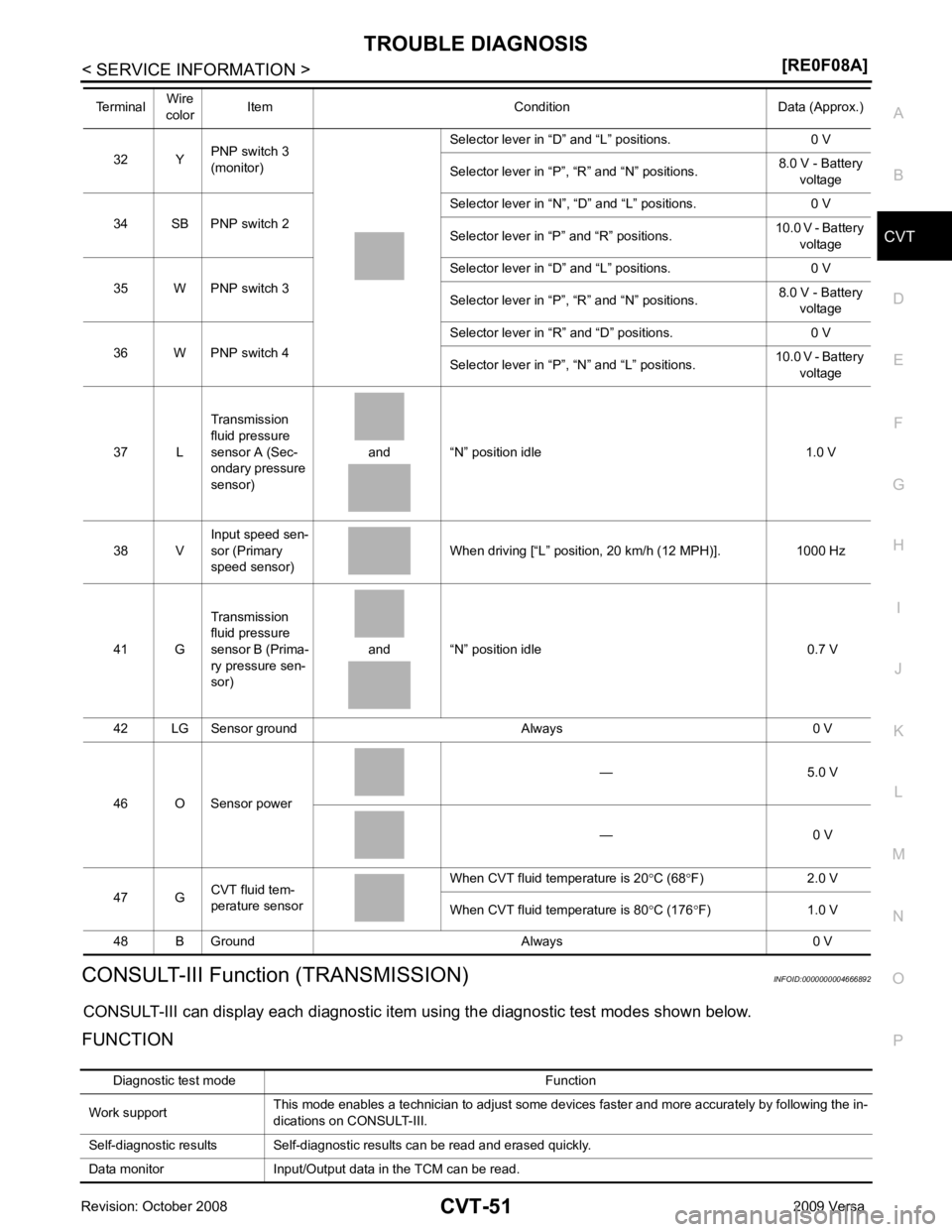

FUNCTION 32 Y

PNP switch 3

(monitor) Selector lever in “D”

and “L” positions. 0 V

Selector lever in “P”, “R” and “N” positions. 8.0 V - Battery

voltage

34 SB PNP switch 2 Selector lever in “N”,

“D” and “L” positions. 0 V

Selector lever in “P ” and “R” positions. 10.0 V - Battery

voltage

35 W PNP switch 3 Selector lever in “D”

and “L” positions. 0 V

Selector lever in “P”, “R” and “N” positions. 8.0 V - Battery

voltage

36 W PNP switch 4 Selector lever in “R” and “D” positions. 0 V

Selector lever in “P”, “N” and “L” positions. 10.0 V - Battery

voltage

37 L Transmission

fluid pressure

sensor A (Sec-

ondary pressure

sensor) and “N” position idle 1.0 V

38 V Input speed sen-

sor (Primary

speed sensor) When driving [“L” position, 20 km/h (12 MPH)]. 1000 Hz

41 G Transmission

fluid pressure

sensor B (Prima-

ry pressure sen-

sor) and “N” position idle 0.7 V

42 LG Sensor ground Always 0 V

46 O Sensor power — 5.0 V

— 0 V

47 G CVT fluid tem-

perature sensor When CVT fluid temperature is 20

°C (68 °F) 2.0 V

When CVT fluid temperature is 80 °C (176 °F) 1.0 V

48 B Ground Always 0 V

Terminal

Wire

color Item Condition Data (Approx.)

Page 996 of 4331

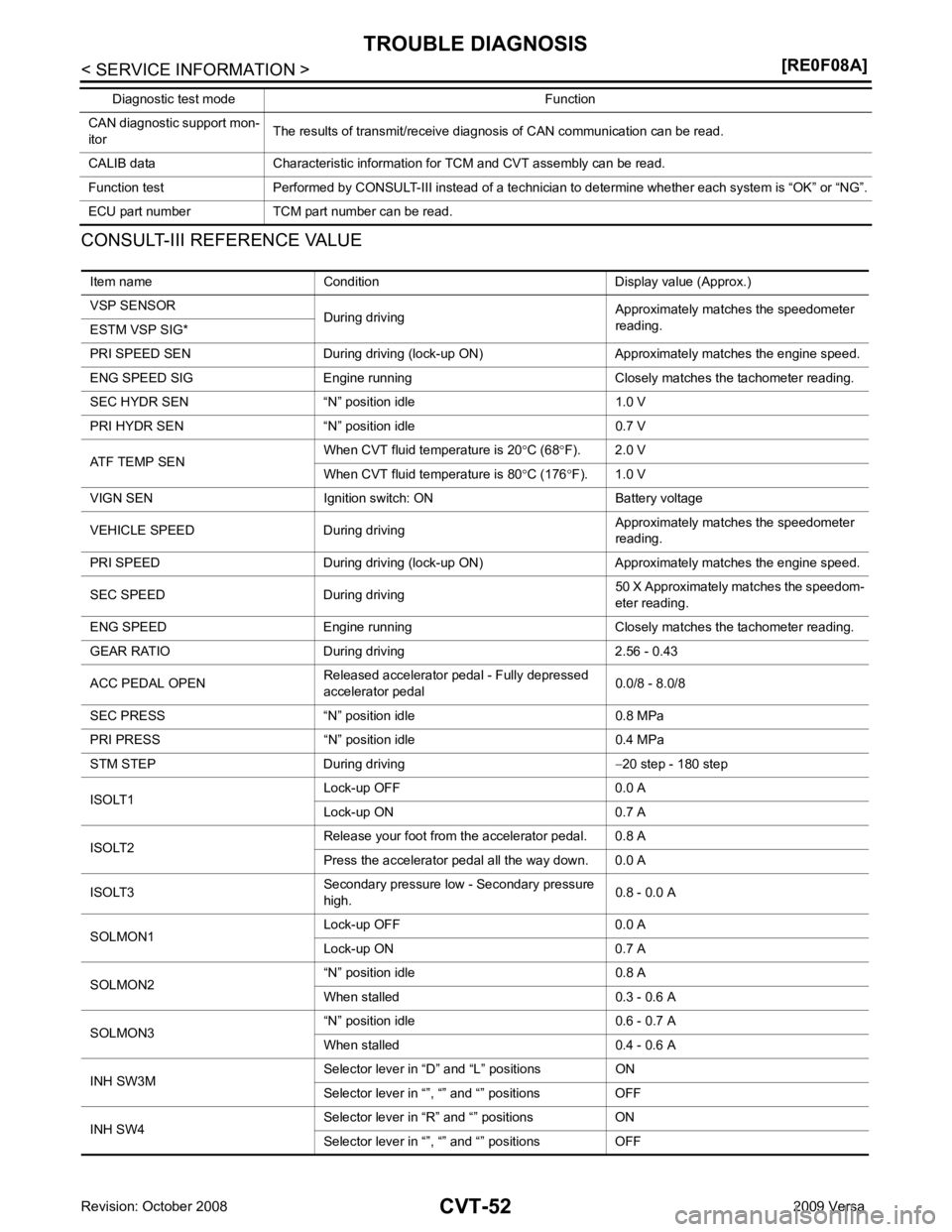

Item name Condition Display value (Approx.)

VSP SENSOR During driving Approximately matches the speedometer

reading.

ESTM VSP SIG*

PRI SPEED SEN During driving (lock-up ON) Approximately matches the engine speed.

ENG SPEED SIG Engine running Closely matches the tachometer reading.

SEC HYDR SEN “N” position idle 1.0 V

PRI HYDR SEN “N” position idle 0.7 V

ATF TEMP SEN When CVT fluid temperature is 20

°C (68 °F). 2.0 V

When CVT fluid temperature is 80 °C (176 °F). 1.0 V

VIGN SEN Ignition switch: ON Battery voltage

VEHICLE SPEED During driving Approximately matches the speedometer

reading.

PRI SPEED During driving (lock-up ON) Approximately matches the engine speed.

SEC SPEED During driving 50 X Approximately matches the speedom-

eter reading.

ENG SPEED Engine running Closely ma tches the tachometer reading.

GEAR RATIO During driving 2.56 - 0.43

ACC PEDAL OPEN Released accelerator pedal - Fully depressed

accelerator pedal 0.0/8 - 8.0/8

SEC PRESS “N” position idle 0.8 MPa

PRI PRESS “N” position idle 0.4 MPa

STM STEP During driving −20 step - 180 step

ISOLT1 Lock-up OFF 0.0 A

Lock-up ON 0.7 A

ISOLT2 Release your foot from the accelerator pedal. 0.8 A

Press the accelerator pedal all the way down. 0.0 A

ISOLT3 Secondary pressure low - Secondary pressure

high. 0.8 - 0.0 A

SOLMON1 Lock-up OFF 0.0 A

Lock-up ON 0.7 A

SOLMON2 “N” position idle 0.8 A

When stalled 0.3 - 0.6 A

SOLMON3 “N” position idle 0.6 - 0.7 A

When stalled 0.4 - 0.6 A

INH SW3M Selector lever in “D

” and “L” positions ON

Selector lever in “”, “” and “” positions OFF

INH SW4 Selector lever in “R” and “” positions ON

Selector lever in “”, “” and “” positions OFF

Page 997 of 4331

CVT

N

O P

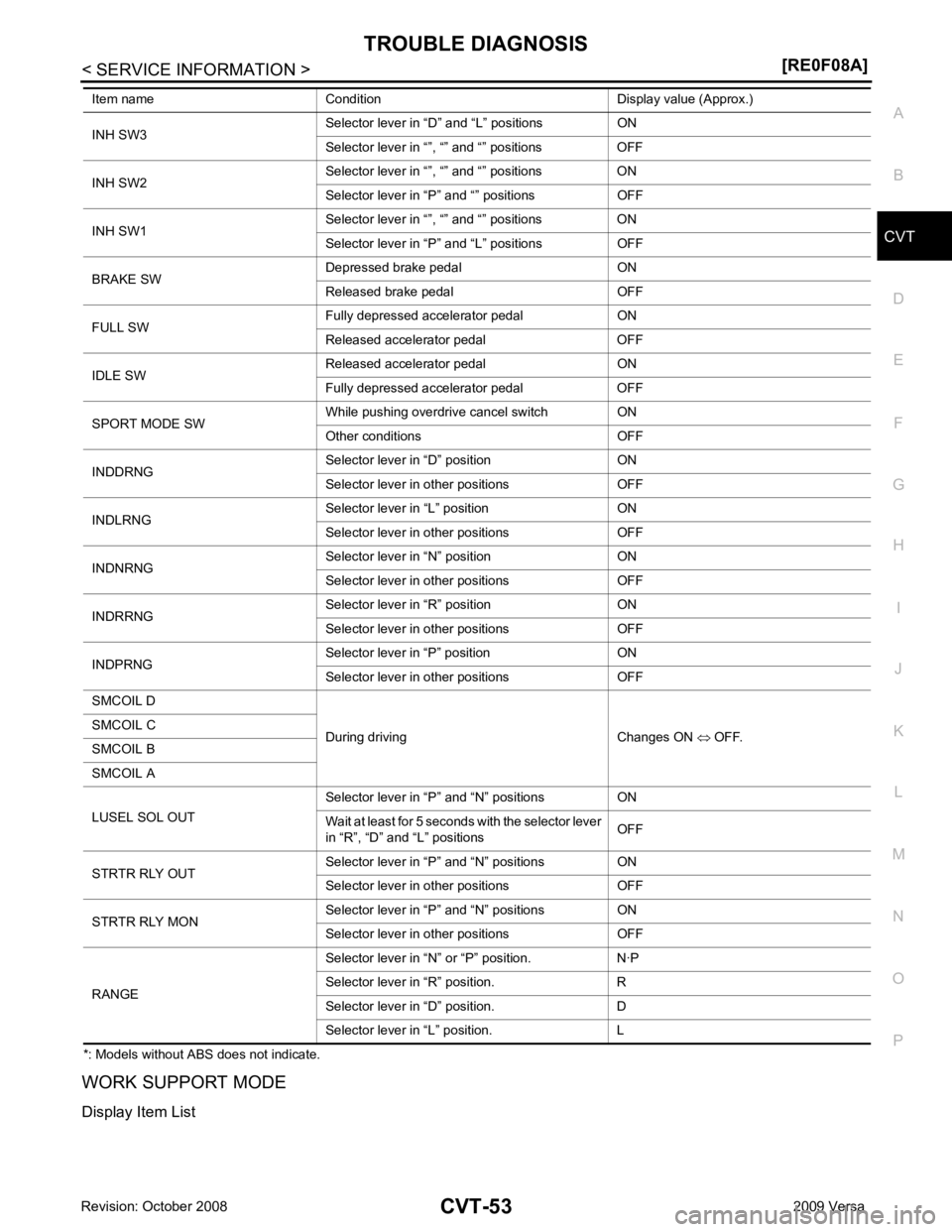

*: Models without ABS does not indicate.

WORK SUPPORT MODE

Display Item List INH SW3

Selector lever in “D

” and “L” positions ON

Selector lever in “”, “” and “” positions OFF

INH SW2 Selector lever in “”, “” and “” positions ON

Selector lever in “P ” and “” positions OFF

INH SW1 Selector lever in “”, “” and “” positions ON

Selector lever in “P ” and “L” positions OFF

BRAKE SW Depressed brake pedal ON

Released brake pedal OFF

FULL SW Fully depressed accelerator pedal ON

Released accelerator pedal OFF

IDLE SW Released accelerator pedal ON

Fully depressed accelerator pedal OFF

SPORT MODE SW While pushing overdrive cancel switch ON

Other conditions OFF

INDDRNG Selector lever in “D” position ON

Selector lever in other positions OFF

INDLRNG Selector lever in “L” position ON

Selector lever in other positions OFF

INDNRNG Selector lever in “N” position ON

Selector lever in other positions OFF

INDRRNG Selector lever in “R” position ON

Selector lever in other positions OFF

INDPRNG Selector lever in “P” position ON

Selector lever in other positions OFF

SMCOIL D

During driving Changes ON ⇔ OFF.

SMCOIL C

SMCOIL B

SMCOIL A

LUSEL SOL OUT Selector lever in “P

” and “N” positions ON

Wait at least for 5 seconds with the selector lever

in “R”, “D” and “L” positions OFF

STRTR RLY OUT Selector lever in “P

” and “N” positions ON

Selector lever in other positions OFF

STRTR RLY MON Selector lever in “P

” and “N” positions ON

Selector lever in other positions OFF

RANGE Selector lever in “N” or “P” position. N·P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “L” position. L

Item name Condition Display value (Approx.)

Page 998 of 4331

How to Perform Trouble Diag-

nosis for Quick and Accurate Repair " . Reference pages are provided following the items.

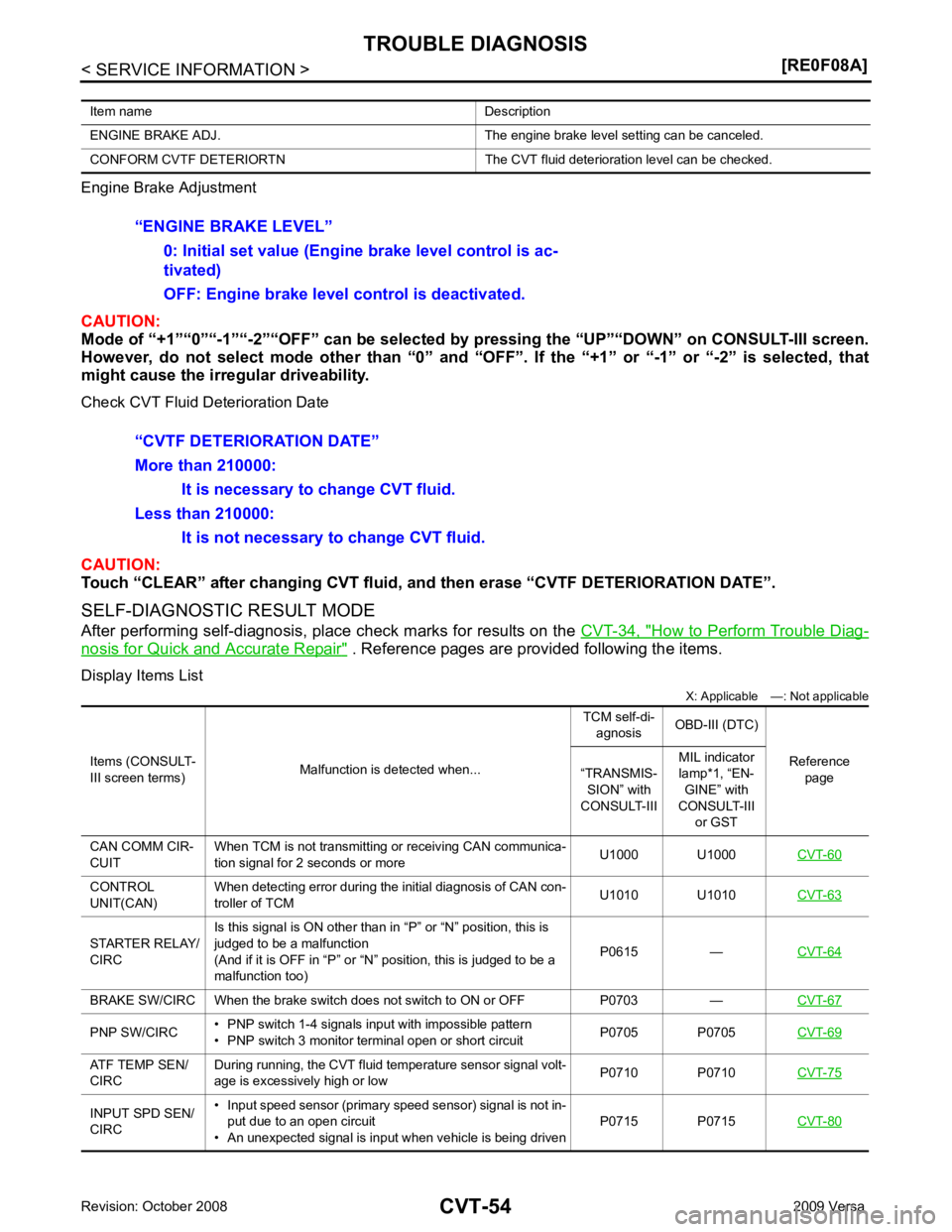

Display Items List X: Applicable —: Not applicable

Item name Description

ENGINE BRAKE ADJ. The engine brake level setting can be canceled.

CONFORM CVTF DETERIORTN The CVT fluid deterioration level can be checked. CONTROL

UNIT(CAN) When detecting error during the initial diagnosis of CAN con-

troller of TCM U1010 U1010

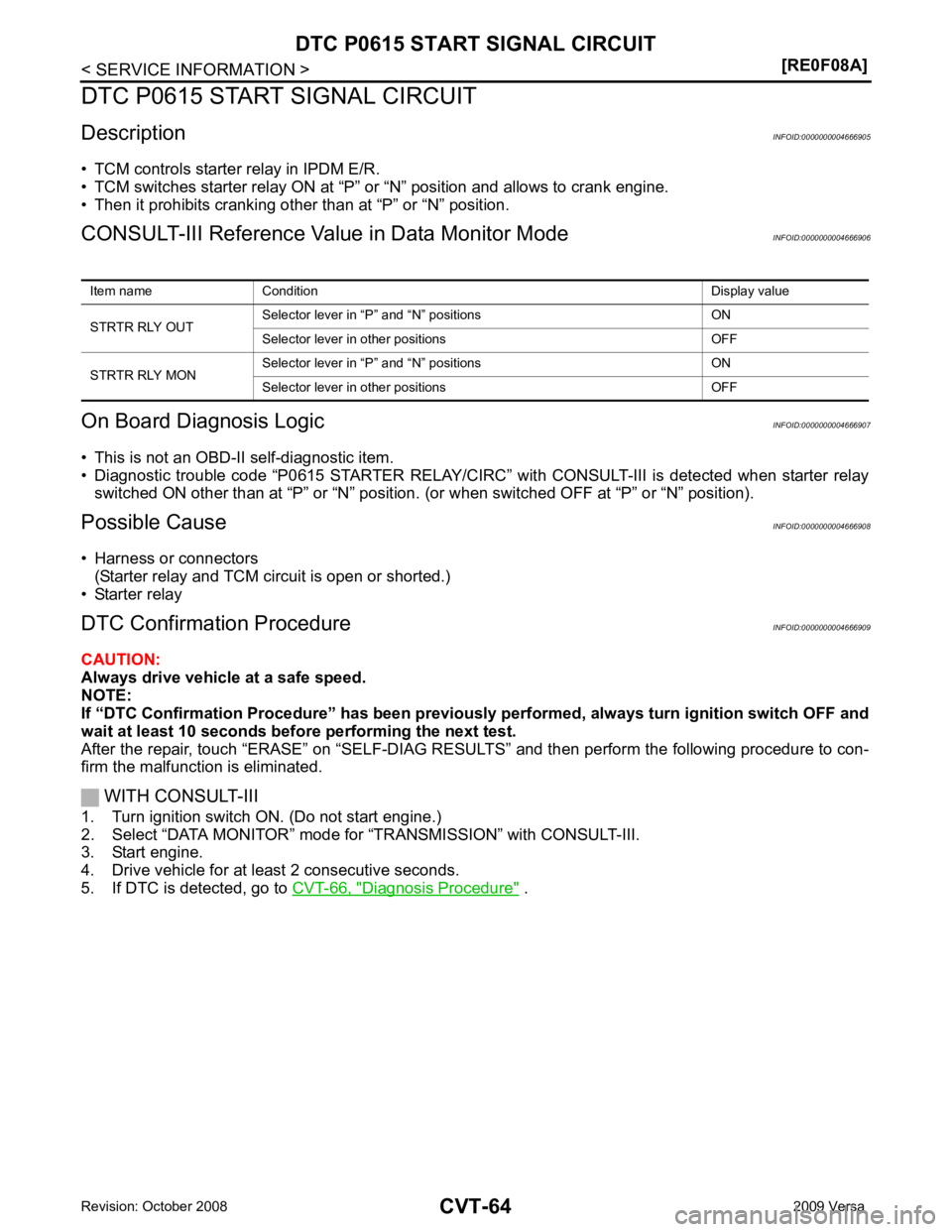

CVT-63STARTER RELAY/

CIRC Is this signal is ON other than in “P” or “N” position, this is

judged to be a malfunction

(And if it is OFF in “P” or “N” position, this is judged to be a

malfunction too) P0615 —

CVT-64BRAKE SW/CIRC When the brake switch does

not switch to ON or OFF P0703 — CVT-67PNP SW/CIRC

• PNP switch 1-4 signals input with impossible pattern

• PNP switch 3 monitor terminal open or short circuit P0705 P0705

CVT-69ATF TEMP SEN/

CIRC During running, the CVT fluid temperature sensor signal volt-

age is excessively high or low P0710 P0710

CVT-75INPUT SPD SEN/

CIRC • Input speed sensor (primary speed sensor) signal is not in-

put due to an open circuit

• An unexpected signal is input when vehicle is being driven P0715 P0715

CVT-80

Page 1000 of 4331

Malfunction Indicator Lamp (MIL) " .

*2: Models without ABS does not indicate.

DATA MONITOR MODE

Display Items List X: Standard, —: Not applicable, : Option

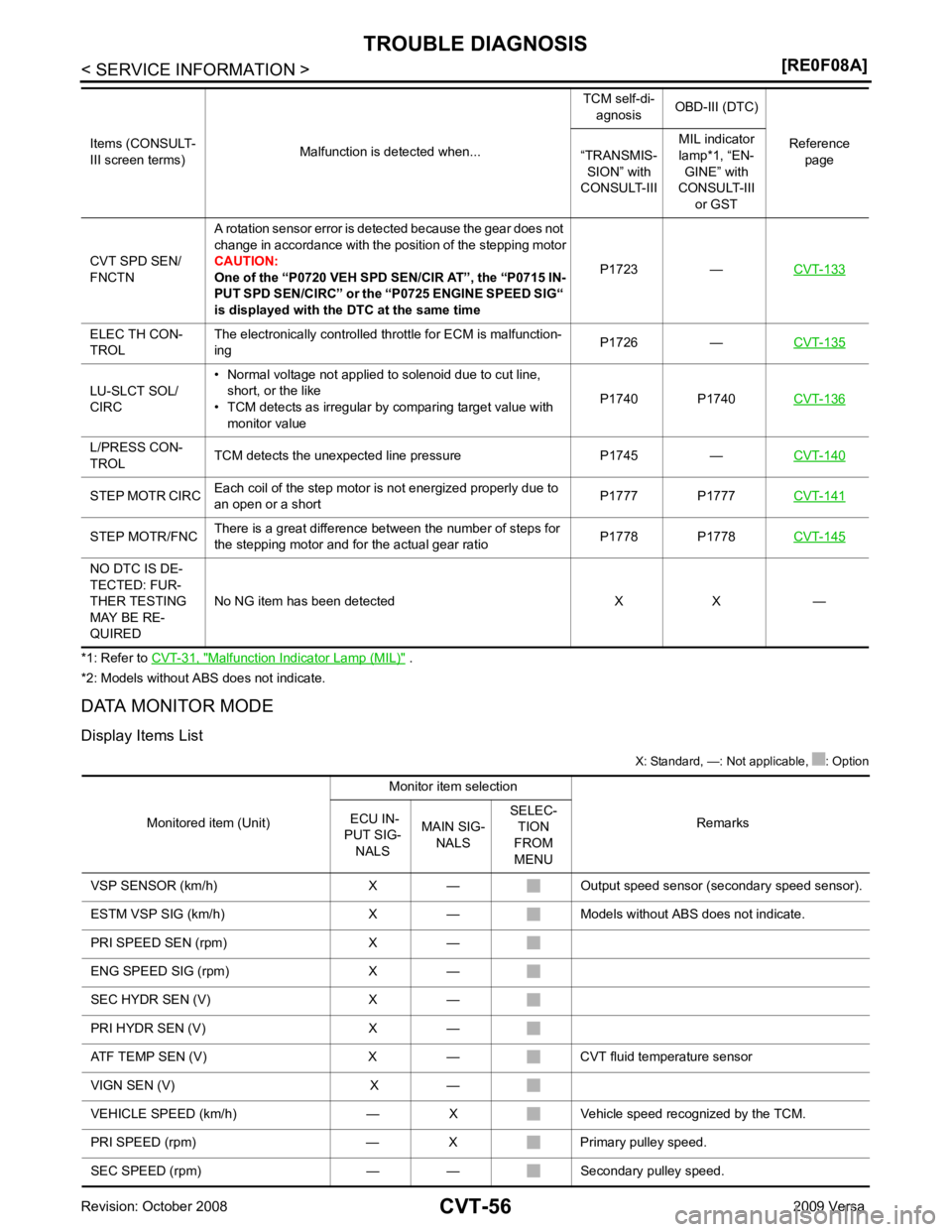

CVT SPD SEN/

FNCTN A rotation sensor error is detected because the gear does not

change in accordance with the position of the stepping motor

CAUTION:

One of the “P0720 VEH SPD SEN/CIR AT”, the “P0715 IN-

PUT SPD SEN/CIRC” or the “P0725 ENGINE SPEED SIG“

is displayed with the DTC at the same time P1723 —

CVT-133ELEC TH CON-

TROL The electronically controlled throttle for ECM is malfunction-

ing P1726 —

CVT-135LU-SLCT SOL/

CIRC • Normal voltage not applied to solenoid due to cut line,

short, or the like

• TCM detects as irregular by comparing target value with

monitor value P1740 P1740

CVT-136L/PRESS CON-

TROL TCM detects the unexpected line pressure P1745 —

CVT-140STEP MOTR CIRC

Each coil of the step motor is not energized properly due to

an open or a short P1777 P1777

CVT-141STEP MOTR/FNC

There is a great difference between the number of steps for

the stepping motor and for the actual gear ratio P1778 P1778

CVT-145NO DTC IS DE-

TECTED: FUR-

THER TESTING

MAY BE RE-

QUIRED No NG item has been detected X X —

Items (CONSULT-

III screen terms) Malfunction is detected when... TCM self-di-

agnosis OBD-III (DTC)

Reference page

“TRANSMIS-

SION” with

CONSULT-III MIL indicator

lamp*1, “EN- GINE” with

CONSULT-III

or GST

Page 1001 of 4331

CVT

N

O P

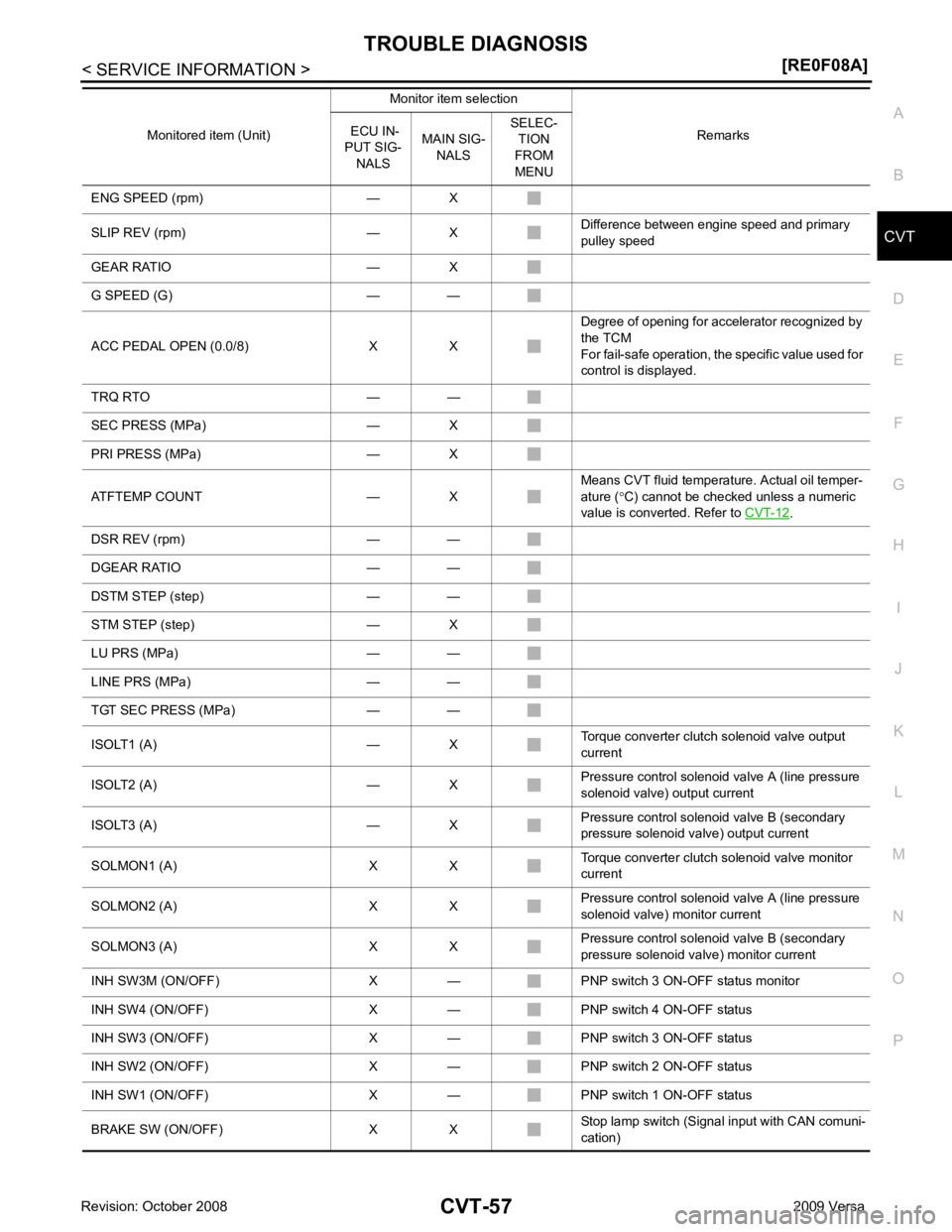

ENG SPEED (rpm) — X

SLIP REV (rpm) — X Difference between engine speed and primary

pulley speed

GEAR RATIO — X

G SPEED (G) — —

ACC PEDAL OPEN (0.0/8) X X Degree of opening for accelerator recognized by

the TCM

For fail-safe operation, the specific value used for

control is displayed.

TRQ RTO — —

SEC PRESS (MPa) — X

PRI PRESS (MPa) — X

ATFTEMP COUNT — X Means CVT fluid temperature. Actual oil temper-

ature ( °C) cannot be checked unless a numeric

value is converted. Refer to CVT-12 .

DSR REV (rpm) — —

DGEAR RATIO — —

DSTM STEP (step) — —

STM STEP (step) — X

LU PRS (MPa) — —

LINE PRS (MPa) — —

TGT SEC PRESS (MPa) — —

ISOLT1 (A) — X Torque converter clutch solenoid valve output

current

ISOLT2 (A) — X Pressure control solenoid valve A (line pressure

solenoid valve) output current

ISOLT3 (A) — X Pressure control solenoid valve B (secondary

pressure solenoid valve) output current

SOLMON1 (A) X X Torque converter clutch solenoid valve monitor

current

SOLMON2 (A) X X Pressure control solenoid valve A (line pressure

solenoid valve) monitor current

SOLMON3 (A) X X Pressure control solenoid valve B (secondary

pressure solenoid va lve) monitor current

INH SW3M (ON/OFF) X — PNP switch 3 ON-OFF status monitor

INH SW4 (ON/OFF) X — PNP switch 4 ON-OFF status

INH SW3 (ON/OFF) X — PNP switch 3 ON-OFF status

INH SW2 (ON/OFF) X — PNP switch 2 ON-OFF status

INH SW1 (ON/OFF) X — PNP switch 1 ON-OFF status

BRAKE SW (ON/OFF) X X Stop lamp switch (Signal input with CAN comuni-

cation)

Monitored item (Unit)

Monitor item selection

Remarks

ECU IN-

PUT SIG- NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

Page 1008 of 4331

Diagnosis Procedure " .

Item name Condition Display value

STRTR RLY OUT Selector lever in “P

” and “N” positions ON

Selector lever in other positions OFF

STRTR RLY MON Selector lever in “P

” and “N” positions ON

Selector lever in other positions OFF

Page 1010 of 4331

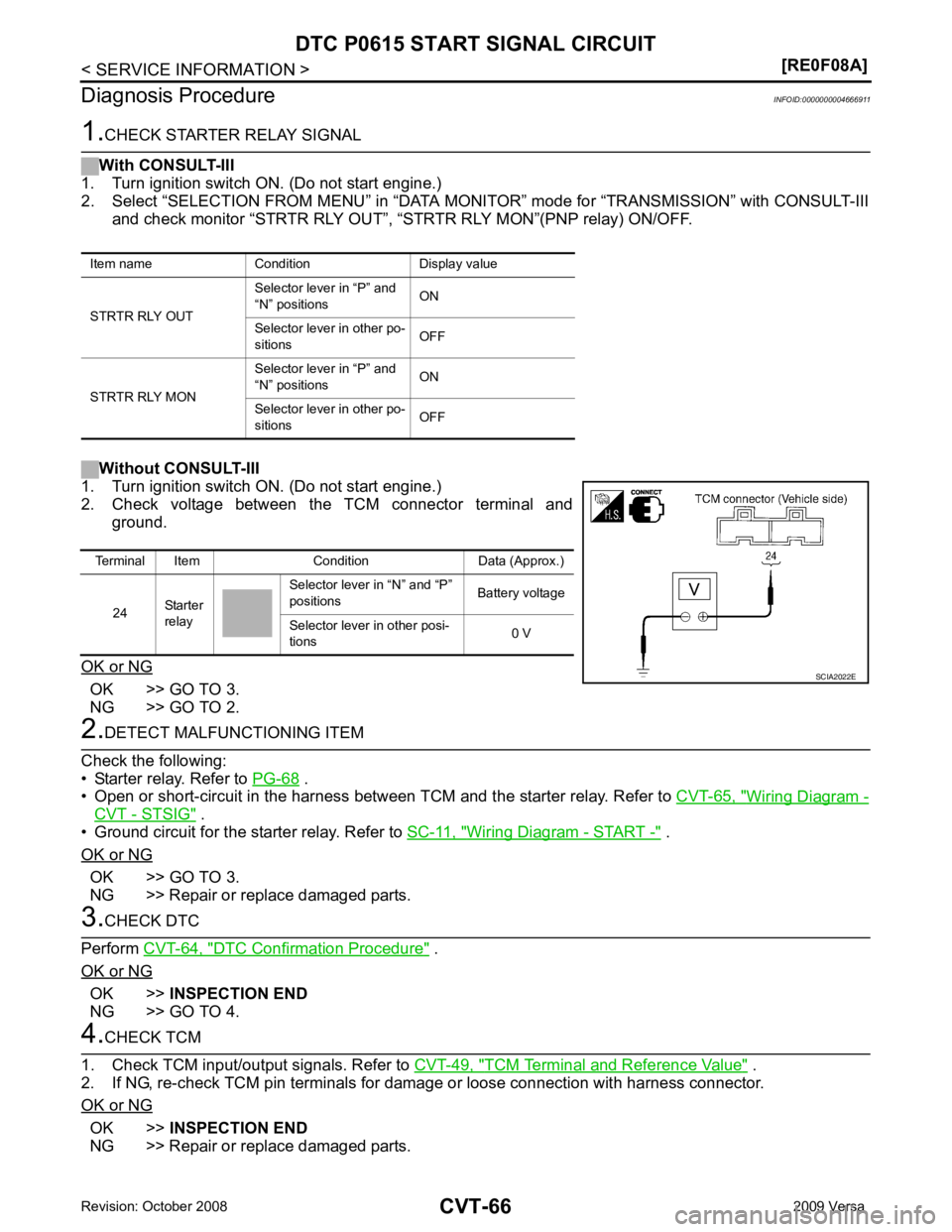

OK >> GO TO 3.

NG >> GO TO 2. .

• Open or short-circuit in the harness between TCM and the starter relay. Refer to CVT-65, " Wiring Diagram -

CVT - STSIG " .

• Ground circuit for the starter relay. Refer to SC-11, " Wiring Diagram - START - " .

OK or NG OK >> GO TO 3.

NG >> Repair or replace damaged parts. DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 4. TCM Terminal and Reference Value " .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Item name Condition Display value

STRTR RLY OUT Selector lever in “P” and

“N” positions ON

Selector lever in other po-

sitions OFF

STRTR RLY MON Selector lever in “P” and

“N” positions ON

Selector lever in other po-

sitions OFFTerminal Item Condition Data (Approx.)

24 Starter

relay Selector lever in “N” and “P”

positions Battery voltage

Selector lever in other posi-

tions 0 V

Page 1012 of 4331

OK >>

INSPECTION END

NG >> GO TO 3. Wiring Diagram - CVT - NON-

DTC " .

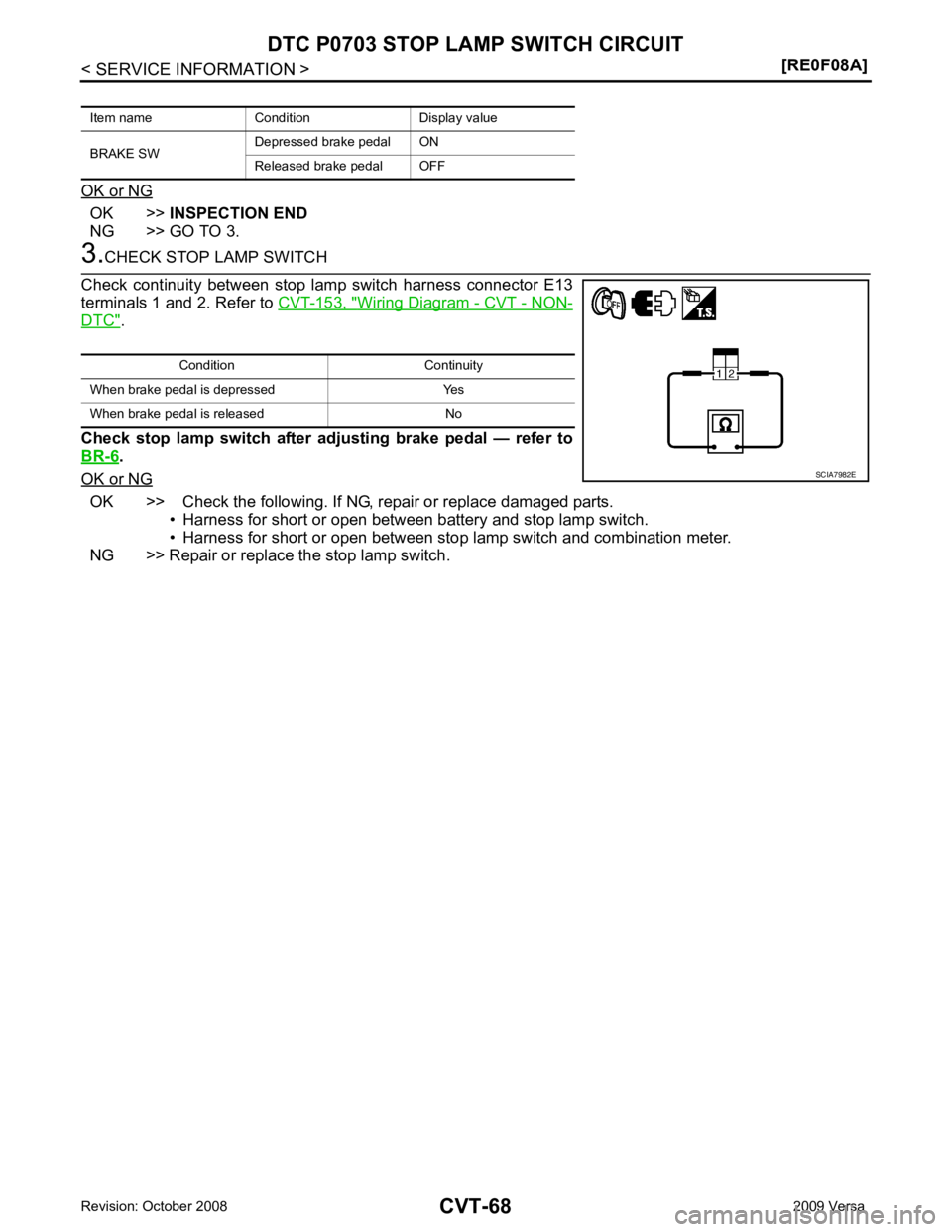

Check stop lamp switch after adjusting brake pedal — refer to

BR-6 .

OK or NG OK >> Check the following. If NG, repair or replace damaged parts.

• Harness for short or open between battery and stop lamp switch.

• Harness for short or open between stop lamp switch and combination meter.

NG >> Repair or replace the stop lamp switch.

Item name Condition Display value

BRAKE SW Depressed brake pedal ON

Released brake pedal OFF Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No