engine control system NISSAN TIIDA 2009 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1705 of 4331

EC

NP

O

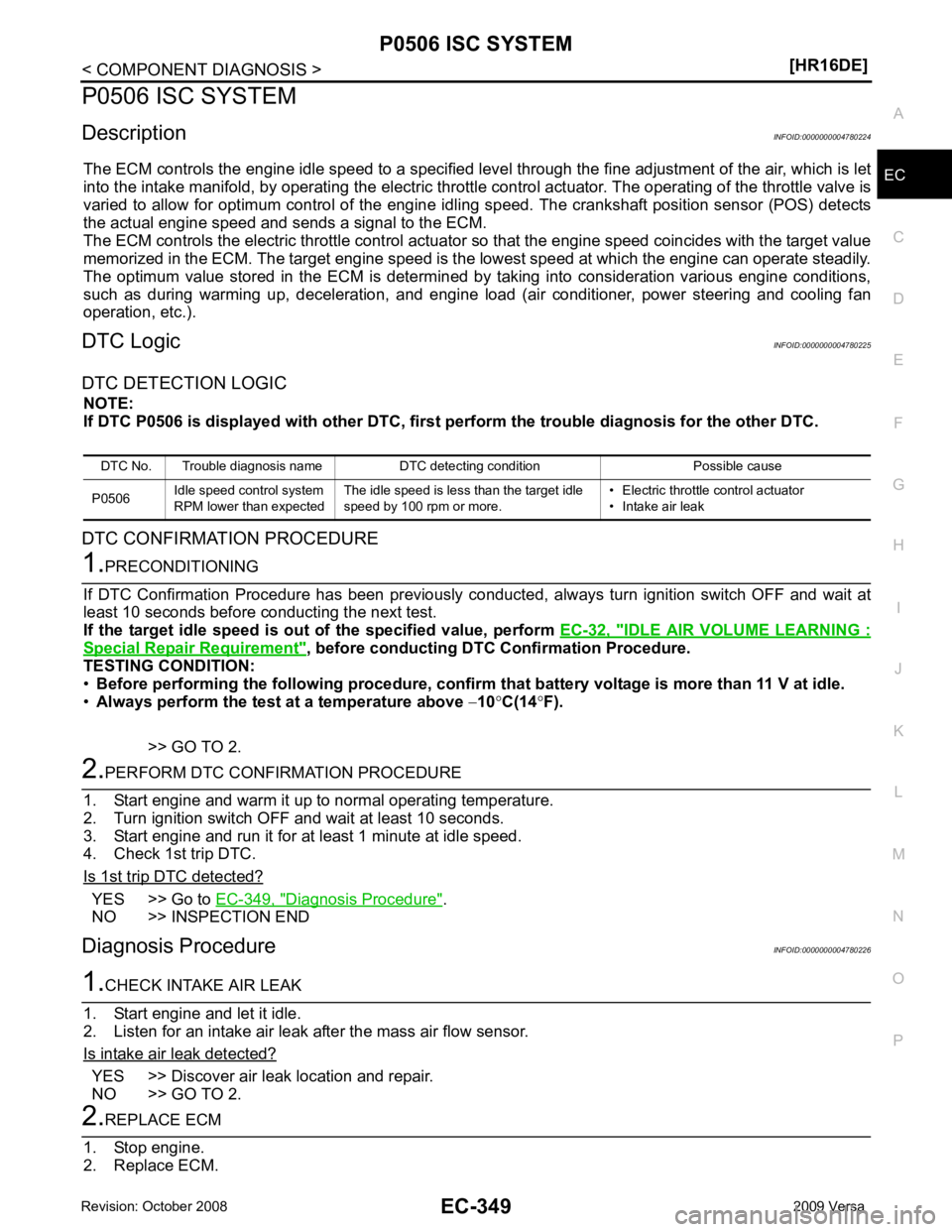

P0506 ISC SYSTEM

Description INFOID:0000000004780224

The ECM controls the engine idle speed to a specified leve l through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is t he lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

DTC Logic INFOID:0000000004780225

DTC DETECTION LOGIC NOTE:

If DTC P0506 is displayed with ot her DTC, first perform the trouble diagnosis for the other DTC.

DTC CONFIRMATION PROCEDURE IDLE AIR VOLUME LEARNING :

Special Repair Requirement " , before conducting DTC Confirmation Procedure.

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

• Always perform the test at a temperature above −10 °C(14 °F).

>> GO TO 2. YES >> Go to

EC-349, " Diagnosis Procedure " .

NO >> INSPECTION END

Diagnosis Procedure INFOID:0000000004780226YES >> Discover air leak location and repair.

NO >> GO TO 2.

Page 1707 of 4331

EC

NP

O

P0507 ISC SYSTEM

Description INFOID:0000000004780227

The ECM controls the engine idle speed to a specified leve l through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is t he lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

DTC Logic INFOID:0000000004780228

DTC DETECTION LOGIC NOTE:

If DTC P0507 is displayed with ot her DTC, first perform the trouble diagnosis for the other DTC.

DTC CONFIRMATION PROCEDURE IDLE AIR VOLUME LEARNING :

Special Repair Requirement " , before conducting DTC Confirmation Procedure.

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

• Always perform the test at a temperature above −10 °C(14 °F).

>> GO TO 2. YES >> Go to

EC-351, " Diagnosis Procedure " .

NO >> INSPECTION END

Diagnosis Procedure INFOID:0000000004780229YES >> GO TO 2.

NO >> Repair or replace.

Page 1711 of 4331

![NISSAN TIIDA 2009 Service Manual Online P0605 ECM

EC-355

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0605 ECM

Description INFOID:0000000004780237

The ECM consists of a microcomputer and connectors for signal

i NISSAN TIIDA 2009 Service Manual Online P0605 ECM

EC-355

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0605 ECM

Description INFOID:0000000004780237

The ECM consists of a microcomputer and connectors for signal

i](/img/5/57398/w960_57398-1710.png)

P0605 ECM

EC-355

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0605 ECM

Description INFOID:0000000004780237

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The ECM controls the engine.

DTC Logic INFOID:0000000004780238

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A

1. Turn ignition switch ON.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-356, " Diagnosis Procedure " .

NO >> GO TO 3. 3.

PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B

1. Turn ignition switch ON and wait at least 1 second.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-356, " Diagnosis Procedure " .

NO >> GO TO 4. 4.

PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION C

1. Turn ignition switch ON and wait at least 1 second.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Repeat step 2 for 32 times.

4. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-356, " Diagnosis Procedure " .

NO >> INSPECTION END PBIA9222J

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0605 Engine control module A) ECM calculation function is malfunctioning.

• ECM

B) ECM EEP-ROM system is malfunctioning.

C) ECM self shut-off function is malfunctioning.

Page 1759 of 4331

![NISSAN TIIDA 2009 Service Manual Online P2127, P2128 APP SENSOR

EC-403

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2127, P2128 APP SENSOR

Description INFOID:0000000004780323

The accelerator pedal position sensor i NISSAN TIIDA 2009 Service Manual Online P2127, P2128 APP SENSOR

EC-403

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2127, P2128 APP SENSOR

Description INFOID:0000000004780323

The accelerator pedal position sensor i](/img/5/57398/w960_57398-1758.png)

P2127, P2128 APP SENSOR

EC-403

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2127, P2128 APP SENSOR

Description INFOID:0000000004780323

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometer which transform the accelerator pedal

position into output voltage, and emit the voltage signal to the ECM.

The ECM judges the current opening angle of the accelerator pedal

from these signals and controls the throttle control motor based on

these signals.

Idle position of the accelerato r pedal is determined by the ECM

receiving the signal from the acce lerator pedal position sensor. The

ECM uses this signal for the engine operation such as fuel cut.

DTC Logic INFOID:0000000004780324

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to

EC-404, " Diagnosis Procedure " .

NO >> INSPECTION END PBIB1741E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2127 Accelerator pedal position

sensor 2 circuit low input An excessively low voltage from the APP

sensor 2 is sent to ECM. • Harness or connectors

(APP sensor 2 circuit is open or shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.]

(Refrigerant pressure sensor circuit is

shorted.)

(EVAP control system pressure sensor

circuit is shorted.)

• Accelerator pedal position sensor (APP sensor 2)

• Crankshaft position sensor (POS)

• Refrigerant pressure sensor

• EVAP control system pressure sensor

P2128

Accelerator pedal position

sensor 2 circuit high input An excessively high voltage from the APP

sensor 2 is sent to ECM.

Page 1768 of 4331

![NISSAN TIIDA 2009 Service Manual Online EC-412< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

P2138 APP SENSOR

Description INFOID:0000000004780333

The accelerator pedal position sensor is installed on the upper end

of the accele NISSAN TIIDA 2009 Service Manual Online EC-412< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

P2138 APP SENSOR

Description INFOID:0000000004780333

The accelerator pedal position sensor is installed on the upper end

of the accele](/img/5/57398/w960_57398-1767.png)

EC-412< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

P2138 APP SENSOR

Description INFOID:0000000004780333

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometer which transform the accelerator pedal

position into output voltage, and emit the voltage signal to the ECM.

The ECM judges the current opening angle of the accelerator pedal

from these signals and controls the throttle control motor based on

these signals.

Idle position of the accelerator pedal is determined by the ECM

receiving the signal from the accelerator pedal position sensor. The

ECM uses this signal for the engine operation such as fuel cut.

DTC Logic INFOID:0000000004780334

DTC DETECTION LOGIC

NOTE:

If DTC P2138 is displayed with DTC P0643, first pe rform the trouble diagnosis for DTC P0643. Refer to

EC-358, " DTC Logic " .

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to

EC-413, " Diagnosis Procedure " .

NO >> INSPECTION END PBIB1741E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2138 Accelerator pedal position

sensor circuit range/per-

formance Rationally incorrect voltage is sent to ECM

compared with the signals from APP sensor

1 and APP sensor 2. • Harness or connector

(APP sensor 1 or 2 circuit is open or

shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

(EVAP control system sensor circuit is

shorted.)

• Accelerator pedal position sensor

(APP sensor 1 or 2)

• Crankshaft position sensor (POS)

• Refrigerant pressure sensor

• EVAP control system pressure sensor

Page 1823 of 4331

![NISSAN TIIDA 2009 Service Manual Online EC

NP

O

41 GR Refrigerant pressure sensor

[Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates.) 1.0 - 4.0 V

42 V EVAP control system pres-

sur NISSAN TIIDA 2009 Service Manual Online EC

NP

O

41 GR Refrigerant pressure sensor

[Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates.) 1.0 - 4.0 V

42 V EVAP control system pres-

sur](/img/5/57398/w960_57398-1822.png)

EC

NP

O

41 GR Refrigerant pressure sensor

[Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates.) 1.0 - 4.0 V

42 V EVAP control system pres-

sure sensor [Ignition switch: ON]

Approximately 1.8 - 4.8 V

43 P Fuel tank temperature sen-

sor [Engine is running] Approximately 0 - 4.8 V

Output voltage varies with fuel

tank temperature

44 B Sensor ground

(Engine coolant temperature

sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

45 G Mass air flow sensor [Engine is running]

• Warm-up condition

• Idle speed 0.9 - 1.3 V

[Engine is running]

• Warm-up condition

• Engine speed: 2,500 rpm 1.4 - 1.9 V

46 V Intake air temperature

sensor [Engine is running] Approximately 0 - 4.8 V

Output voltage varies with intake

air temperature.

48 BR Sensor ground

(Refrigerant pressure sen-

sor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

49 W A/F sensor 1 [Engine is running]

• Warm-up condition

• Engine speed: 2,000 rpm Approximately 1.8 V

Output voltage varies with air fuel

ratio.

50 W Heated oxygen sensor 2 [Engine is running]

• Revving engine from idle to 3,000 rpm quickly after the following conditions are

met.

- Engine: After warming up

- Keeping the engine speed between 3,500

and 4,000 rpm for 1 minute and at idle for 1

minute under no load. 0 - 1.0 V

51 O Sensor ground

(EVAP control system pres-

sure sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

52 LG Sensor ground

(Mass air flow sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

53 B A/F sensor 1 [Ignition switch: ON]Approximately 2.2 V

55 O Sensor ground

(Intake air temperature sen-

sor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

59 O Sensor ground

(Heated oxygen sensor 2) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

TERMI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

Page 1825 of 4331

![NISSAN TIIDA 2009 Service Manual Online EC

NP

O

73 P

Intake valve timing control

solenoid valve [Engine is running]

• Warm-up condition

• Idle speed BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

• Warm-up condition

• When revving NISSAN TIIDA 2009 Service Manual Online EC

NP

O

73 P

Intake valve timing control

solenoid valve [Engine is running]

• Warm-up condition

• Idle speed BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

• Warm-up condition

• When revving](/img/5/57398/w960_57398-1824.png)

EC

NP

O

73 P

Intake valve timing control

solenoid valve [Engine is running]

• Warm-up condition

• Idle speed BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

• Warm-up condition

• When revving engine up to 2,000 rpm quick- ly 7 - 10 V

74 W Sensor power supply

(Refrigerant pressure

sensor) [Ignition switch: ON]

Approximately 5 V

75 BR Sensor power supply

[Crankshaft position sensor

(POS)] [Ignition switch: ON]

Approximately 5 V

76 W EVAP control system pres-

sure sensor power supply [Ignition switch: ON]

Approximately 5 V

78 O Sensor power supply

[Camshaft position sensor

(PHASE)] [Ignition switch: ON]

Approximately 5 V

83 P CAN communication line — —

84 L CAN communication line — —

88 LG DATA link connector — —

93 O Ignition switch [Ignition switch: OFF]

0V

[Ignition switch: ON] BATTERY VOLTAGE

(11 - 14 V)

99 R Stop lamp switch [Ignition switch: OFF]

• Brake pedal: Fully released Approximately 0 V

[Ignition switch: OFF]

• Brake pedal: Slightly depressed BATTERY VOLTAGE

(11 - 14 V)

102 SB Sensor power supply

(Accelerator pedal position

sensor 2) [Ignition switch: ON]

Approximately 5 V

103 GR Accelerator pedal position

sensor 2 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.3 - 0.6 V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 1.95 - 2.4 V

104 Y Sensor ground

(Accelerator pedal position

sensor 2) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

105 G Power supply for ECM [Ignition switch: ON]BATTERY VOLTAGE

(11 - 14 V)

106 P Sensor power supply

(Accelerator pedal position

sensor 1) [Ignition switch: ON]

Approximately 5 V

108 B ECM ground [Engine is running]

• Idle speed Body ground

TERMI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

Page 1829 of 4331

EC

NP

O

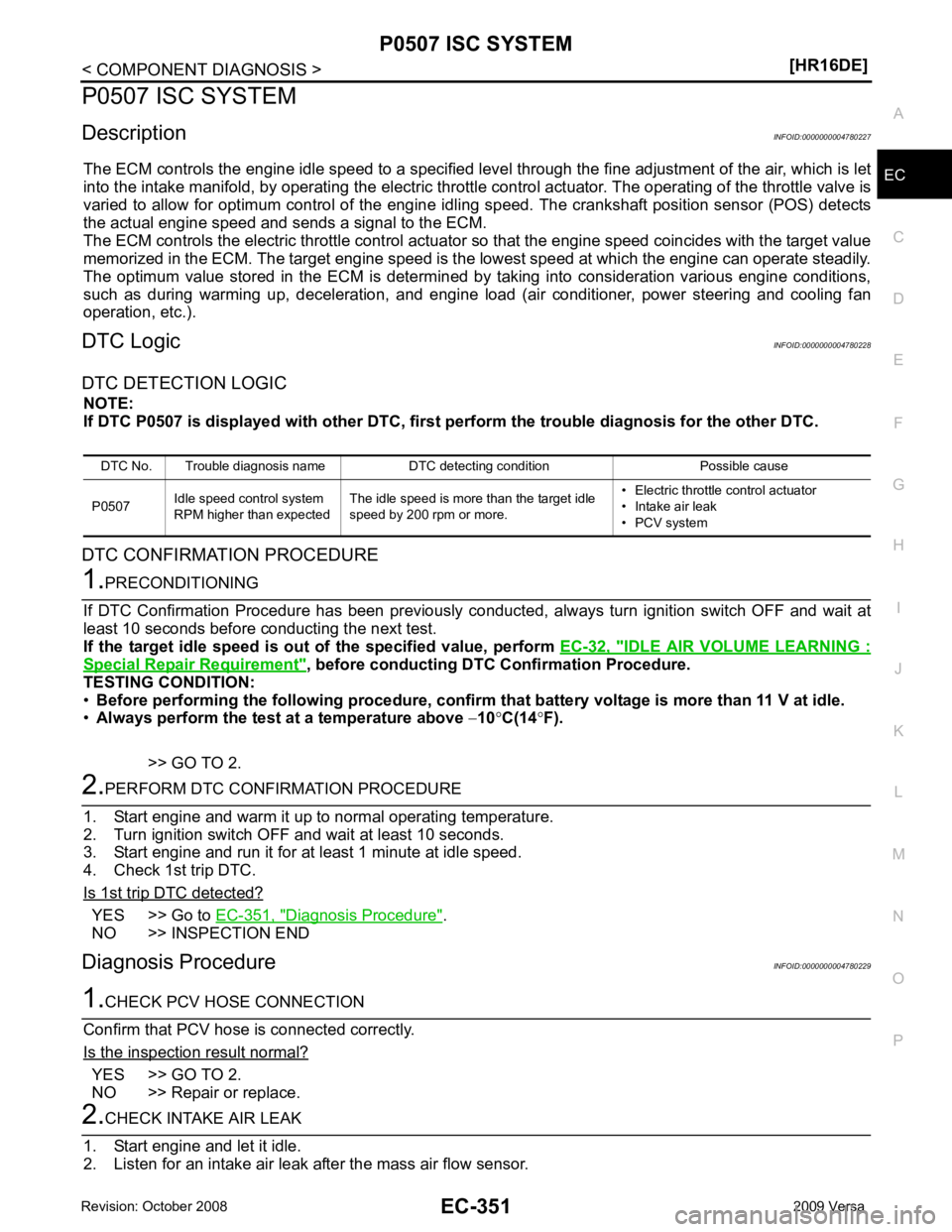

DTC RELATED ITEM

Detected items

Engine operating condition in

fail-safe mode Remarks

Malfunction indicator

lamp circuit Engine speed will not rise

more than 2,500 rpm due to

the fuel cut When there is an open circuit on MIL circuit, the ECM cannot warn the driver by

lighting up MIL when there is malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses

are continuously detected as NG for 5 trips, ECM warns the driver that engine

control system malfunctions and MIL circuit is open by means of operating fail-

safe function.

The fail-safe function also operates when above diagnoses except MIL circuit

are detected and demands the driver to repair the malfunction. DTC No. Detected items Engine operating condition in fail-safe mode

P0011 Intake valve timing control The signal is not energized to the intake valve timing control solenoid valve and the valve control does not function.

P0102

P0103 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118 Engine coolant tempera-

ture sensor circuit Engine coolant temperature will be determined by ECM based on the following condition.

CONSULT-III displays the engine coolant temperature decided by ECM.

Condition Engine coolant temperature decided

(CONSULT-III display)

Just as ignition switch is turned ON

or START 40

°C (104 °F)

More than approx. 4 minutes after

engine starting 80

°C (176 °F)

Except as shown above 40 - 80

°C (104 - 176 °F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122

P0123

P0222

P0223

P2135 Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) by the return spring.

P0605 ECM (When ECM calculation function is malfunctioning:) ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1805 Brake switch ECM controls the electric throttle control actuator by regulating the throttle opening to a small range.

Therefore, acceleration will be poor.

Vehicle condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

P2100

P2103 Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2101 Electric th rottle control

function ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) by the return spring.

Page 1831 of 4331

EC

NP

O

DTC Index

INFOID:0000000004780387

× :Applicable —: Not applicable

2 • P0031 P0032 Air fuel ratio (A/F) sensor 1 heater

• P0037 P0038 Heated oxygen sensor 2 heater

• P0075 Intake valve timing control solenoid valve

• P0130 P0131 P0132 P0133 P2A00 Air fuel ratio (A/F) sensor 1

• P0137 P0138 P0139 Heated oxygen sensor 2

• P0441 EVAP control system purge flow monitoring

• P0443 P0444 P0445 EVAP canister purge volume control solenoid valve

• P0447 P0448 EVAP canister vent control valve

• P0451 P0452 P0453 EVAP control system pressure sensor

• P0603 ECM power supply

• P0710 P0720 P0725 P0731 P0732 P0733 P0734 P0740 P0744 P0745 P0750 P0755 P1705 P1760 A/T related sensors,

solenoid valves and switches

• P1217 Engine over temperature (OVERHEAT)

• P1805 Brake switch

• P2100 P2103 Throttle control motor relay

• P2101 Electric throttle control function

• P2118 Throttle control motor

3 • P0011 Intake valve timing control • P0171 P0172 Fuel injection system function

• P0300 - P0304 Misfire

• P0420 Three way catalyst function

• P0442 P0456 EVAP control system (SMALL LEAK, VERY SMALL LEAK)

• P0455 EVAP control system (GROSS LEAK)

• P0506 P0507 Idle speed control system

• P1148 Closed loop control

• P1421 Cold start control

• P1715 Primary speed sensor

• P2119 Electric throttle control actuator

Priority Detected items (DTC) DTC*

1

Items

(CONSULT-III screen terms) SRT code Trip MIL Reference page

CONSULT-III

GST* 2

ECM*3

U0101 0101*4

LOST COMM (TCM) — 1 ×EC-126 U0140

0140*4

LOST COMM (BCM) — 1 ×EC-128 U1001

1001*4

CAN COMM CIRCUIT — 2 — EC-126P0031 0031 A/F SEN1 HTR (B1) — 2

×EC-136 P0032 0032 A/F SEN1 HTR (B1) — 2

×EC-136 P0037 0037 HO2S2 HTR (B1) — 2

×EC-140 P0038 0038 HO2S2 HTR (B1) — 2

×EC-140 P0075 0075 INT/V TIM V/CIR-B1 — 2

×EC-144 P0101 0101 MAF SEN/CIRCUIT-B1 — 2

×EC-148 P0102 0102 MAF SEN/CIRCUIT-B1 — 1

×EC-156 P0103 0103 MAF SEN/CIRCUIT-B1 — 1

×EC-156 P0112 0112 IAT SEN/CIRCUIT-B1 — 2

×EC-162 P0113 0113 IAT SEN/CIRCUIT-B1 — 2

×EC-162 P0116 0116 ECT SEN/CIRC — 2

×EC-165 P0117 0117 ECT SEN/CIRC — 1

×EC-167

Page 1833 of 4331

EC

NP

O

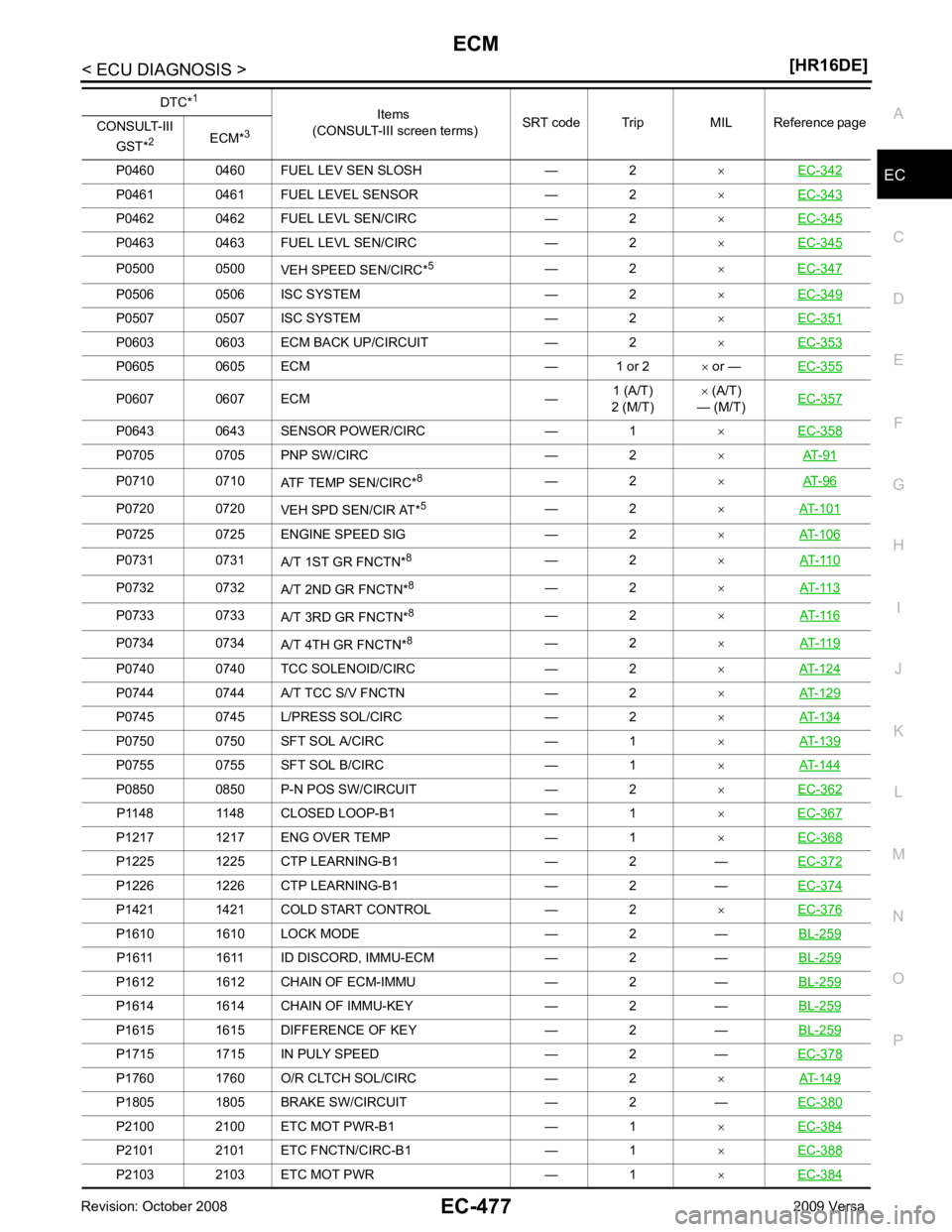

P0460 0460 FUEL LEV SEN SLOSH — 2

×EC-342 P0461 0461 FUEL LEVEL SENSOR — 2

×EC-343 P0462 0462 FUEL LEVL SEN/CIRC — 2

×EC-345 P0463 0463 FUEL LEVL SEN/CIRC — 2

×EC-345 P0500 0500

VEH SPEED SEN/CIRC*5

— 2 ×EC-347 P0506 0506 ISC SYSTEM — 2

×EC-349 P0507 0507 ISC SYSTEM — 2

×EC-351 P0603 0603 ECM BACK UP/CIRCUIT — 2

×EC-353 P0605 0605 ECM — 1 or 2

× or — EC-355 P0607 0607 ECM —

1 (A/T)

2 (M/T) ×

(A/T)

— (M/T) EC-357 P0643 0643 SENSOR POWER/CIRC — 1

×EC-358 P0705 0705 PNP SW/CIRC — 2

×AT-91 P0710 0710

ATF TEMP SEN/CIRC*8

— 2 ×AT-96 P0720 0720

VEH SPD SEN/CIR AT*5

— 2 ×AT-101 P0725 0725 ENGINE SPEED SIG — 2

×AT-106 P0731 0731

A/T 1ST GR FNCTN*8

— 2 ×AT-110 P0732 0732

A/T 2ND GR FNCTN*8

— 2 ×AT-113 P0733 0733

A/T 3RD GR FNCTN*8

— 2 ×AT-116 P0734 0734

A/T 4TH GR FNCTN*8

— 2 ×AT-119 P0740 0740 TCC SOLENOID/CIRC — 2

×AT-124 P0744 0744 A/T TCC S/V FNCTN — 2

×AT-129 P0745 0745 L/PRESS SOL/CIRC — 2

×AT-134 P0750 0750 SFT SOL A/CIRC — 1

×AT-139 P0755 0755 SFT SOL B/CIRC — 1

×AT-144 P0850 0850 P-N POS SW/CIRCUIT — 2

×EC-362 P1148 1148 CLOSED LOOP-B1 — 1

×EC-367 P1217 1217 ENG OVER TEMP — 1

×EC-368 P1225 1225 CTP LEARNING-B1 — 2 —

EC-372P1226 1226 CTP LEARNING-B1 — 2 —

EC-374P1421 1421 COLD START CONTROL — 2

×EC-376 P1610 1610 LOCK MODE — 2 —

BL-259P1611 1611 ID DISCORD, IMMU-ECM — 2 —

BL-259P1612 1612 CHAIN OF ECM-IMMU — 2 —

BL-259P1614 1614 CHAIN OF IMMU-KEY — 2 —

BL-259P1615 1615 DIFFERENCE OF KEY — 2 —

BL-259P1715 1715 IN PULY SPEED — 2 —

EC-378P1760 1760 O/R CLTCH SOL/CIRC — 2

×AT-149 P1805 1805 BRAKE SW/CIRCUIT — 2 —

EC-380P2100 2100 ETC MOT PWR-B1 — 1

×EC-384 P2101 2101 ETC FNCTN/CIRC-B1 — 1

×EC-388 P2103 2103 ETC MOT PWR — 1

×EC-384 DTC*

1

Items

(CONSULT-III screen terms) SRT code Trip MIL Reference page

CONSULT-III

GST* 2

ECM*3